Full cycle dry distillation process and system for producing shale oil from oil shale (coal)

A technology of oil shale and shale oil, which is applied in the petroleum industry, special carbonization, coking ovens, etc., can solve problems such as difficult promotion, environmental pollution, complex equipment, etc., and achieve high gas purification efficiency, large adjustable range, Effect of improving dry distillation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

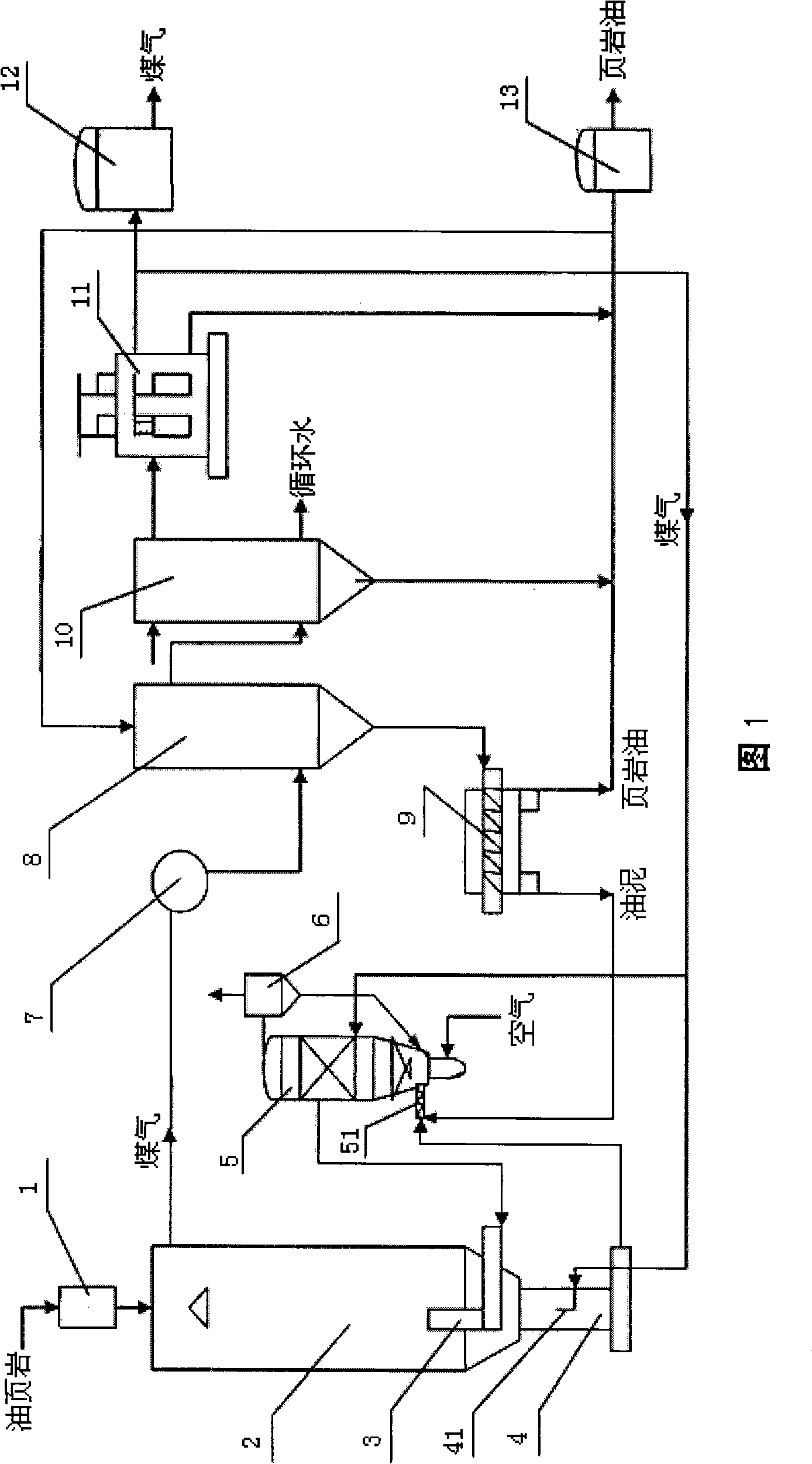

[0018] The specific embodiments of the present invention will be further described in detail below with reference to the accompanying drawings:

[0019] As shown in Figure 1, the full-cycle dry distillation system and process flow for producing shale oil from oil shale (coal) of the present invention are as follows:

[0020] (1) Dry distillation of oil shale: The dry distillation system consists of an oil shale input storage tank 1, an oxygen-free gas heating dry distillation furnace 2 and a semi-coke discharge device 4. The dry distillation furnace 2 is equipped with a preheated gas input pipe 3. The semi-coke discharge device 4 is equipped with a cold gas input pipe 41. The dry distillation process of oil shale is as follows: the preheated gas is fed into the dry distillation furnace through the preheated gas input pipe 3, and the oil shale rises from the bottom to the oil shale. The input storage tank 1 is sent from the top of the dry distillation furnace to the dry distillatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com