Intelligent high-speed drilling and tapping center machine tool

A high-speed, intelligent technology, applied in the direction of metal processing machinery parts, large fixed members, metal processing equipment, etc., to achieve the effect of improving dynamic response, improving X-axis rigidity, and increasing connection stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

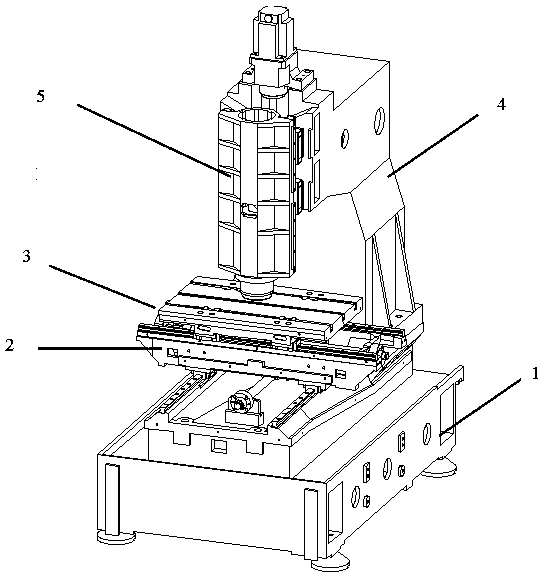

[0016] Such as figure 1 As shown, the bed 1 is stably placed on the ground through 4 anchor screws; the sliding seat 2 and the bed 1 are connected with M8 screws through the slider on the bed; It is connected with the bed 1 through 8 M18 screws; the spindle box 5 is installed and fastened on the column 3 with M8 screws through the slide block on itself.

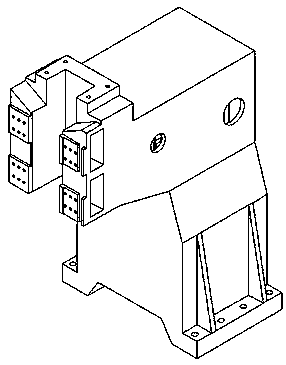

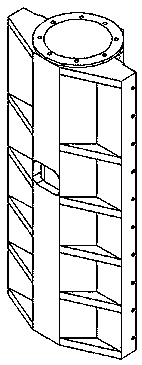

[0017] The Y-direction sliding seat is 5mm shorter in length and 150mm in length. The column 4 is integrally formed with an inverted L-shaped structure made of cast iron. The column base of the column 4 adopts two column feet, which are in an inverted U-shaped structure. The distance between the center of the main shaft and the center of the screw is 170mm, the distance between the guide rail surface and the main shaft is reduced to 5mm, the distance between the center of the spindle box 5 and the center of the screw is shortened, the range is within 200mm, and the guide rail surface is close to the axis. The base span of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com