Fluidized-bed boiler

A fluidized bed boiler and fluidized bed technology are applied in the field of fluidized bed boilers, which can solve the problems of insufficient primary air volume, pollutant discharge, low desulfurization rate, etc., so as to improve fuel utilization rate, reduce pollutant discharge and desulfurization efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

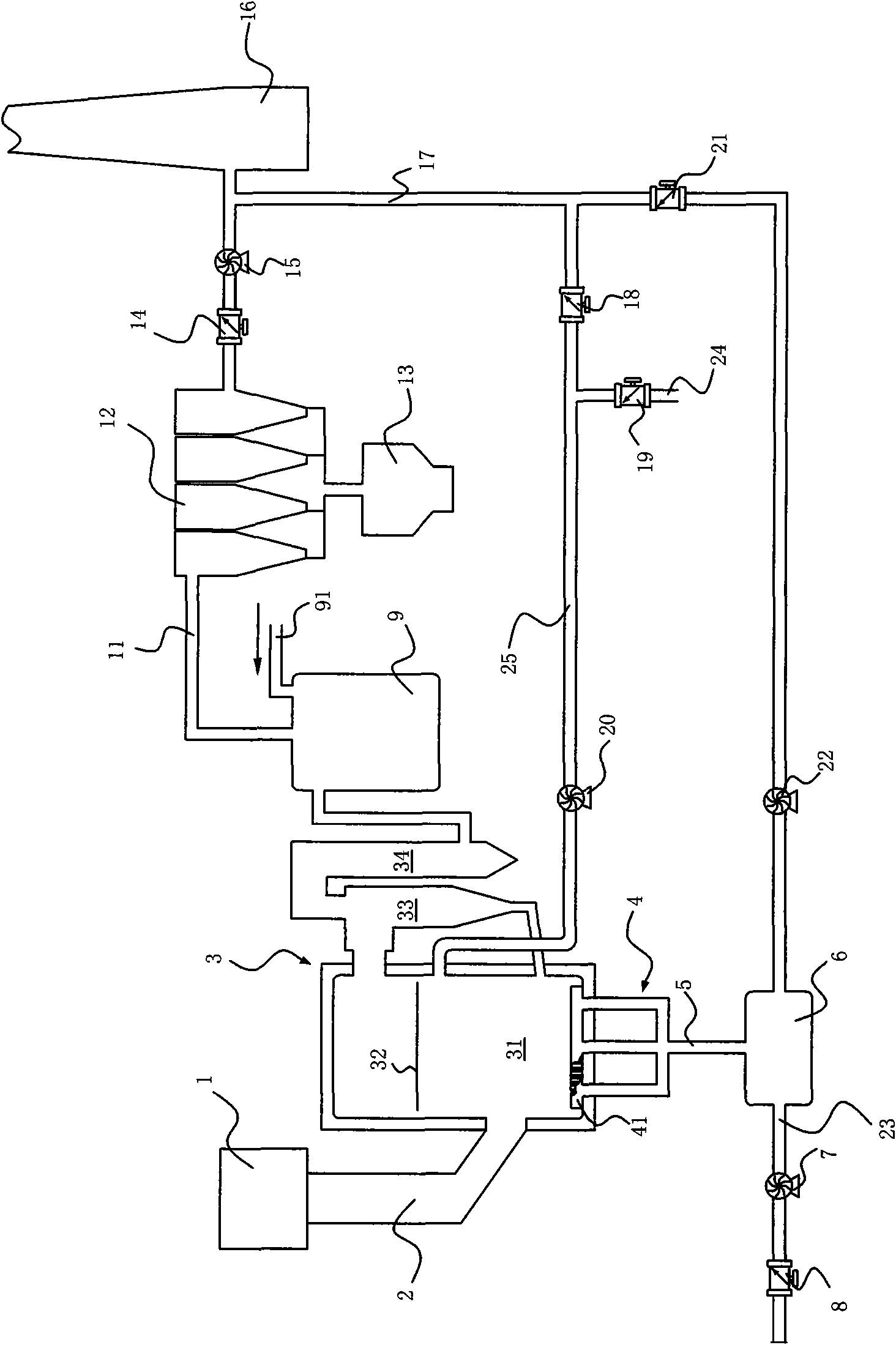

[0017] Such as figure 1 A fluidized bed boiler is shown, which includes a fuel tank 1 for storing coal or other fuels, and the fuel tank 1 is connected to a boiler body 3 .

[0018] The boiler body 3 comprises a circulating fluidized bed combustion chamber 31 connected to a cyclone separator 33; the fluidized bed height zone 32 is shown in the figure. The outlet of the cyclone separator 33 is connected with a heating assembly 34, and the heating assembly 34 includes a superheater, an economizer and an air preheater.

[0019] The bottom of the combustion chamber is provided with an air distribution plate 41 with a wind cap, which communicates with a blower 7 through the wind chamber 4, and the blower enters the combustion chamber 31 with compressed air through the wind chamber and the wind cap; the combustion process in the combustion chamber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com