Boiler abnormal working condition diagnosis and operation optimization method based on fault tree

A technology for abnormal working conditions and operation optimization. It is applied in reasoning methods, instruments, data processing applications, etc., and can solve problems such as furnace shutdown, low efficiency, and unsatisfactory processing results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

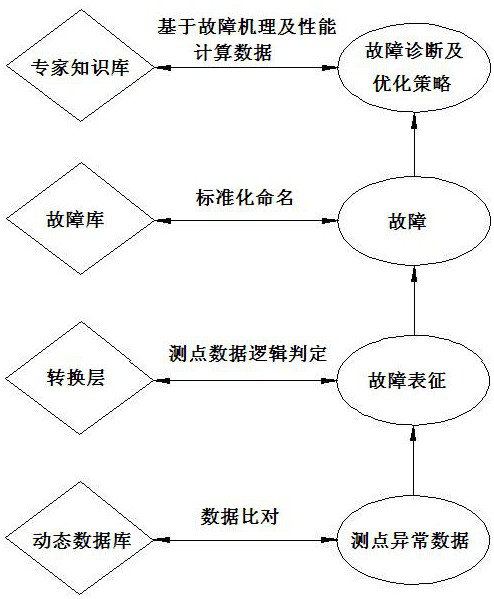

[0021] A fault tree-based method for diagnosing abnormal operating conditions of boilers and optimizing operation, the method comprising the following steps:

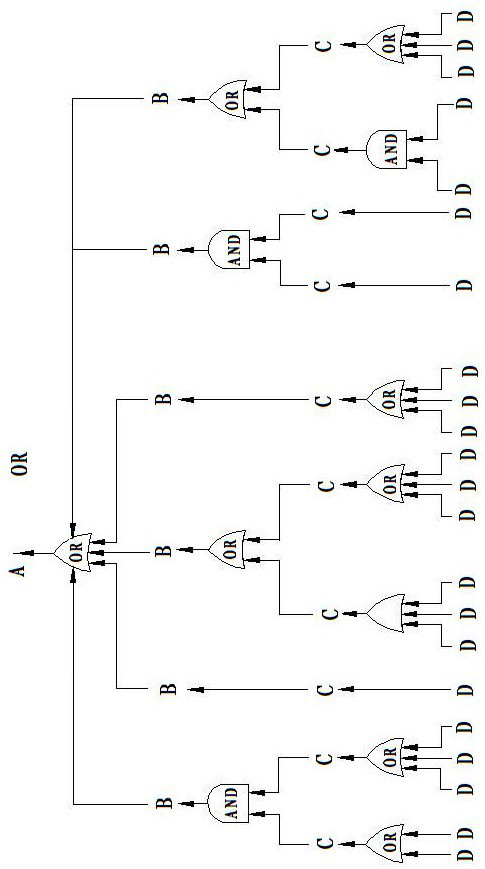

[0022] Step 1: Sort out expert knowledge, establish an expert knowledge base, and build a top-level decision-making mechanism for fault trees;

[0023] Step 2: Build a fault library covering all abnormal working conditions of various types of boilers, and construct the intermediate transition layer of the fault tree;

[0024] Step 3: Use the boiler design data and operating data to build a dynamic database of boiler performance, compare the actual operating data of the boiler, and establish the basic layer of the fault tree;

[0025] Step 4: Establish an intermediate conversion layer unit, connect the abnormal data of the boiler measurement point and the abnormal working condition of the boiler, and connect the fault tree with the boiler database correspondingly.

Embodiment 2

[0027] According to the fault tree-based boiler abnormal working condition diagnosis and operation optimization method described in embodiment 1, the expert knowledge base includes all abnormal working condition diagnosis and operation optimization strategies of various types of boilers, and the expert knowledge synthesizes the fault Mechanism, boiler design concept and operation mechanism, boiler basic design data, specifically furnace type, heating surface structure and layout, thermal calculation, hydrodynamic calculation, wall temperature calculation, smoke wind resistance calculation and pulverizing system calculation, relative to fault For each abnormal working condition in the database, there is a corresponding abnormal working condition diagnosis and a corresponding operation optimization strategy in the expert knowledge base.

Embodiment 3

[0029] According to the fault tree-based diagnosis and operation optimization method for boiler abnormal working conditions described in Embodiment 1, the fault database covers all abnormal working conditions of various types of boilers, and establishes a set of standardized naming system based on abnormal working conditions. The representation language for each abnormal working condition is named.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com