Municipal sludge-coal-water slurry co-fired organic working medium boiler

A technology for municipal sludge and coal-water slurry, which is applied in the direction of burning fuel, incinerator, and combustion method in the melting state, can solve the problems of small load adjustment range, high operating pressure and reduction, and reduce NOx emission and load. The effect of good adjustment performance and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

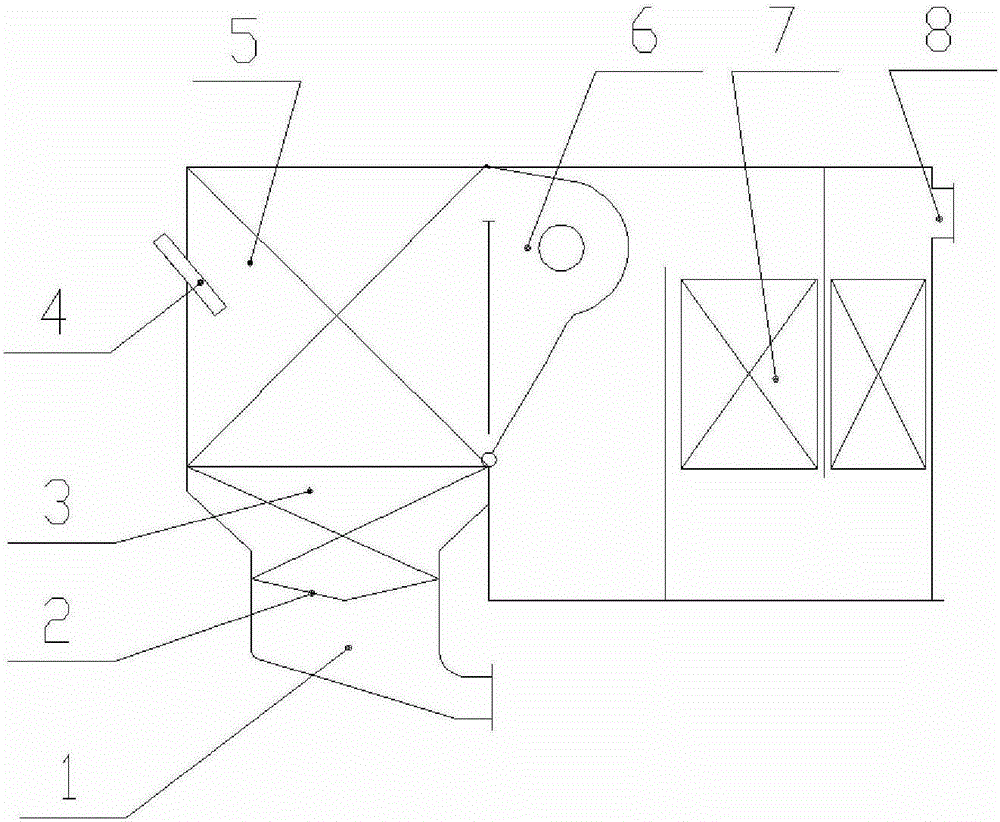

[0024] Such as figure 1 As shown, the organic working fluid boiler for municipal sludge-coal-water slurry co-firing includes: bellows 1, air distribution plate 2, dense phase area 3, fuel feeding port 4, dilute phase area 5, vortex separation burnout device 6, tail Convection heating surface part 7, outlet flue 8.

[0025] The water content of municipal sludge is very high, usually between 85% and 95%, and because of the nature of municipal sludge itself, dehydration is extremely difficult, and municipal sludge with high water content is not suitable for use as fuel. Configuring municipal sludge and coal powder into municipal sludge-coal water slurry mixed fuel can effectively solve this problem. The coal block is broken into coal powder with a particle size of less than 1mm. Municipal sludge and coal powder can be mixed according to the ratio range of 1:3 to 1:1. After being fully mixed, it becomes municipal sludge-coal water slurry mixed fuel. In the actual production proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com