Sludge multi-stage drying device, fluidized bed combustion treatment device and fluidized bed combustion treatment method

A sludge incineration and dryer technology, applied in combustion methods, dewatering/drying/concentrating sludge treatment, incinerators, etc. The effect of simplicity, small footprint, and low manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

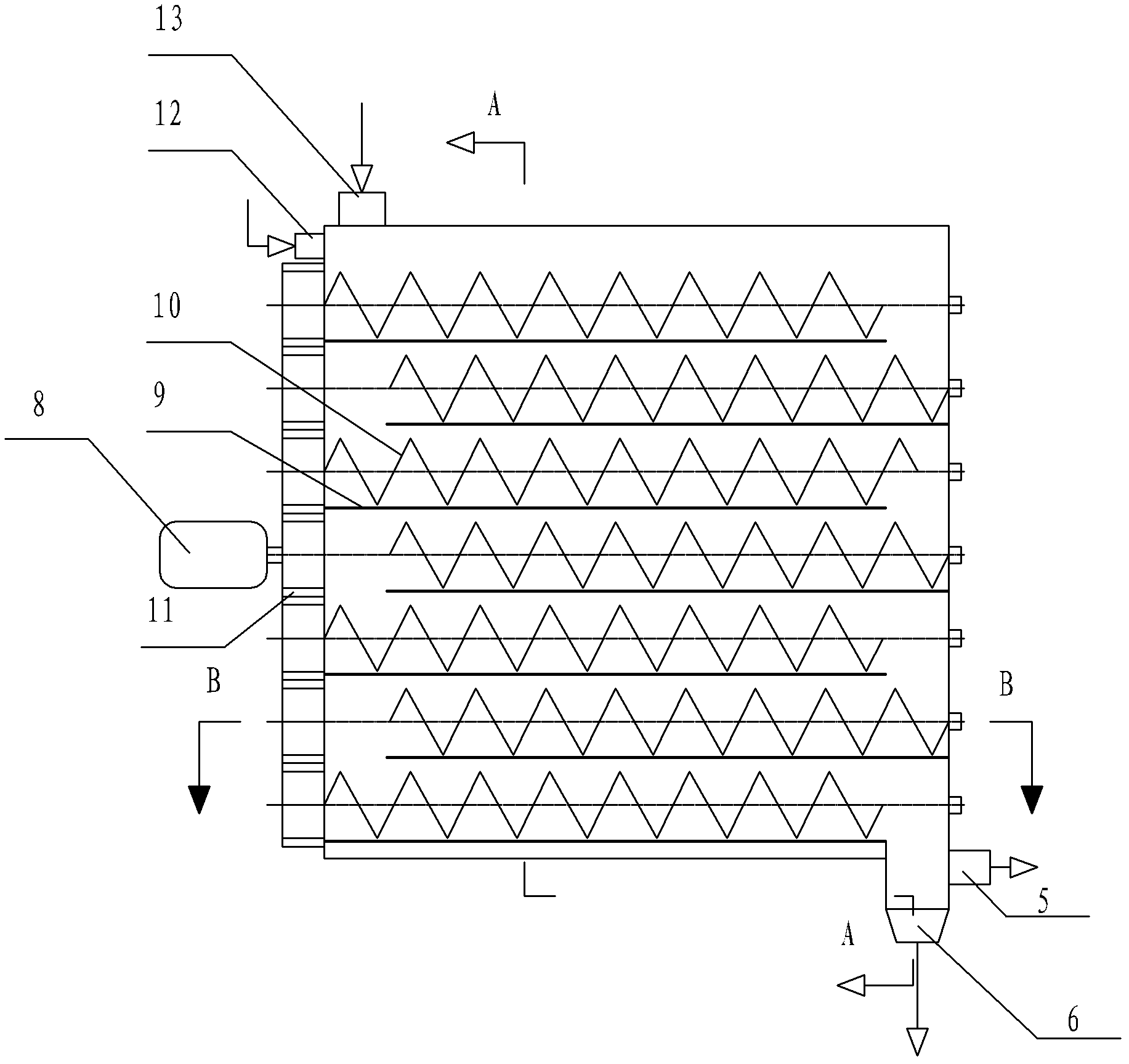

[0024] Specific implementation mode one: combine Figure 1 to Figure 3 To illustrate this embodiment, the sludge multi-stage dryer of this embodiment includes a drying chamber 23, a motor 8, a plurality of gears 11, at least three stages of augers, and an auger chassis 9 with the same number of stages as the auger;

[0025] The at least three stages of augers are horizontally installed in the drying chamber 23 from top to bottom, adjacent augers on the same floor are arranged in a staggered manner, and an auger chassis 9 is arranged below each stage of auger 24, and the motor 8 is installed in the drying chamber On the outer wall of 23, the motor 8 establishes a transmission relationship with the augers at all levels through the gear 11. The upper cover of the drying chamber 23 is provided with a wet sludge inlet 13, and the upper part of the side wall of the drying chamber 23 is provided with a steam inlet 12. The drying chamber 23 A dry sludge outlet 6 is provided on the bot...

specific Embodiment approach 2

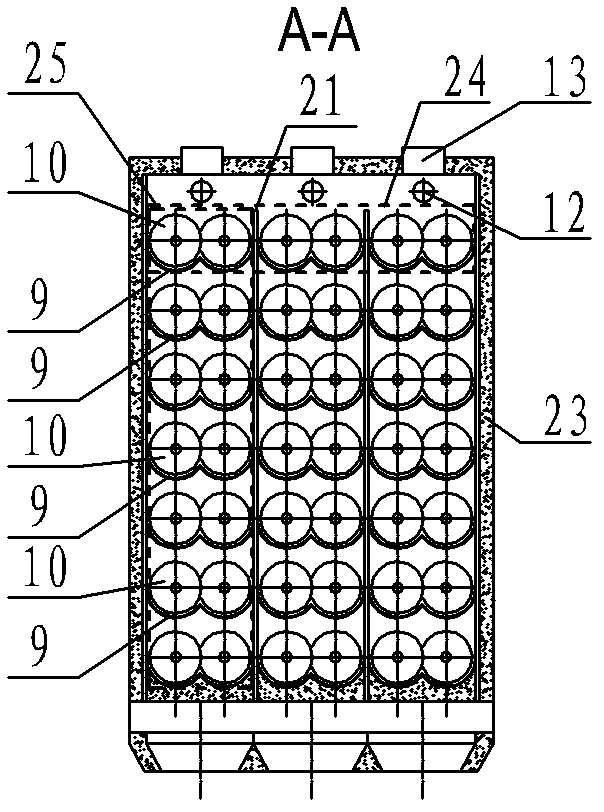

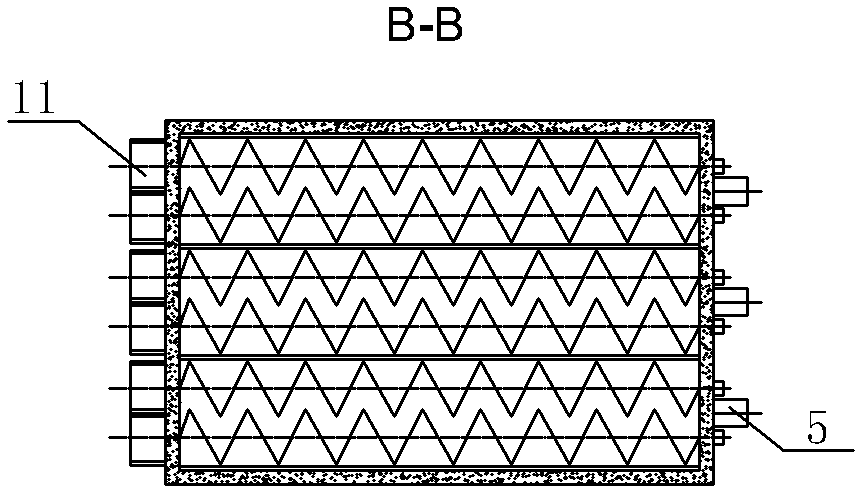

[0026] Specific implementation mode two: combination Figure 1 to Figure 3 To describe this embodiment, each stage of the auger in this embodiment includes a double auger 10 . Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0027] Specific implementation mode three: combination Figure 1 to Figure 3 Describe this embodiment, each level of auger in this embodiment includes a pair of augers, named double auger 10, the pair of augers are arranged side by side in the horizontal direction, and a transmission relationship is established between the two augers through a gear 11, The double augers 10 in the same row among at least three stages of augers are named drying section augers 25 , and a support member 21 is arranged between the two drying section augers 25 . With such a setting, the efficiency is high. Other compositions and connections are the same as in the first embodiment.

[0028] Specific implementation mode four: combination Figure 1 to Figure 3 Describe this embodiment, each level of auger in this embodiment includes a pair of augers, named double auger 10, the pair of augers are arranged side by side in the horizontal direction, and a transmission relationship is established between ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Calorific value | aaaaa | aaaaa |

| Calorific value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com