Open-loop turbine engine steady state control method

A technology of turbine engine and steady-state control, applied in engine components, machines/engines, mechanical equipment, etc., can solve problems such as engine speeding, overtemperature, etc., and achieve good results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0024] The invention provides an open-loop turbine engine steady-state control method, comprising the steps of:

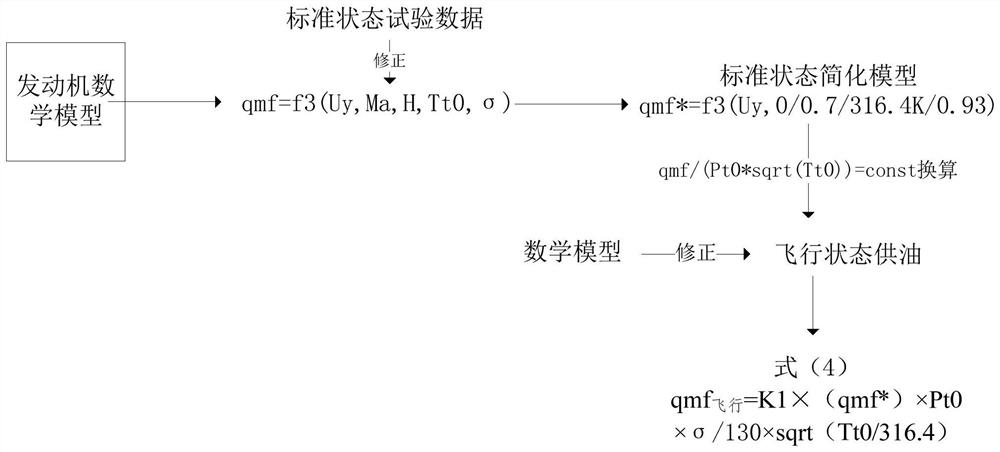

[0025] Step 1, through the mathematical model of the engine, the functional relationship between engine thrust and fuel flow under different flight conditions is established as follows:

[0026] Fn=f1(qmf, H, Ma, Tt0, σ) (1)

[0027] Among them, Fn is the net thrust of the engine; qmf is the fuel flow of the engine; H is the flight altitude, which comes from the information of the aircraft; Ma is the flight Mach number, which comes from the information of the aircraft; Tt0 is the total temperature of the incoming flow, which comes from the information of the aircraft; pressure recovery coefficient.

[0028] Establish the functional relationship between engine throttle voltage Uy and thrust:

[0029] Fn=f2(Uy, H, Ma, Tt0, σ) (2)

[0030] Amo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com