Coal-fired power station boiler reheater working medium flow online correction method

A technology of a coal-fired power station and a correction method, which is applied in the direction of measuring flow/mass flow, liquid/fluid solid measurement, volume change compensation/correction device, etc., can solve problems that have not been considered, and achieve improved accuracy and good versatility And robustness, good effect of dynamic characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with specific embodiments. The exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not as a limitation to the present invention.

[0050] First of all, the following examples need to be explained: the boiler in this example is HG-1025 / 17.3-WM18 type, the boiler load is 300MW, the boiler adopts subcritical, natural circulation, one intermediate reheating, double arch single furnace, "W" Flame combustion method, double flue at the rear, flue gas baffle temperature adjustment, balanced ventilation, solid slag discharge, open-air layout, all-steel frame suspension drum furnace.

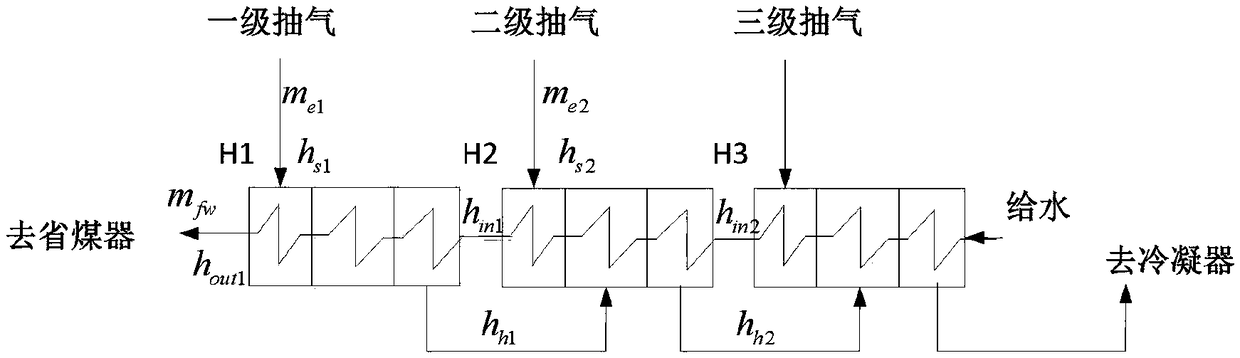

[0051] The external heat flow of the reheater and recuperator system is considered to be evenly distributed along the tube length and circumference; the tube wall metal of the heat exchanger is only considered for radial heat transfer; the working medium in the tube is inco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com