Liquid chlorine gasifying system

A technology of chlorine gas and vaporizer, which is applied in the direction of fixed-capacity gas storage tanks, gas/liquid distribution and storage, pressure vessels, etc. Small footprint, high production safety and stability, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

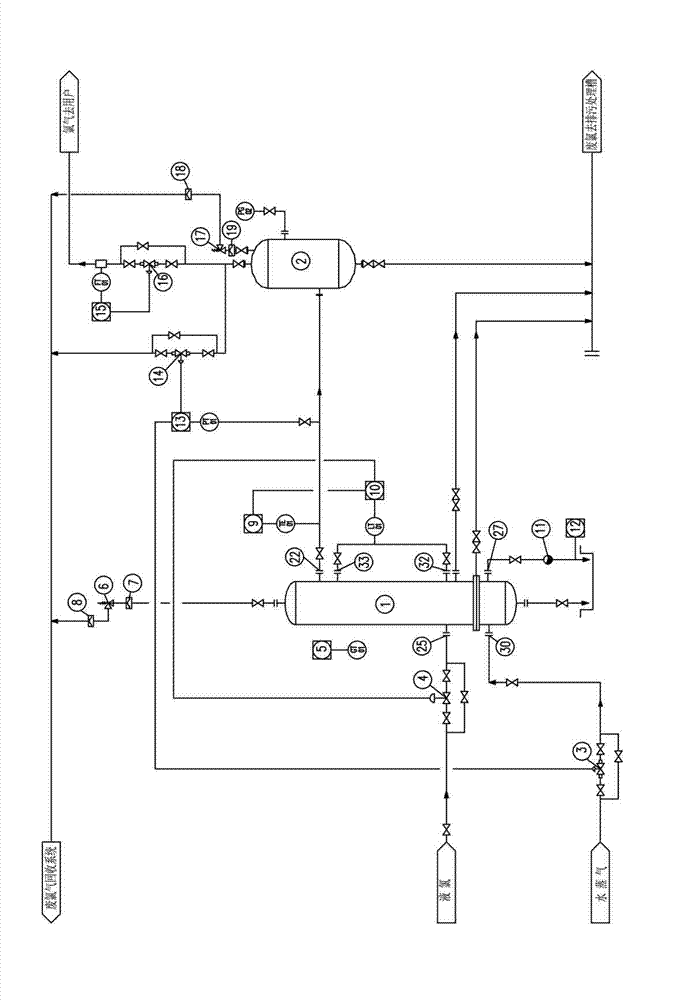

[0023] like figure 1 As shown, a liquid chlorine gasification system is composed of a liquid chlorine gasification part, a water vapor heat exchange part and a chlorine gas buffer part.

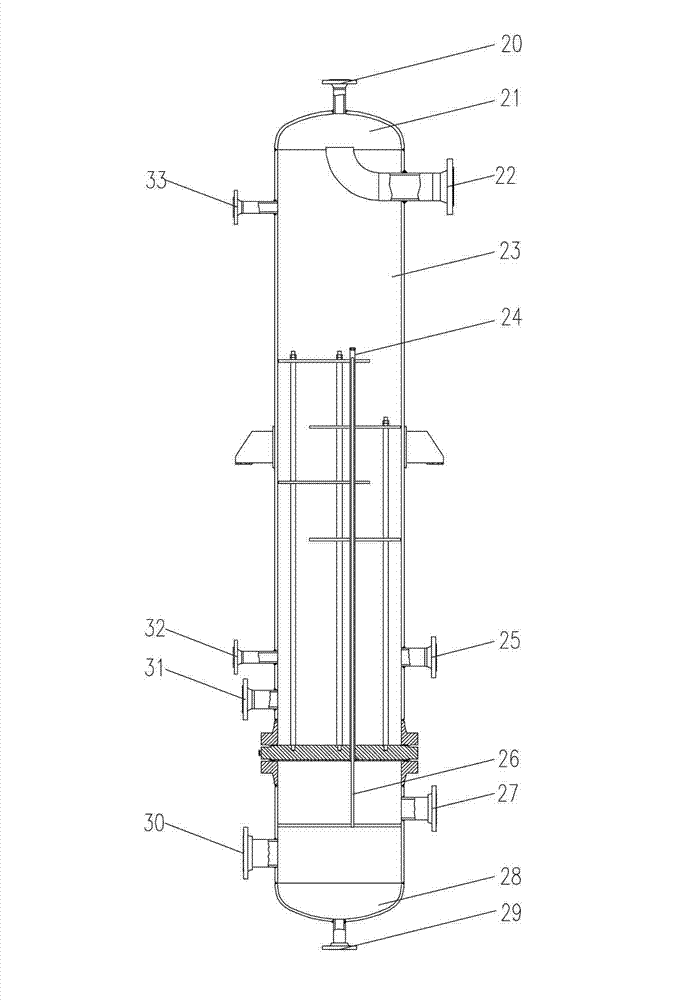

[0024] The liquid chlorine gasification part is: the liquid chlorine inlet (25) of the gasifier (1) is connected to the liquid level regulating valve (4), and the chlorine gas outlet (22) of the gasifier (1) is connected to the buffer tank ( 2) Connection, a temperature measuring gauge (9) and a pressure measuring gauge (13) are installed on the pipeline between the chlorine gas outlet (22) of the gasifier (1) and the buffer tank (2), and the temperature measuring gauge (9) Cascaded with the liquid level gauge (10), the liquid level gauge (10) is connected with the liquid level gauge port I (33), liquid level gauge port II (32) and liquid level regulating valve ( 4) Connection; the periphery of the vaporizer (1) is provided with a chlorine gas leakage detection and alarm device (5).

[0025...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com