Fluidized bed furnace used for vanadium extraction and decarbonization of stone coal

A fluidized furnace and decarburization technology, applied in furnaces, fluidized bed furnaces, furnace types, etc., can solve the problems of adverse effects on the vanadium extraction process from stone coal, difficulty in realizing fluidized combustion, affecting the operation of fluidized furnaces, etc., to improve decarburization efficiency and Stability, simple structure, and the effect of reducing the slag discharge temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

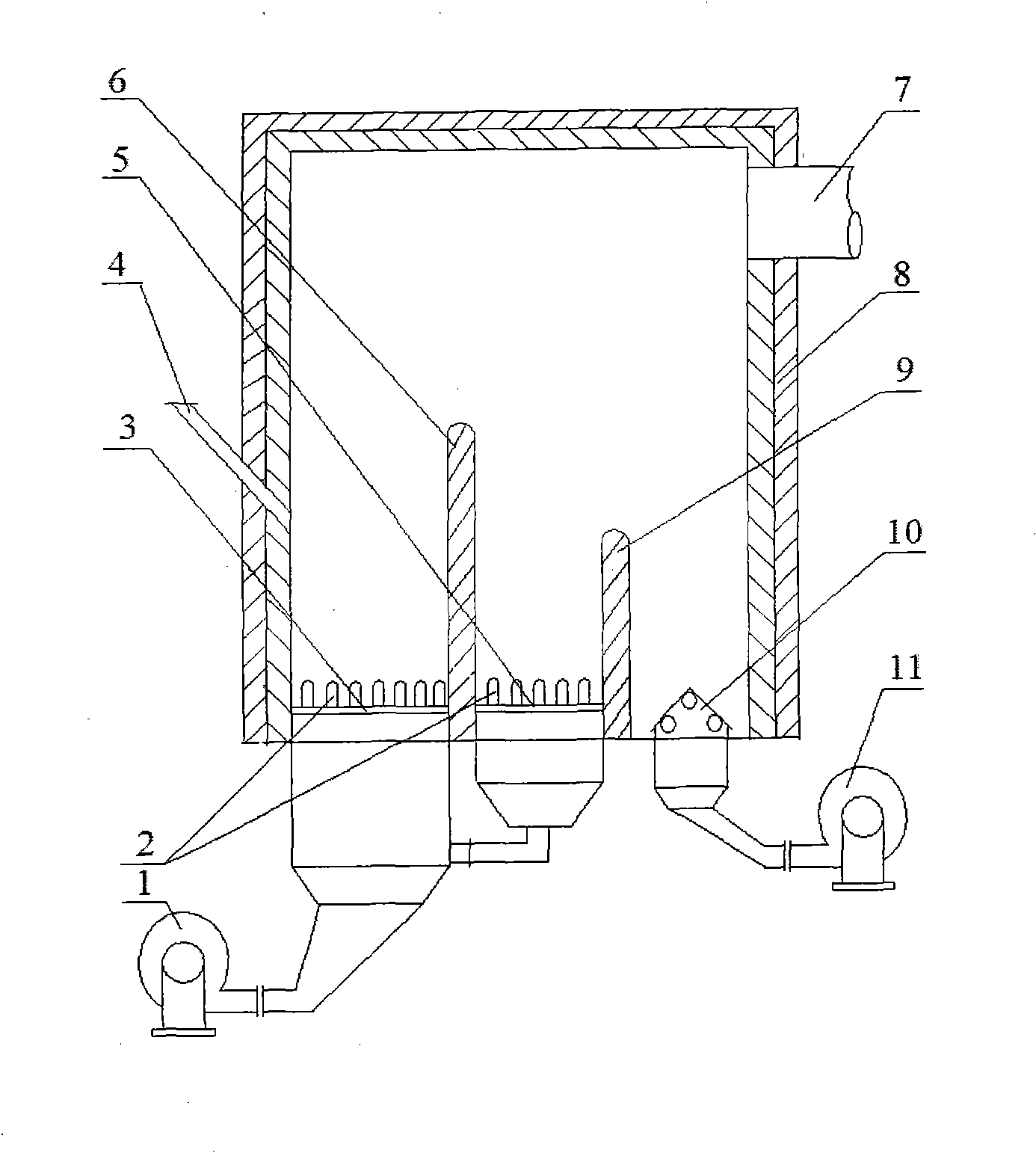

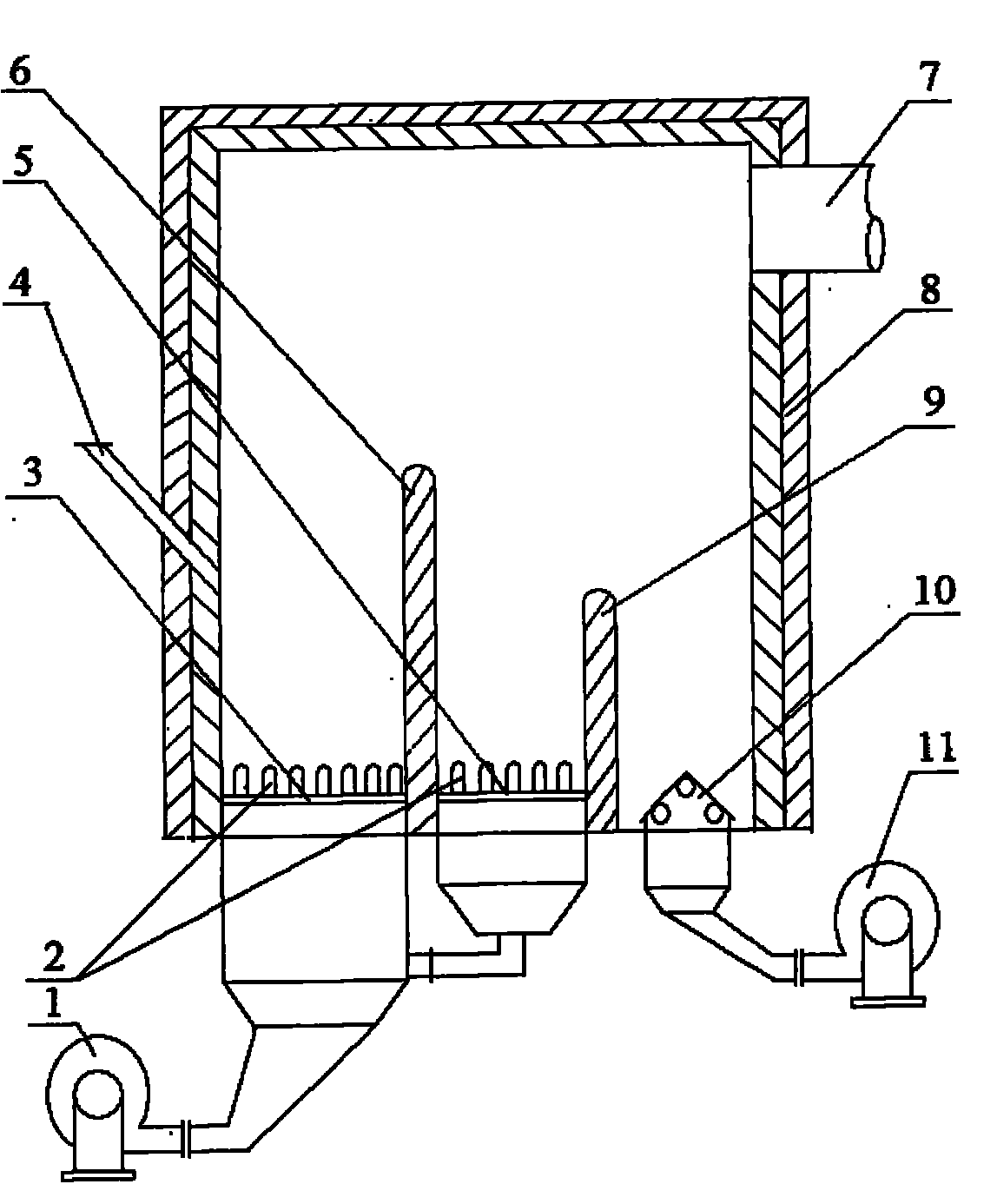

[0016] A fluidized fluidized furnace for vanadium extraction and decarburization of stone coal, its structure is shown in Figure 1: the main bed 3, the auxiliary bed 5 and the cooling bed 10 located at the bottom of the furnace body 8 are respectively separated by the first fire wall from left to right 6 is separated from the second firewall 9. Both the main bed 3 and the auxiliary bed 5 are evenly provided with gas burners 2, and the gas burners 2 are externally connected to the gas source through the gas pipeline; The lower air duct of the cooling bed 10 communicates with the second fan 11 through a pipeline; a flue 7 is arranged on the upper right side of the furnace body 8 , and a feed pipe 4 is arranged on the left middle part of the furnace body 8 .

[0017] In this embodiment, the height of the furnace port of the feed pipe 4 from the bottom of the furnace is 5 / 20 to 8 / 20 of the height of the furnace body 8, and the height of the first fire wall 6 is 5 / 10 to 8 / 20 of the...

Embodiment 2

[0021] A fluidized fluidized furnace for vanadium extraction and decarburization of stone coal. Except following technical parameter, all the other are with embodiment.

[0022] The width of the main bed 3 is 5 / 12 to 6 / 12 of the inner width of the furnace body 8, and the width of the auxiliary bed 5 is 9 / 40 to 10 / 40 of the inner width of the furnace body 8. The wall distance between the left side outer eaves of the cooling bed 10 bed surface and the second fire-retaining wall 9 and the right side outer eaves of the cooling bed 10 bed surface are 5 / 5 of the inner wall distance of the body of heater 8 from the inner wall of the body of heater 8. 120~6 / 120.

[0023] The working process of this specific embodiment is: first ignite the gas burners 2 on the main bed 3 and the auxiliary bed 5, and turn on the first blower fan 1 to make it operate with a small air volume; Boiling combustion is realized in the upper space of the main bed 3. With the gradual increase of stone coal raw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com