Patents

Literature

53results about How to "Improve dynamic accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

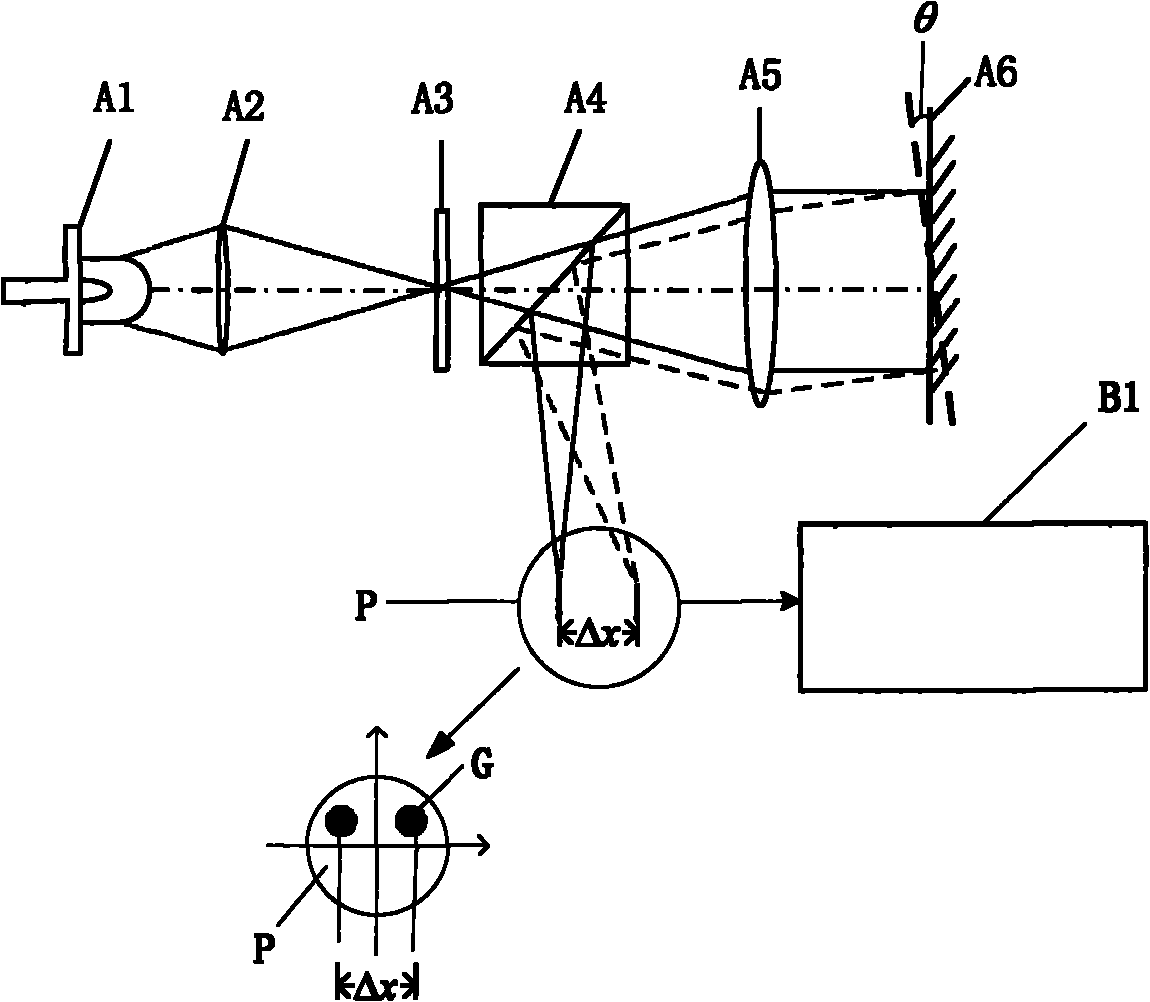

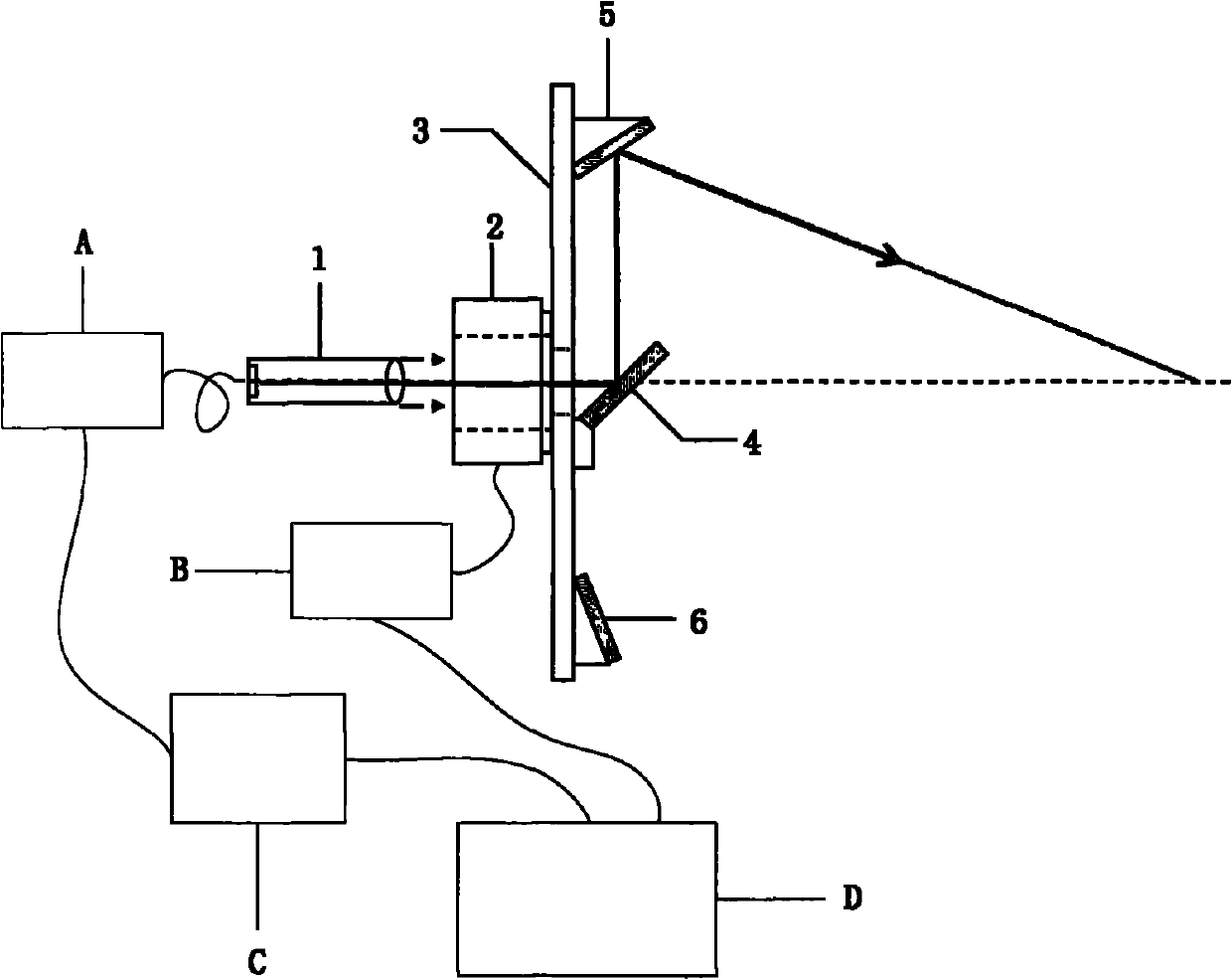

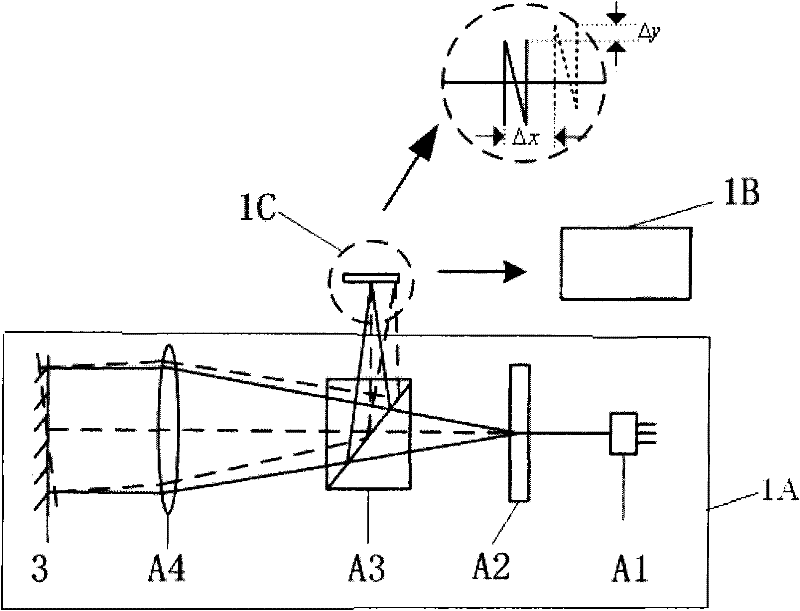

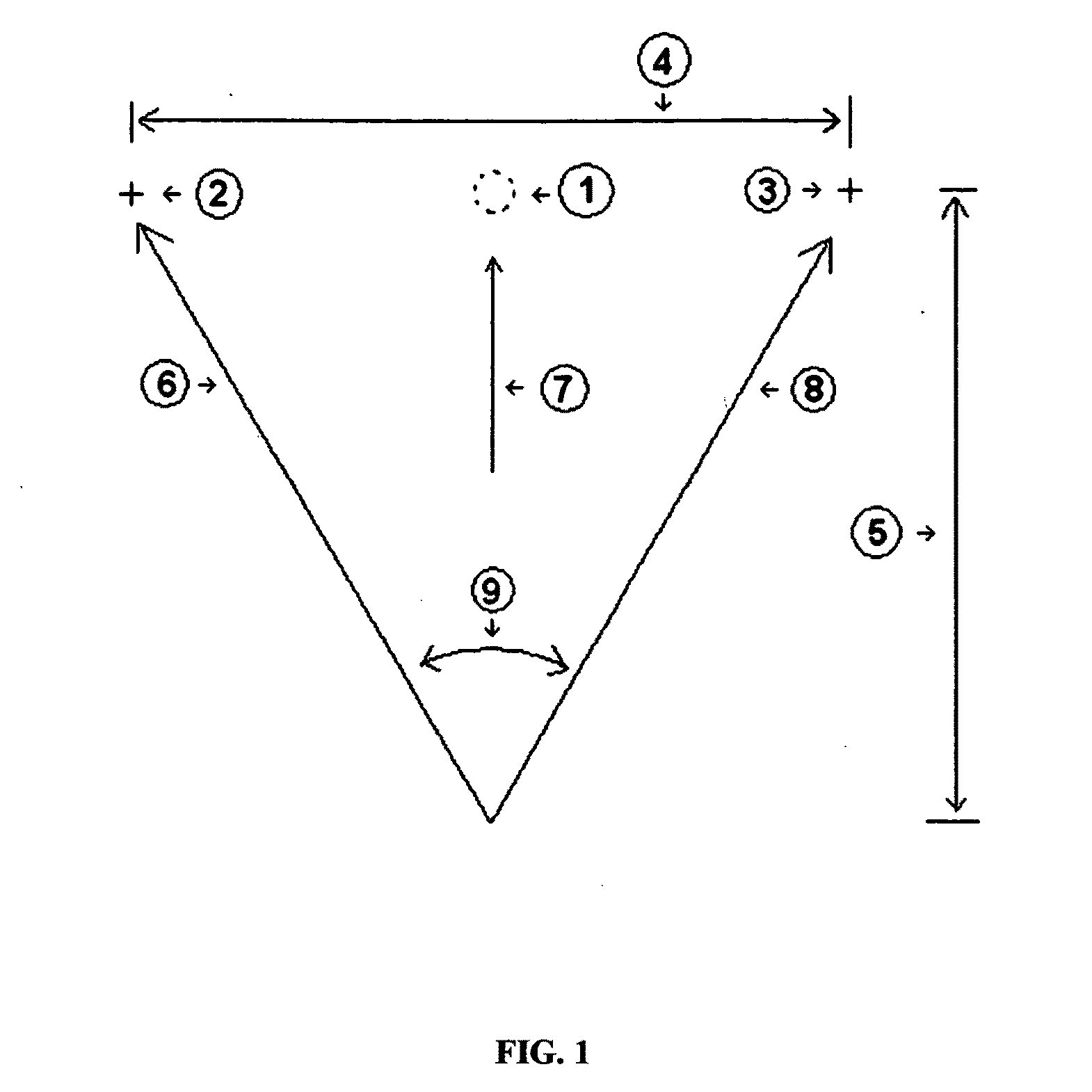

Device and method for detecting dynamic properties of two-dimensional directional mirror

InactiveCN102023082AEliminate measurement errorsEasy to implementAngle measurementTesting optical propertiesData acquisitionEngineering

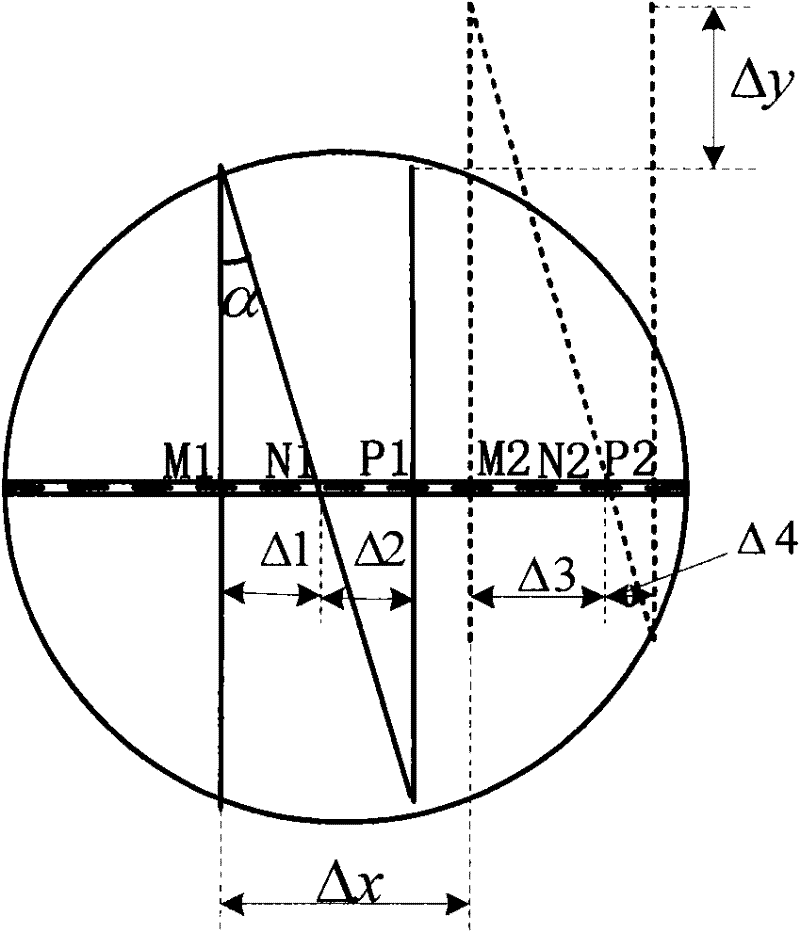

The invention relates to a device and method for detecting the dynamic properties of a two-dimensional directional mirror. The device comprises a dynamic photoelectric autocollimator, a controller of the dynamic photoelectric autocollimator, a hollow rotary platform, a controller of the hollow rotary platform, a rotary target, an adjustment platform, a data acquiring and processing system and a computer measurement and control system. Under the guidance of the computer measurement and control system, a target simulation reflector on the rotary target is driven by the rotary platform to simulate an optical target in movement, the dynamic photoelectric autocollimator provides the rapid and high-precision angle miss distance for the two-dimensional directional mirror, the data acquiring and processing system feeds back and controls the two-dimensional directional mirror to track the target simulation movement in real time, and the computer measurement and control system processes the measurement data of the photoelectric autocollimator in real time to obtain the data reflecting the dynamic response properties of the two-dimensional directional mirror. The device and method provided by the invention can be used for detection of properties of the two-dimensional directional mirror, such as axis shaking, step response, dynamic continuous tracking and the like.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

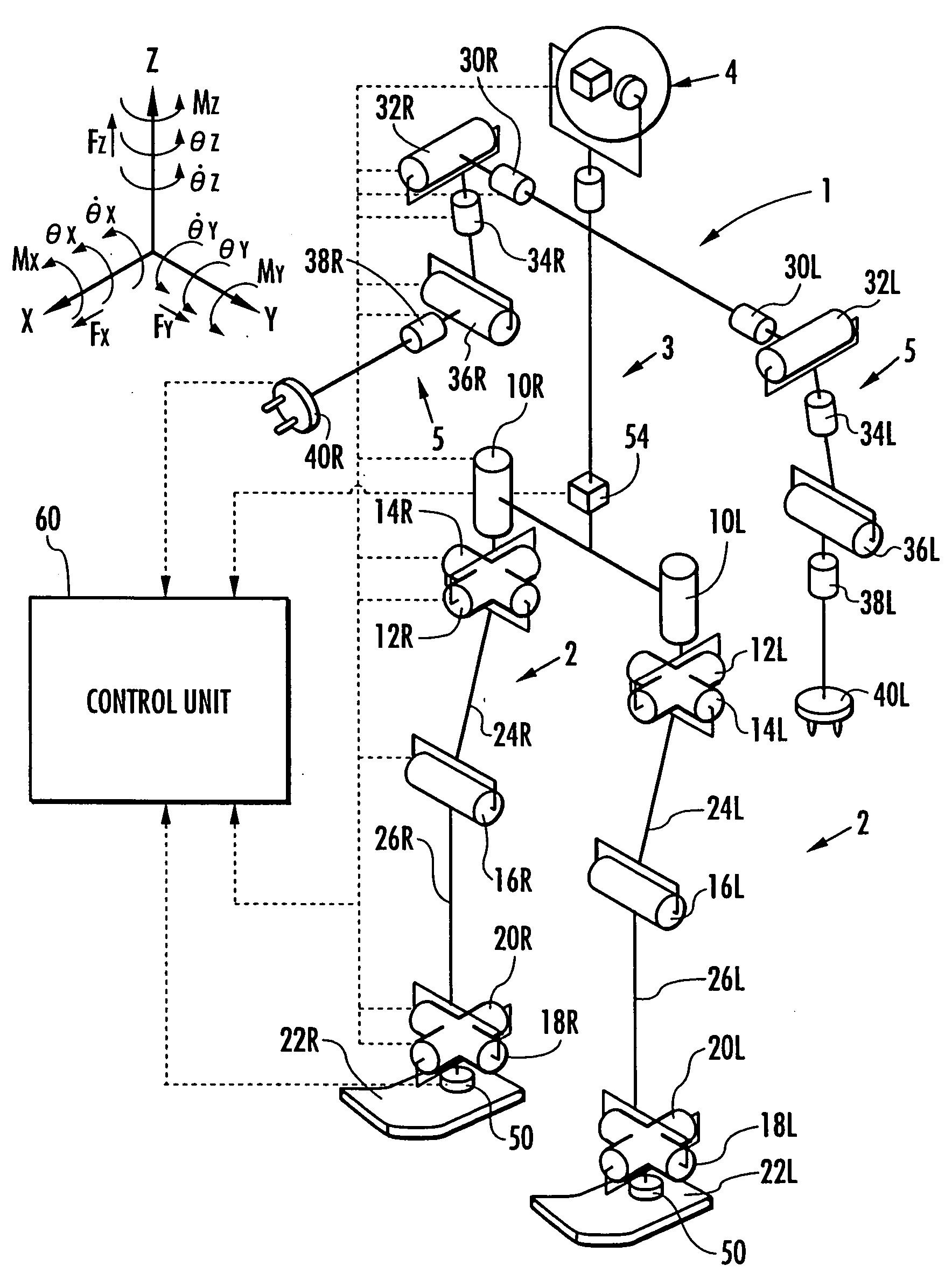

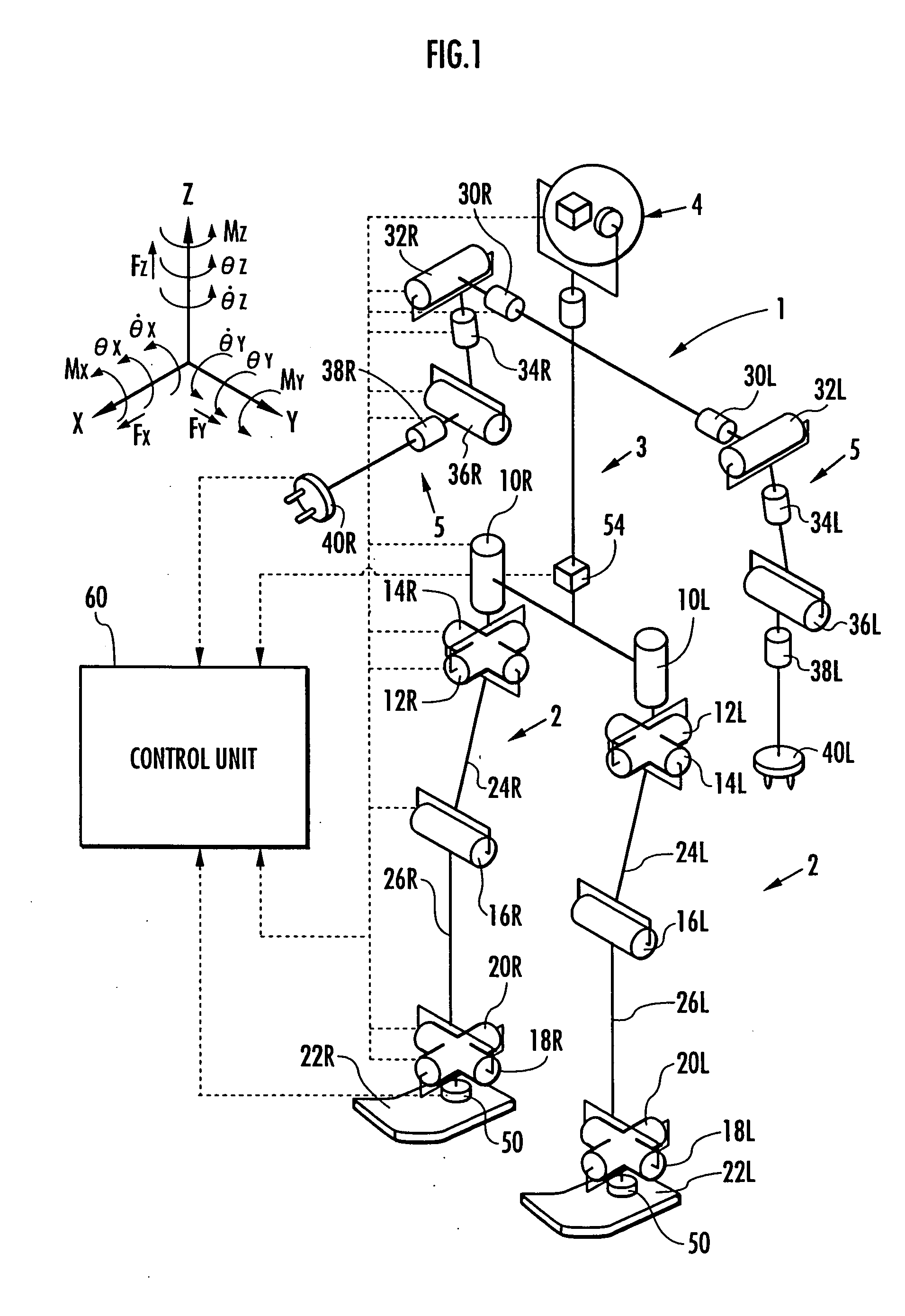

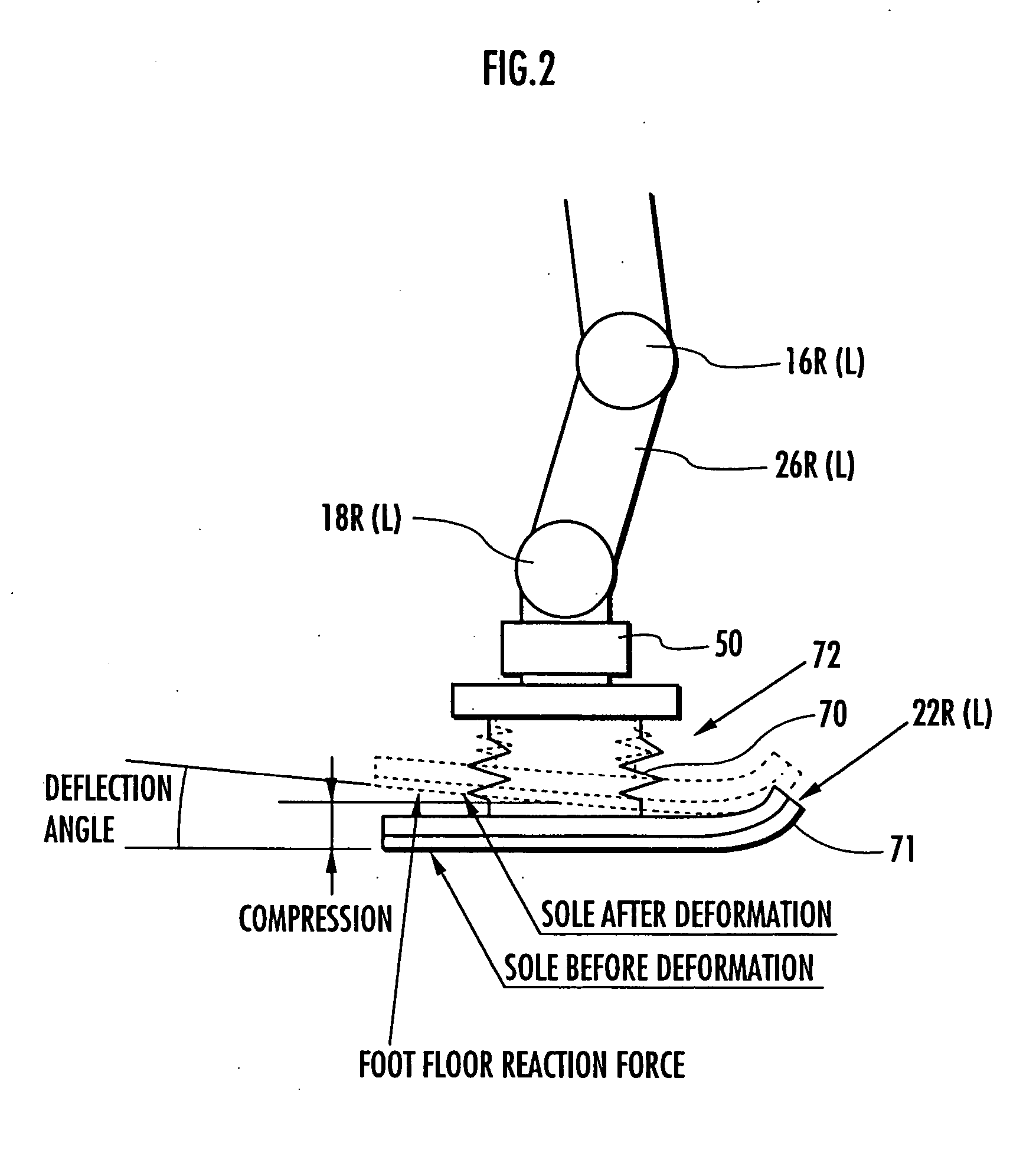

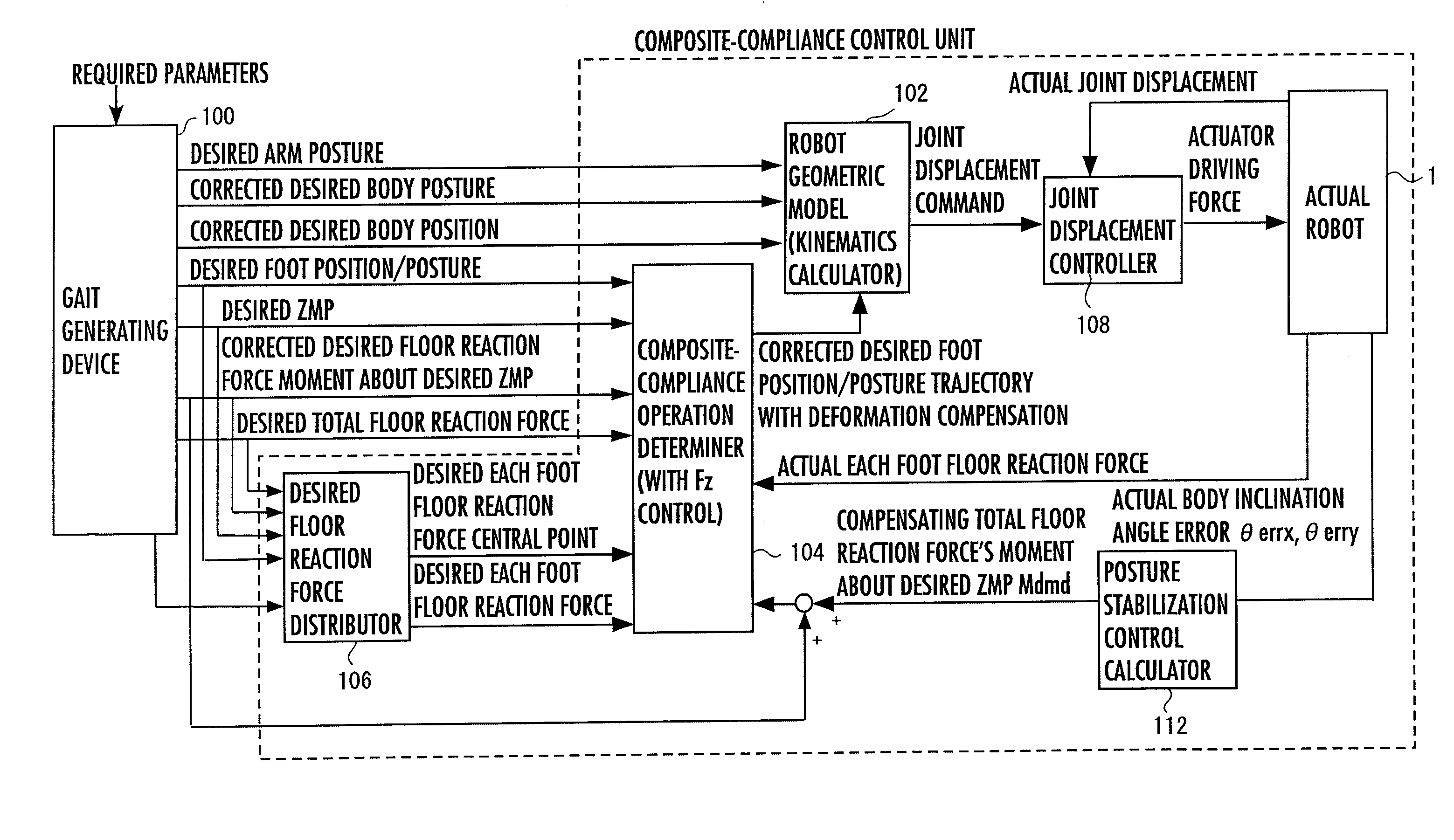

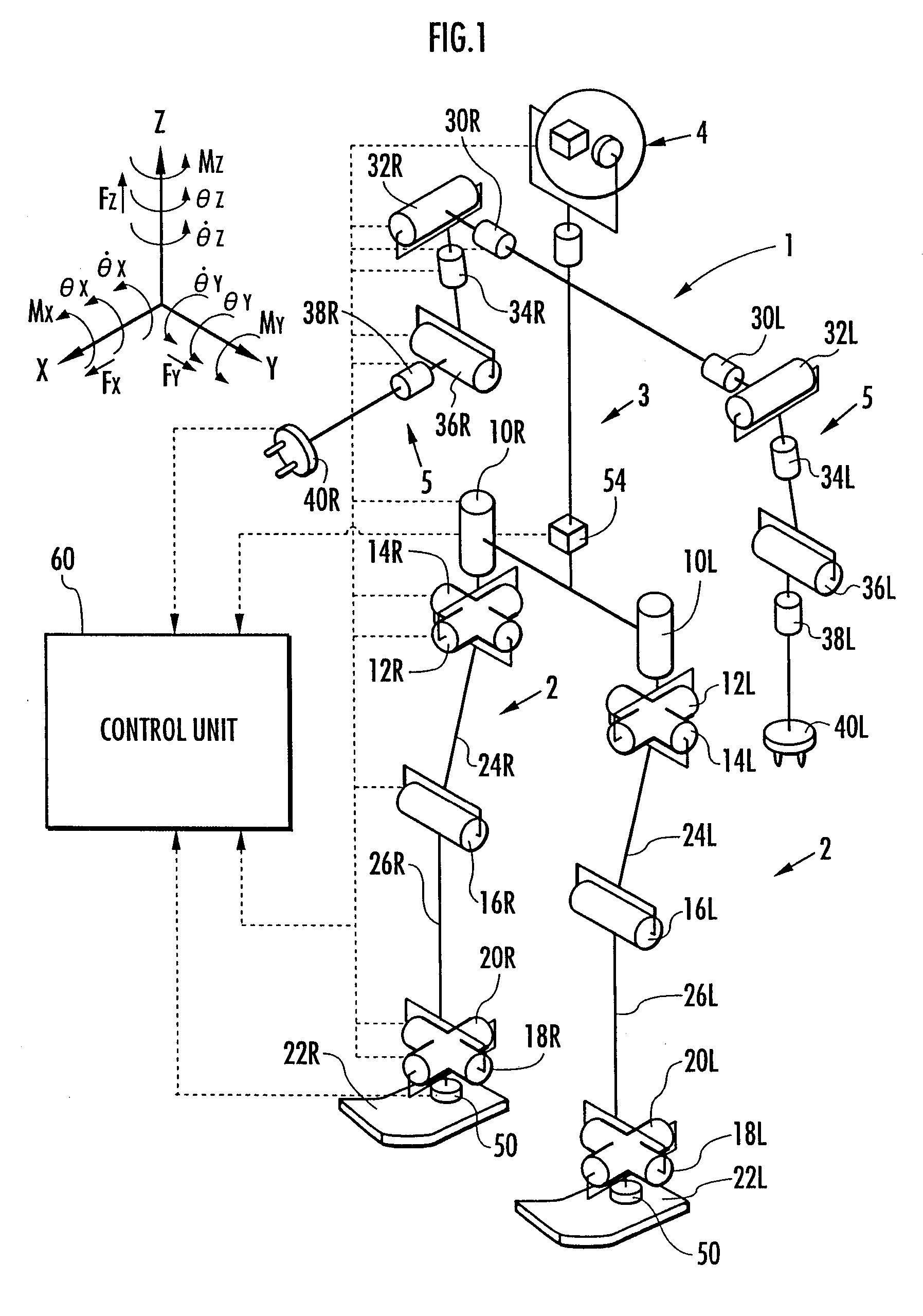

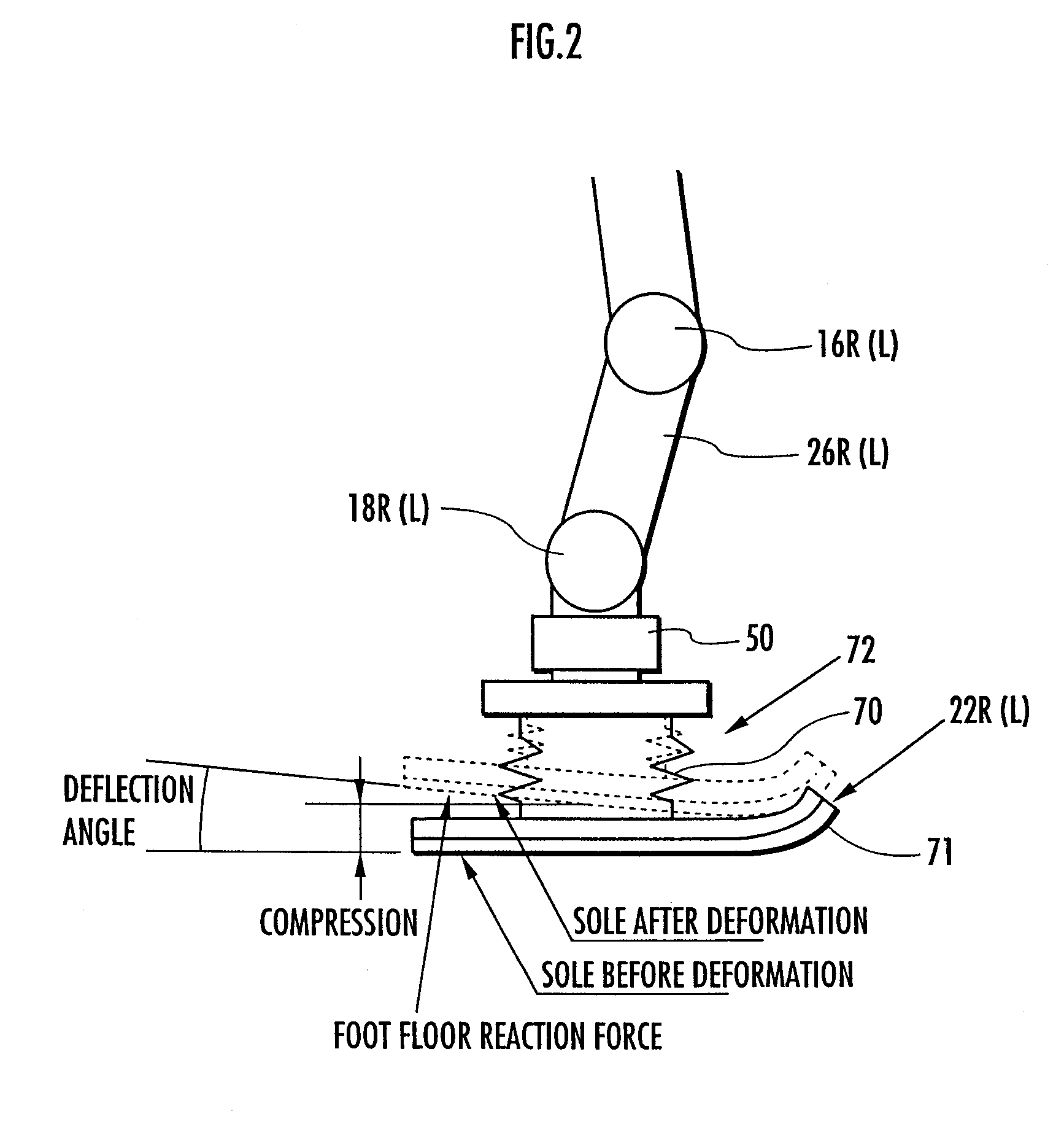

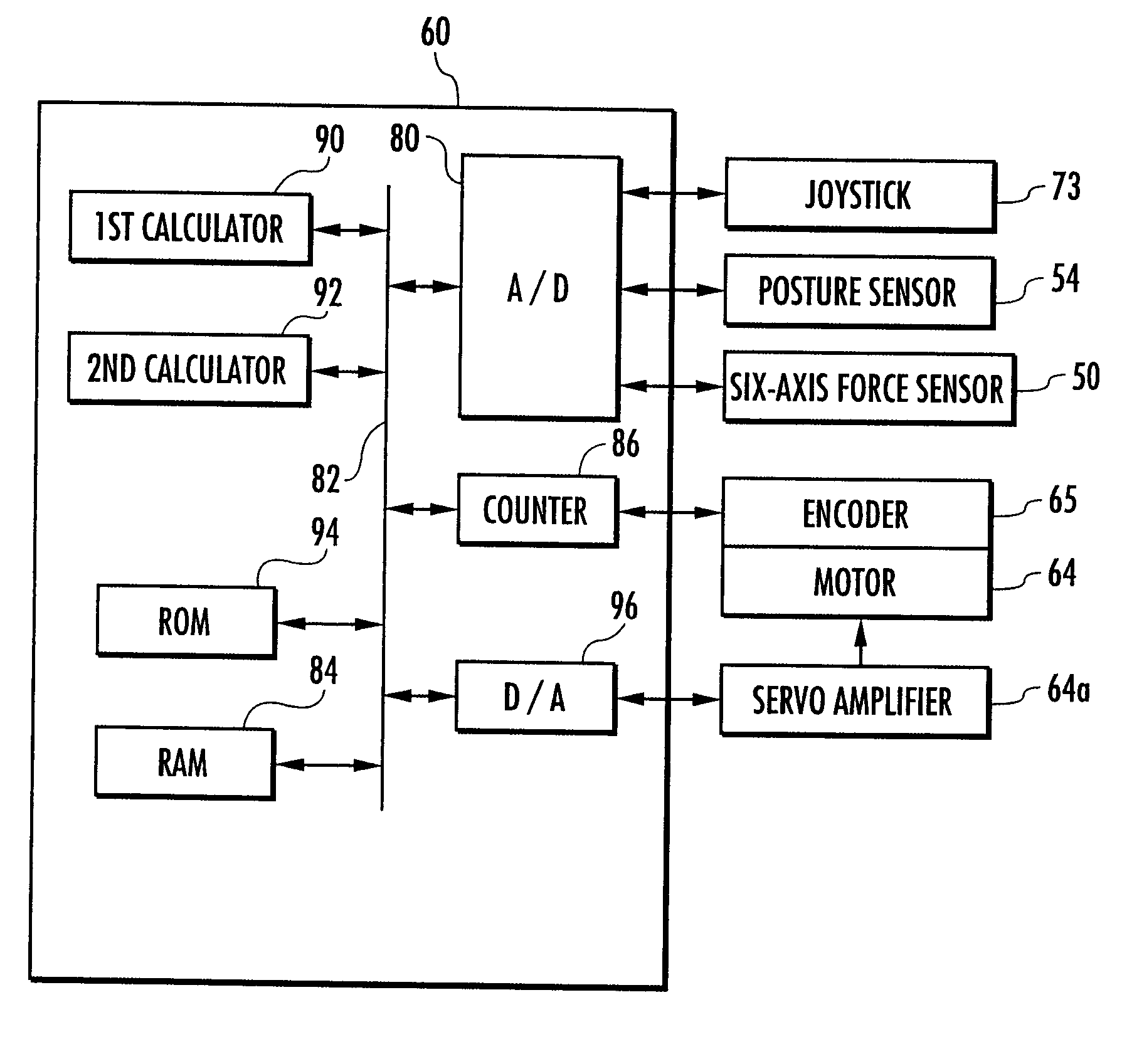

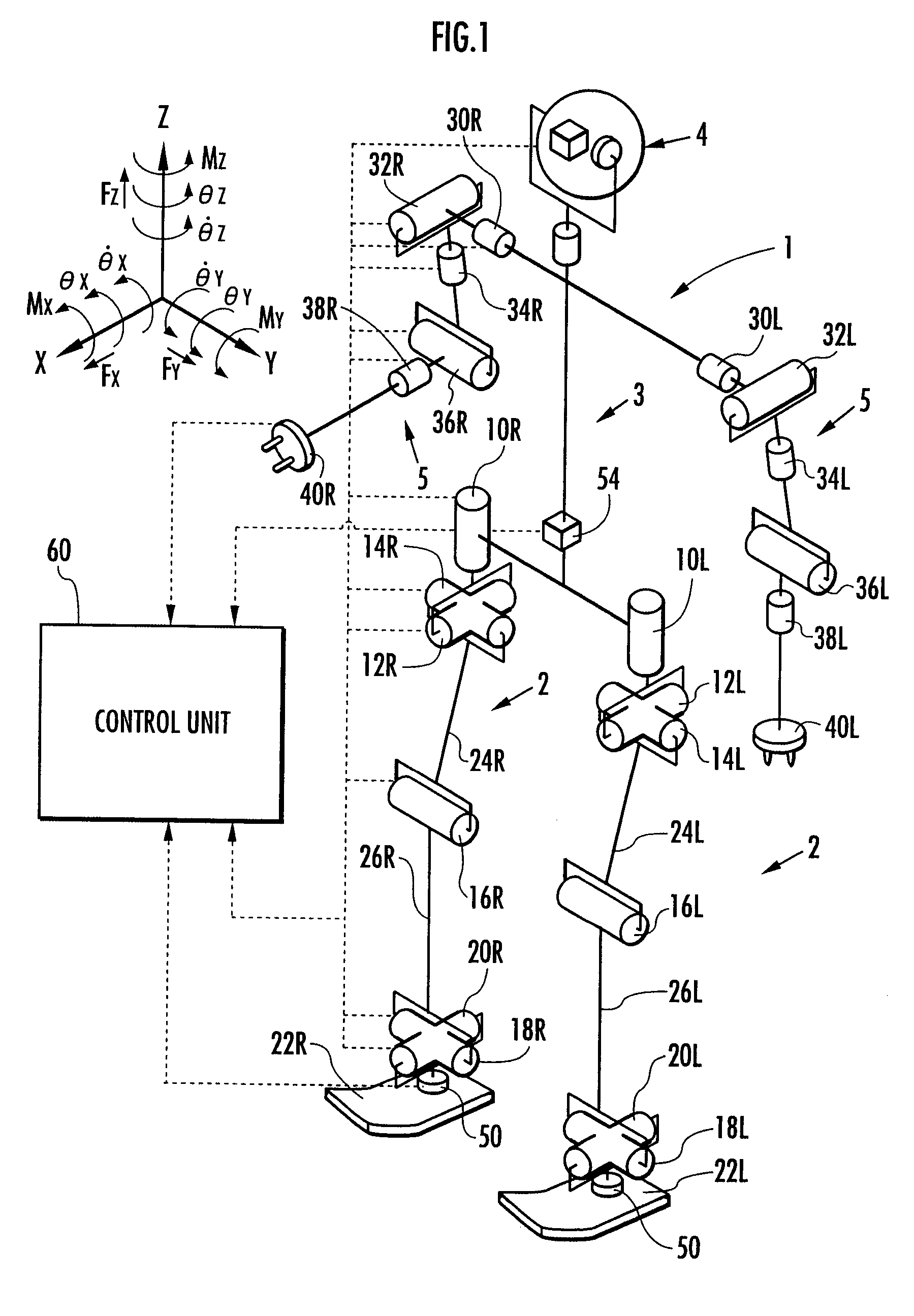

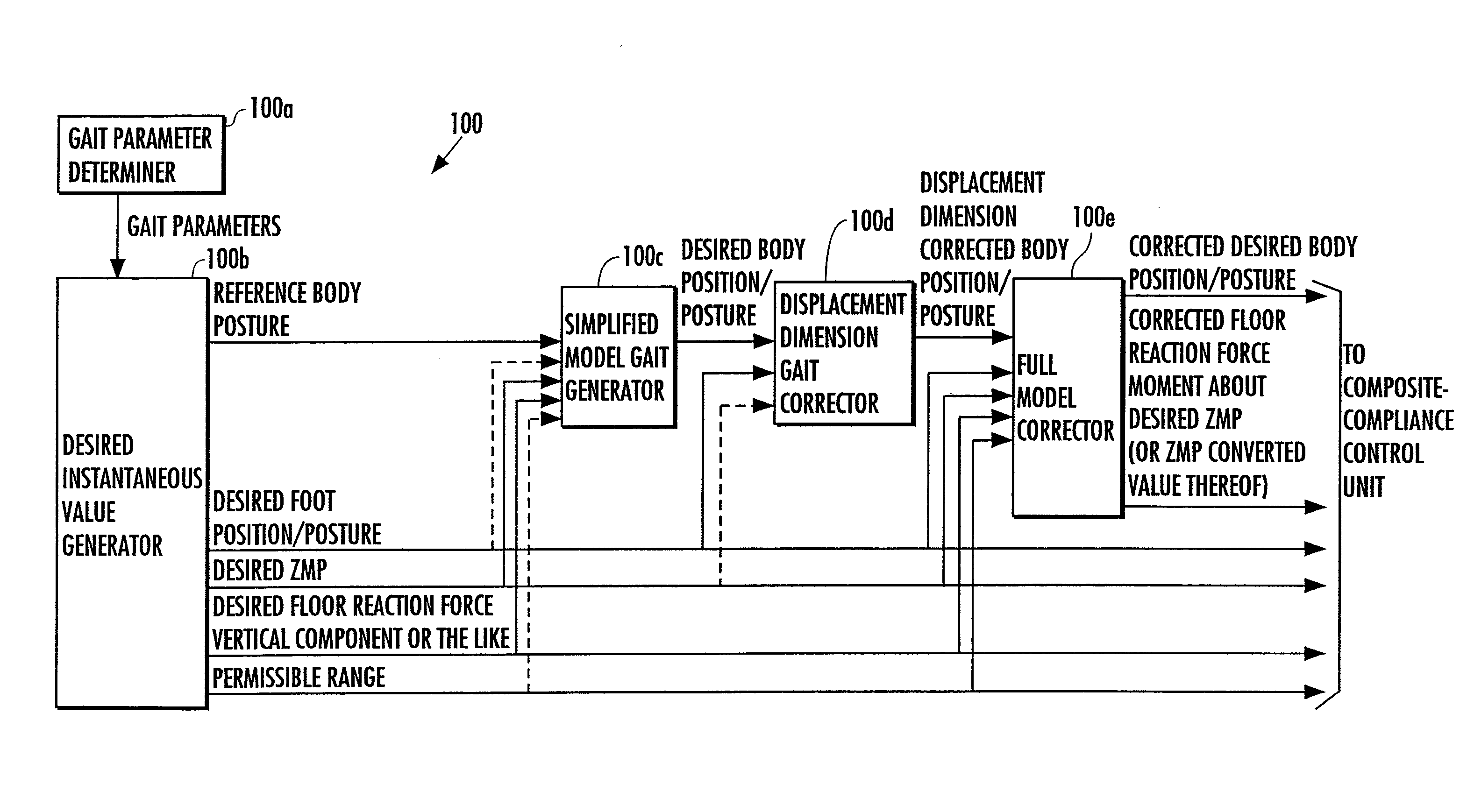

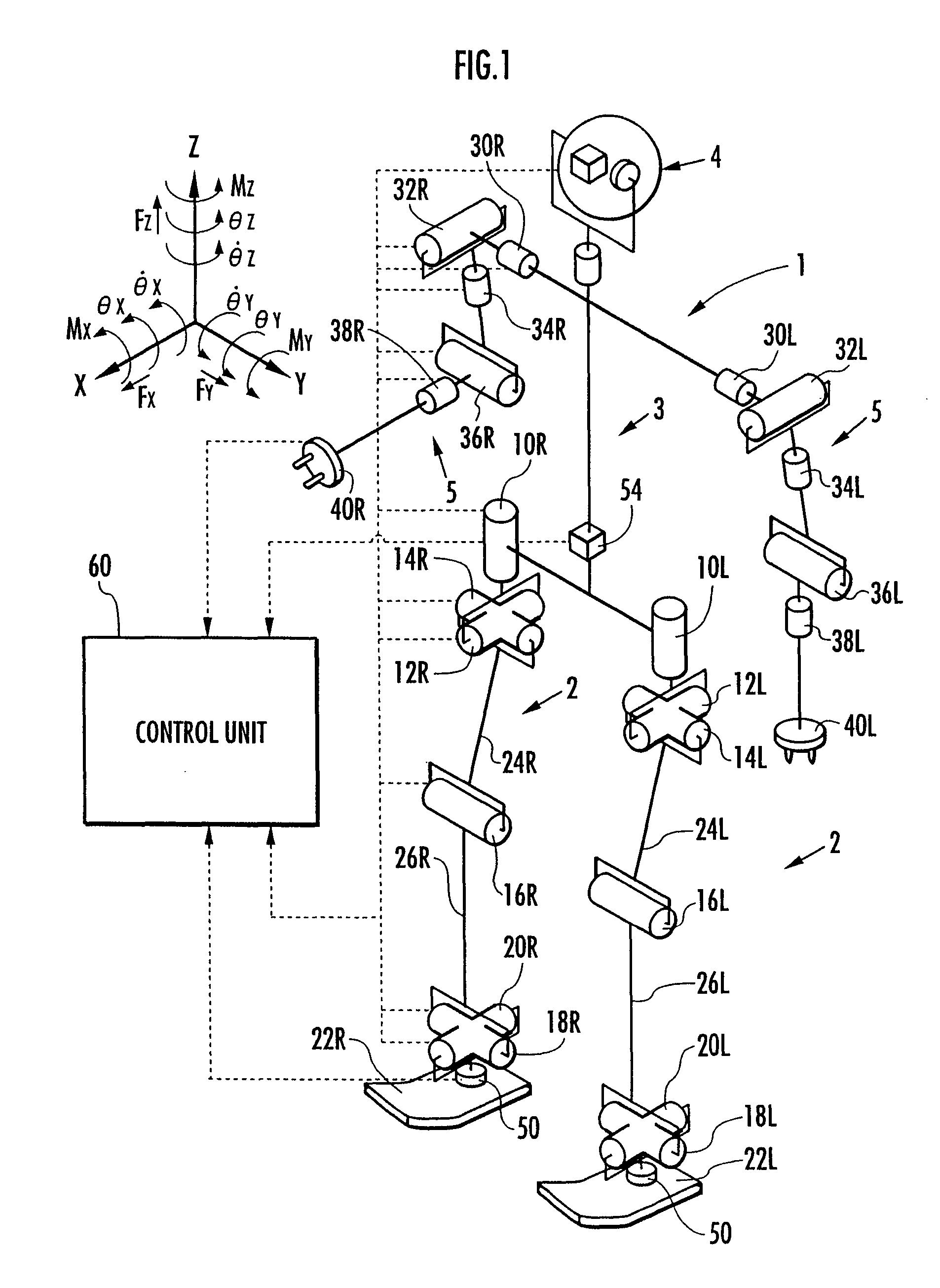

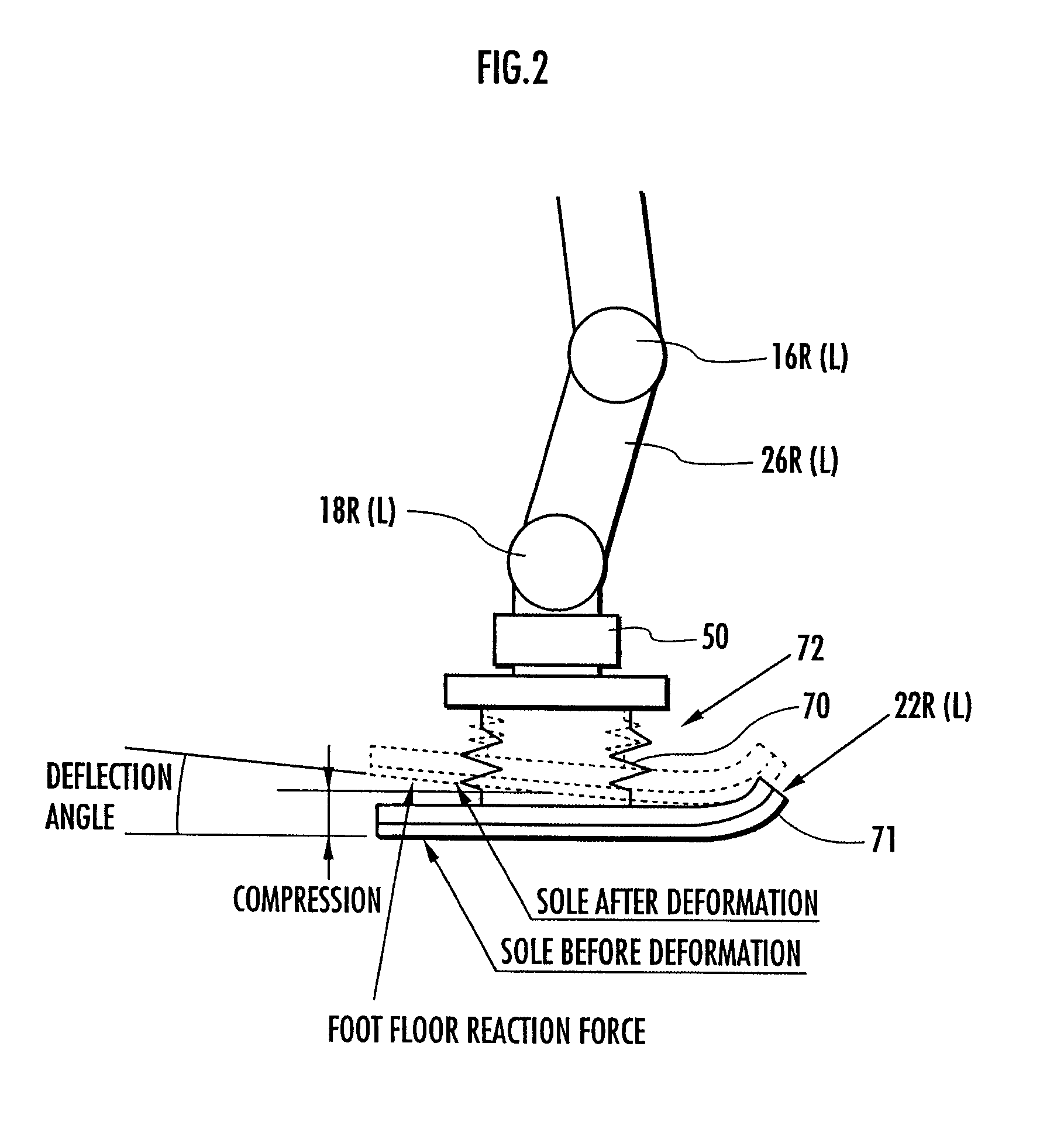

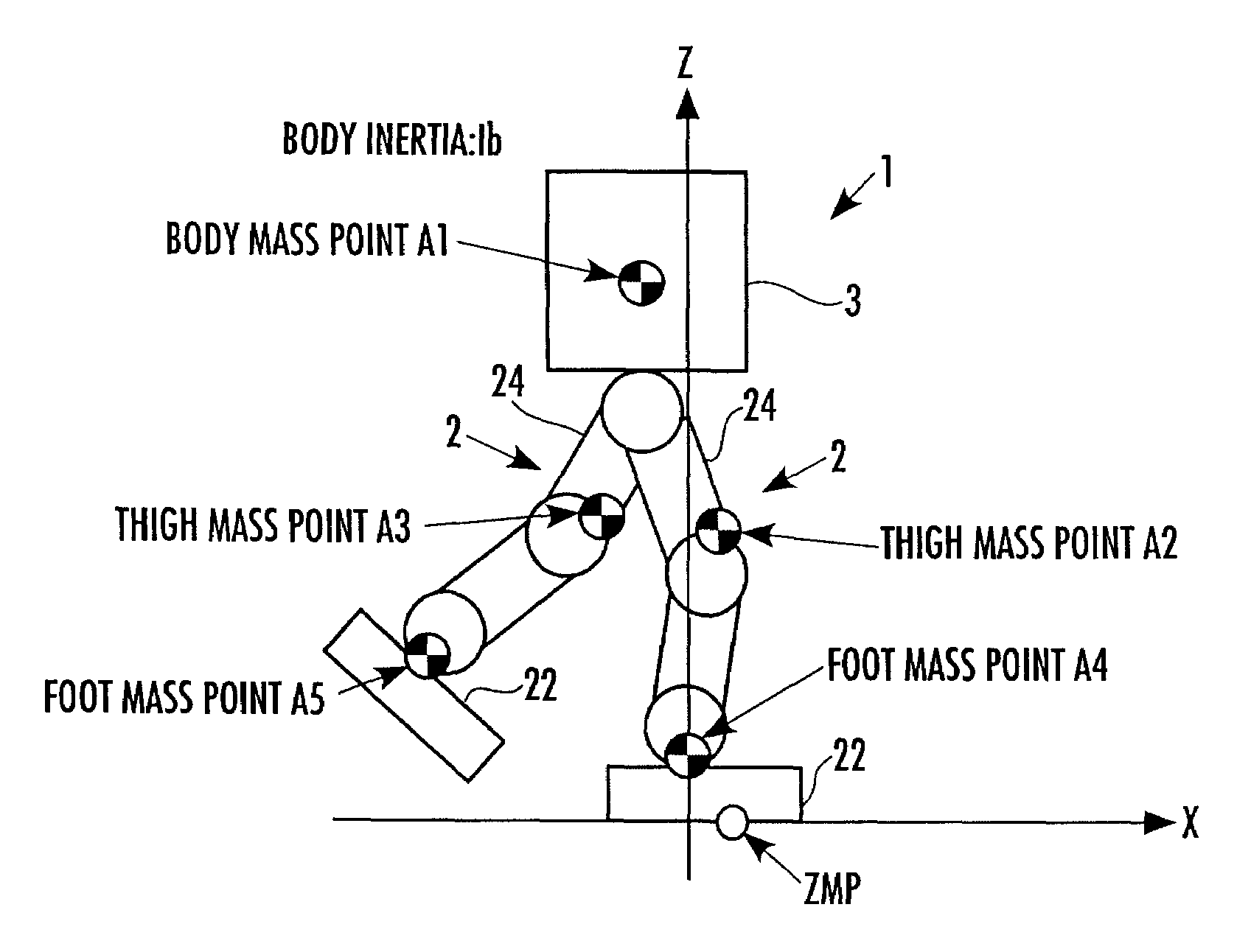

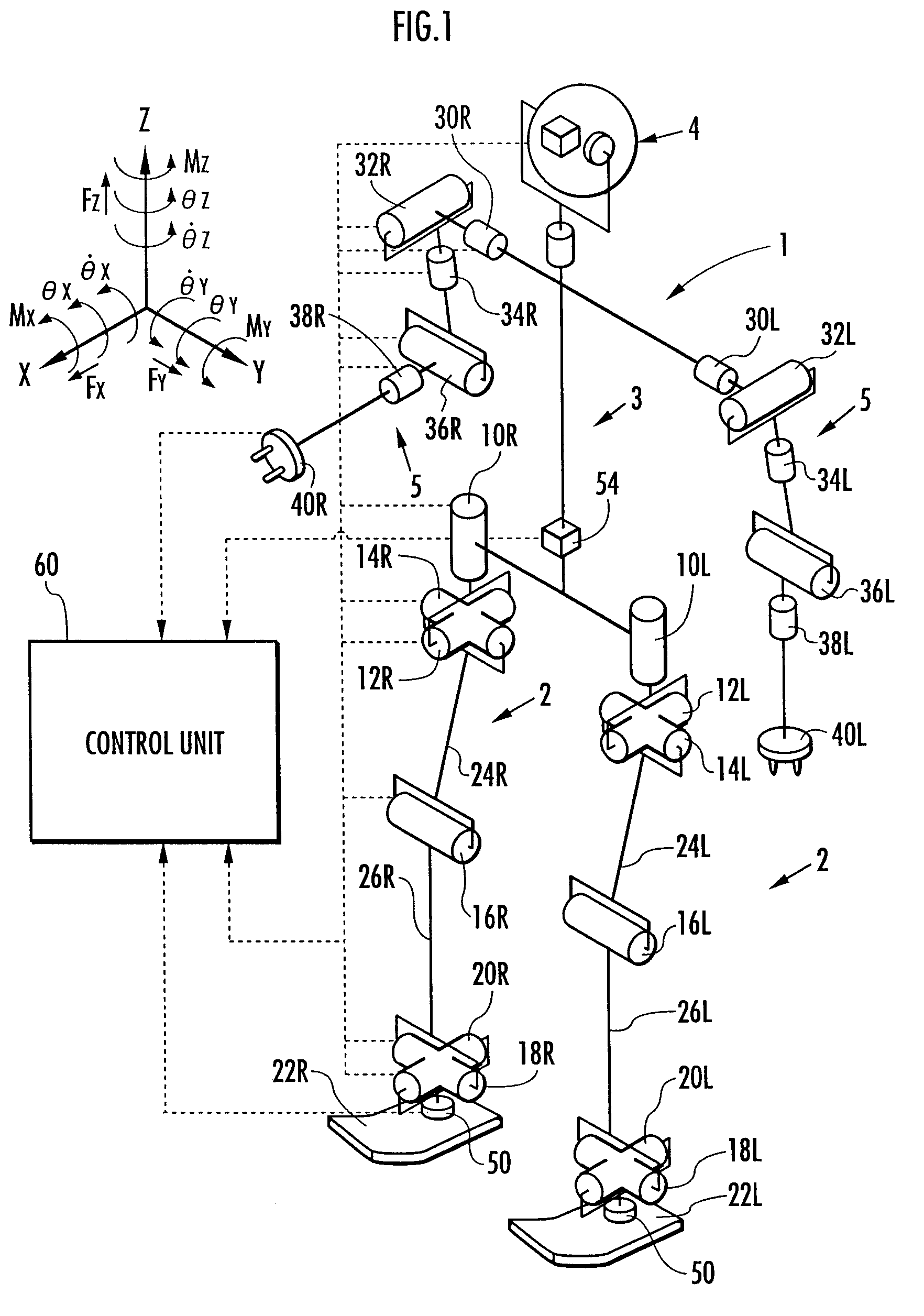

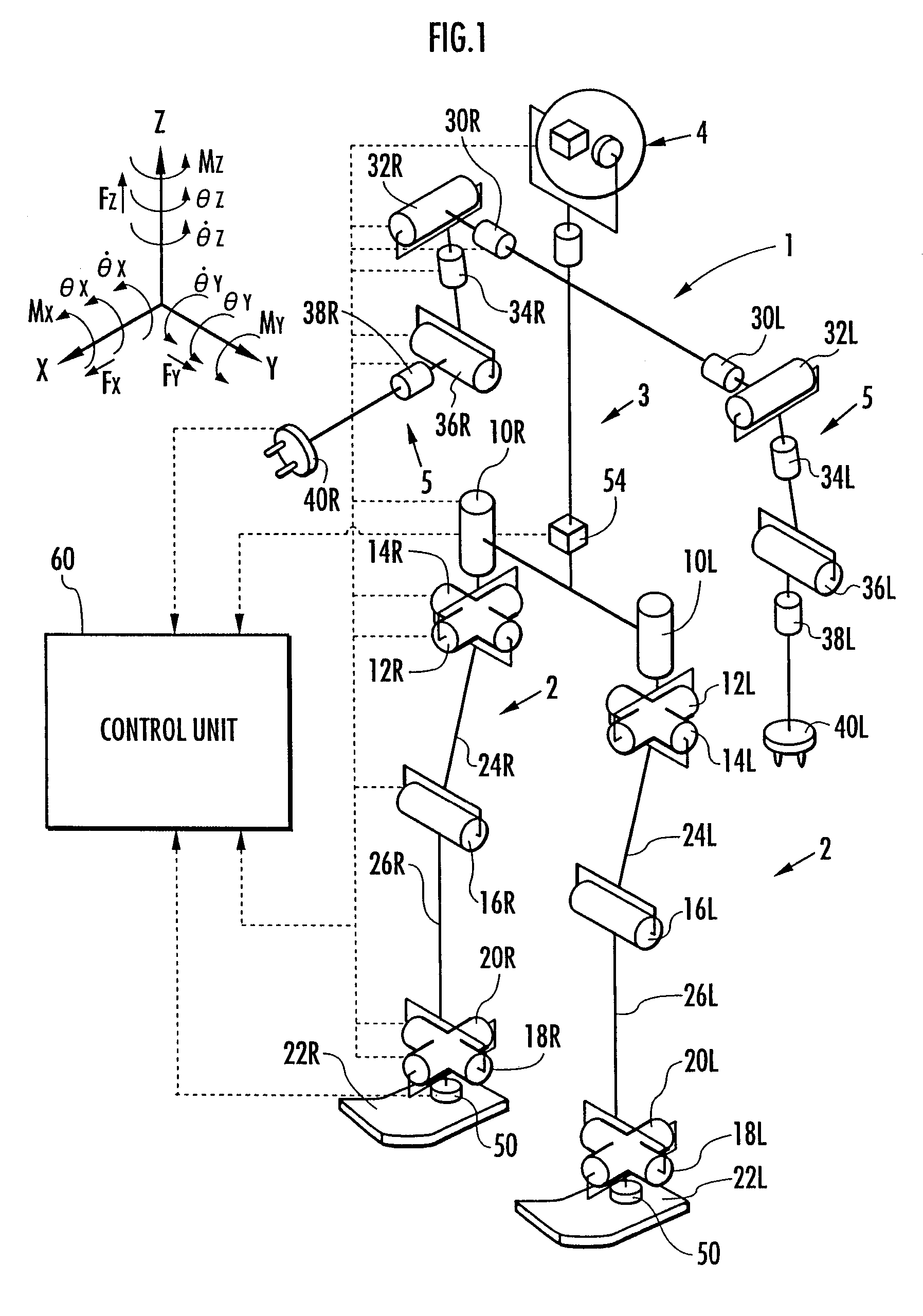

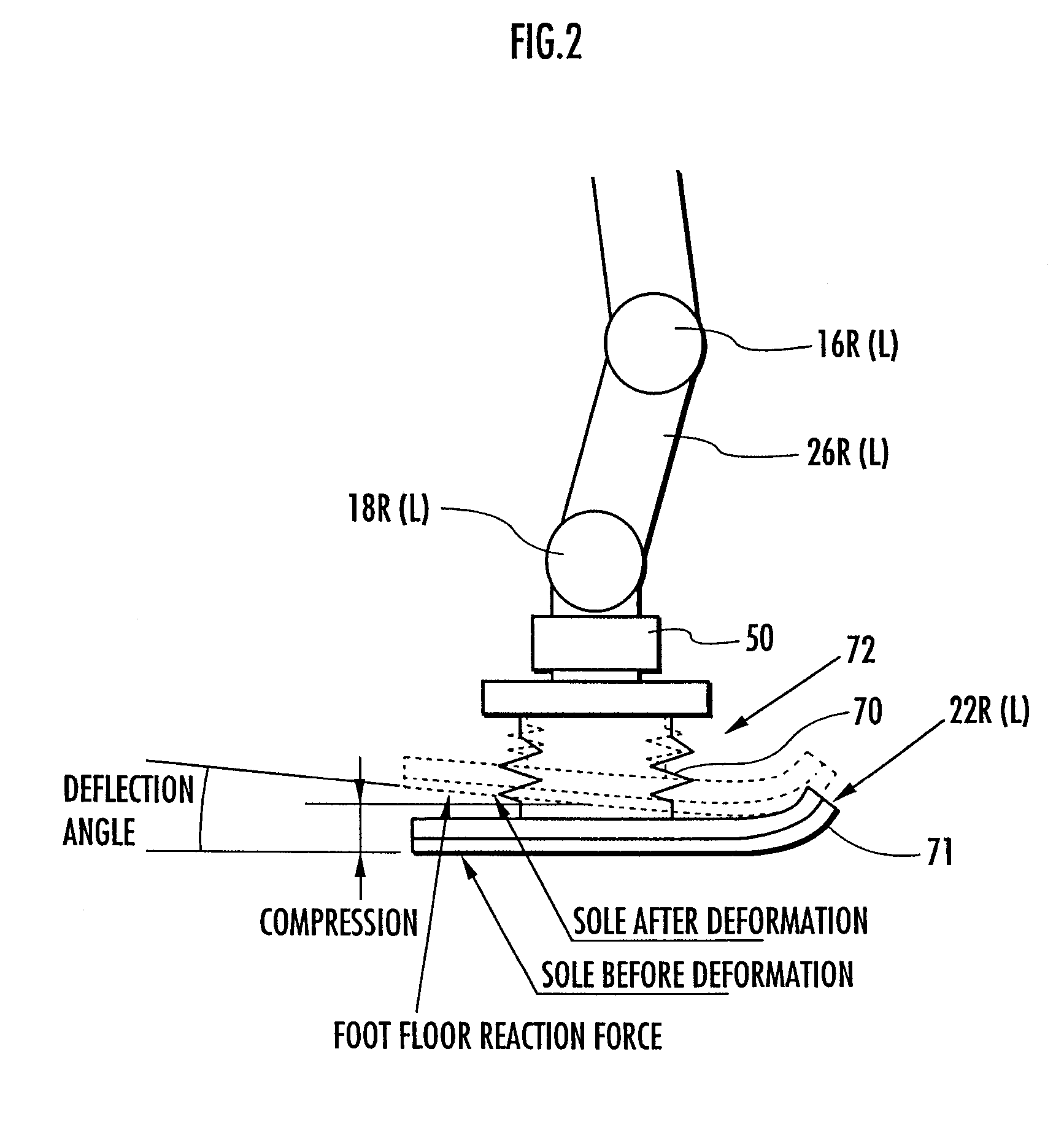

Gait generating device of legged mobile robot and legged mobile robot controller

ActiveUS20060184276A1Prevent the robot from spinning and fallingAvoid relative motionProgramme-controlled manipulatorComputer controlMobile robot controlDynamic models

A permissible range of a restriction object amount, which is a vertical component of a floor reaction force moment or a component of the floor reaction force moment in floor surface normal line direction, or a vertical component of an angular momentum changing rate of the robot or a component of the angular momentum changing rate in floor surface normal line direction, is set, and at least a provisional instantaneous value of a desired motion is input to a dynamic model so as to determine an instantaneous value of a model restriction object amount as an output of the dynamic model. An instantaneous value of a desired motion is determined by correcting the provisional instantaneous value of the desired motion such that at least the instantaneous value of the model restriction object amount falls within the permissible range.

Owner:HONDA MOTOR CO LTD

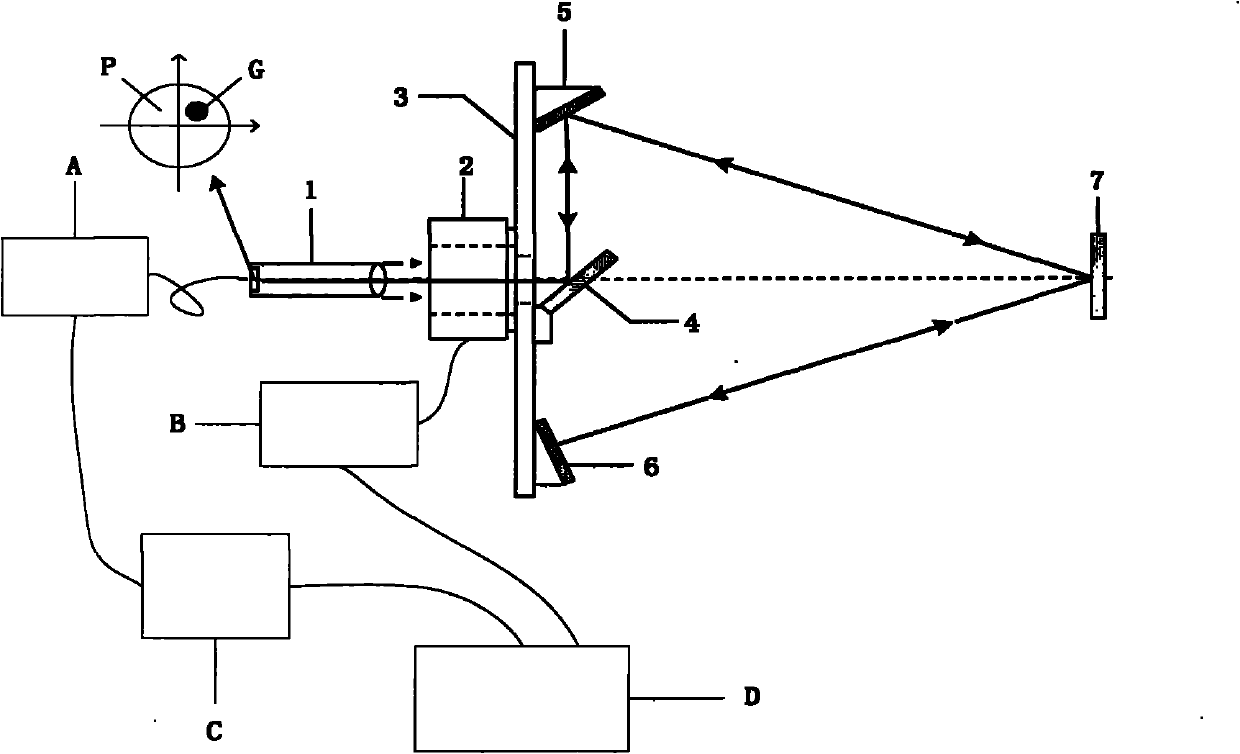

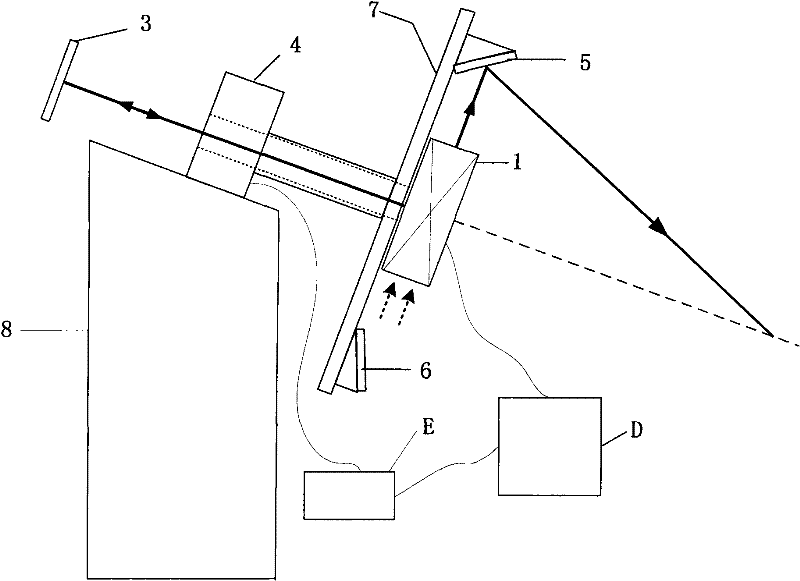

Optical dynamic target device with high accuracy

InactiveCN102226701ARealize online detectionReal-time compensation of spatial anglesMeasurement devicesMultiplexingMeasurement precision

The invention relates to an optical dynamic target device with high accuracy, which comprises an adjusting platform, a main revolution shafting, a rotating arm, a multifunctional multiplexing dynamic laser self-collimation meter, an external fixing reference reflector, a computer and the like, wherein the multifunctional multiplexing dynamic laser self-collimation meter simulates a space motion target, is simultaneously used as an active angle measuring unit, is combined with the external fixing reference reflector to convert the shake of an optical dynamic target shafting into the dynamic change of a two-dimensional angle; the online measurement is carried out on the dynamic error quantity which is caused by the shake of the dynamic target shafting; and a computer modifies the static calibration value of an optical dynamic target in real time according to the shake error of the shafting, thereby accurately determining the space angle of the dynamic target at any moment. The device provided by the invention effectively improves the dynamic accuracy of the optical dynamic target and provides the more accurate detection device and detection method for the measuring accuracy of a photoelectric tracking measuring system.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

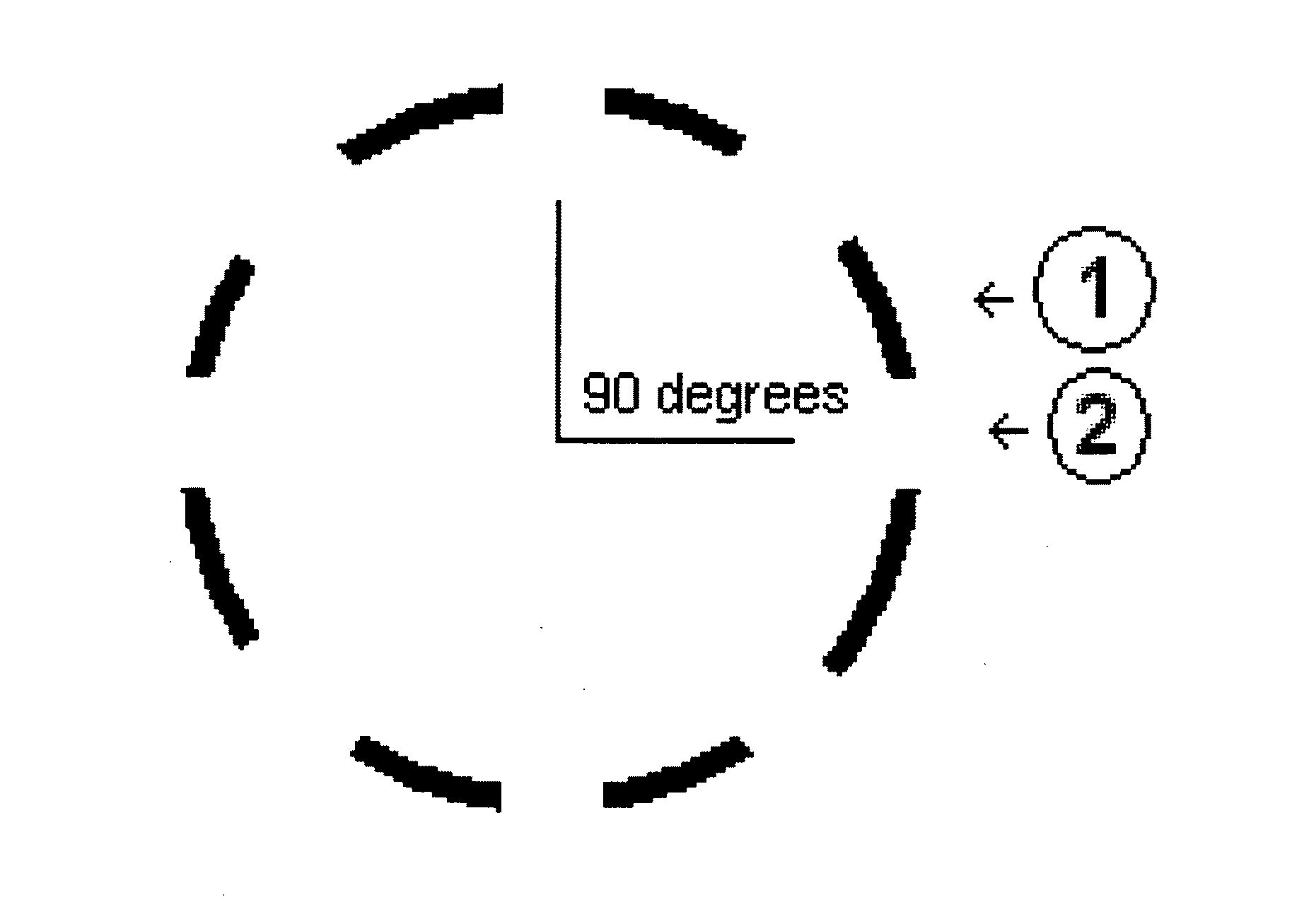

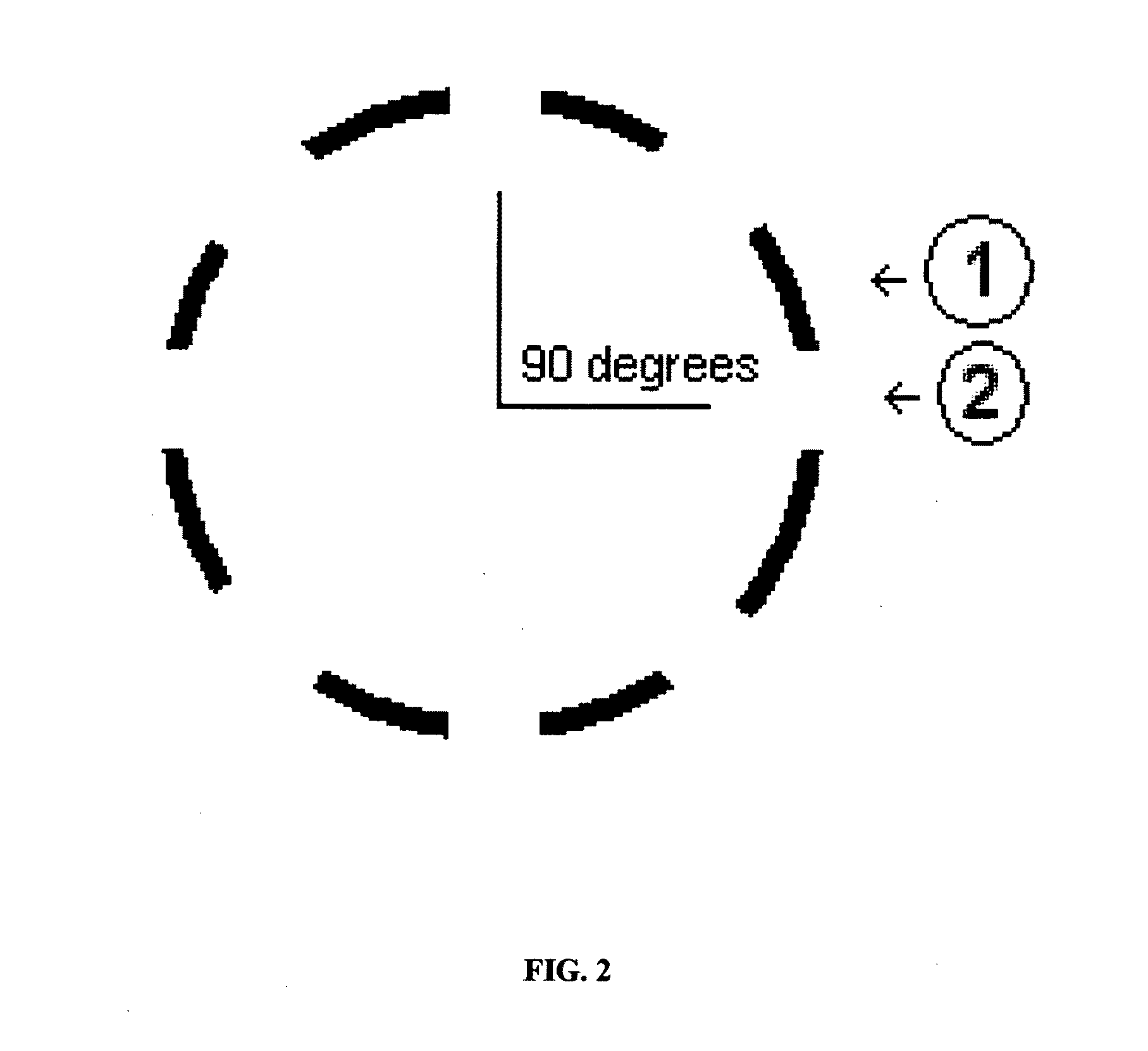

Animated image vision test

Owner:ALLAN N HYTOWITZ

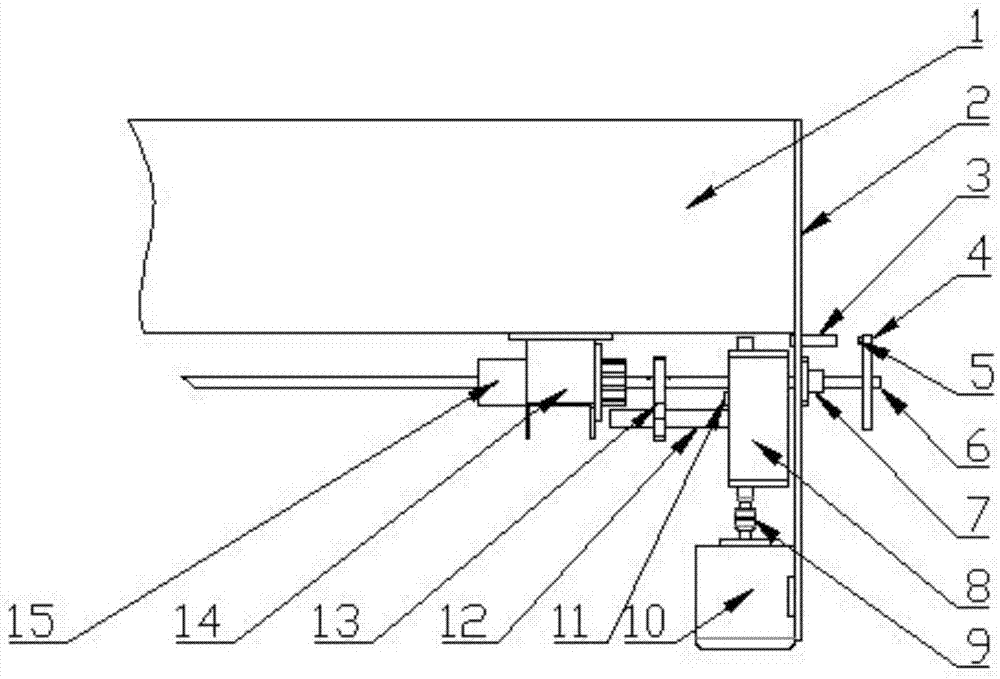

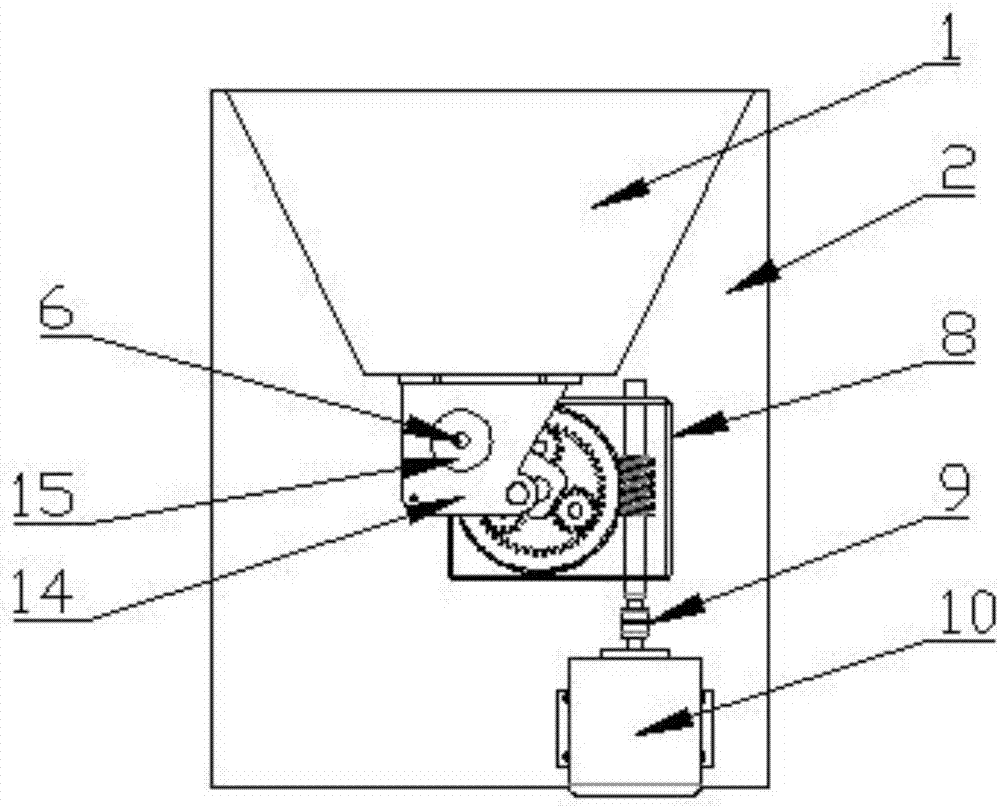

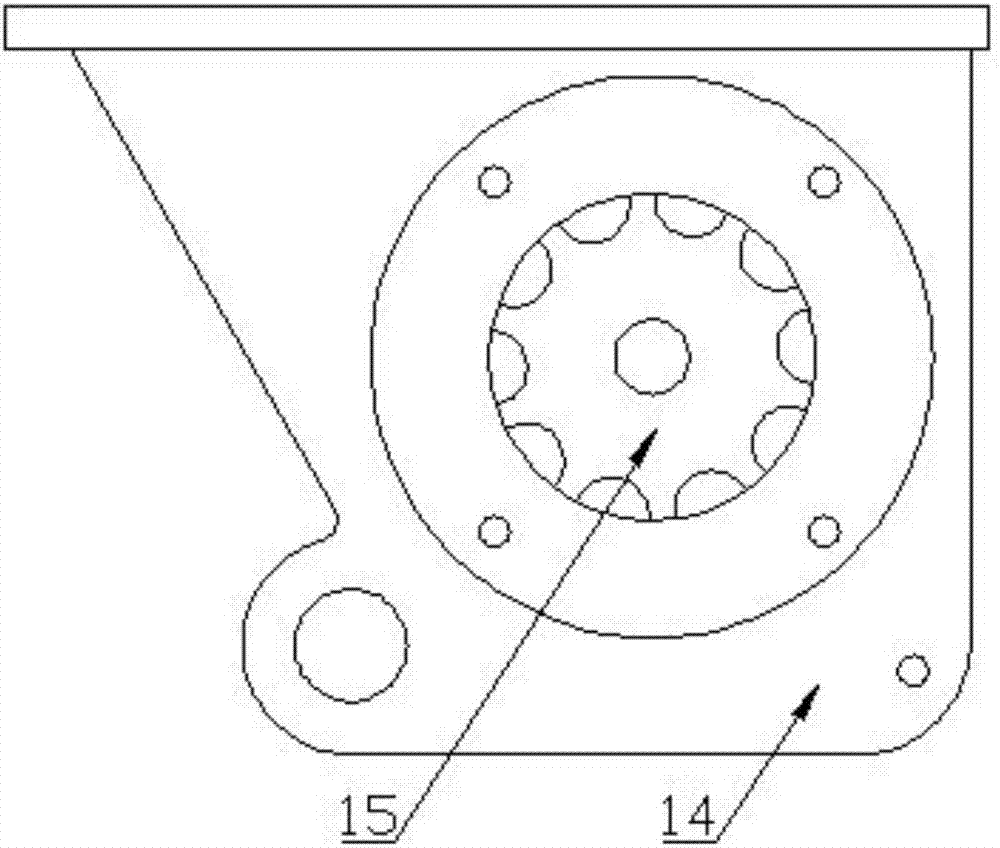

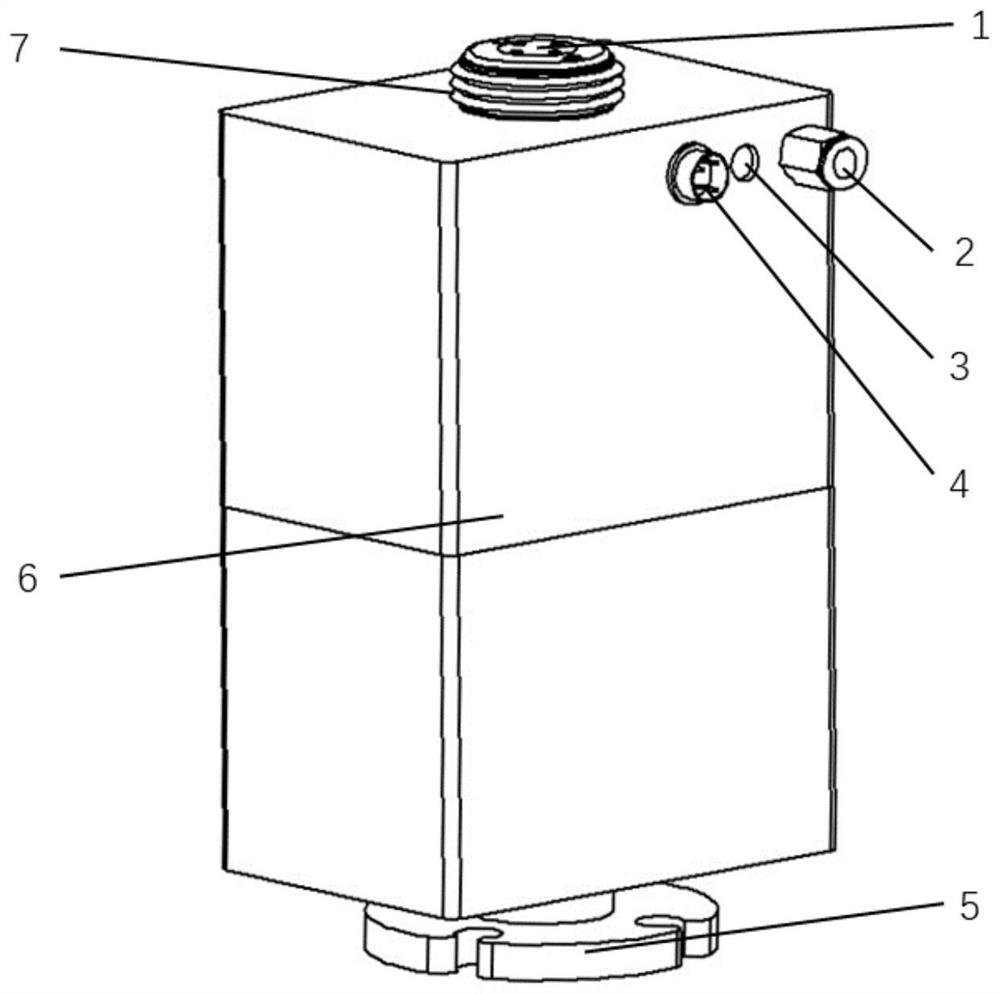

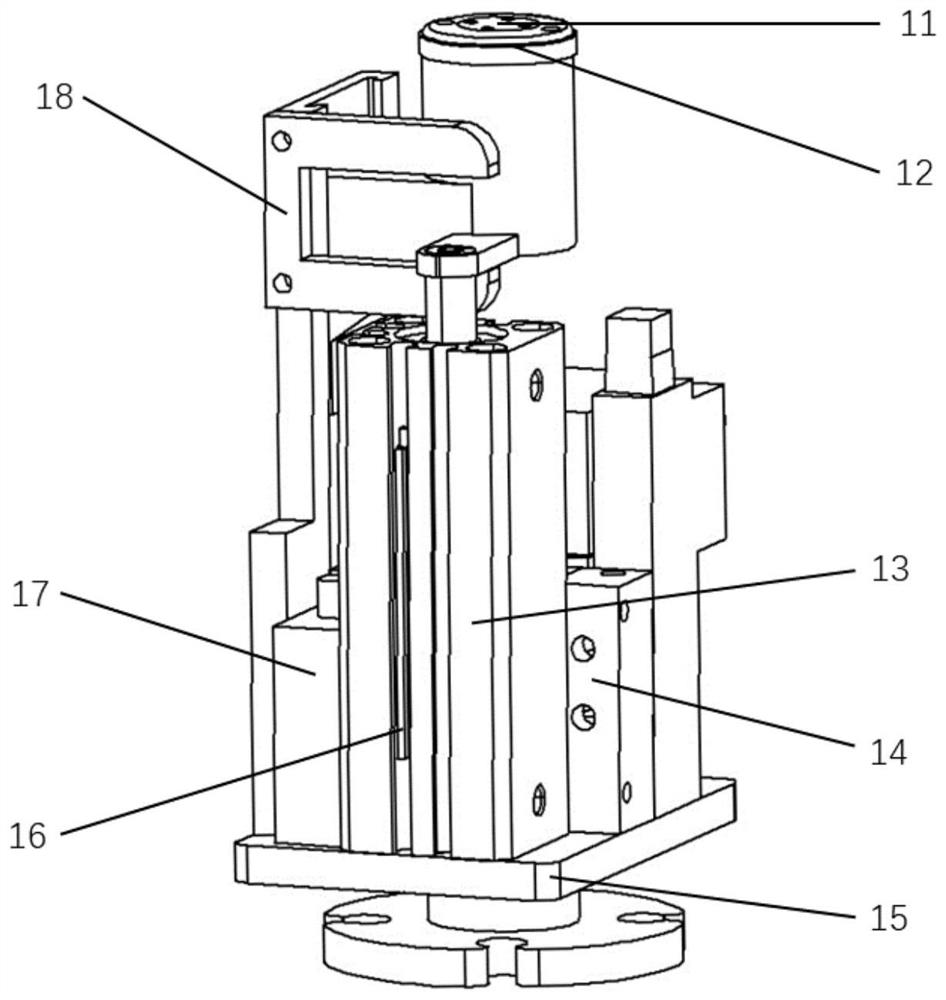

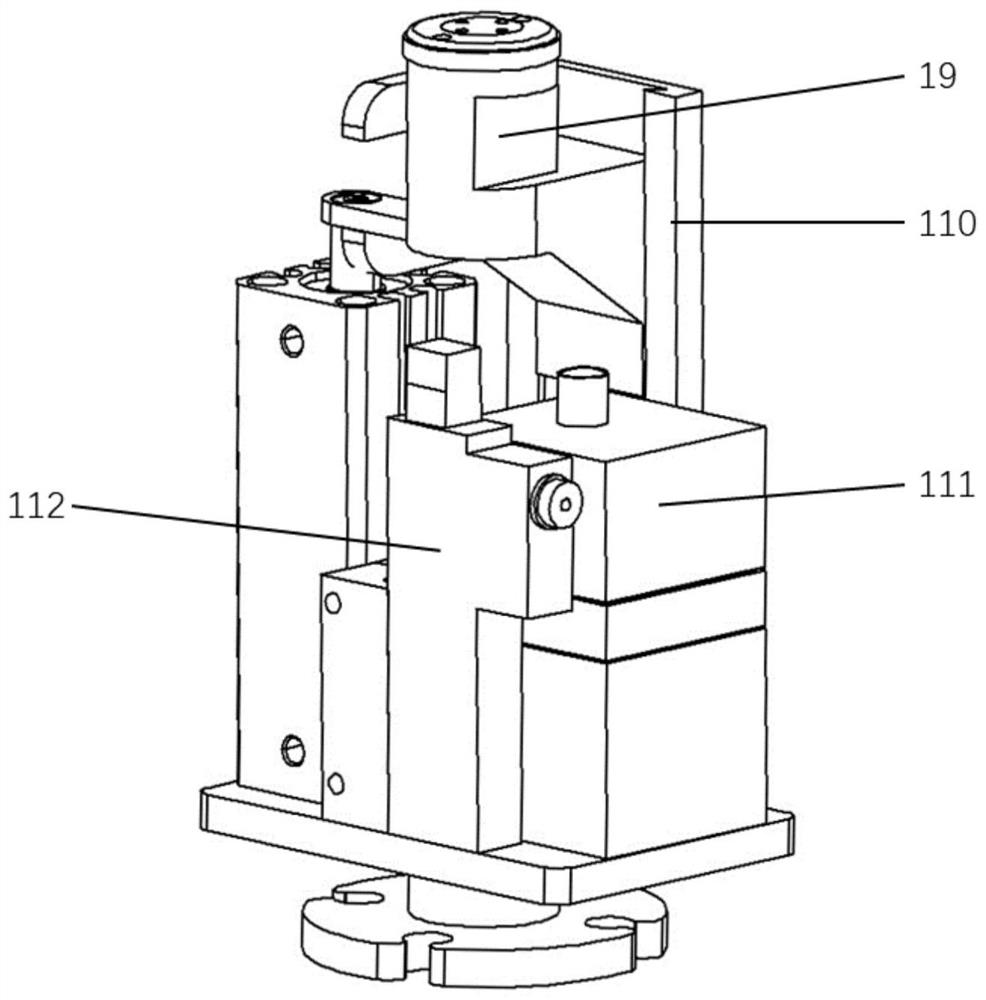

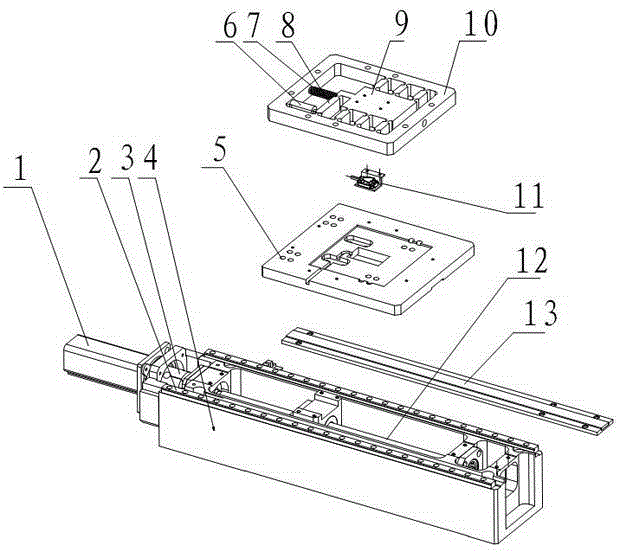

Variable rate fertilization adjustment device and control method of same

ActiveCN106941842AReduce loadImprove dynamic accuracyProgramme controlComputer controlMotor driveControl system

The invention relates to a variable rate fertilization adjustment device and a control method of same. The adjustment device includes a fertilizer box, a machine frame, a fertilization executing apparatus, and an opening degree adjustment apparatus. The fertilization executing apparatus includes a plurality of fertilizer ejectors, an outer groove wheel, and a fertilizer ejection shaft. The fertilizer ejectors are disposed below the fertilizer box in an array and are linked to work, thus uniformly performing variable adjustment on fertilization quantity; the opening degree adjustment apparatus includes a speed reducing mechanism, a lead screw nut mechanism, a paddle mechanism, a stepping motor and a control system thereof. During operation, the stepping motor drives a lead screw to rotate with combination of the speed reducing mechanism, so that the paddle on the lead screw moves axially along the lead screw and triggers the fertilizer ejection shaft to move axially, thereby further changing opening degree of the outer groove wheel to adjust fertilizer ejection quantity. In the device, a planetary wheel speed reducing mechanism is added, so that torque is increased and load on the stepping motor is reduced, and so that accurate control on the axial movement of the fertilizer ejection shaft is achieved by means of rotation of the stepping motor, thereby increasing dynamic precision of the variable rate fertilization adjustment device.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

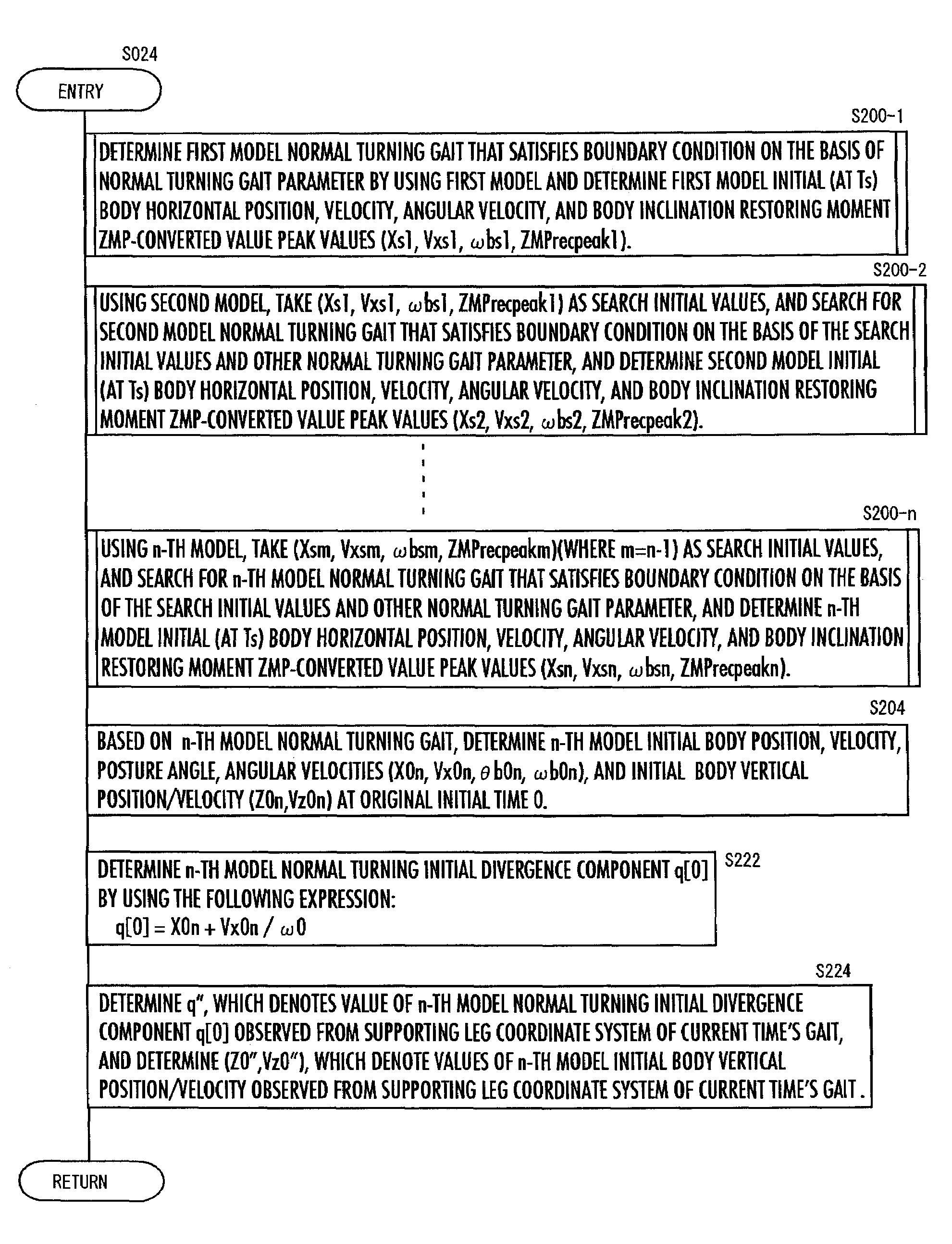

Gait generating system for mobile robot

ActiveUS20070168080A1Easy and efficientEasily searchComputer controlSimulator controlMobile robotEngineering

A gait generating system for a mobile robot has n dynamic models and determines a first gait parameter defining a desired gait such that the boundary condition of a gait on a first dynamic model is satisfied. The first gait parameter is corrected step by step by using an m-th dynamic model (m: integer satisfying 2≦m≦n), which is each dynamic model other than the first dynamic model, and an m-th gait parameter that satisfies the boundary condition on the m-th dynamic model is determined. The m-th gait parameter is determined by correcting an object of an (m−1)th gait parameter to be corrected on the basis of the degree of deviation of the gait generated on the m-th dynamic model by using the (m−1)th gait parameter from the boundary condition. A final determined n-th gait parameter and an n-th dynamic model are used to generate a desired gait.

Owner:HONDA MOTOR CO LTD

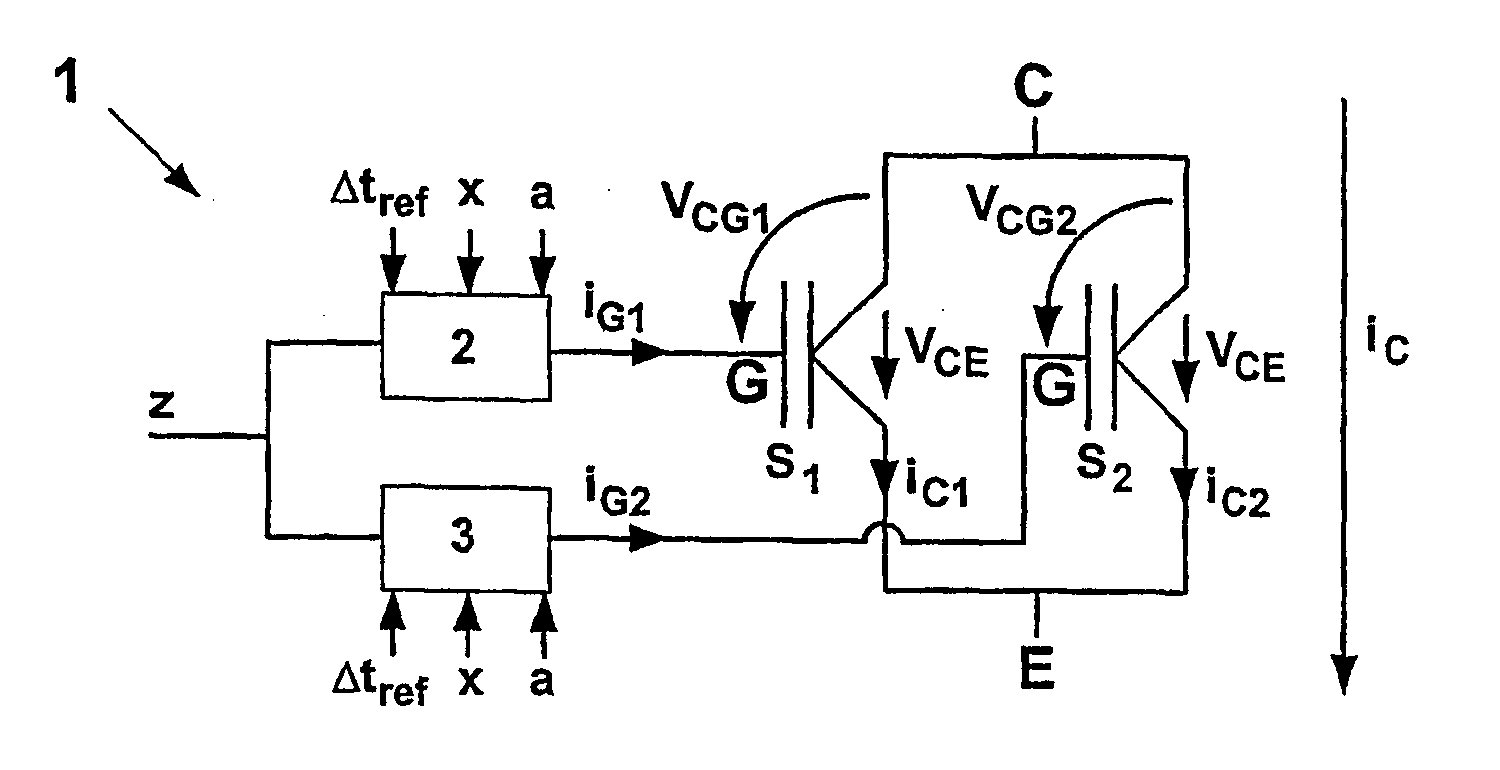

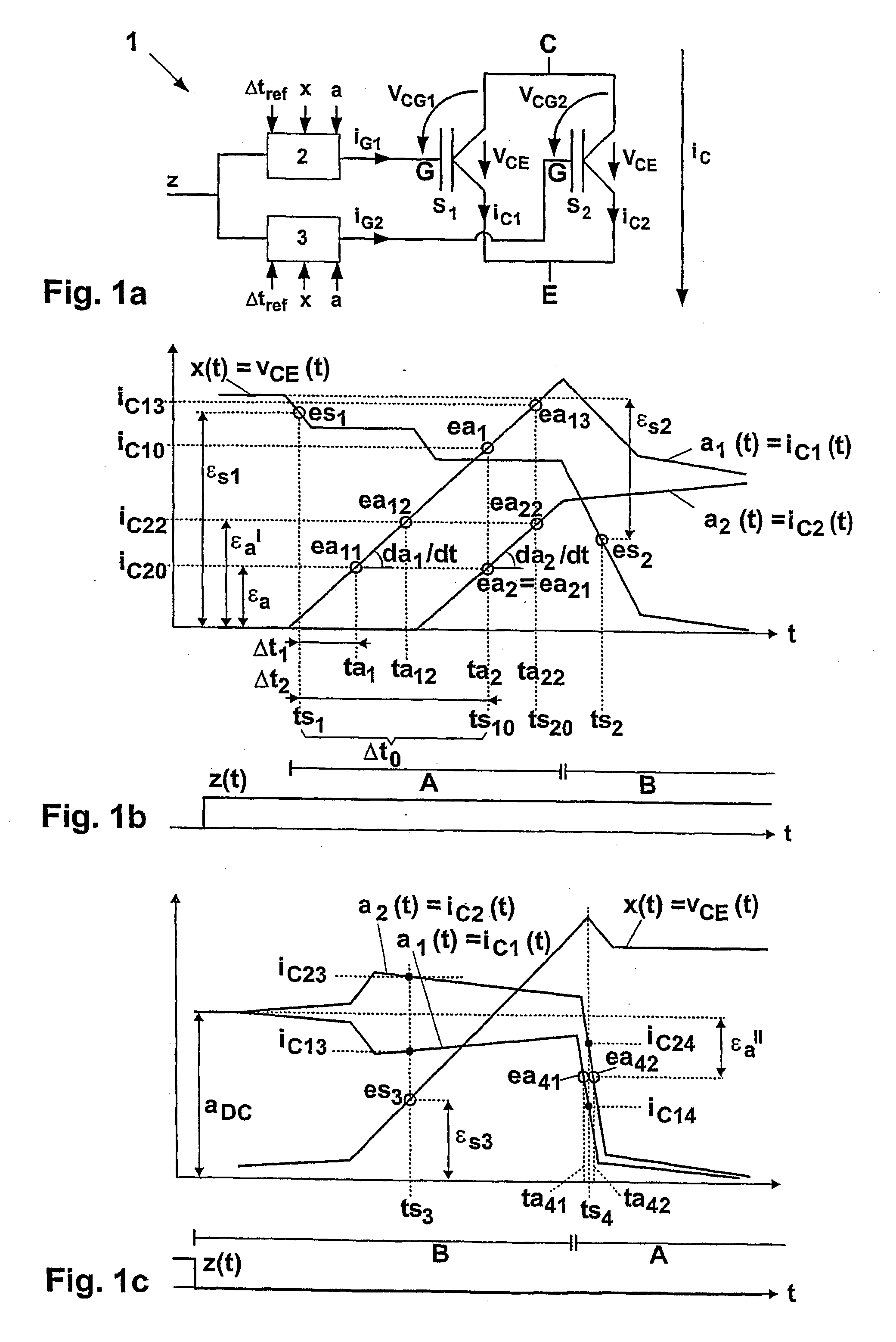

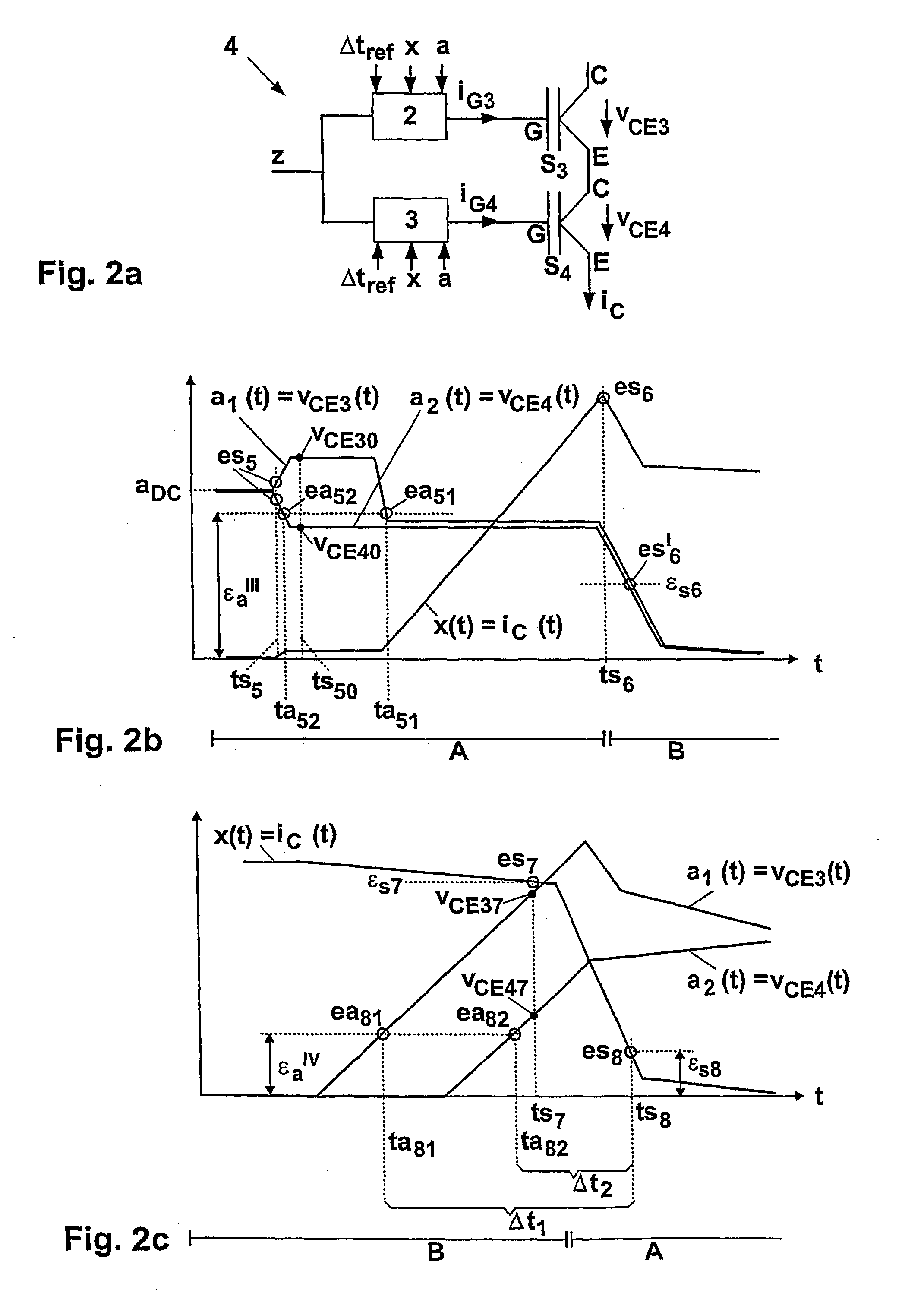

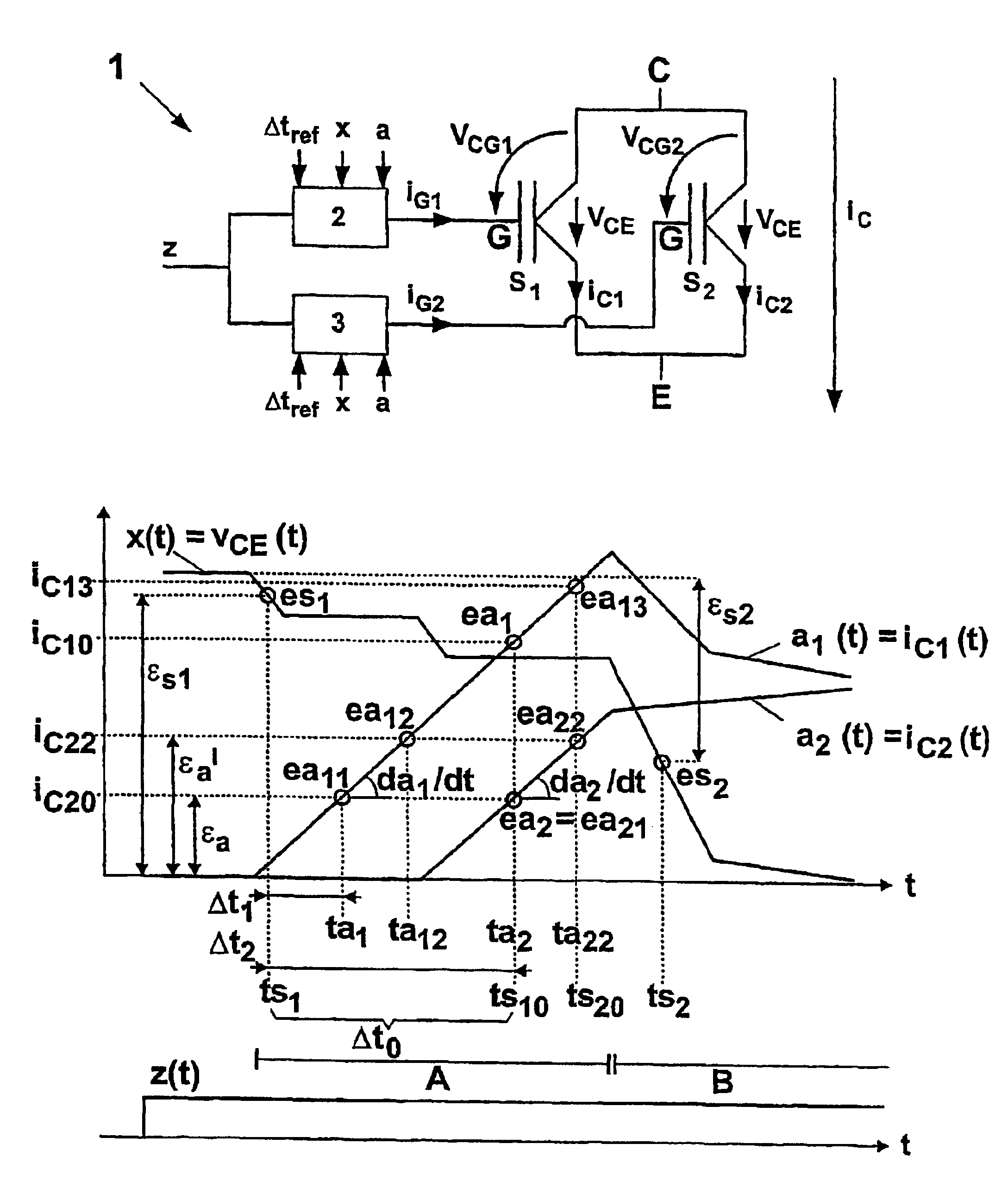

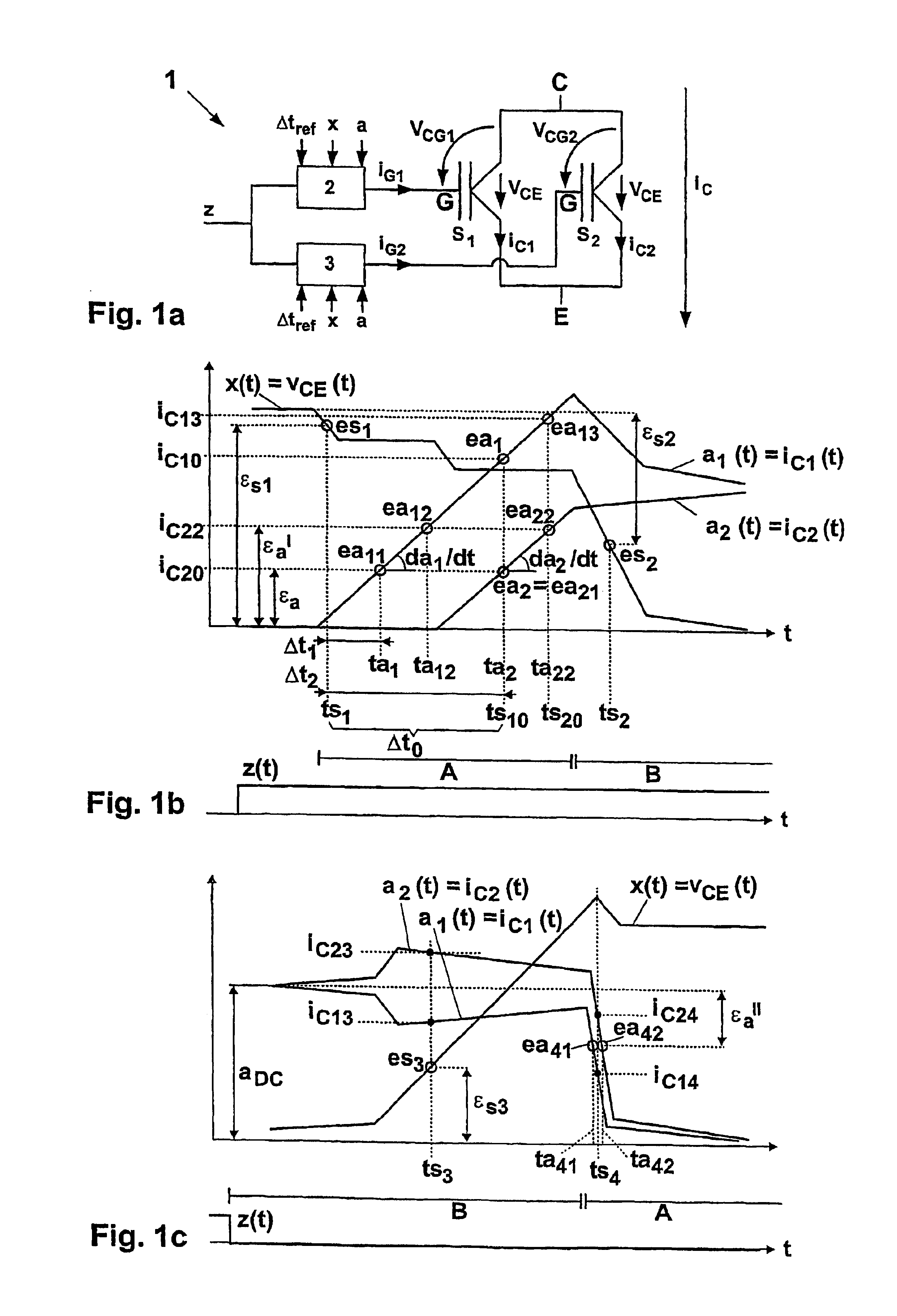

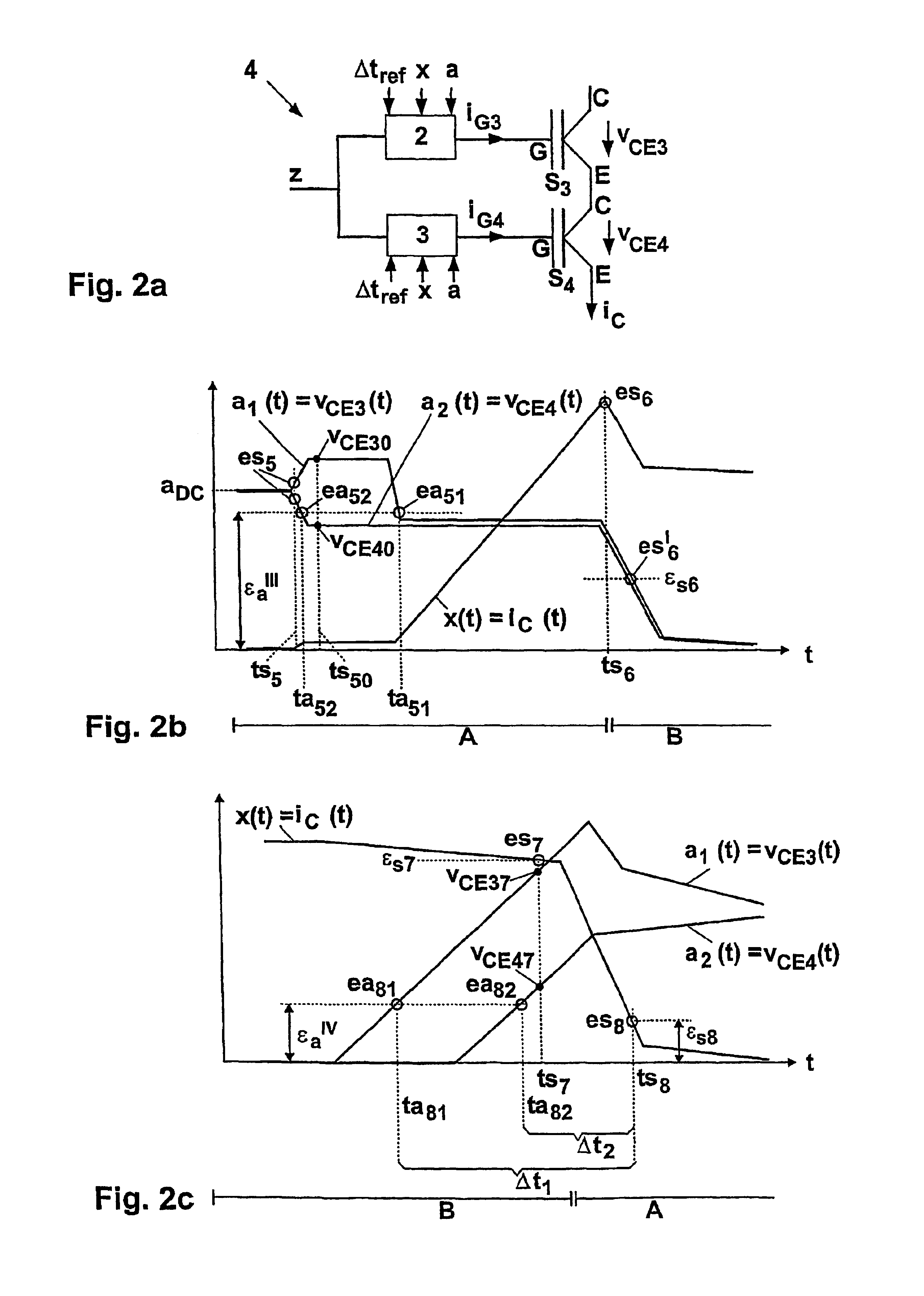

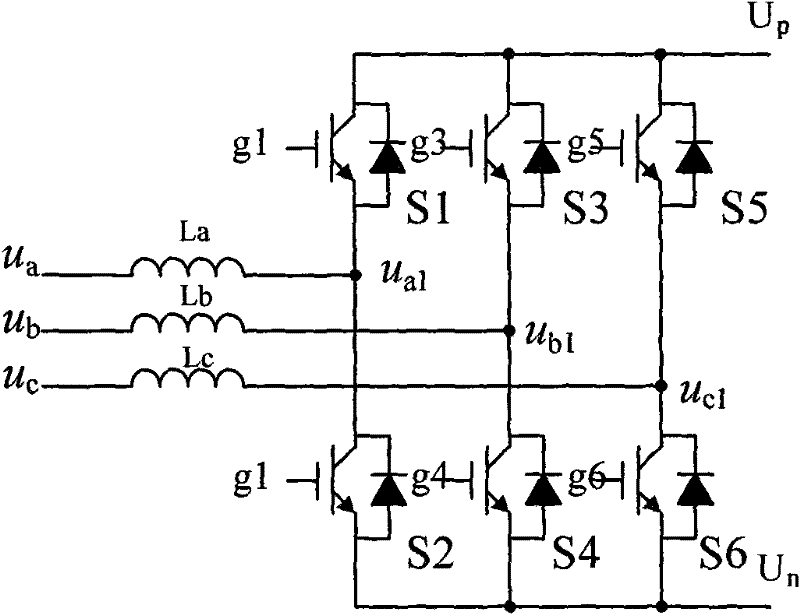

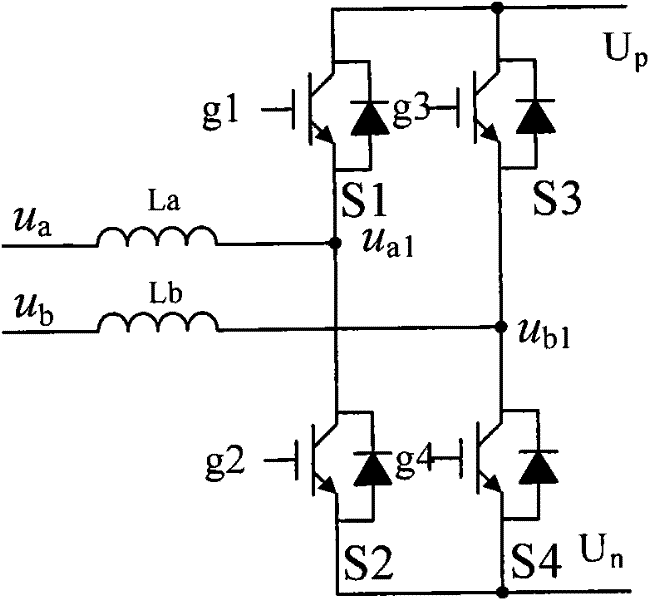

Method for the dynamic balancing of series- and parallel-wired power semiconductor circuits

InactiveUS20040056646A1Improve dynamic accuracyMultiple-port networksOne-port networksDynamic load balancingState variable

A method for dynamically balancing the loads in a circuit (1, 4) of semiconductor power switches arranged in series or in parallel is disclosed. Individual switching signals (iG1, iG2) for the semiconductor power switches (S1 . . . S4) are generated by determining a system-widely valid synchronous sampling time (tsj) independently for each semiconductor power switch (S1 . . . S4) due to a synchronous event (es) of the whole circuit (1, 4). Control loop offsets between actual values (ai) measured synchronously at the sampling time (tsj) and given desired values (as) of an asynchronous state variable (a(t)) of the semiconductor power switches (S1 . . . S4) are reduced in the same or in following switching cycles. Alternatively, control loop offsets between actual time values (tai) and desired time values (tas) are minimized, wherein the actual time values (tai) are measured upon exceeding a globally provided threshold value (epsilona) of an asynchronous state variable (a(t)) of the semiconductor power switches (S1 . . . S4). Embodiments relate to: Offsetting the sampling time (tsj) in time by a globally provided time interval (Deltat0), providing desired values locally or globally, e.g. by averaging of actual values (ai, tai), additional balancing of the gradients of asynchronous time variables (a(t)). A central sampling command can be dispensed with and the switching synchronicity is improved, switching times are shortened and dynamic switching losses are reduced.

Owner:POWER INTEGRATIONS INC

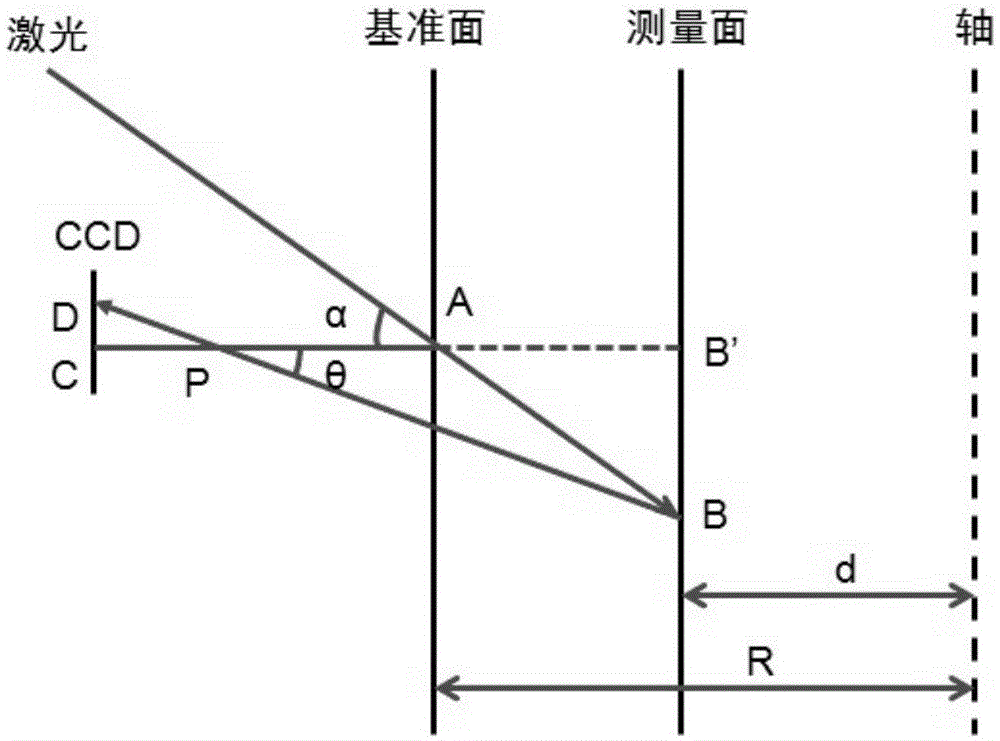

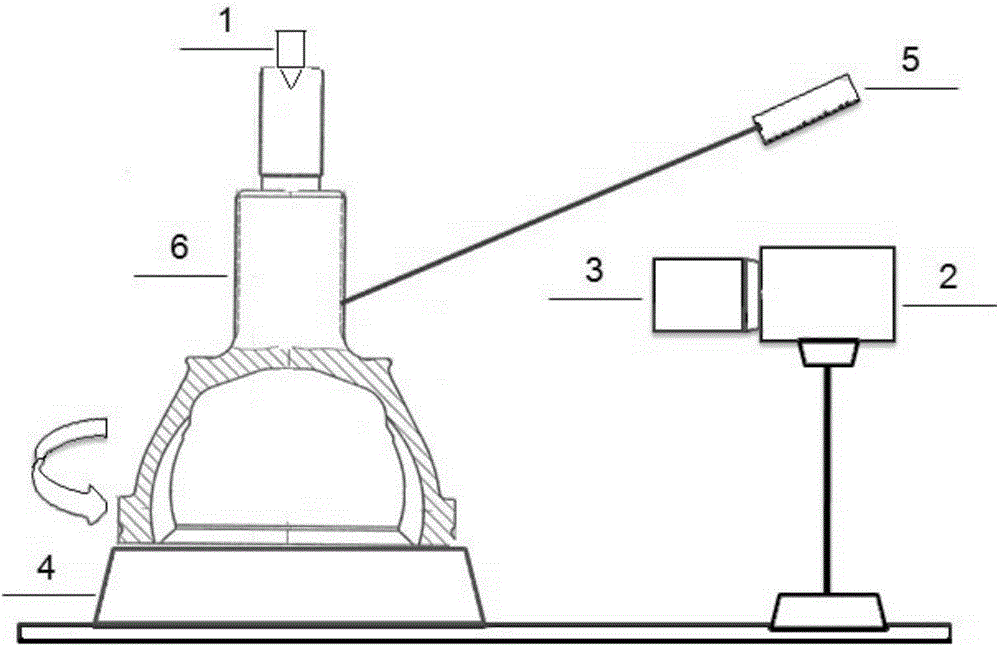

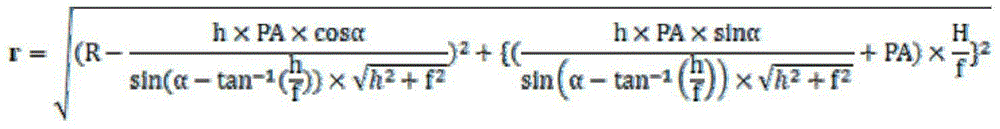

Apparatus and method for measuring spline dimension of besides-star wheel

ActiveCN103604389AHigh measurement accuracyImprove detection efficiencyUsing optical meansMeasurement deviceImaging processing

Disclosed in the utility model is a triangulation method-based apparatus for measuring a spline dimension of a besides-star wheel. The measuring apparatus comprises a laser, a camera, a lens, and a mechanical structure for fixing a tested workpiece. In addition, a method for measuring a spline dimension of a besides-star wheel is also disclosed. According to the method, laser is used as structured light; the CCD camera carries out shooting to obtain a spline profile; and the spline dimension is obtained by calibration and image processing and calculation. Therefore, non-contact measurement of a major diameter, a small diameter, a distance between two pins, and a division error of the spline of the besides-star wheel can be realized. On the basis of the design of the apparatus, definition and contrast of the profile image of the spline are enhanced; due to the structure of fixation of a rotating plate and a top pin with synchronous rotation of the besides-star wheel, the high dynamic precision is realized and the precision reduction caused by mechanical structure wearing is reduced. Moreover, the highest repetition precison for besides-star wheel spline dimension measurement can reach +0.01mm; and the stability is good.

Owner:SHANGHAI JIAO TONG UNIV +1

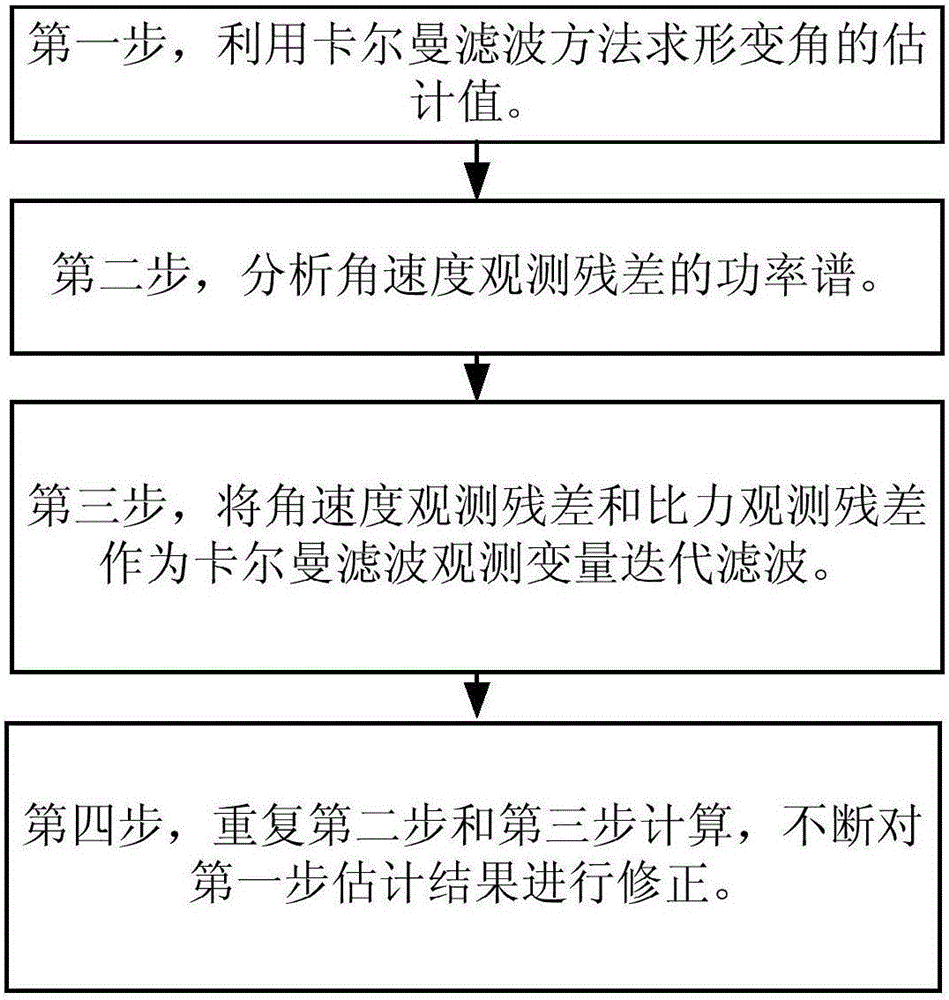

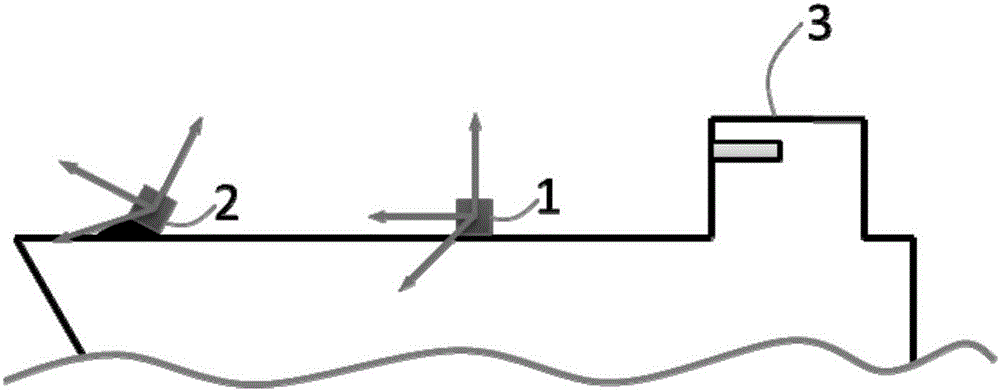

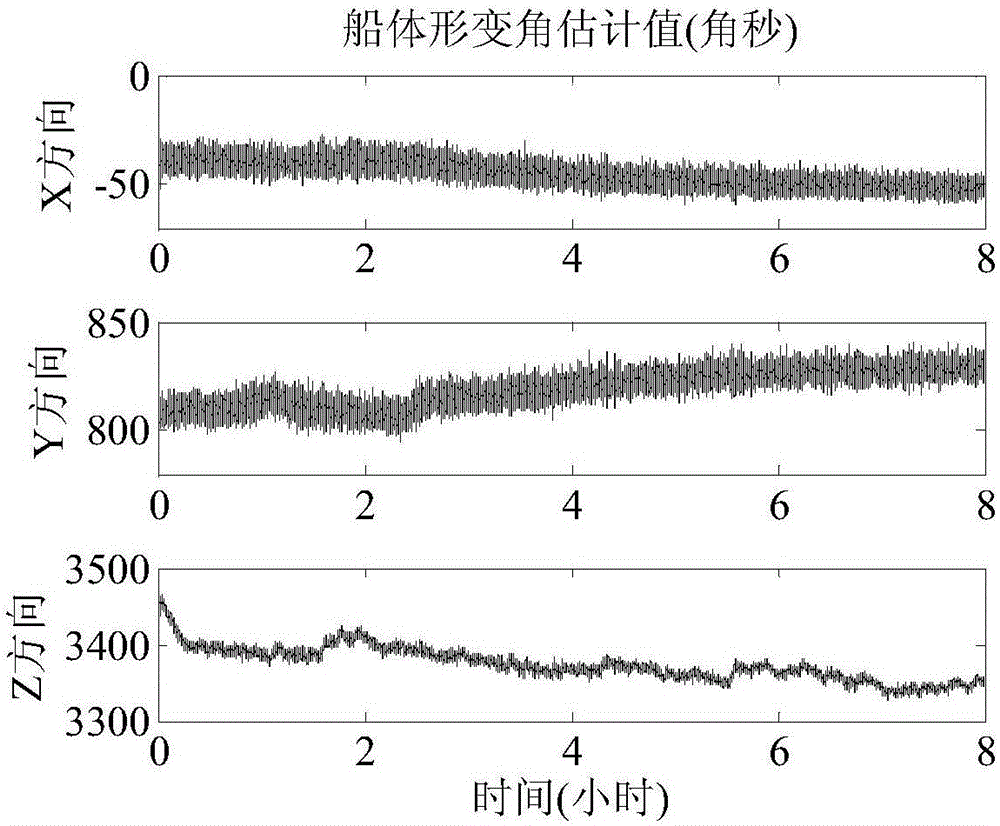

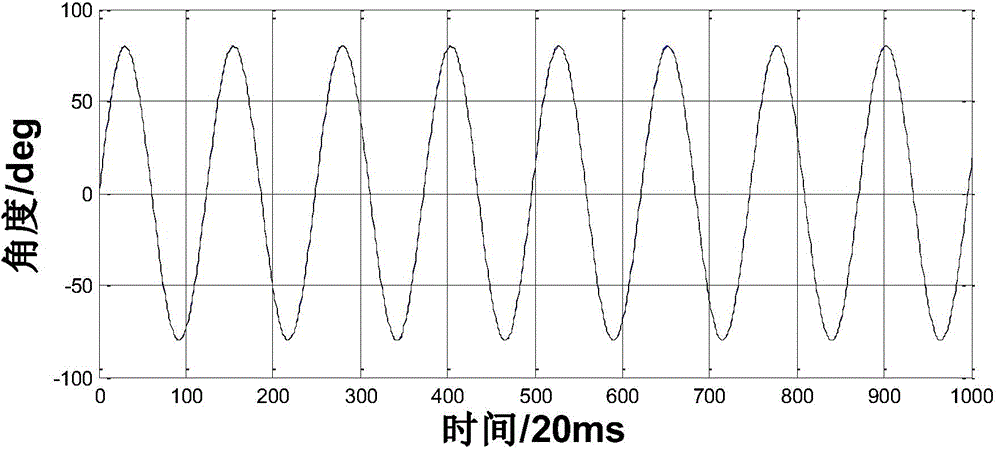

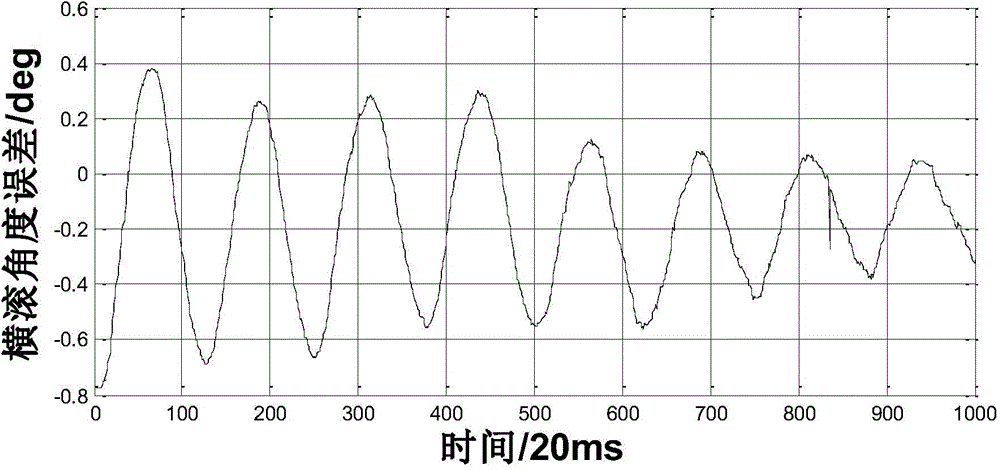

Method for measuring hull deformation angle based on inertia instruments and iterative filtering algorithm

ActiveCN106802143AImprove robustnessHigh precisionAngle measurementNavigation by speed/acceleration measurementsAccelerometerGyroscope

The invention belongs to the technical field of transfer alignment in inertial navigation, and particularly relates to a method for measuring hull deformation angle based on inertia instruments, such as a gyroscope, an accelerometer and the like, and an iterative filtering algorithm. The method comprises the following steps: 1, evaluating an estimated value (FORMULA) of the deformation angle by utilizing a Kalman filtering method; 2, analyzing the power spectrum of an angular velocity observation residual; 3, using the angular velocity observation residual and a specific force observation residual as Kalman filtering observation variables for iterative filtering; 4, through calculation repetition of the second step and the third step, constantly correcting an estimated result in the first step till a corrected value (FORMULA) of the deformation angle is close to but not equal to a true value (FORMULA). By the method, in allusion to the environmental characteristics that a large ship is low in speed and swings weakly, the measurement accuracy of the deformation angle in a vertical direction can be significantly improved; meanwhile, the method is relatively small in calculation amount, and is suitable for online real-time measurement.

Owner:NAT UNIV OF DEFENSE TECH

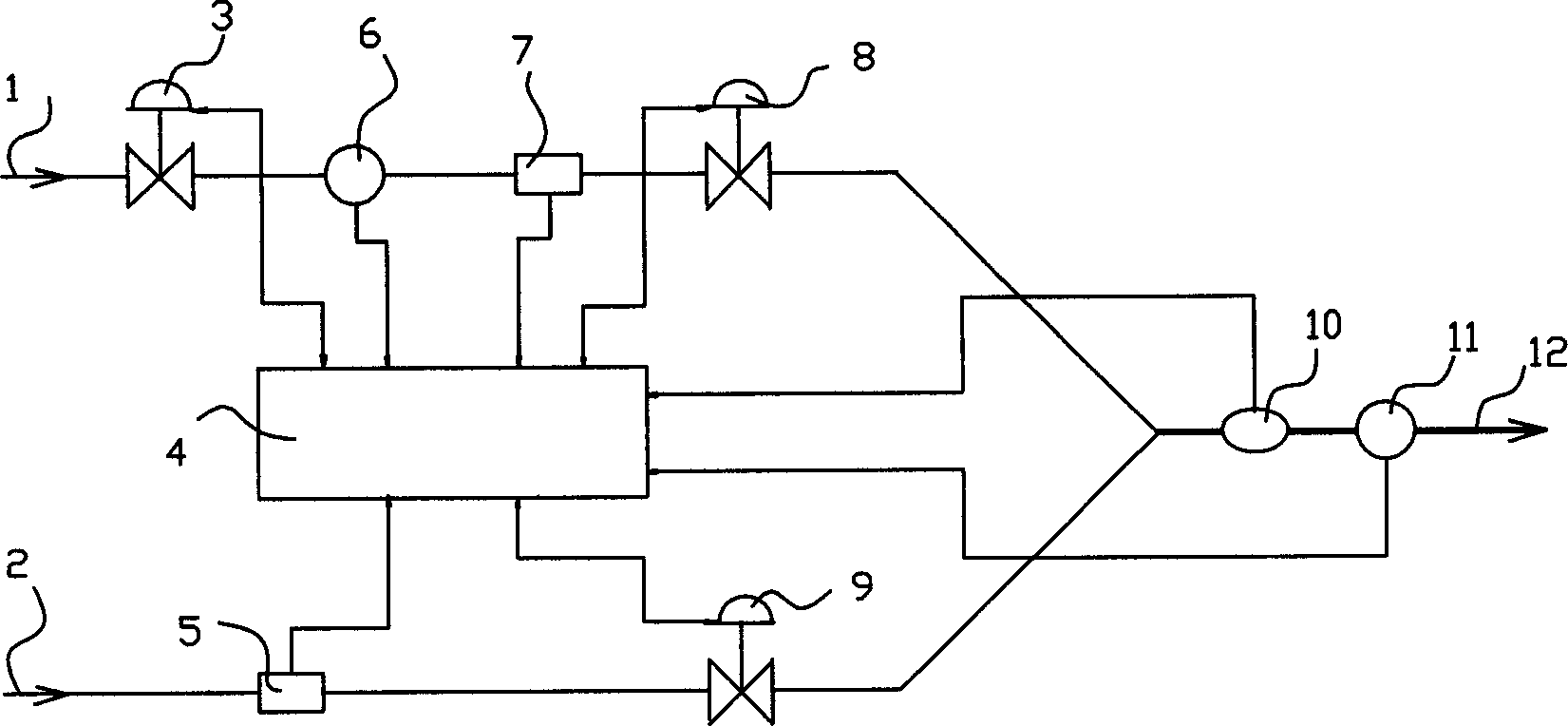

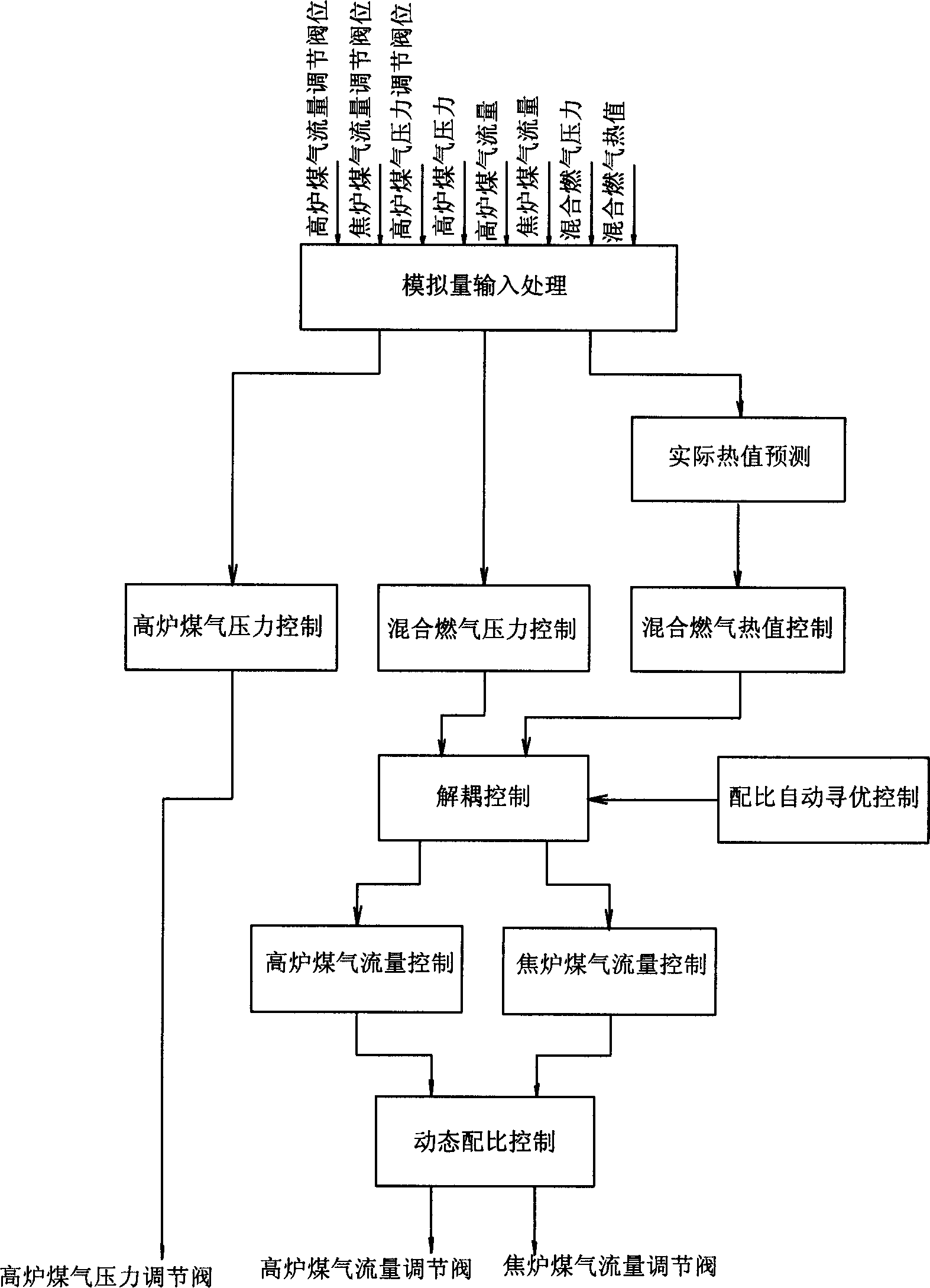

Heat value stabilizing control system of mixed gas and computer-controlled model

In the invention, a blast-furnace gas pressure-control valve, a blast-furnace gas pressure sensor, a blast-furnace gas flow sensor and a blast-furnace gas flow-control valve are mounted on the blast-furnace gas input conduit; on the coke-oven gas input conduit are disposed a coke-oven gas flow sensor and a coke-oven gas flow-control valve and on the mixed gas output conduit are mounted a mixed gas heat valve sensor and a mixed gas pressure sensor. In addition, a computer control device has an electric connection with the pressure-control valve, the pressure sensor, the flow sensor and flow-control valve of the blast-furnace gas, the flow sensor and flow-control valve of the coke-oven gas and the heat value sensor and the pressure sensor of the mixed gas.

Owner:SHANDONG IRON & STEEL CO LTD

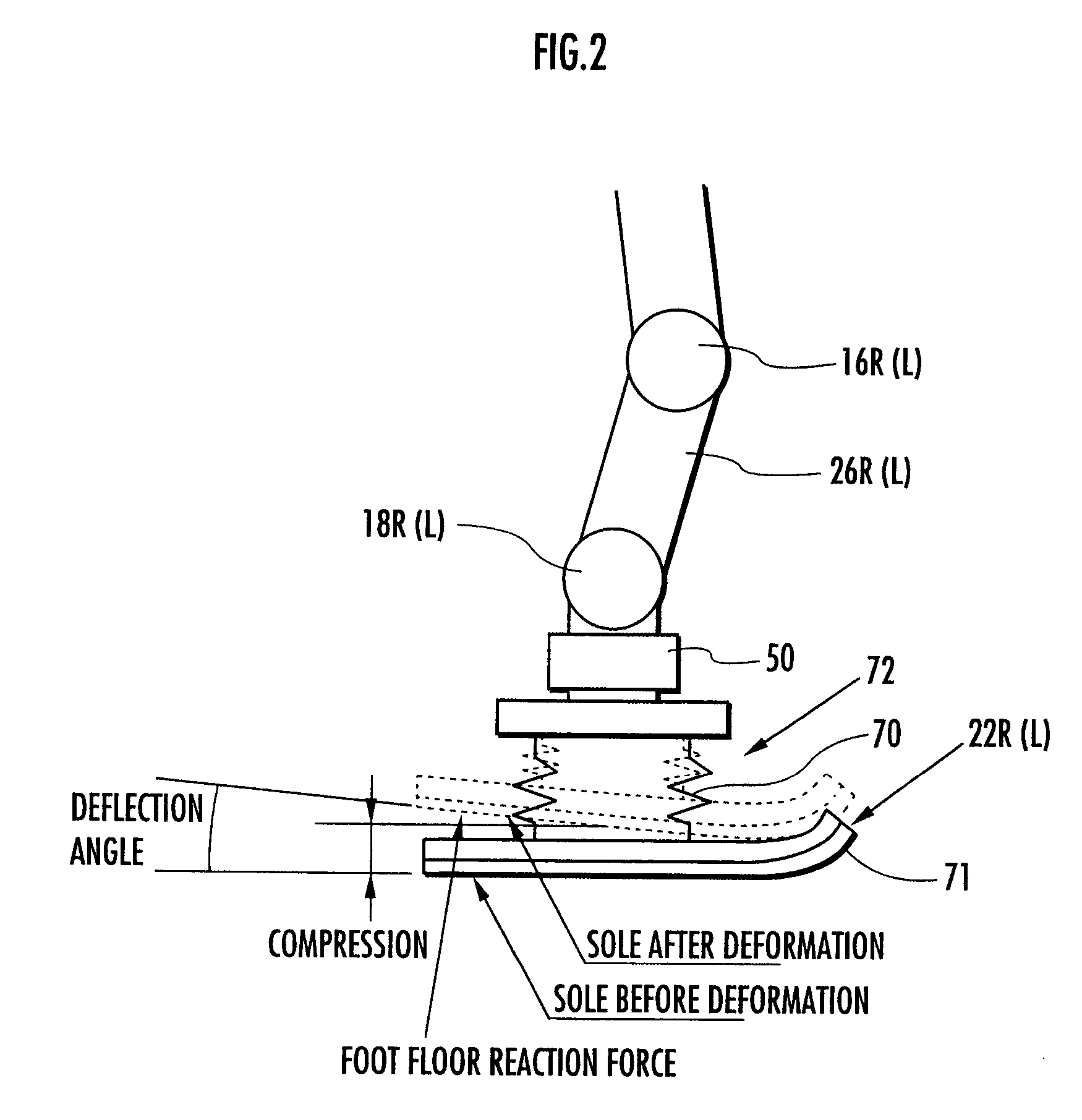

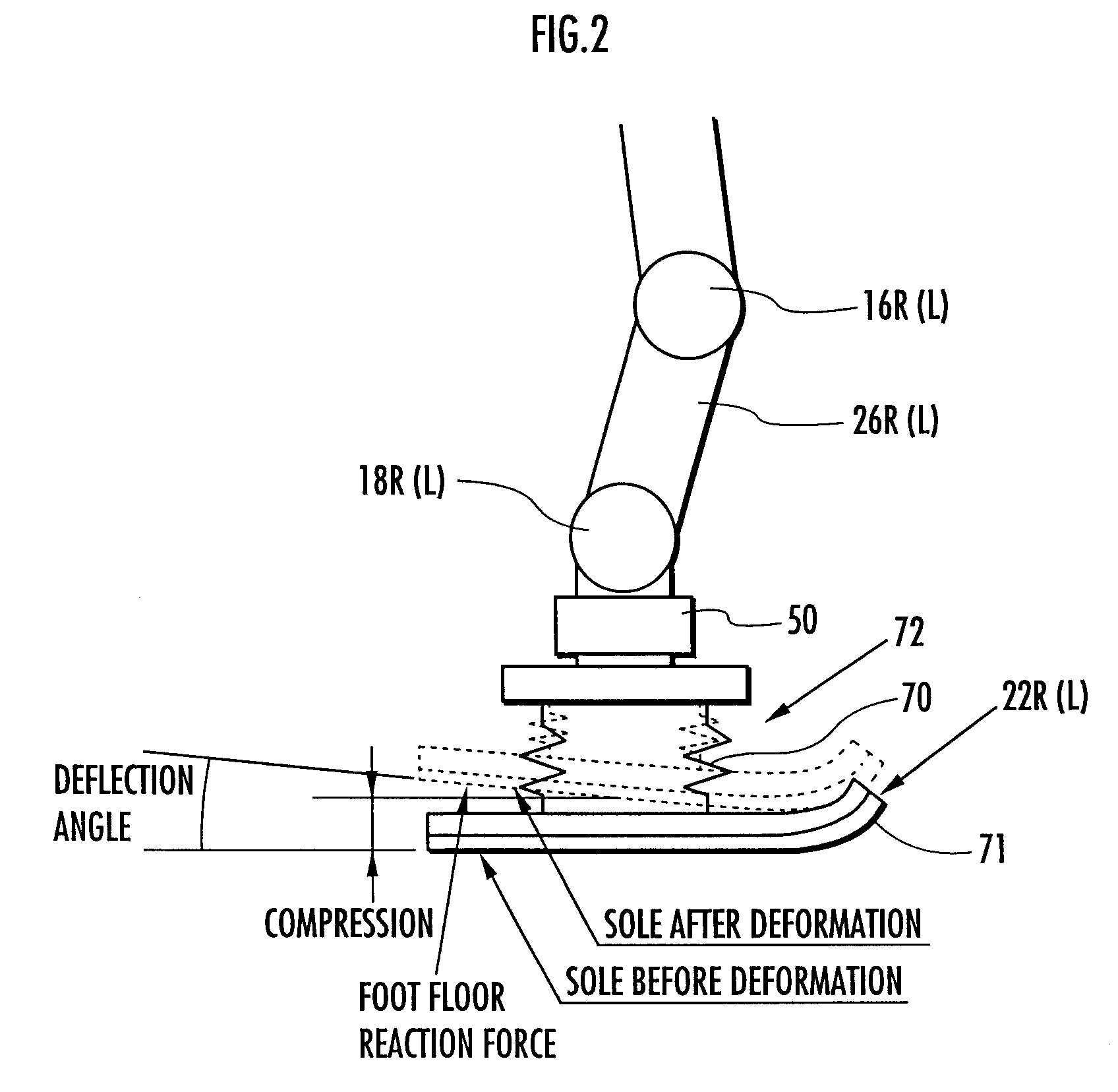

Gait generating device for moving robot

InactiveUS20070061038A1Improve reliabilityAccurately determineComputer controlSimulator controlMobile robotEngineering

To generate a desired gait of a robot 1 such that a permissible range of a predetermined component (a translational floor reaction force horizontal component or the like) of a floor reaction force acting on the mobile robot 1, a gait generating system for a mobile robot creates a provisional motion, which indicates a provisional value of a desired motion, and repeats processing for correcting the provisional motion by using a first dynamic model and a second dynamic model having a dynamic accuracy that is higher than that of the first dynamic model until a predetermined condition is satisfied, thereby obtaining a final corrected motion as the desired motion. Relative to the provisional motion and a corrected motion at each correction, a difference between a predetermined component of a floor reaction force produced on the second dynamic model and a predetermined component of a floor reaction force produced on the first dynamic model is determined as a floor reaction force error, and a change amount of the error at each correction is also determined. A corrected motion when the change amount has converged to zero is determined as the desired motion.

Owner:HONDA MOTOR CO LTD

Gait generator for mobile robot

InactiveUS7873436B2Accurate settingImprove dynamic accuracyProgramme-controlled manipulatorComputer controlDynamic modelsDynamic topic model

When the placement of the elements (mass points, links having inertia, etc.) of a model expressing a robot 1 is determined according to a first geometric restrictive condition from an instantaneous desired motion of the robot 1 that has been created using a dynamic model, this placement is defined as a first placement, and the placement determined according to a second geometric restrictive condition from a corrected instantaneous desired motion that has been obtained by correcting the instantaneous desired motion is defined as a second placement. The corrected instantaneous desired motion is determined such that the moment component calculated from the difference between the first and the second placements approximates a predetermined value. The instantaneous desired motion is created using a dynamic model of the robot. Thus, the motion of the instantaneous desired gait of the robot that has been created using the dynamic model is properly corrected without using a dynamic model, leading to higher dynamic accuracy of an instantaneous desired gait including the corrected motion.

Owner:HONDA MOTOR CO LTD

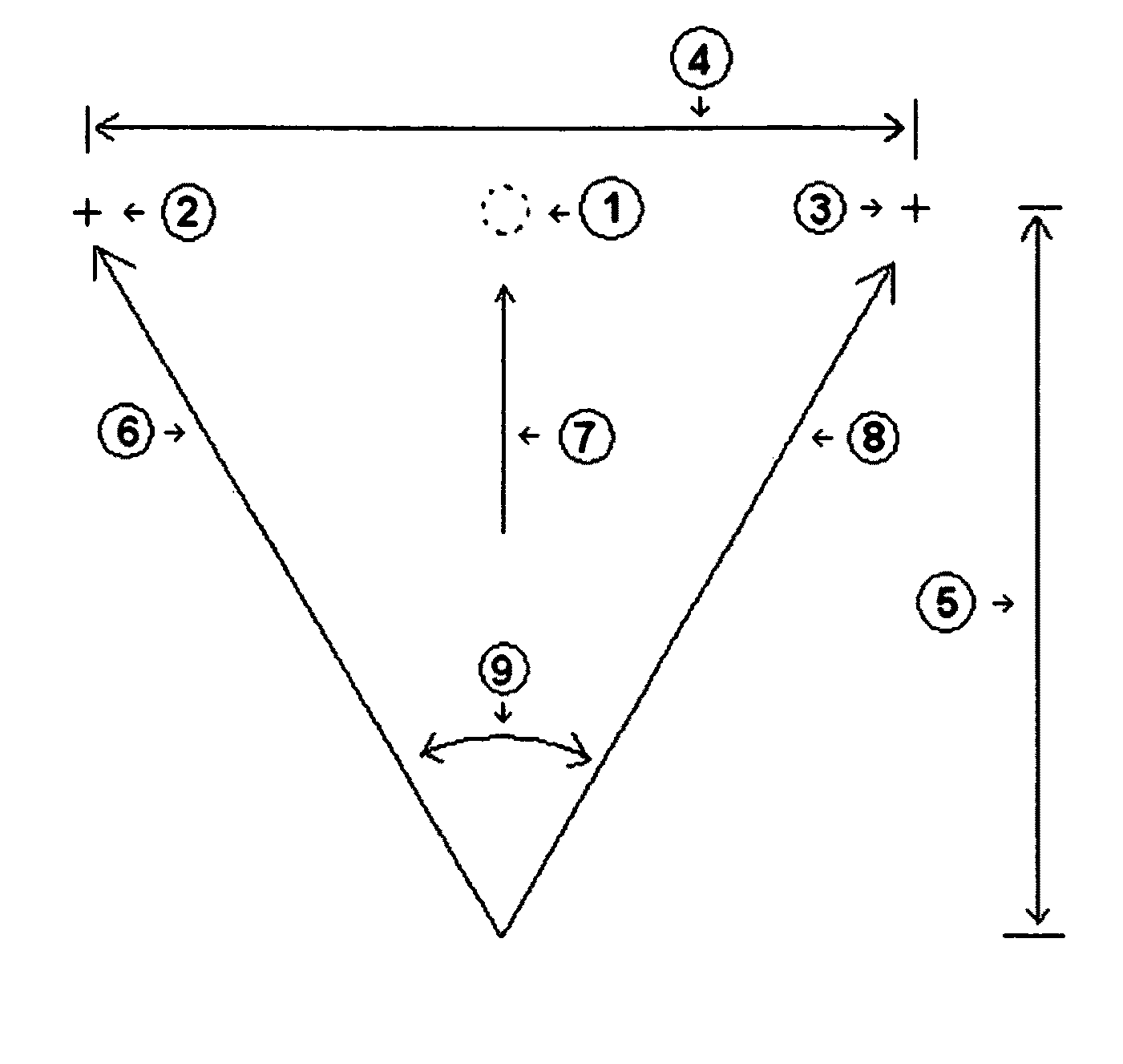

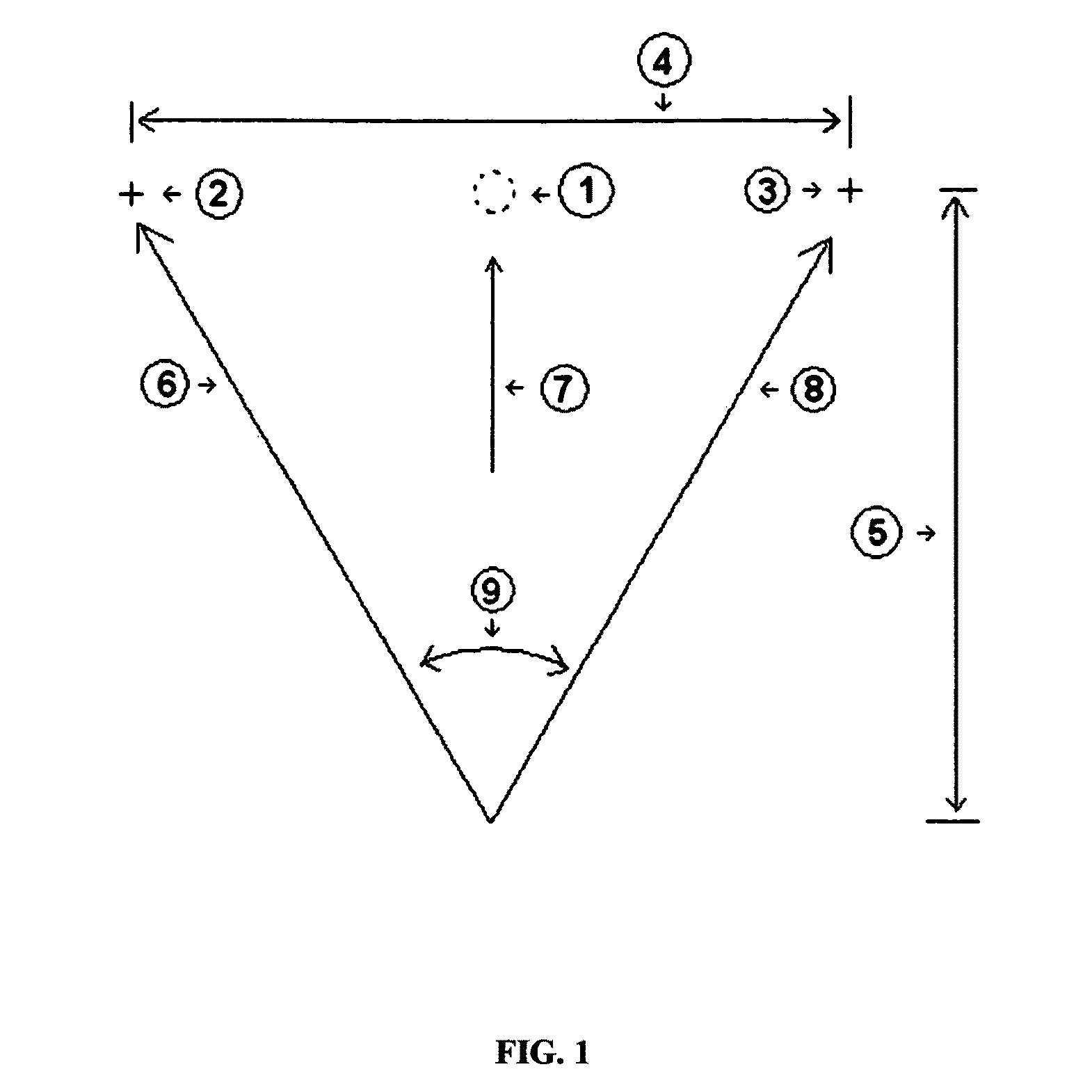

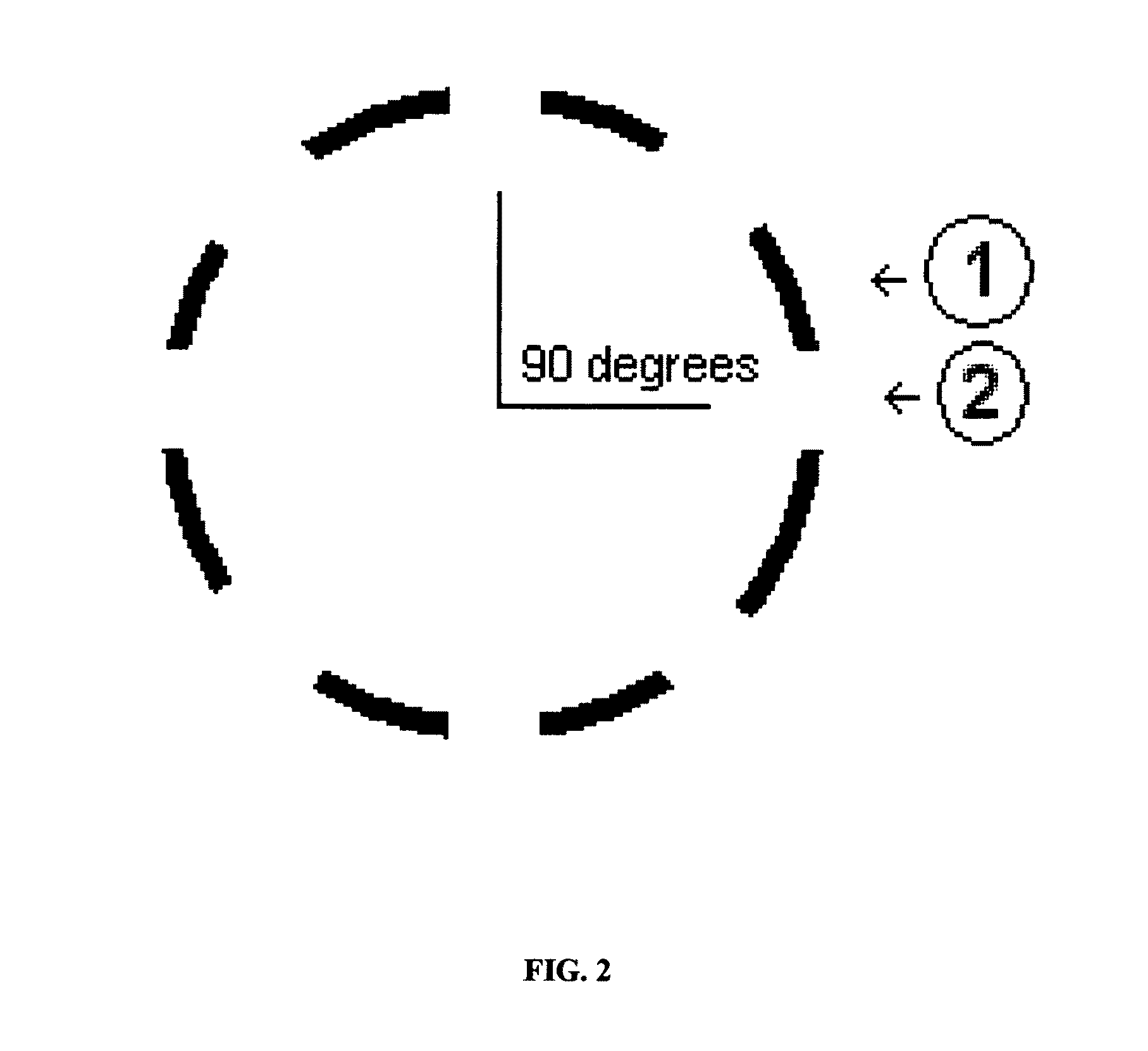

Animated image vision test

Animated image vision tests take advantage of the ability of our eyes to detect both distance and motion. Moving images, such as rotating segmented circles, let the eyes detect motion as to the size, distance, and rotation direction of that moving image. That motion detection is much more precise than the interpretation of multiple static letters or static images. Using rotating images for vision testing rather than static images creates an acuity test more accurate than current tests, a test that is faster to use, and a test that doesn't require the ability to read.

Owner:ALLAN N HYTOWITZ

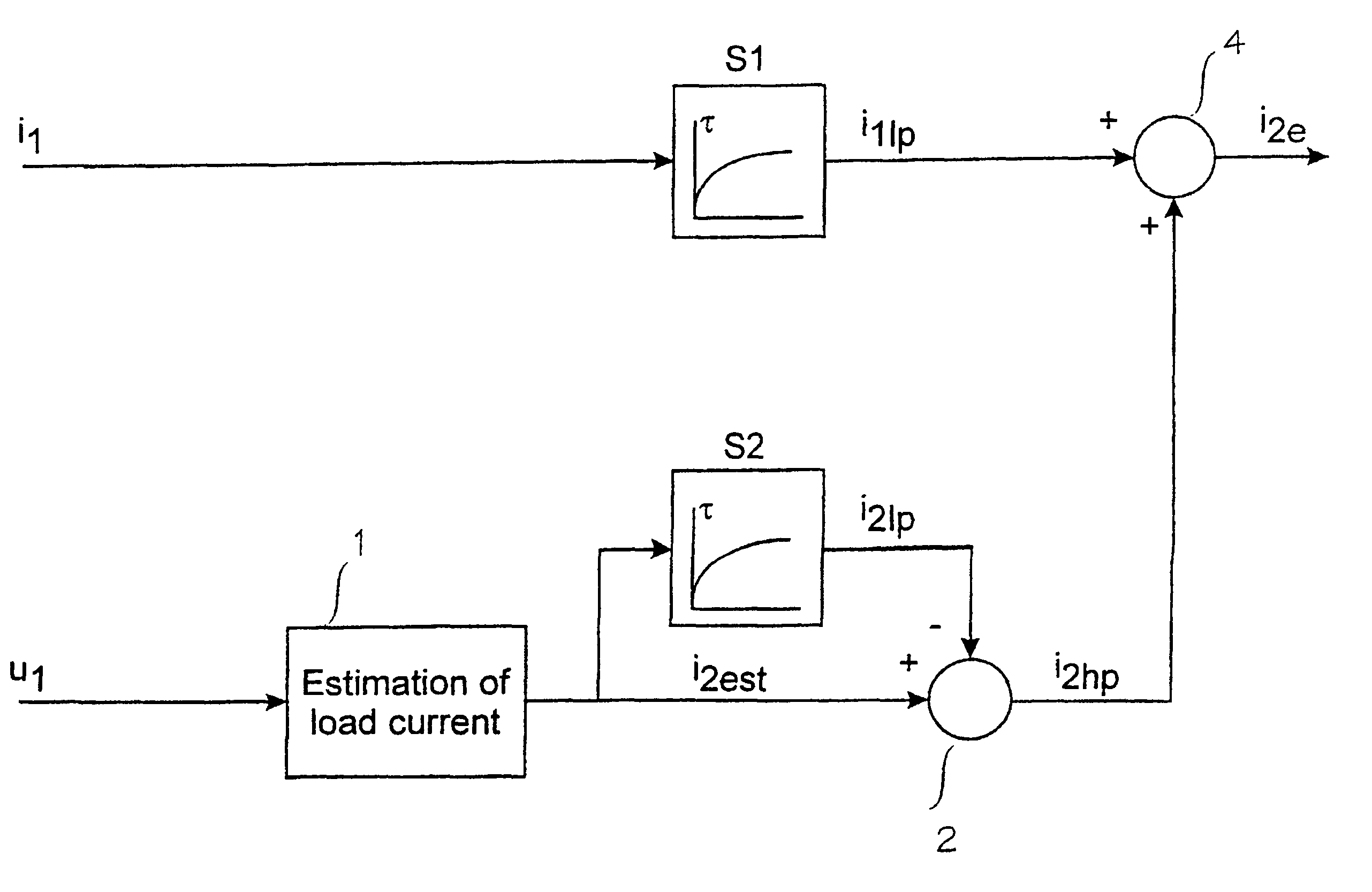

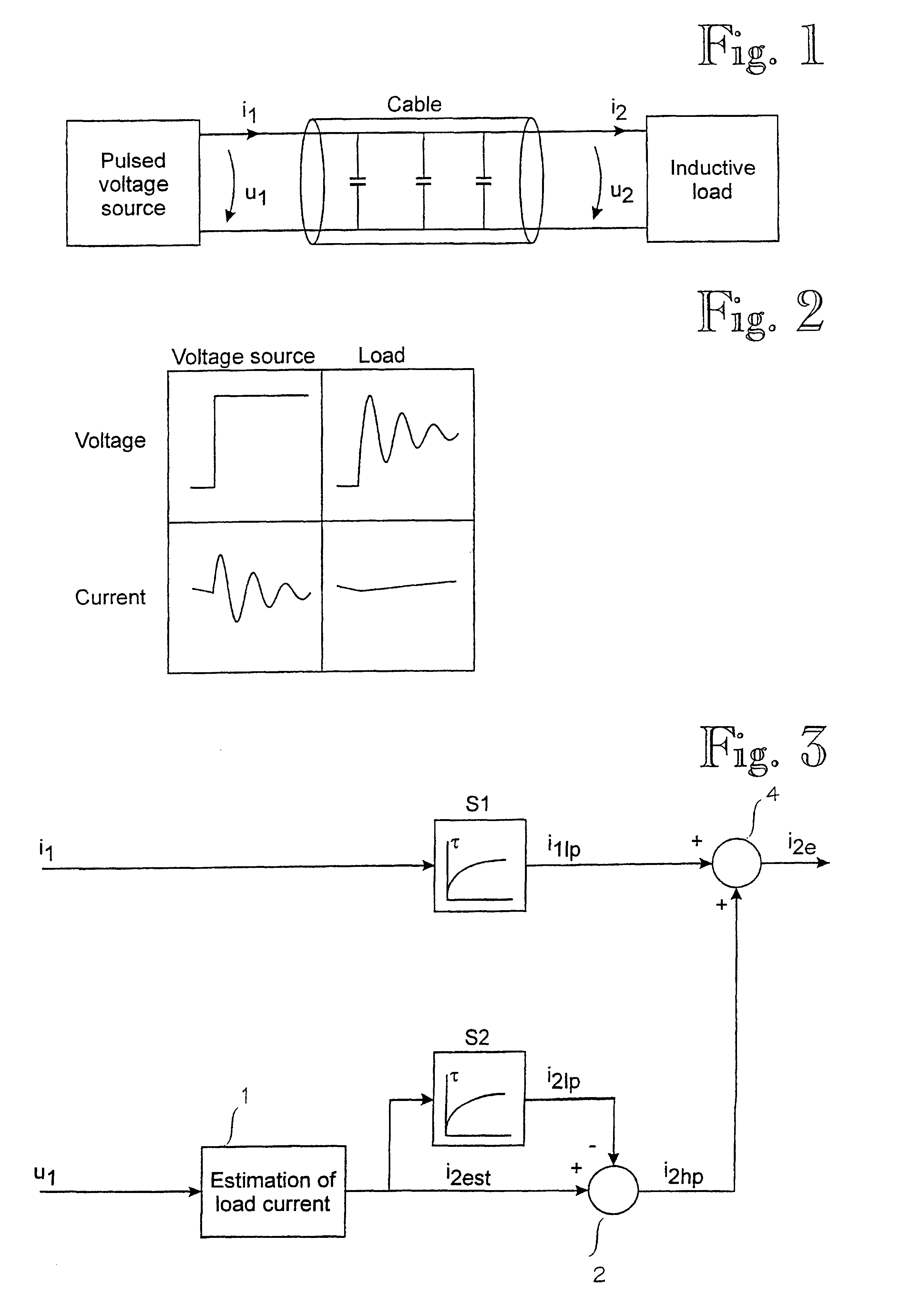

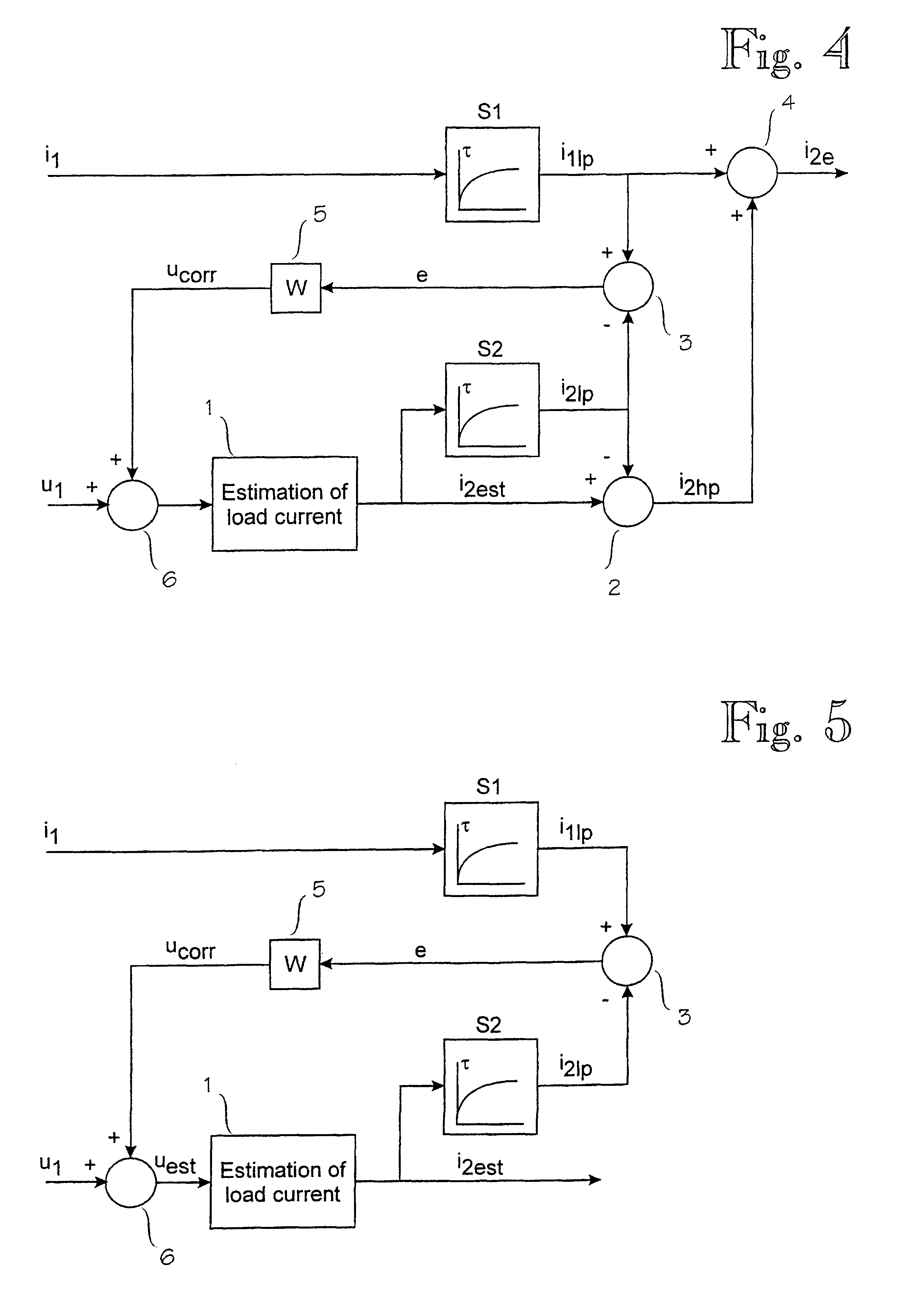

Method for defining instantaneous value of current of pulse-controlled inductive load

InactiveUS6195274B1Avoids drawbackHighly reliable estimateCurrent measurements onlyDc circuit to reduce harmonics/ripplesInductive loadPulse voltage

A method of defining an instantaneous value of a current (i2e) of a pulse-controlled inductive load when the impedance of the load is known, the method comprising the steps of: measuring the output voltage (u1) of a pulsed voltage source, and measuring the output current (i1) of the pulsed voltage source. The method is characterized by further comprising the steps of: low-pass filtering the measured output current (i1) of the pulsed voltage source to produce a fundamental wave current (i1lp), defining a load current estimate (i2est) by computation on the basis of the measured output voltage (u1) of the pulsed voltage source and the impedance of the load, high-pass filtering the load current estimate (i2est), and defining the instantaneous value of the load current (i2e) by adding the high-pass-filtered load current estimate (i2hp) to the fundamental wave current (i1p).

Owner:ABB (SCHWEIZ) AG

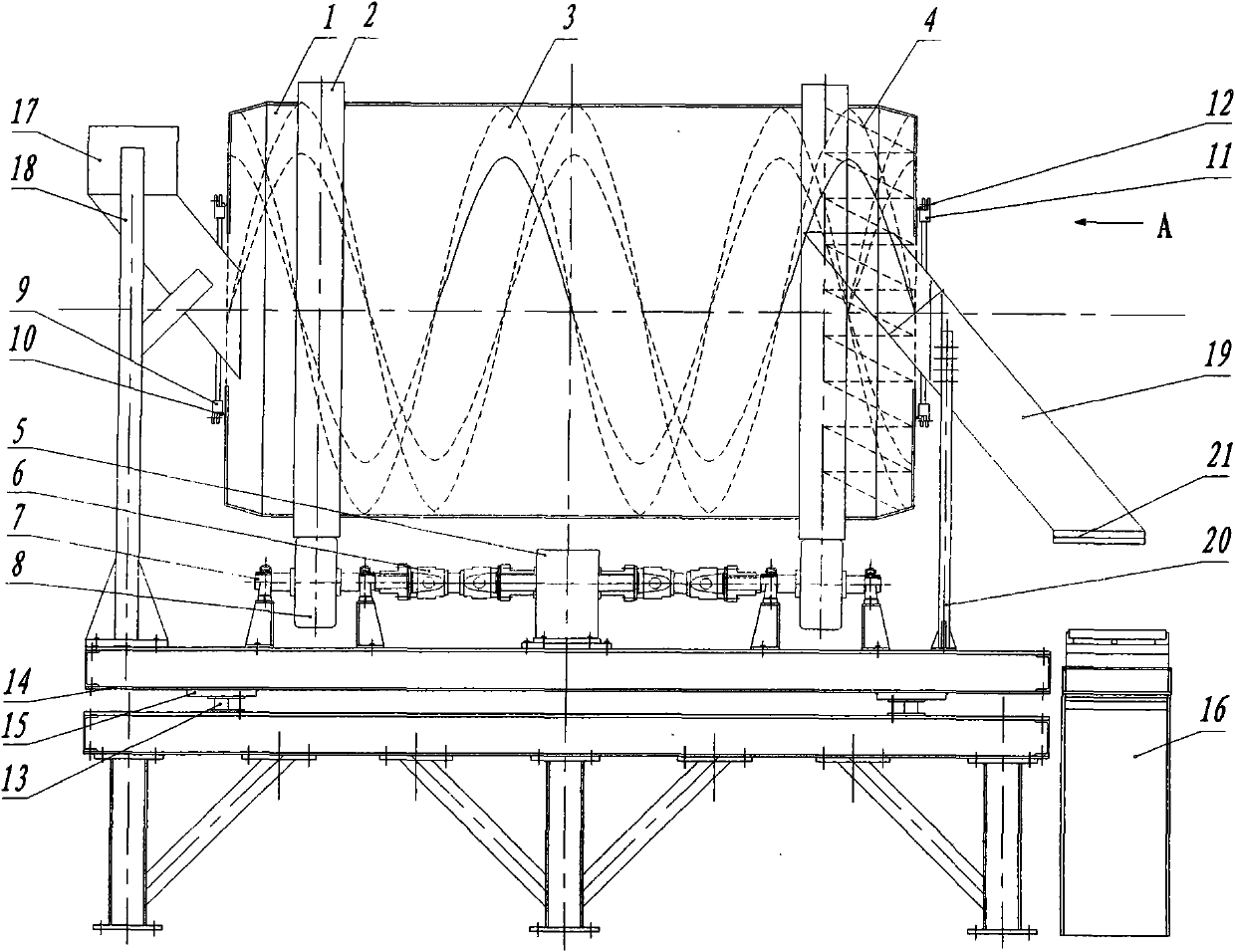

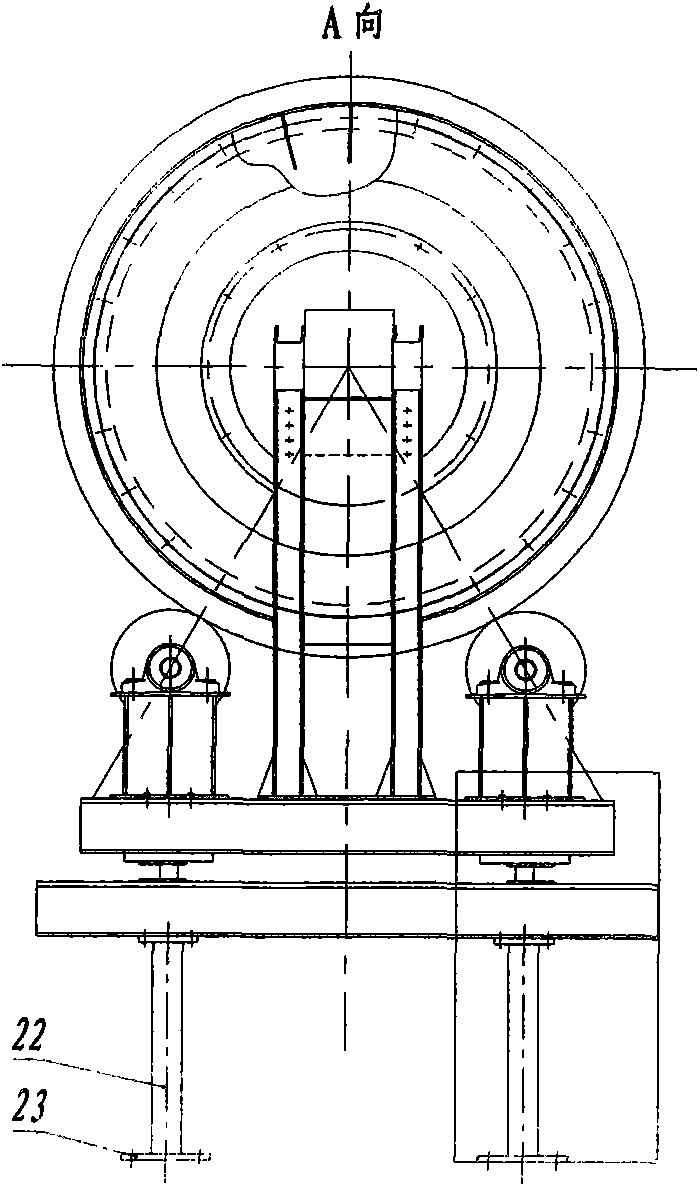

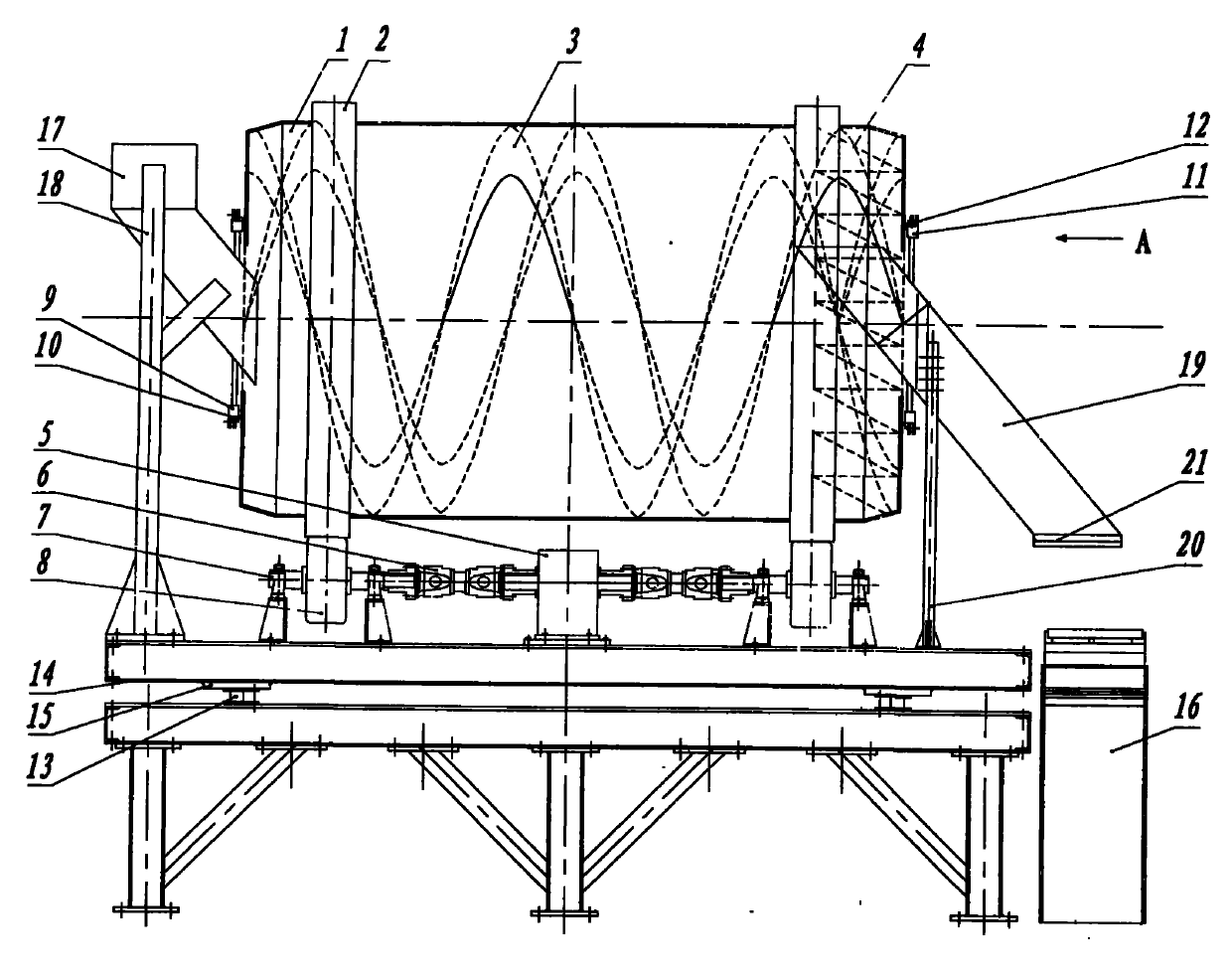

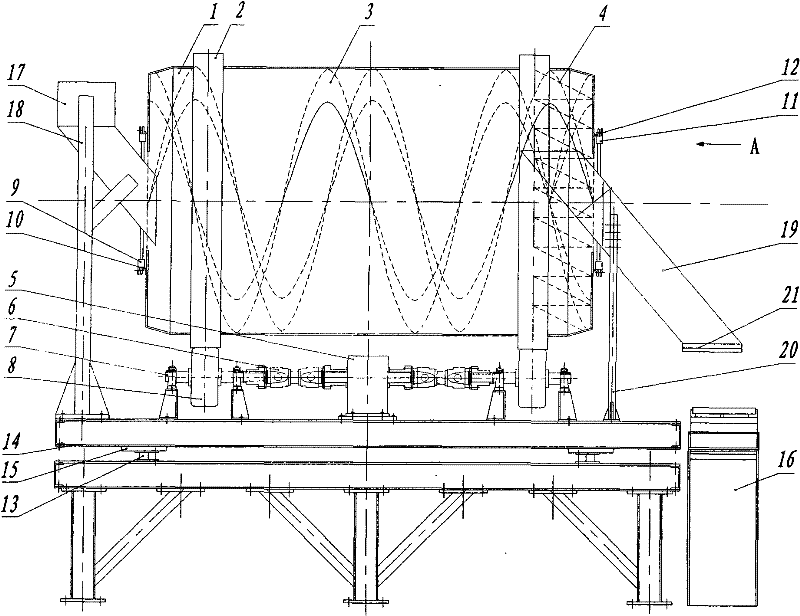

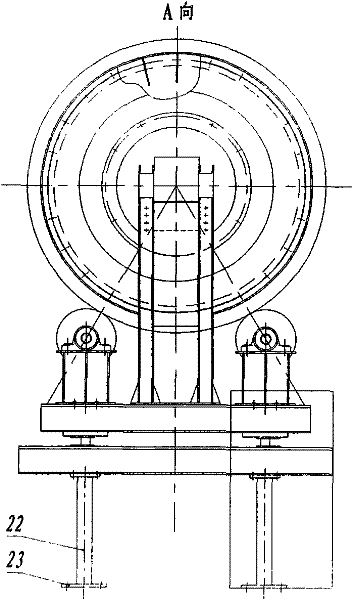

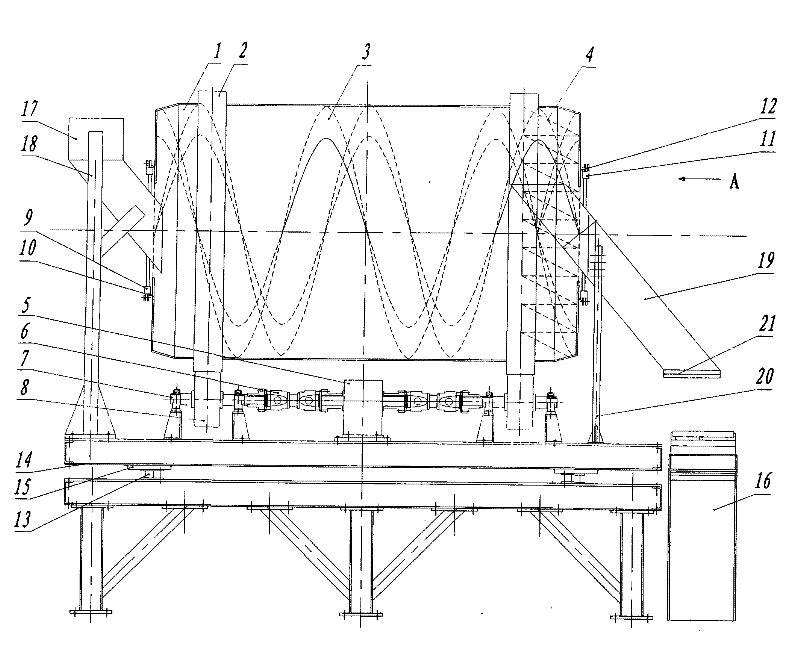

Mixer for mixing rubber and plastic particles

The invention relates to a mixer for mixing rubber and plastic particles, which comprises a mixing roller device and a transmission device which are matched with each other. Both the mixing roller device and the transmission device are arranged on a weighing device which is arranged on a support base. The weighing device, the mixing roller device and the transmission device are respectively connected with a control system which is arranged on one side of the support base through circuits. The mixing roller device is driven by a driving wheel through a rolling ring to rotate. The roller has positive rotation and reverse rotation. During positive rotation, an inner spiral pushing auger drives material particles in the roller to lift, rotate, roll and move tangentially and axially along the roller to uniformly mix the materials. Meanwhile, the materials move to the side of a discharge outlet axially under the action of a spiral thrusting force, and the materials are discharged from the discharge outlet through a material lifting plate finally. The mixer for mixing the rubber and plastic particles has the characteristics of high production efficiency, excellent mixing effect, high discharge speed, adjustable speed, accurate discharge, capacity of preventing the material particles from re-bonding, full-automatic control, full closeness, no dust or noise pollution, and the like.

Owner:SHANDONG UNIV

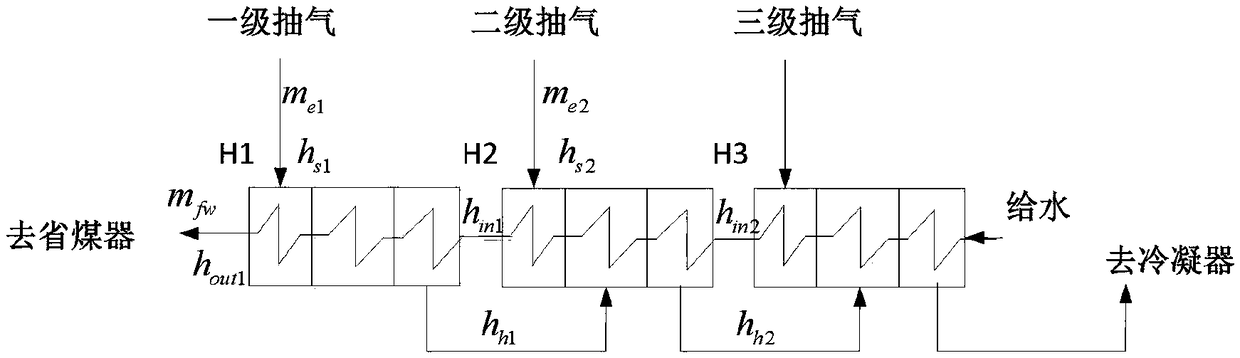

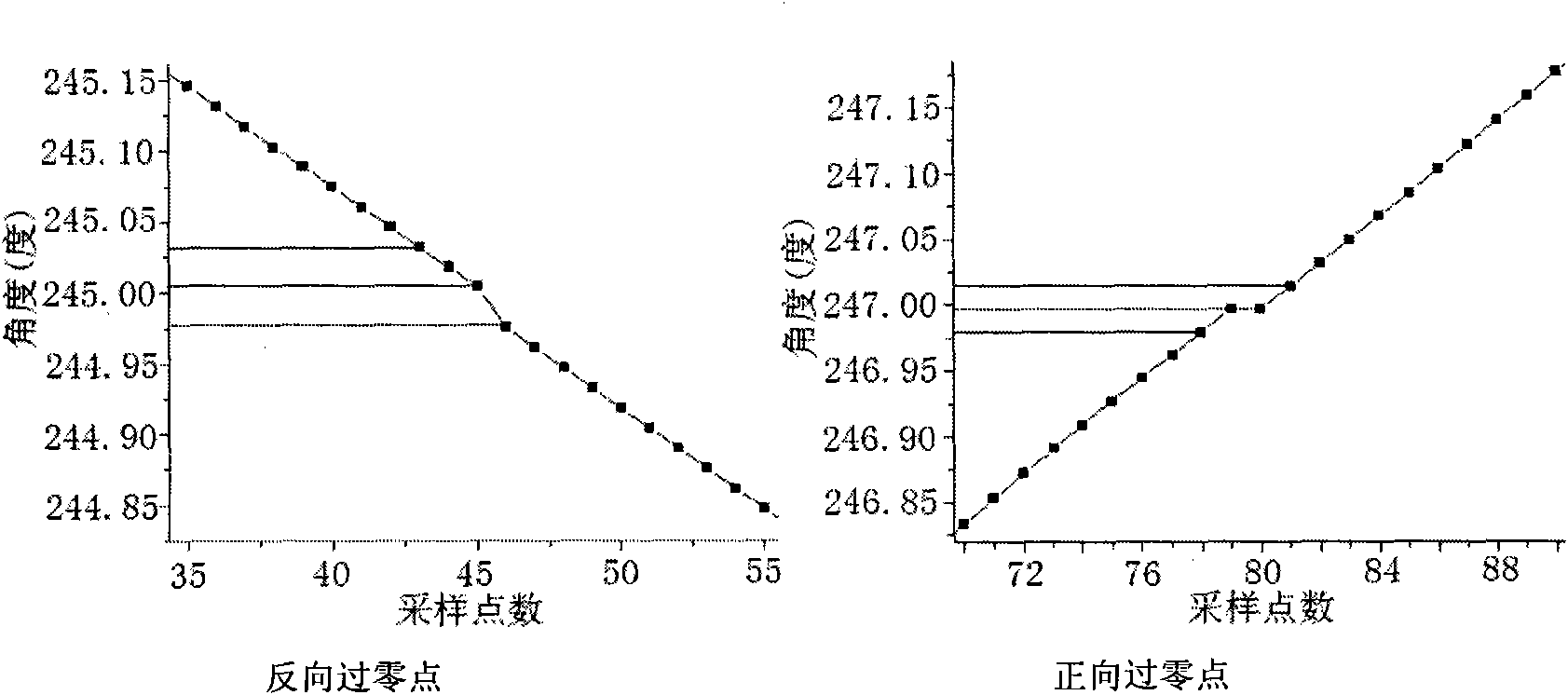

Testing system and method for dynamic precision of micro attitude module

ActiveCN104897169ADynamic accuracy is reliable and preciseIncrease credibilityMeasurement devicesData synchronizationControl engineering

The invention discloses a testing system and method for dynamic precision of a micro attitude module. The testing system and method has the following main characteristics: data of a high-precision double-shaft rotary table (1) and the micro attitude module (2) in a dynamic environment are simultaneously acquired by using a data synchronous acquisition plate (3), coarse synchronization of the data of both the high-precision double-shaft rotary table (1) and the micro attitude module (2) is accomplished in the data synchronous acquisition plate (3), and the data of both the high-precision double-shaft rotary table (1) and the micro attitude module (2) is packaged and sent to a PC data processing module (4); and the PC data processing module (4) carries out fine synchronization on the data of both the high-precision double-shaft rotary table (1) and the micro attitude module (2) and calculates the dynamic precision index of the micro attitude module (2). The testing system and method provided by the invention adopt the manner of two-step data synchronization, overcome the problem of unsynchronization of the data of the rotary table and the micro attitude module in the prior art, guarantee synchronism and consistency of the data of the high-precision double-shaft rotary table and the micro attitude module and have improved accuracy and reliability.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

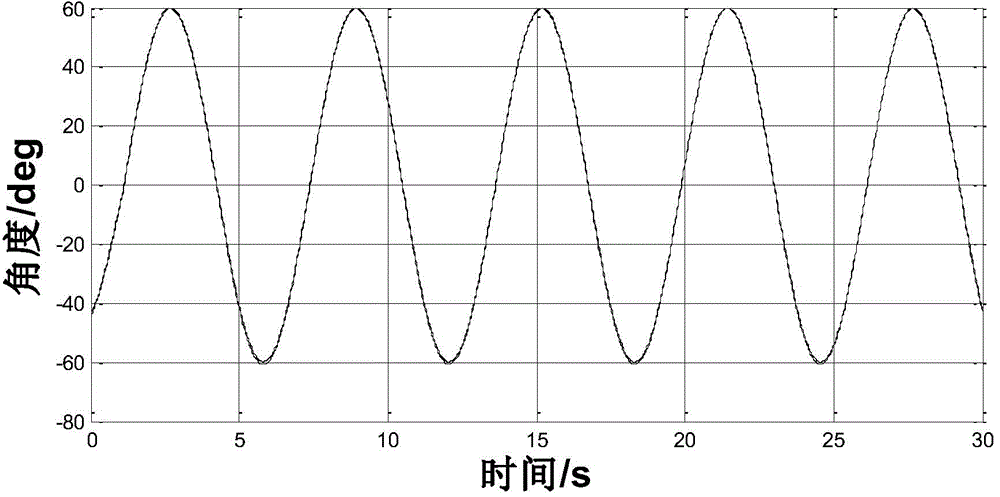

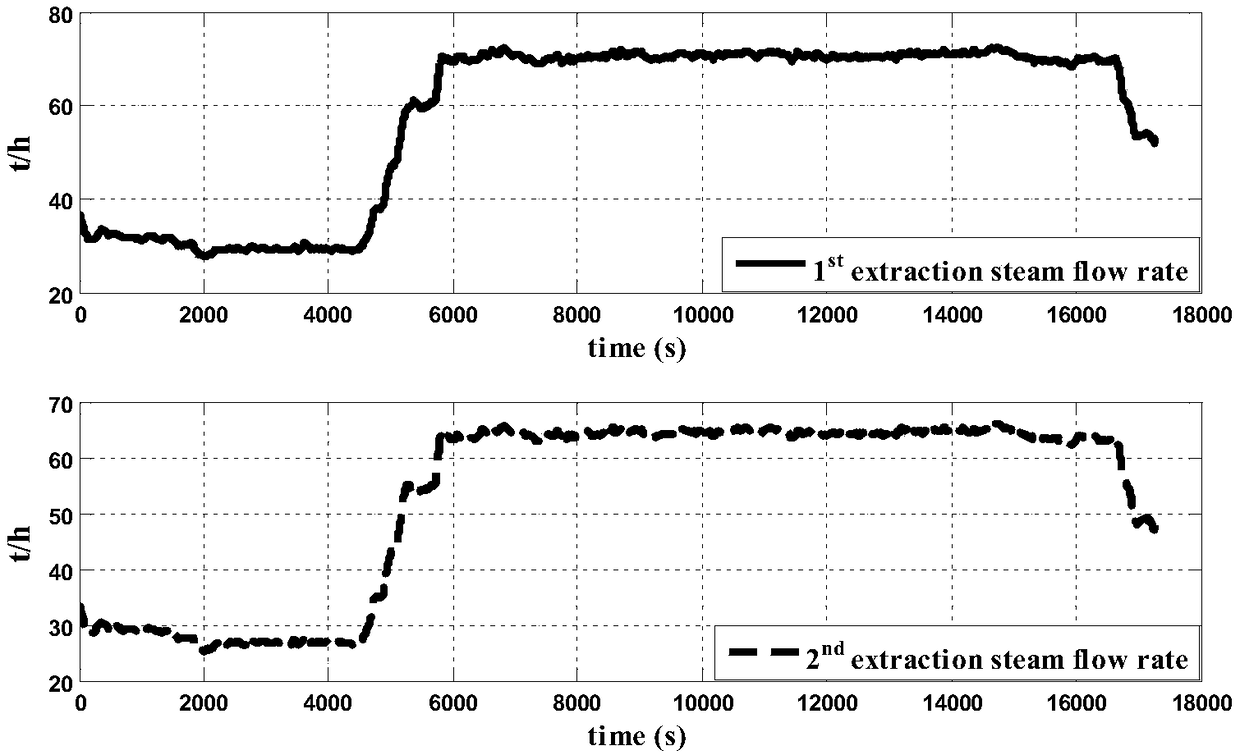

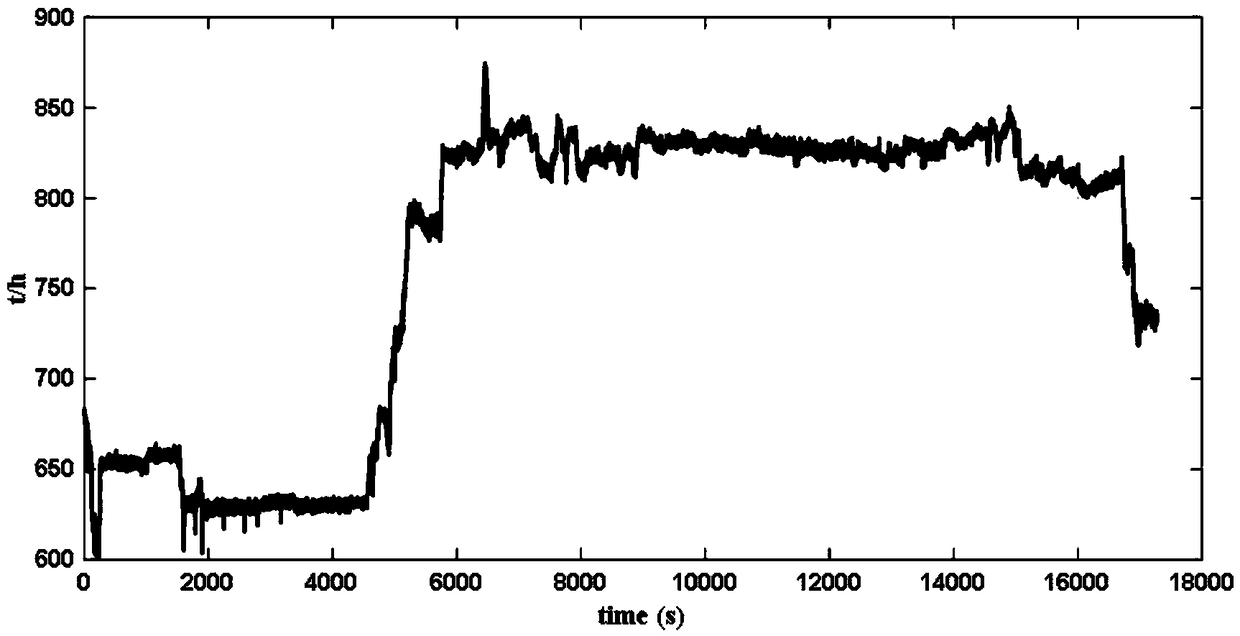

Coal-fired power station boiler reheater working medium flow online correction method

InactiveCN109141541AAchieve correctionAccurate online real-time monitoringVolume/mass flow measurementVolume variation compensation/correction apparatusEnergy balancingMeasurement point

The invention discloses a coal-fired power station boiler reheater working medium flow online correction method. The method comprises the following steps: acquiring related boiler running data in realtime from an engineer station in a boiler distributed control system (DCS) after selecting fixed sampling time; establishing a working medium physical property parameter library for online computation of water and vapor enthalpy values; setting a design parameter of a boiler related superheater system according to boiler design drawing; performing dead pixel processing and data smoothing processing on the collected running parameter of the boiler; establishing a boiler reheating system working medium mass and energy balancing equation based on mass and energy balancing; modifying an energy balancing equation in the step 4 according to heat storage change of a working medium and a metal heat-absorbing surface under the temperature pressure change; obtaining temperature, pressure and flow at each measurement point of the reheater system from the measurement point, and obtaining the temperature, pressure and flow related data of the working medium; simultaneously acquiring exhaust volumes of the primary exhaust and the secondary exhaust by combining the corrected mass and energy balancing equation; and finally obtaining the corrected reheater working medium flow.

Owner:ZHONGBEI UNIV

Method for the dynamically balancing series- and parallel-wired power semiconductor circuits

InactiveUS7071661B2Fast switching speedSimple methodElectronic switchingElectric variable regulationSwitching cycleState variable

A method for dynamically balancing the loads in a circuit (1, 4) of semiconductor power switches arranged in series or in parallel is disclosed. Individual switching signals (iG1, iG2) for the semiconductor power switches (S1 . . . S4) are generated by determining a system-widely valid synchronous sampling time (tsj) independently for each semiconductor power switch (S1 . . . S4) due to a synchronous event (es) of the whole circuit (1, 4). Control loop offsets between actual values (ai) measured synchronously at the sampling time (tsj) and given desired values (as) of an asynchronous state variable (a(t)) of the semiconductor power switches (S1 . . . S4) are reduced in the same or in following switching cycles. Alternatively, control loop offsets between actual time values (tai) and desired time values (tas) are minimized, wherein the actual time values (tai) are measured upon exceeding a globally provided threshold value (εa) of an asynchronous state variable (a(t)) of the semiconductor power switches (S1 . . . S4). Embodiments relate to: Offsetting the sampling time (tsj) in time by a globally provided time interval (Δt0), providing desired values locally or globally, e.g. by averaging of actual values (ai, tai), additional balancing of the gradients of asynchronous time variables (a(t)). A central sampling command can be dispensed with and the switching synchronicity is improved, switching times are shortened and dynamic switching losses are reduced.

Owner:POWER INTEGRATIONS INC

Gait generating device of mobile robot

InactiveUS7715944B2Accurate settingImprove dynamic accuracyProgramme-controlled manipulatorComputer controlDynamic modelsSimulation

The placement of the elements (mass points or rigid bodies having inertia) of a model expressing a robot 1 determined according to a first geometric restrictive condition from an instantaneous desired motion of the robot 1 is defined as a first placement, and provisional corrected instantaneous desired motions corresponding to a second placement and a third placement having predetermined relationships with the first placement are determined. The position / posture of a predetermined part 3 (body) of the robot 1 are determined by weighted averages of the position / posture of the aforesaid provisional corrected instantaneous desired motions. Thus, the motion of an instantaneous desired gait created using a dynamic model is properly corrected thereby achieving both improved dynamic accuracy between the motion and a floor reaction force of the instantaneous desired gait and a minimized change in the posture of a predetermined part, such as the body, of the robot without using a dynamic model.

Owner:HONDA MOTOR CO LTD

Localization method and helmet and computer readable storage medium using the same

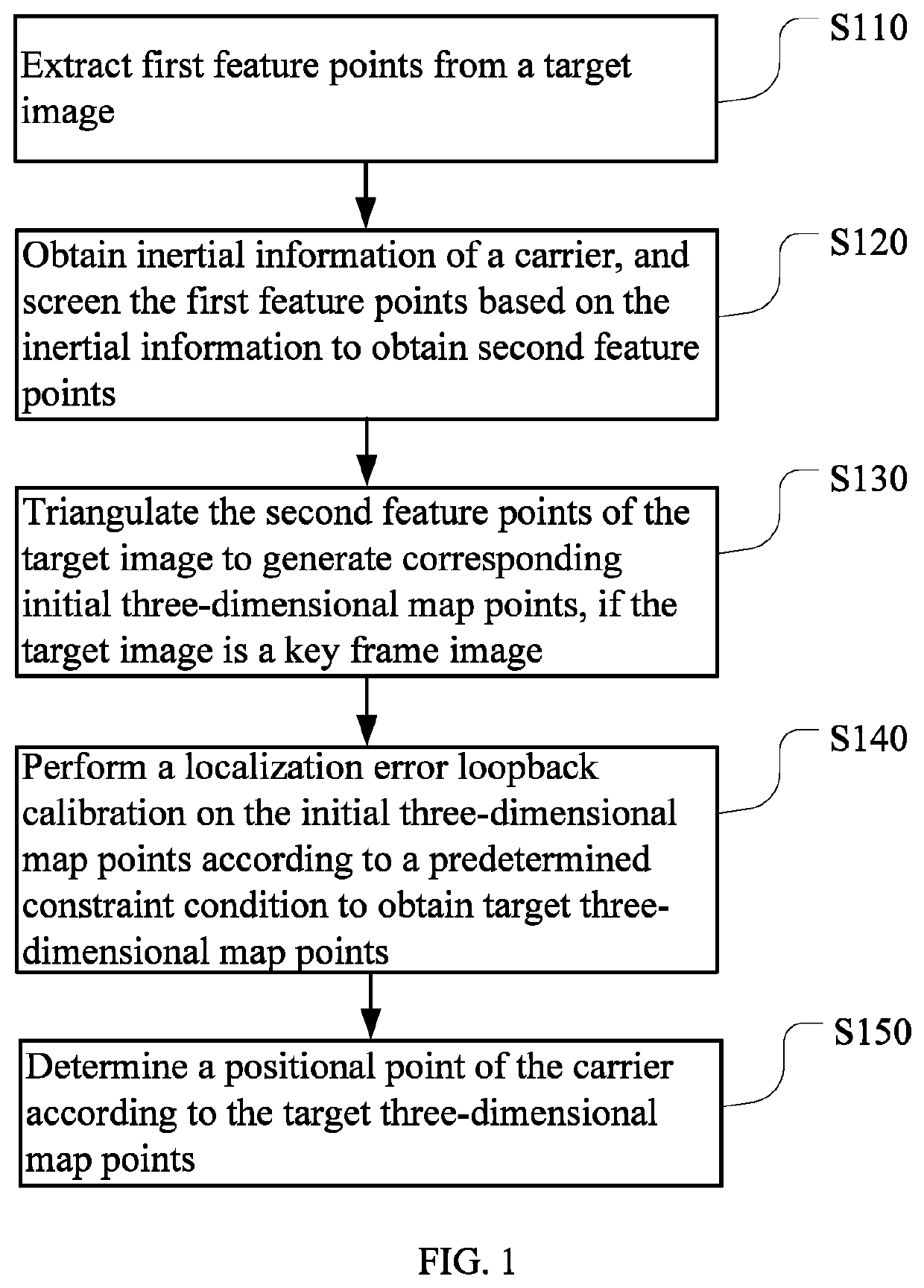

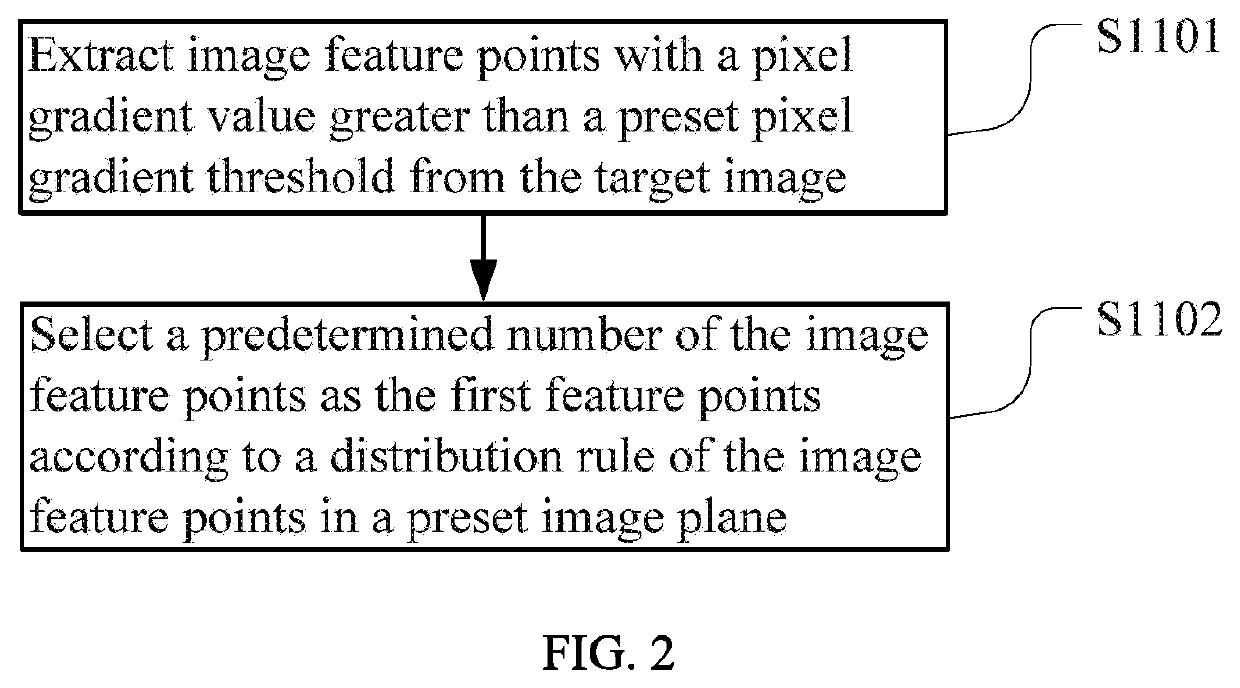

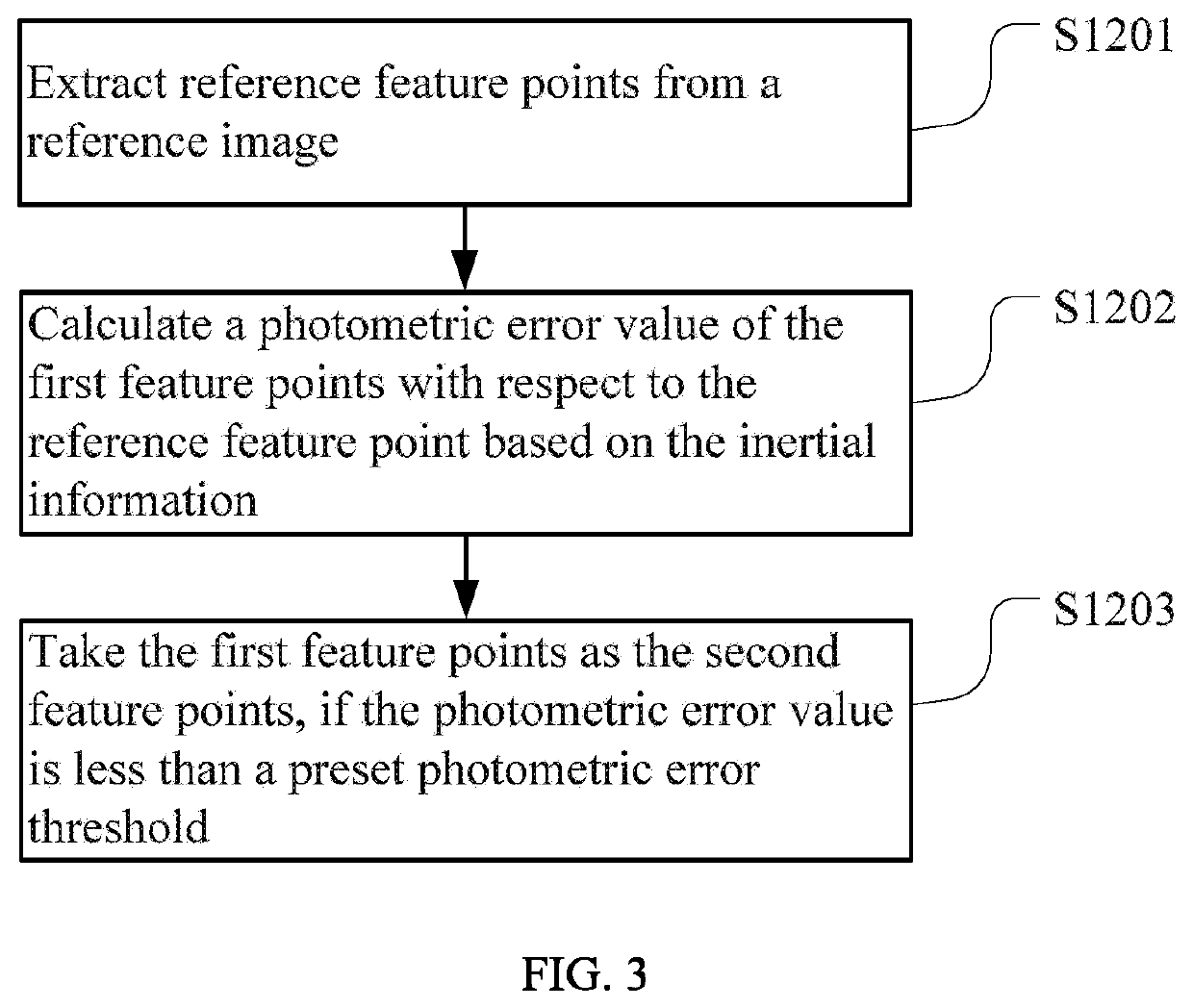

ActiveUS20210182633A1Improve dynamic accuracyGood effectPosition fixationCharacter and pattern recognitionPattern recognitionComputer graphics (images)

The present disclosure provides a localization method as well as a helmet and a computer readable storage medium using the same. The method includes: extracting first feature points from a target image; obtaining inertial information of the carrier, and screening the first feature points based on the inertial information to obtain second feature points; triangulating the second feature points of the target image to generate corresponding initial three-dimensional map points, if the target image is a key frame image; performing a localization error loopback calibration on the initial three-dimensional map points according to at least a predetermined constraint condition to obtain target three-dimensional map points; and determining a positional point of the specific carrier according to the target three-dimensional map points. In this manner, the accuracy of the localization of a dynamic object such as a person when moving can be improved.

Owner:UBTECH ROBOTICS CORP LTD

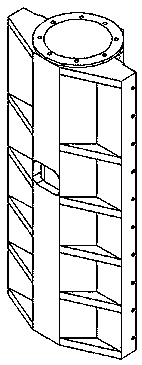

Reluctance type inclination angle sensor

ActiveCN102901487ASimple structureLow costUsing electrical meansIncline measurementSoft magnetEngineering

The invention provides a reluctance type inclination angle sensor. The reluctance type inclination angle sensor comprises a cylindrical body, an end cover, a connecting piece and a mandrel, a fixed plate, an annular soft magnet, E-type soft magnet coils and a detection circuit, wherein a through groove is formed in the center of the mandrel; the fixed plate is connected with the mandrel through the through groove; the fixed plate and the mandrel penetrate through and are arranged in the annular soft magnet; two side edges of the fixed plate are fixedly connected with the inner side surface of the annular soft magnet; the connecting piece is positioned on the cylindrical body and / or the end cover and is matched with and connected with two ends of the mandrel; the E-type soft magnet coils are arranged on the outer side surface of the cylindrical body; the cylindrical body is in sealed connection with the end cover to form a closed cavity; the annular soft magnet and the cylindrical body are eccentrically fixed through the fixed plate; and the detection circuit is connected with the E-type soft magnet coils and is used for detecting an oscillation frequency value, wherein an inclination angle is obtained by mapping the oscillation frequency value.

Owner:BEIJING UNIV OF POSTS & TELECOMM

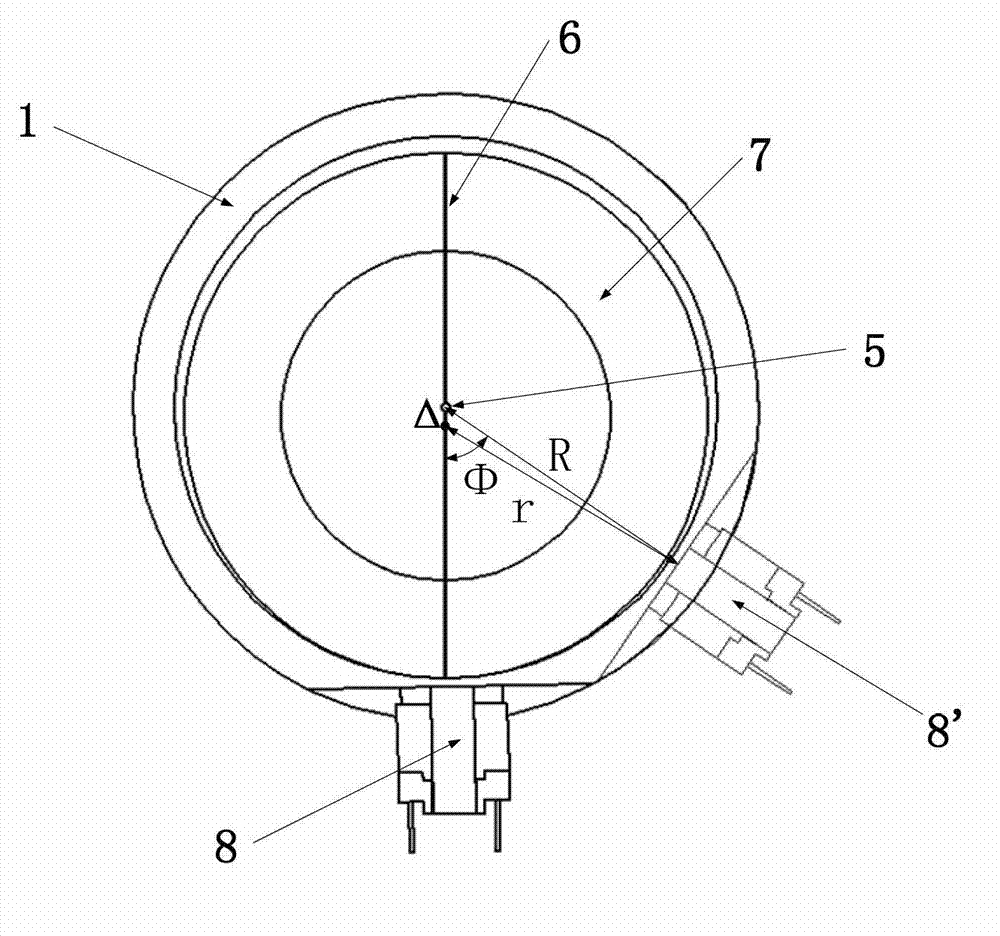

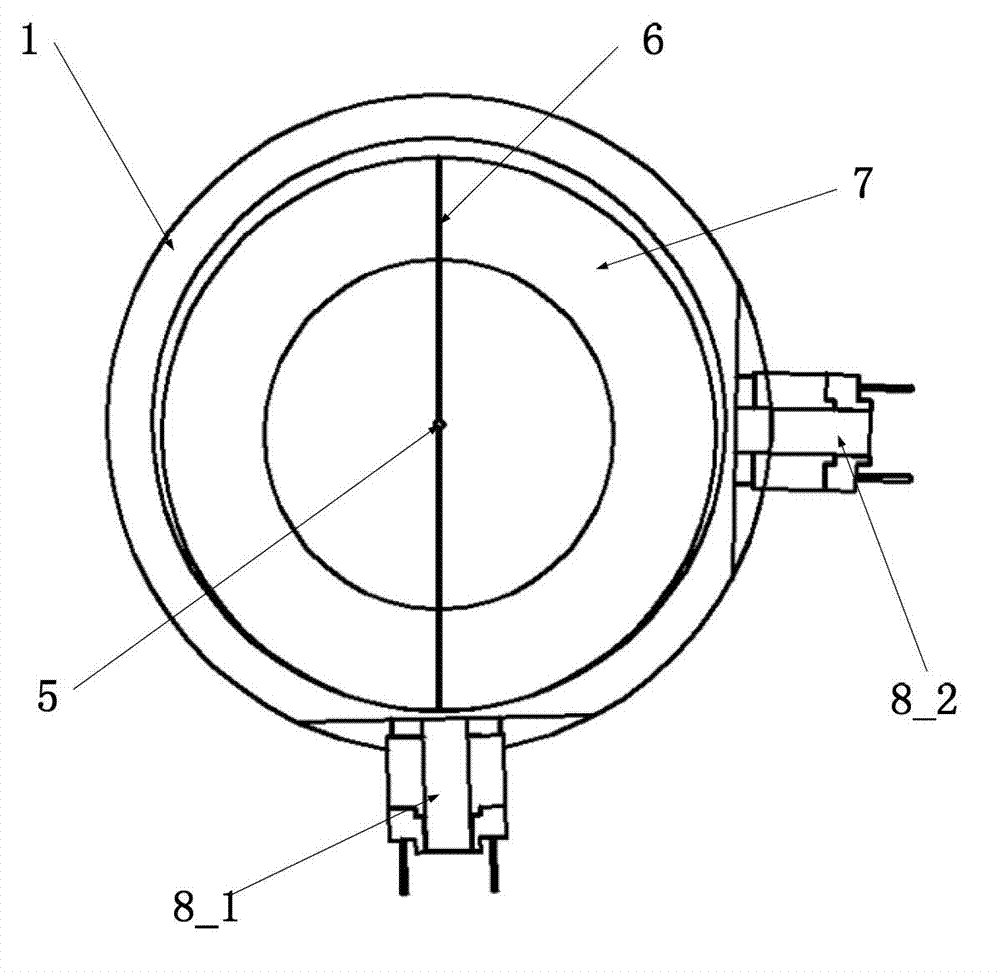

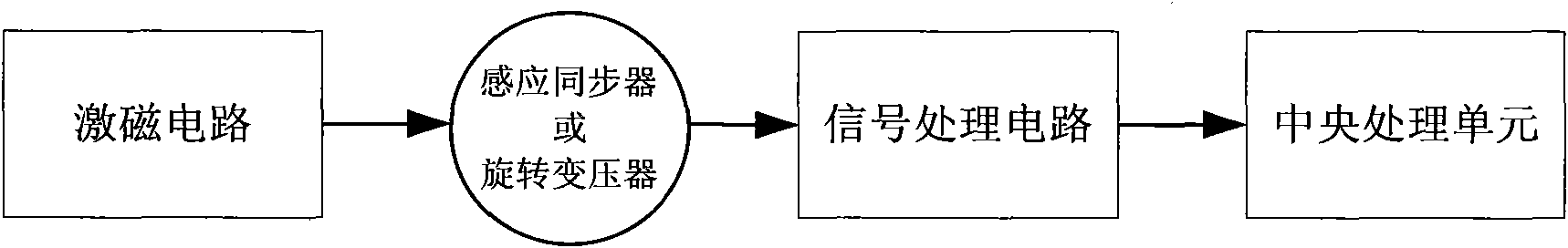

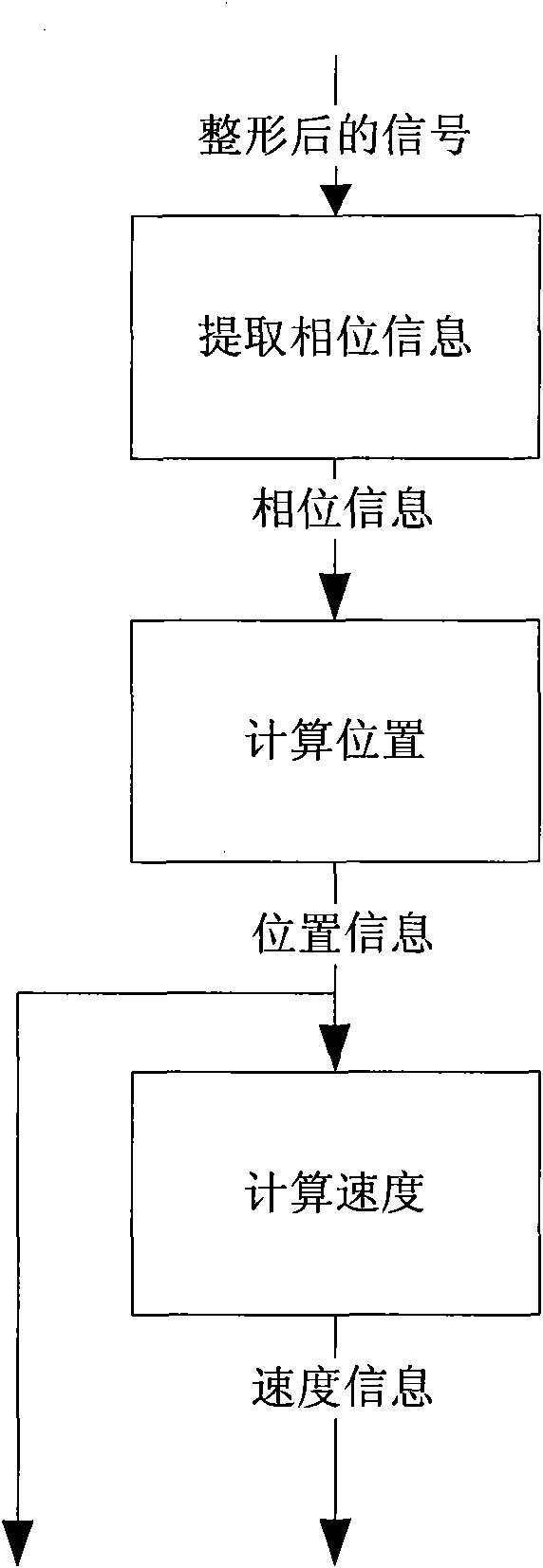

Position and speed measuring device based on inductosyn or rotary transformer

InactiveCN101881784ANo velocity calculation errorsSimple structureIndication/recording movementDevices using electric/magnetic meansLow speedSignal processing circuits

The invention discloses a position and speed measuring device based on an inductosyn or a rotary transformer. The device adopts a phase discrimination type processing method and comprises an exciting circuit, an inductosyn or a rotary transformer, a signal processing circuit and a central processing unit. An exciting signal is generated by the exciting circuit and subject to power amplification, a power signal passes through the inductosyn or the rotary transformer, the signal processing circuit carries out filtering, amplification, phase shift and reshaping on the power signal, and then the processed signal is sent to the central processing unit. The central processing unit obtains position information through the phase information of a signal, obtains speed information through a position information difference, obtains acceleration information through a speed information difference, and carries out dynamic error correction on phase or speed according to speed and acceleration information. The invention is simple to realize, has low cost and high accuracy, is suitable for both a high-speed operation condition and a low-speed operation condition, and can be applied to the fields of aerospace, military, industry and the like to realize dynamic position and speed measurement.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

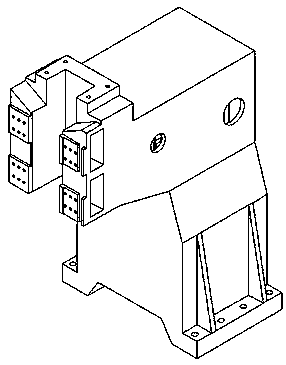

Compact high-precision constant-force actuator and application method

InactiveCN112238396ALifting Force Sensing AccuracyReduce frictionGrinding drivesGrinding feed controlControl systemControl engineering

The invention relates to a compact high-precision constant-force actuator and an application method thereof. The compact high-precision constant-force actuator comprises a motive force assembly, a transmission assembly, a control system, a motive force control assembly and a sensor assembly; and the motive force assembly outputs motive force through the transmission assembly, the sensor assembly acquires information of output force and a posture of the transmission assembly, and sends the information of the output force and the posture of the transmission assembly to the control system, and the control system adjusts the output force of the motive force assembly according to the information of the output force through the motive force control assembly. The compact high-precision constant-force executor is provided, through extension and retraction of the device (compact high-precision constant-force executor), position errors of a robot are compensated, and contact force is precisely adjusted according to a set value so that the product quality of machined parts can be effectively improved, and the production cost is reduced.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

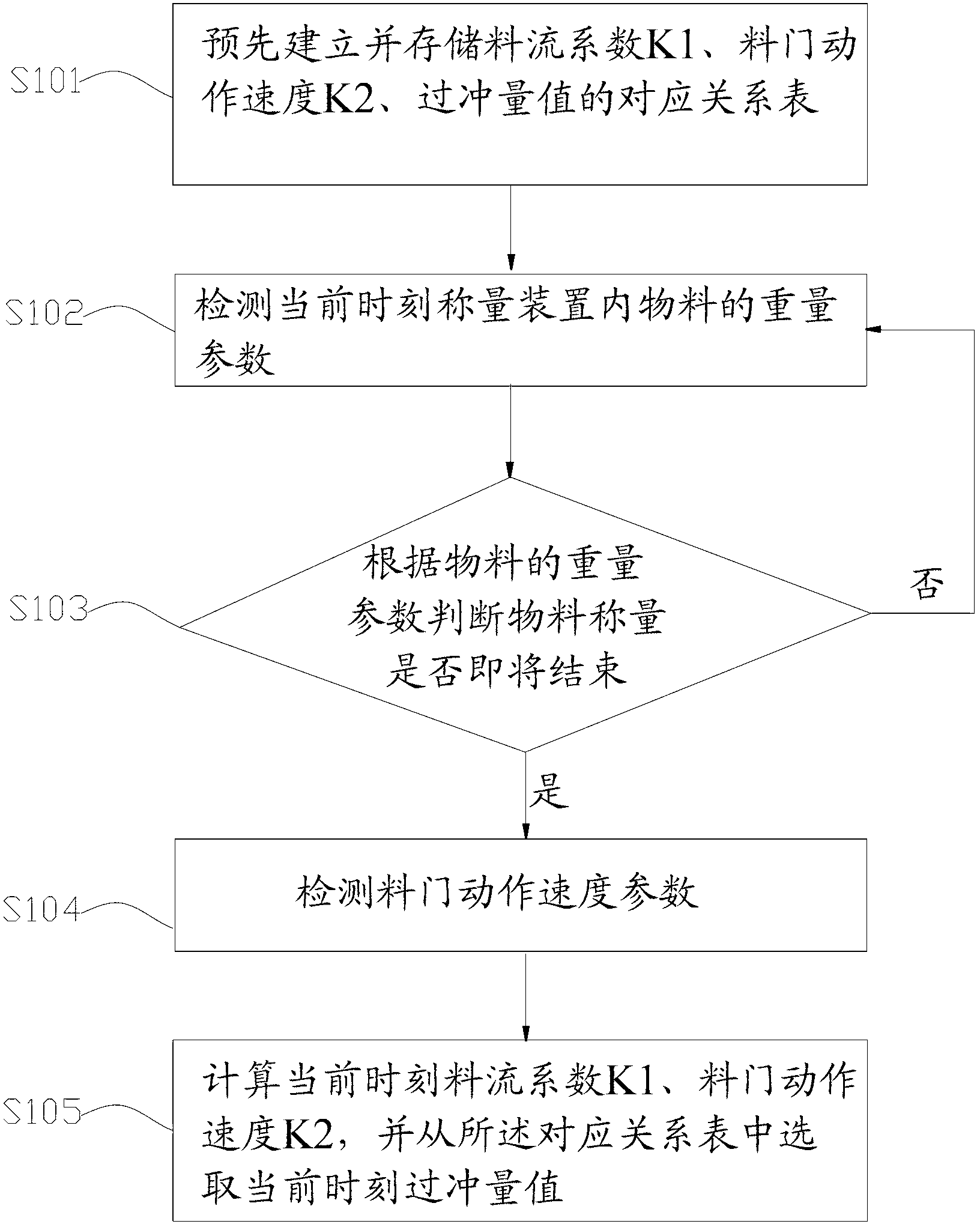

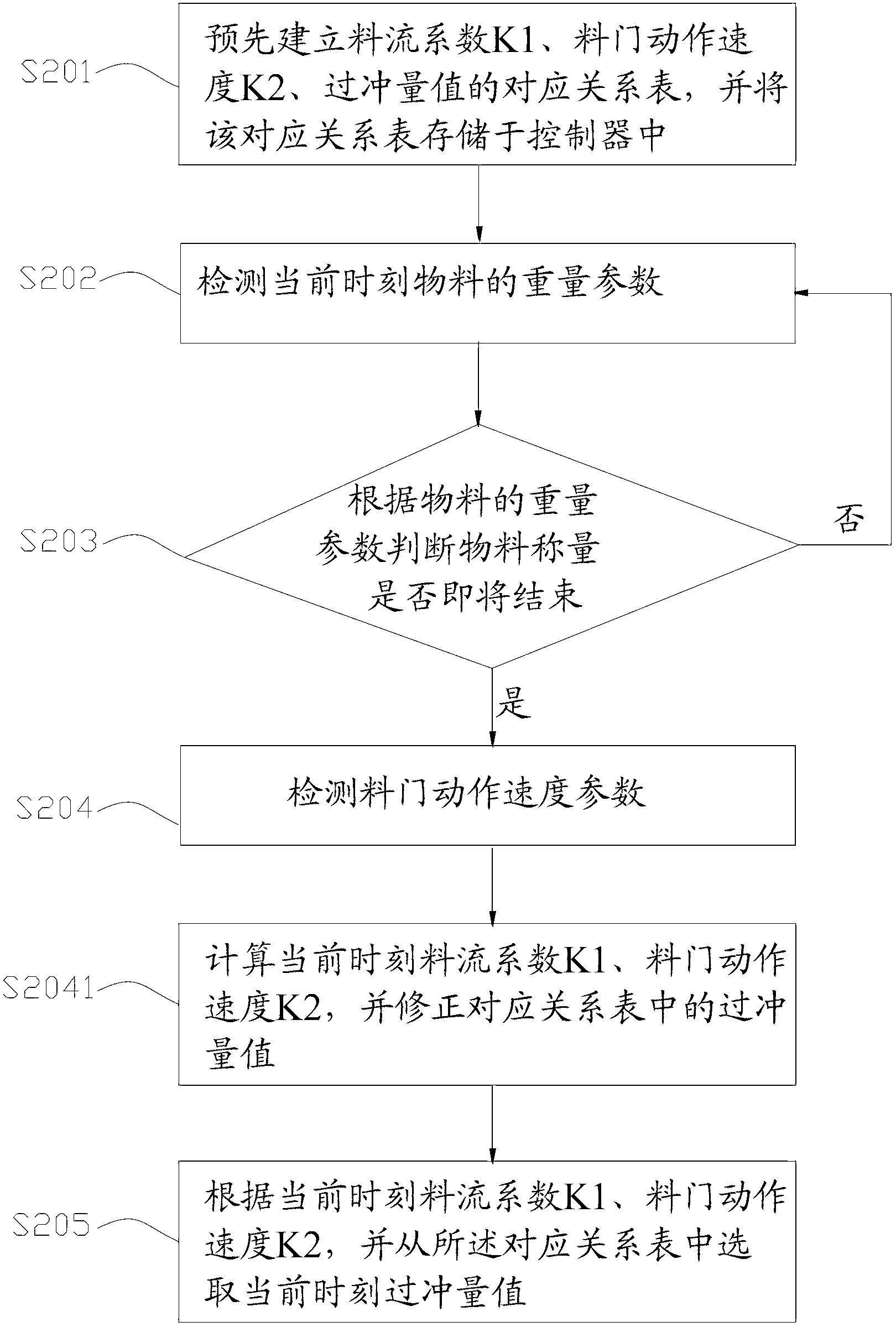

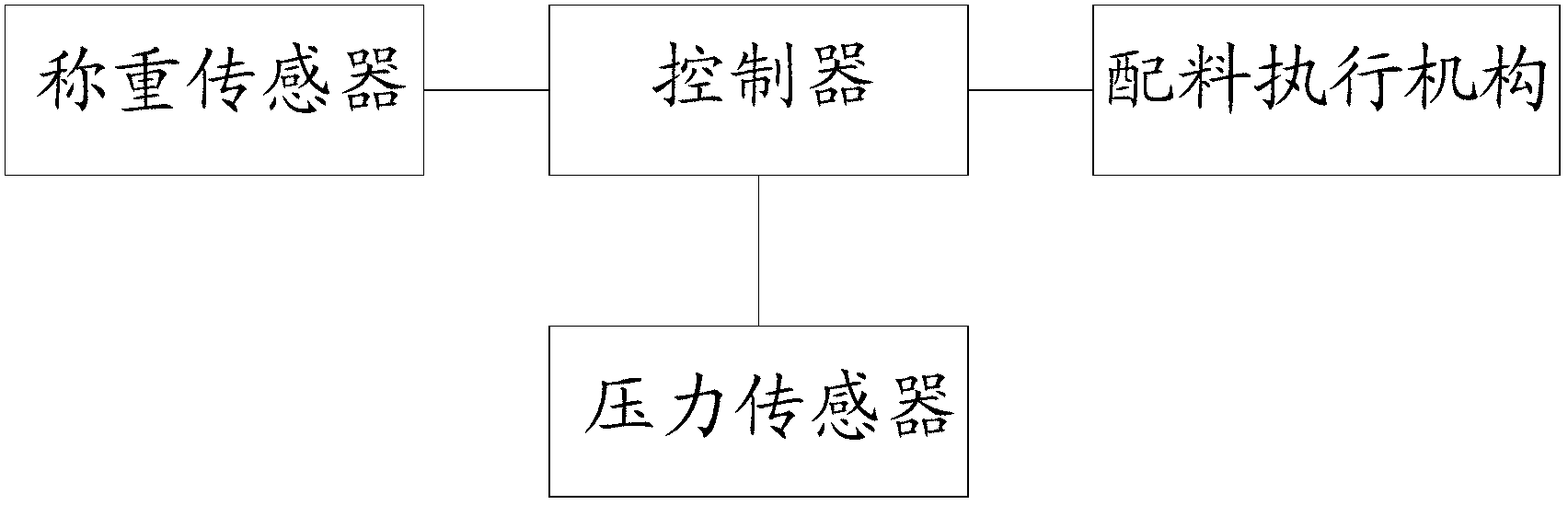

Overshoot compensation control method and overshoot compensation control system for material in mixing plant

ActiveCN102700000AImprove dynamic accuracyHigh precisionMixing operation control apparatusProcess engineeringCurrent time

The invention discloses an overshoot compensation control method and an overshoot compensation control system for material in a mixing plant. The overshoot compensation control method comprises the following step: pre-establishing a material flow coefficient K1, a material gate operating speed K2 and a corresponding relation table for overshoot values; selecting an overshoot value of the current state from the corresponding relation table by detecting a material flow coefficient K1 when the weighing of the material is about to finish and a material gate operating speed K2 when the material gate is closed, and according to a material flow coefficient K1 and a material gate operating speed K2 corresponding to the current time; and setting the overshoot value as the compensation value for calculating weighing hopper and material weight. According to the method, the material flow condition and the material gate operating speed can be detected promptly; and a proper overshoot value is selected from the corresponding relation table according to real situation to serve as the compensation value of the current overshoot value. The method provided by the invention has the advantage that the material weighing dynamic accuracy is improved to a great extent, so as to improve batching accuracy and product quality.

Owner:XUZHOU XCMG MAINTENANCE MACHINERY CO LTD

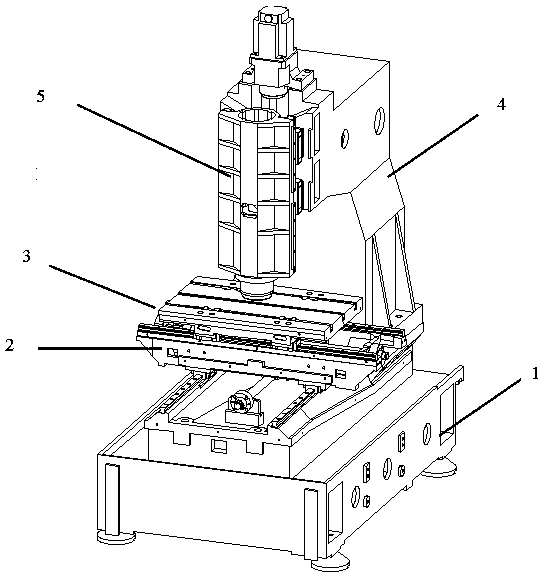

Intelligent high-speed drilling and tapping center machine tool

PendingCN108381199AImprove torsion resistanceRigidity without compromising stabilityLarge fixed membersIntelligent lightingResonance

The invention discloses an intelligent high-speed drilling and tapping center machine tool. The machine tool comprises a machine tool body, a stand column, a sliding base, a spindle box, a workbench and other basic parts, wherein the machine tool body is connected to the stand column through screws, the sliding base is connected to the machine tool body through a sliding block on the machine toolbody with screws, and the spindle box is connected to the stand column through a sliding block by means of screws. The machine tool has the advantages that a stand column structure adopts an inverted-L-shaped structure, a column base adopts an inverted-U-shaped structure, and therefore the rigidity and the stability of connection with the machine tool body can be enhanced; and the machine tool stability and the machine tool assembly efficiency can be improved, the high rigidity and the high efficiency of the machine tool improve the cutting performance of a spindle, and meanwhile, the problemsof the resonance phenomenon and the machine tool precision when a workpiece is machined by the machine tool can be solved.

Owner:沈阳优尼斯智能装备有限公司

Accuracy compensation method of coaxial macro-micro composite linear motion platform device

InactiveCN103170845BGuaranteed continuityNo lagMeasurement/indication equipmentsOther manufacturing equipments/toolsElectricityLinear motion

Owner:SANYING MOTIONCONTORL TIANJIN INSTR CO LTD

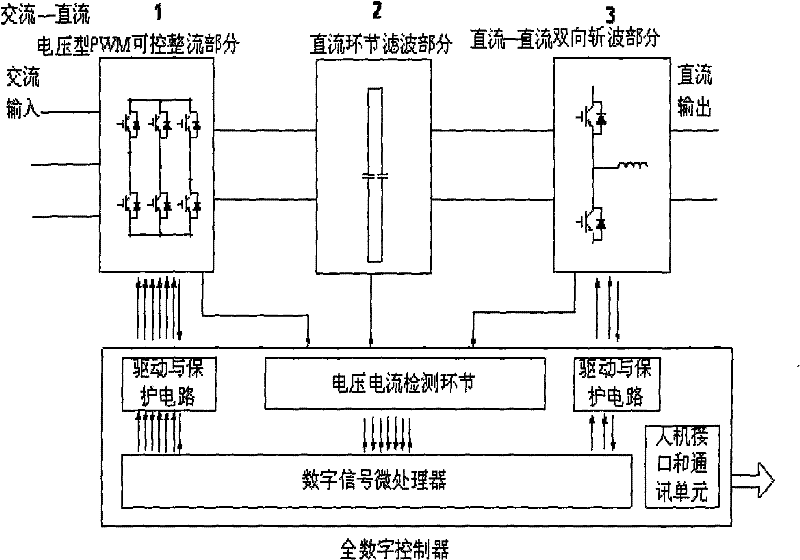

Battery charging and discharging device

ActiveCN101604853BQuick switchHarmonic reductionBatteries circuit arrangementsCurrent/voltage measurementCapacitancePower factor

A battery charge and discharge device comprises a battery charge and discharge assembly and a full digital controller, which is characterized in that the battery charge and discharge assembly is composed of an AC-DC voltage PWM controllable rectifier part, a DC link filter part and an AC-DC bidirectional chopper part which are in cascade connection; the AC-DC voltage PWM controllable rectifier part is formed by the cascade connection of an AC inlet inductance and a full control rectifier bridge, wherein the AC inlet inductance is formed by the cascade connection of a transformer output leakage inductance and an AC inductance, and the bridge arm of the full control rectifier bridge is formed by the cascade connection of power switching elements; the DC link filter part is formed by the parallel connection of a DC capacitance and a high frequency absorption capacitance; the AC-DC bidirectional chopper part is formed by the series connection of power switching elements and a DC output inductance. The battery charge and discharge device has the advantages that power factor approaches 1 when the battery is being charged, input current harmonics content is low, output voltage range is wide, output current precision is high and the like, and the battery charge and discharge device realizes safe machine halt in case of power failure at the same time.

Owner:武汉长海电力推进和化学电源有限公司

Gate generating system for mobile robot

ActiveUS7319302B2Improve dynamic accuracyTruly satisfactoryProgramme-controlled manipulatorComputer controlDynamic modelsEngineering

A gait generating system for a mobile robot has n dynamic models and determines a first gait parameter defining a desired gait such that the boundary condition of a gait on a first dynamic model is satisfied. The first gait parameter is corrected step by step by using an m-th dynamic model (m: integer satisfying 2≦m≦n), which is each dynamic model other than the first dynamic model, and an m-th gait parameter that satisfies the boundary condition on the m-th dynamic model is determined. The m-th gait parameter is determined by correcting an object of an (m−1)th gait parameter to be corrected on the basis of the degree of deviation of the gait generated on the m-th dynamic model by using the (m−1)th gait parameter from the boundary condition. A final determined n-th gait parameter and an n-th dynamic model are used to generate a desired gait.

Owner:HONDA MOTOR CO LTD

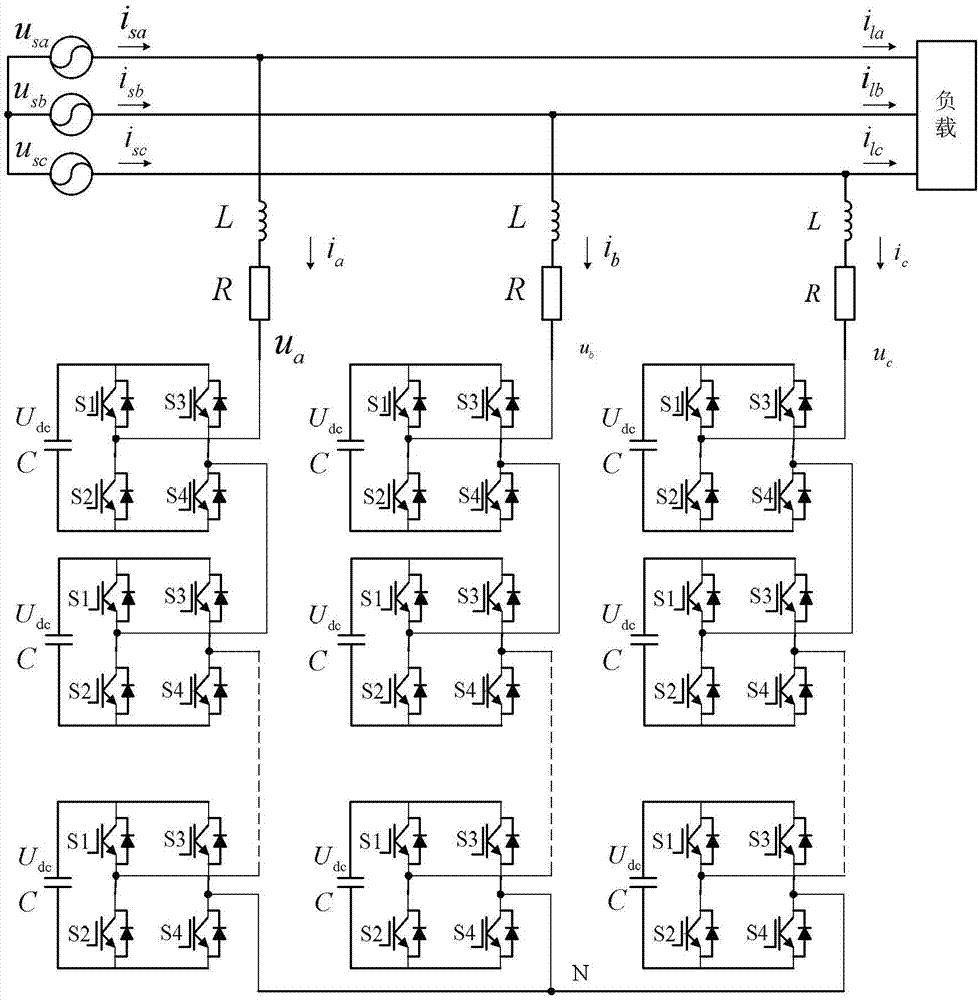

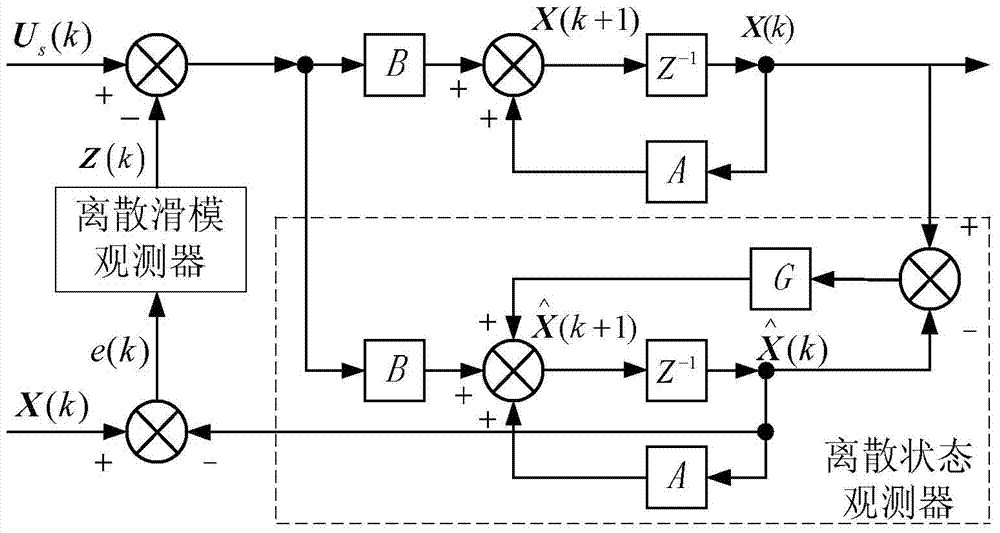

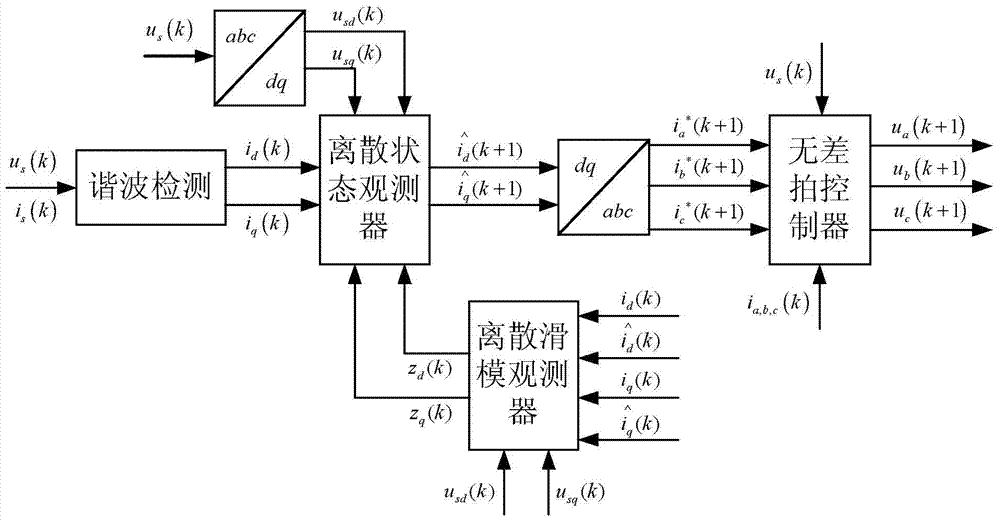

H-bridge cascaded statcom deadbeat control method based on discrete state observer and sliding mode observer

ActiveCN103606936BImprove tracking performanceImprove the compensation effectFlexible AC transmissionReactive power adjustment/elimination/compensationMathematical modelState observer

The invention discloses an H-bridge cascading STATCOM dead-beat control method based on a discrete state observer and a discrete sliding-mode observer, and relates to the H-bridge cascading STATCOM control technology. The H-bridge cascading STATCOM dead-beat control method aims to solve the problem that an existing dead-beat control method must be matched with a good reference current prediction method and a common prediction method needs to be dependent on an accurate mathematical model, so that the existing dead-beat control method is seriously limited in actual application. According to the H-bridge cascading STATCOM dead-beat control method, the discrete state observer is constructed according to a simple mathematical model of an H-bridge cascading STATCOM, and a reference instruction current at a k+1 moment is obtained by means of calculation at a k moment by adopting the prediction function of the discrete state observer, so that dead-beat control is realized in a true sense; the discrete sliding-mode observer is constructed for conducting real-time observation on ud (k) and uq (k) of three-phase voltage values output by the STATCOM under a dq coordinate system. The H-bridge cascading STATCOM dead-beat control method based on the discrete state observer and the discrete sliding-mode observer is applied to reactive compensation and harmonic wave filtering of a power grid.

Owner:山东汉德自动化控制设备有限公司

Mixer for mixing rubber and plastic particles

The invention relates to a mixer for mixing rubber and plastic particles, which comprises a mixing roller device and a transmission device which are matched with each other. Both the mixing roller device and the transmission device are arranged on a weighing device which is arranged on a support base. The weighing device, the mixing roller device and the transmission device are respectively connected with a control system which is arranged on one side of the support base through circuits. The mixing roller device is driven by a driving wheel through a rolling ring to rotate. The roller has positive rotation and reverse rotation. During positive rotation, an inner spiral pushing auger drives material particles in the roller to lift, rotate, roll and move tangentially and axially along the roller to uniformly mix the materials. Meanwhile, the materials move to the side of a discharge outlet axially under the action of a spiral thrusting force, and the materials are discharged from the discharge outlet through a material lifting plate finally. The mixer for mixing the rubber and plastic particles has the characteristics of high production efficiency, excellent mixing effect, high discharge speed, adjustable speed, accurate discharge, capacity of preventing the material particles from re-bonding, full-automatic control, full closeness, no dust or noise pollution, and the like.

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com