Heat value stabilizing control system of mixed gas and computer-controlled model

A technology of mixed gas and stable control, which is applied in the direction of controlling combustion, lighting and heating equipment, etc., and can solve the problems of complex coupling, inability to solve the mutual influence of calorific value adjustment and pressure adjustment of mixed gas, and many disturbances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation.

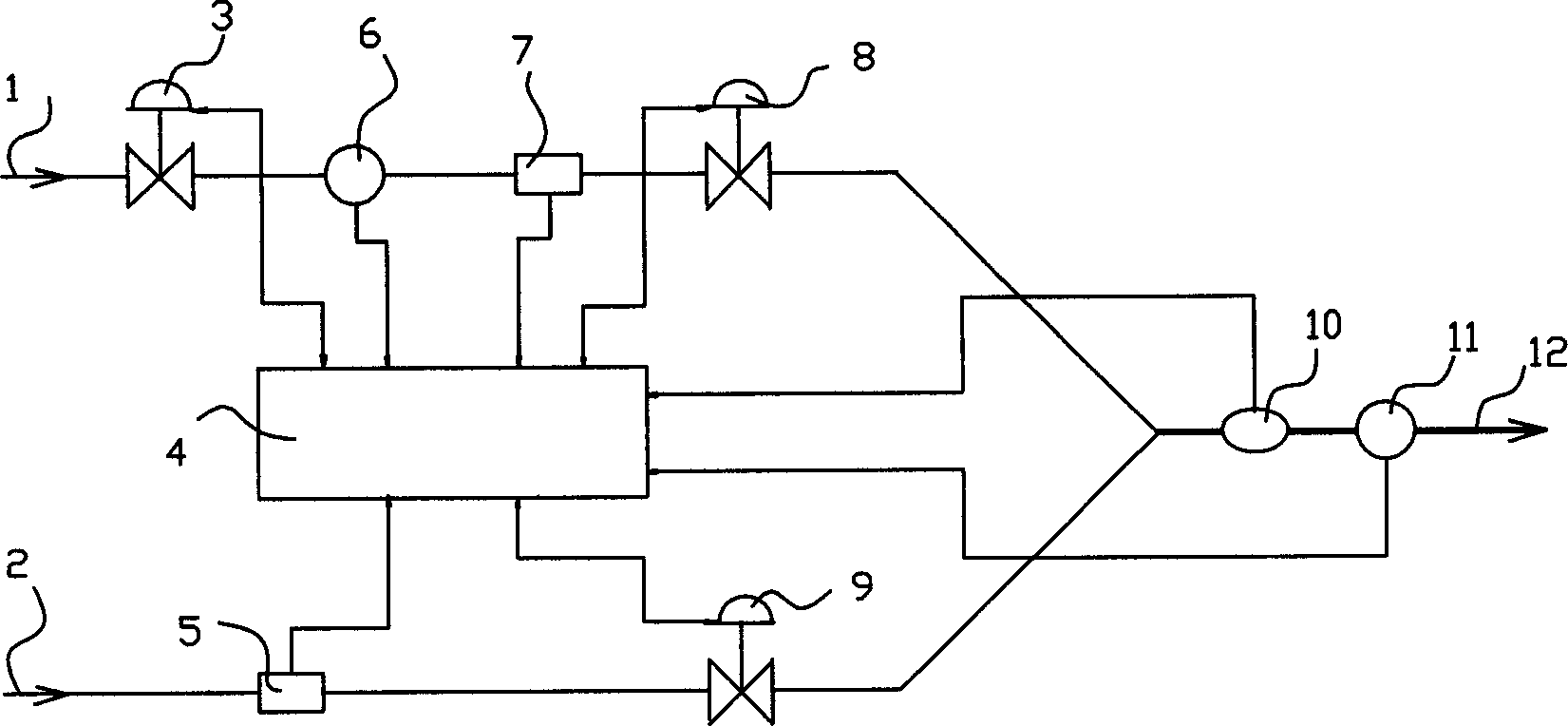

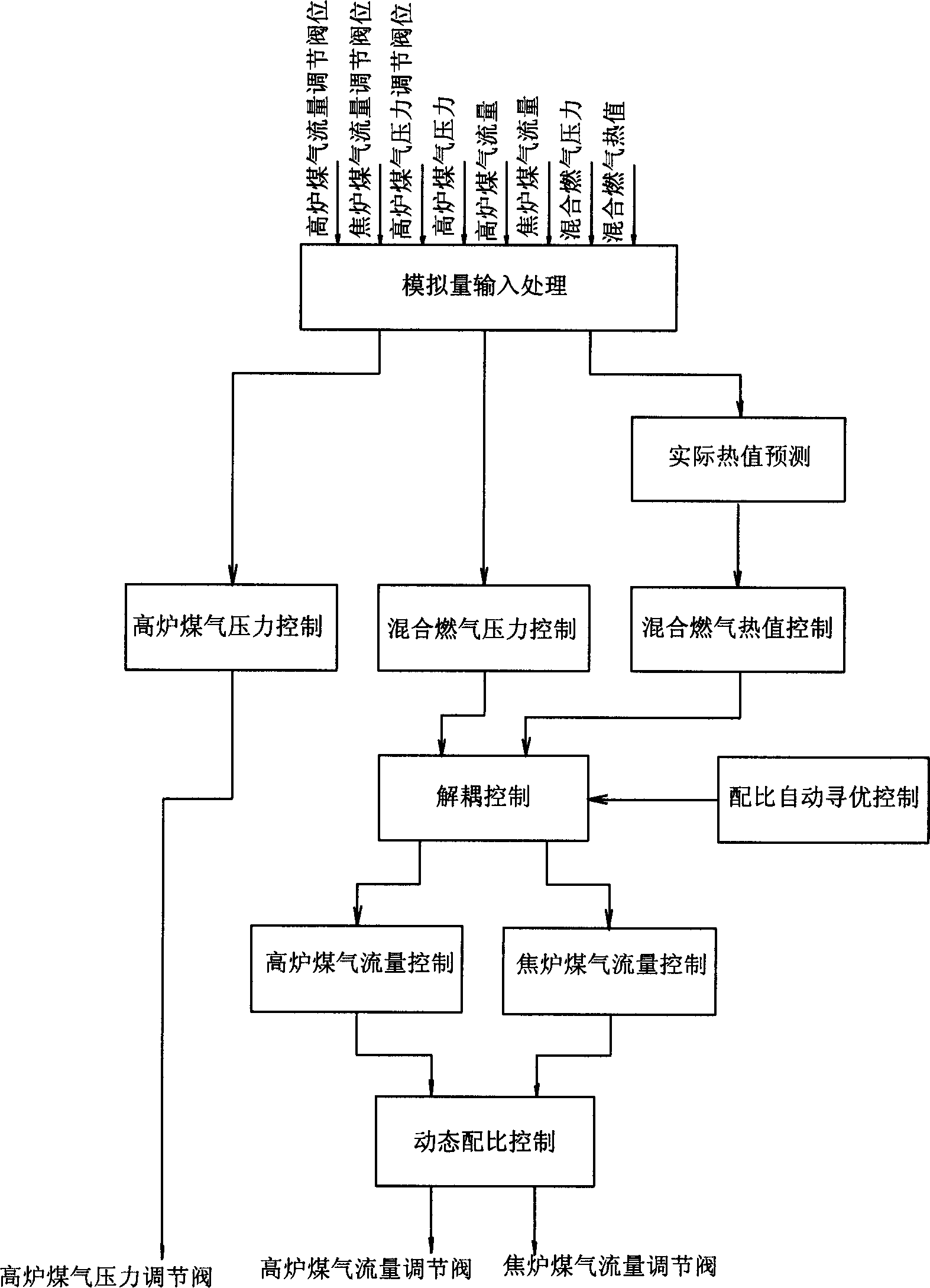

[0011] by attaching figure 1 It can be seen that the calorific value stabilization control system of the mixed gas in this scheme includes a blast furnace gas input pipeline (1), a coke oven gas input pipeline (2) and a mixed gas output pipeline (12) connected to the two gas input pipelines. In this scheme, a blast furnace gas pressure regulating valve (3), a blast furnace gas pressure sensor (6), a blast furnace gas flow sensor (7) and a blast furnace gas flow regulating valve (8) are installed on the blast furnace gas input pipeline (1); A coke oven gas flow sensor (5) and a coke oven gas flow regulating valve (9) are installed on the gas input pipeline (2); a mixed gas calorific value sensor (10) and a mixed gas pressure sensor are installed on the mixed gas output pipeline (12) (11); In addition, there is a computer contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com