Novel biomass anti-burning type water heating boiler

A hot water boiler and biomass technology, applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of high production cost, complicated operation, frequent feeding, etc., and achieve good environmental performance and high combustion efficiency. , the effect of improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

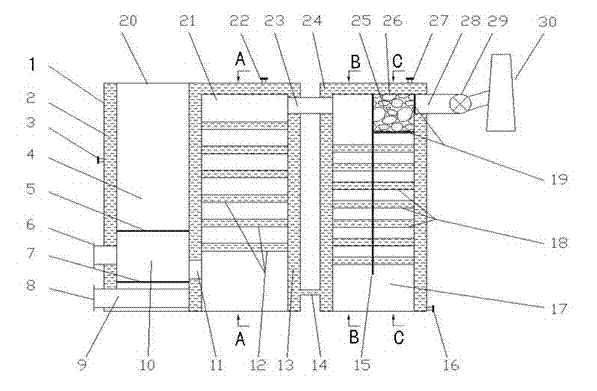

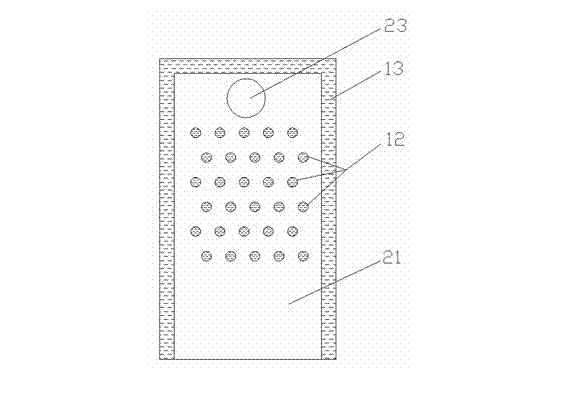

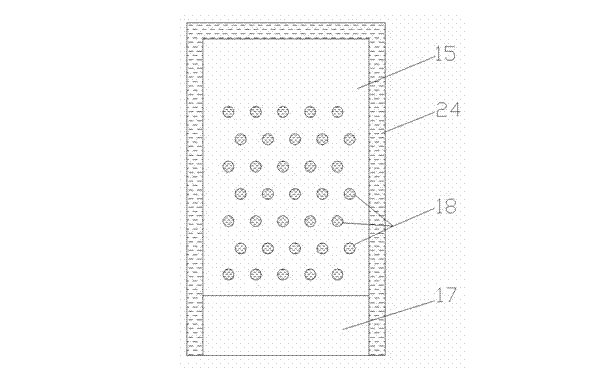

[0019] The present invention will be further described with reference to the accompanying drawings in conjunction with specific embodiments.

[0020] Such as figure 1 As shown, the present invention includes a boiler body 1, and an upper furnace 4 and a lower furnace 10 arranged up and down in the boiler body, an upper grate 5 is arranged between the upper furnace 4 and the lower furnace 10, and an ash collection is arranged below the lower furnace 10. Chamber 9, a lower fire grate 7 is set between the lower furnace 10 and the ash collection chamber 9, and a damper 6 and an ash outlet 8 are provided on the front of the furnace body to communicate with the lower furnace 10 and the ash collection chamber 9 respectively. The upper furnace 4 is directly connected to the top of the boiler body 1 to communicate with the outside world, and the inlet is set as a feed port 20 . When the boiler is in normal operation, the fuel is directly added from the feed port 20 on the top of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com