Operation monitoring method and system of heating furnace

A technology for operation monitoring and heating furnaces, applied in the direction of furnace control devices, lighting and heating equipment, furnaces, etc., can solve problems affecting the optimal operation of heating furnaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] First of all, those skilled in the art should understand that the embodiments described here are only used to explain the technical principles of the present invention, and are not intended to limit the protection scope of the present invention. For example, although the various steps of the method of the present invention are described in a specific order in the present application, these orders are not limiting, and those skilled in the art can perform the steps in different orders without departing from the basic principles of the present invention. Follow the steps described.

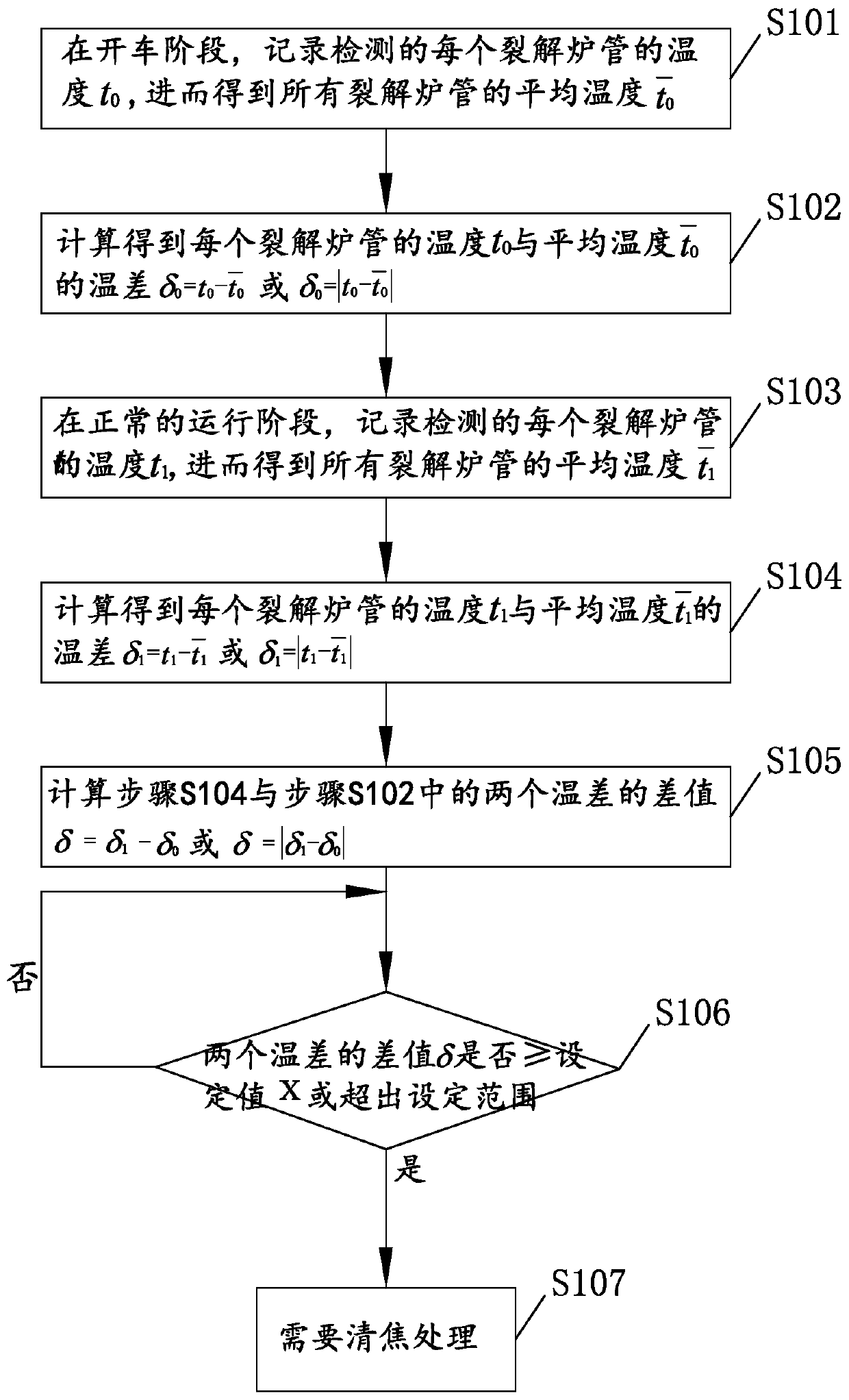

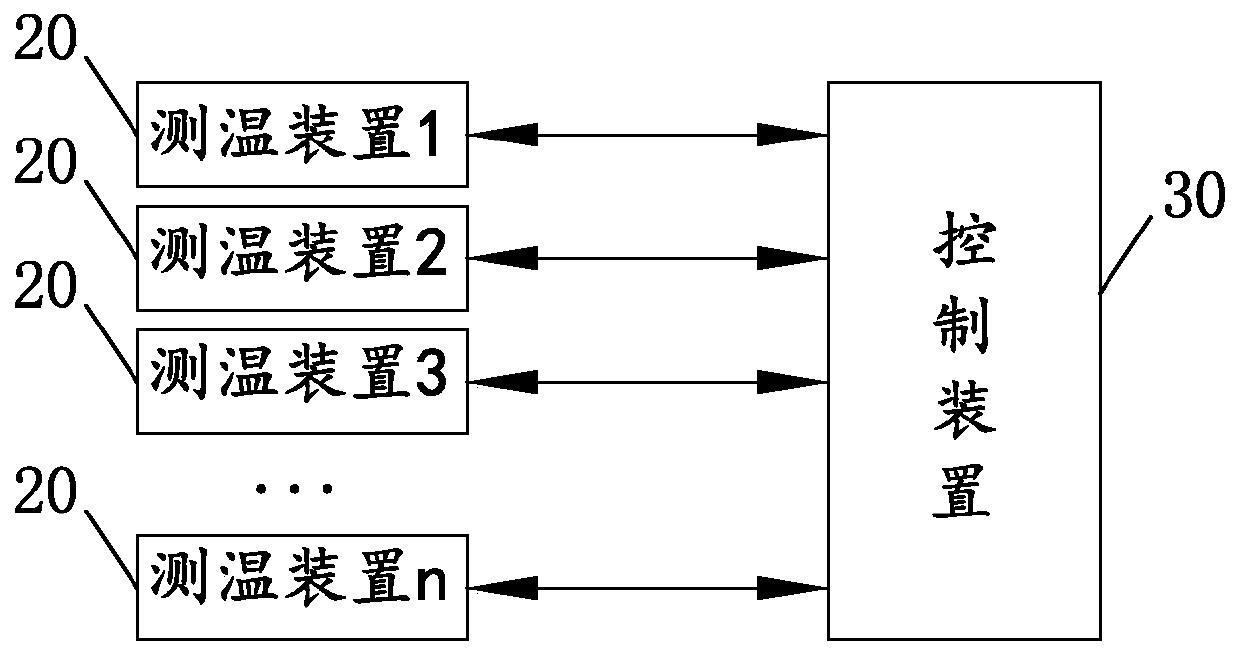

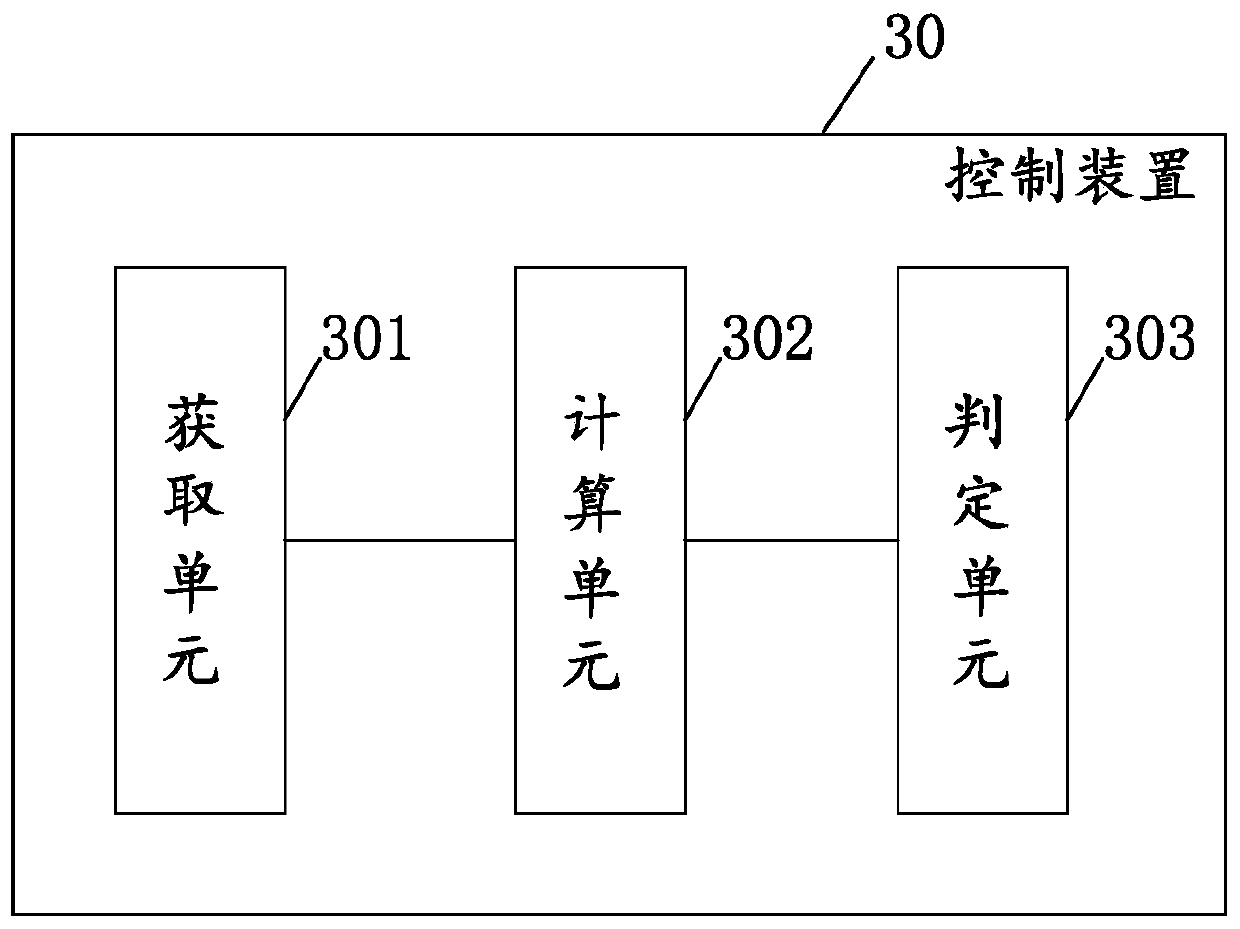

[0041] The invention provides an operation monitoring method of a heating furnace. Specifically, the heating furnace includes several cracking furnace tubes. The present invention can obtain the temperature value of each cracking furnace tube outlet section at different times, and obtain the average temperature value of all cracking furnace tubes at corresponding times, and then calculate and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com