Straw circulation fluidized-bed combustion boiler

A technology of circulating fluidized bed and straw, which is applied in the direction of fluidized bed combustion equipment, fuel for combustion in a molten state, and combustion methods, etc., which can solve the problems of high cost of imported equipment, low combustion efficiency, and large pollutant emissions, and achieve Reduced crushing machinery requirements, low fluidization speed, and good particle size adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

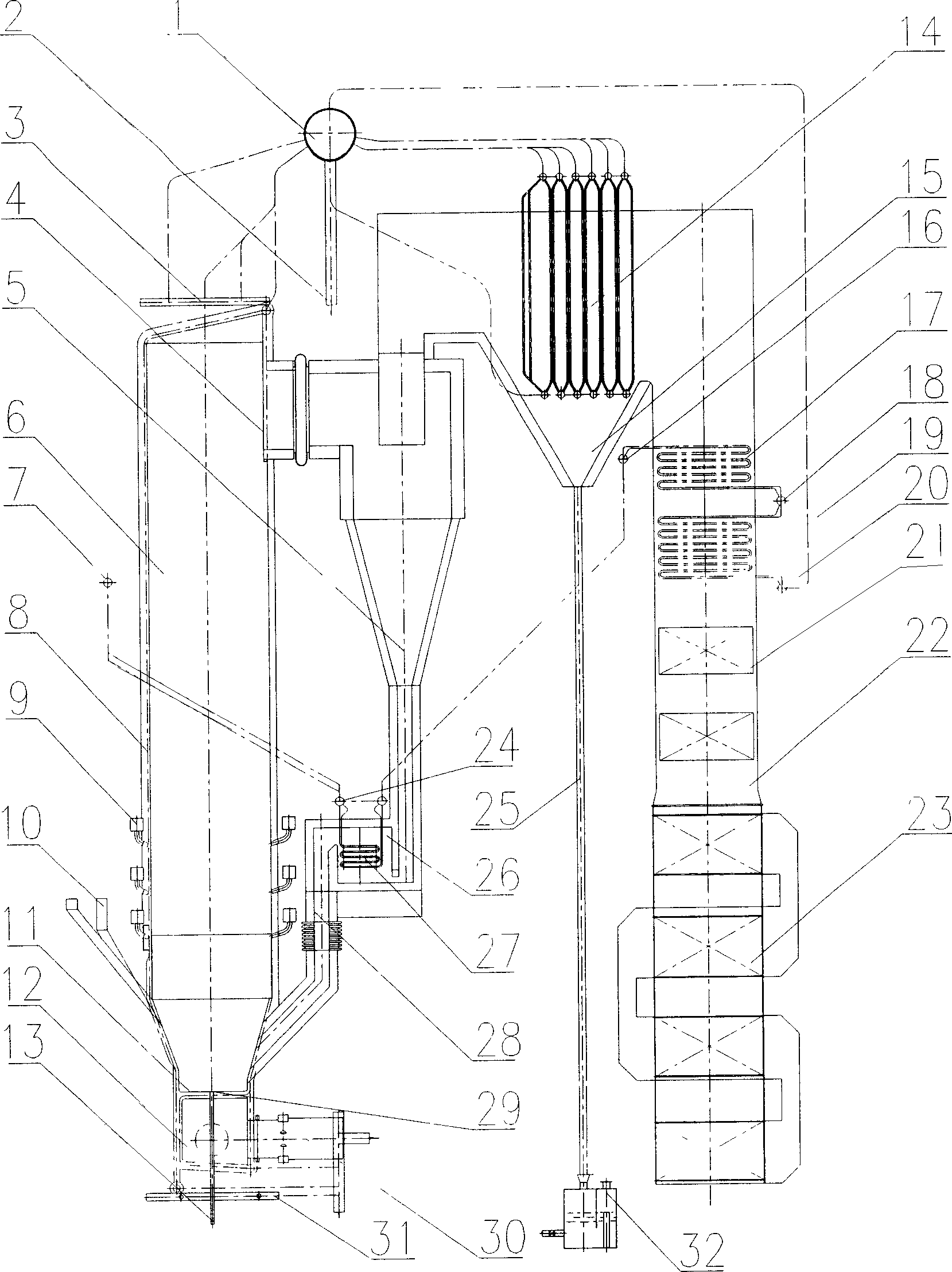

[0032] The received base of cotton stalks contains 36.54% carbon, 4.87% hydrogen, 40.54% oxygen, 0.24% nitrogen, 0.13% sulfur, 1.68% ash, 16% moisture, and a low calorific value of 12921.52 kJ / kg. When the boiler is started, the under-bed ignition starting method is adopted. The starting fuel (diesel or natural gas) and the combustion air from the primary fan are burned in the starting combustion chamber 30 to generate high-temperature flue gas. The high-temperature flue gas and mixed air are mixed in the combustion chamber to about 880°C. Enter the water-cooled air chamber 12, and enter the furnace 6 through the water-cooled air distribution plate 11 to heat the bed material (quartz sand, river sand, potassium feldspar or medium corundum, with a particle size distribution of 200 μm to 1 mm). Because the volatile content of cotton stalks is high and the ignition temperature is relatively low, when the bed material is heated to 400° C., the chopped cotton stalk fuel with a leng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com