Gas reburning energy-increasing environment-friendly boiler

A gas and hot water boiler technology, applied in the boiler field, can solve problems such as difficult environmental protection, single performance of combustion equipment, and unsatisfactory combustion performance, and achieve the effects of improving utilization, saving coal, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Specific explanation below with reference to accompanying drawing:

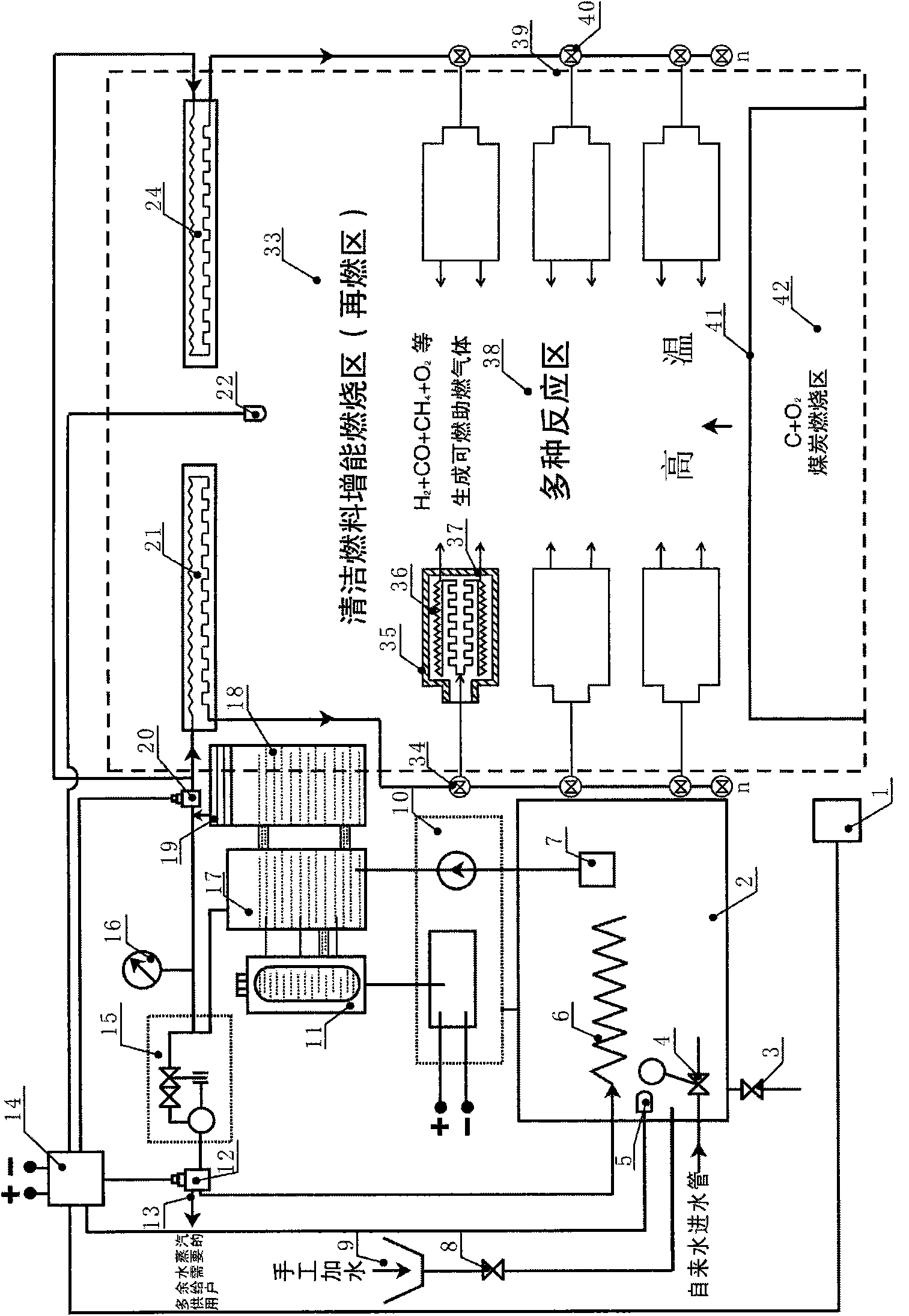

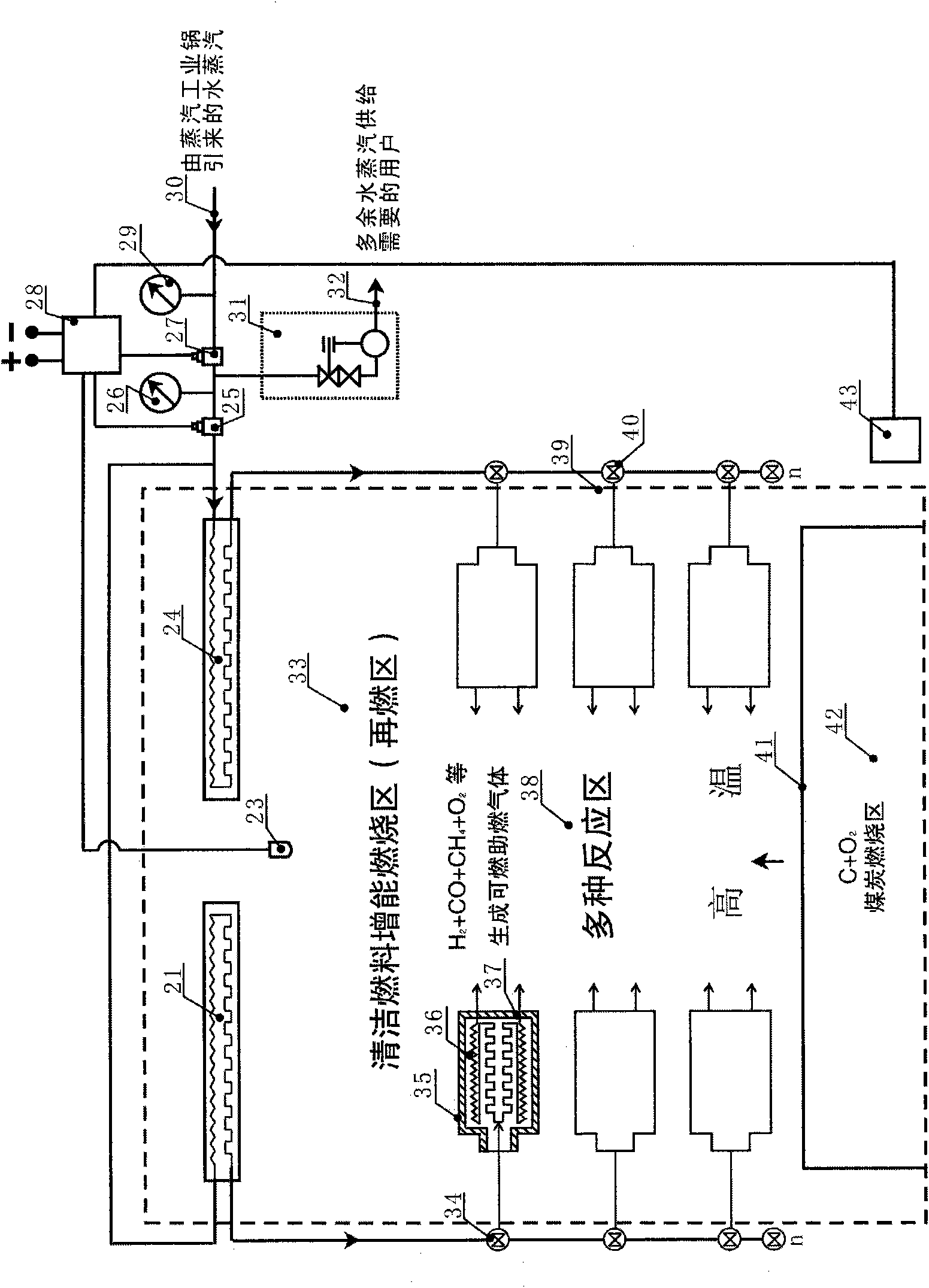

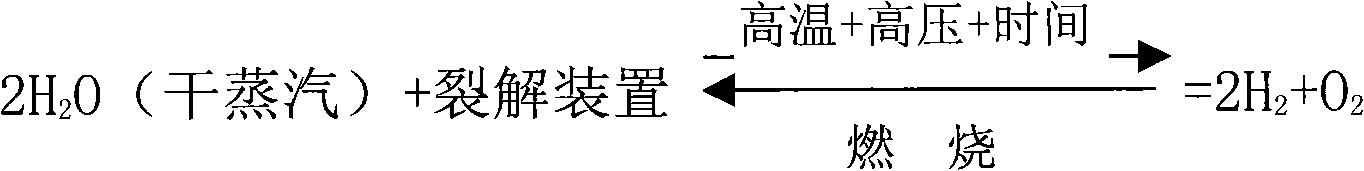

[0018] figure 1 Energy-enhancing hot water boiler for gas reburning: it is divided into two parts, namely, the dry steam of water to produce combustible and combustion-supporting gas and the reburning energy-enhancing part of fuel combustion gas.

[0019] The part of producing combustible and combustion-supporting gas from the dry steam of water includes: a water supply tank 2, an automatic water supply system 10 for supplying water to the water supply tank 2, and the water supply tank 2 communicates with a pressure water tank 17 to supply water to the pressure water tank 17. The pressure water tank 17 and the steam generator 18 are connected and communicated by upper and lower horizontal pipes. The side part of the steam generator 18 is installed in the reburning energization combustion chamber 39 of the boiler, in order to allow the steam generator 18 to accept high temperature and generate more ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com