Method for acquiring coal parameter of thermal power generating unit boiler cost minimum mixed coal

A technology with the lowest cost and thermal power unit, applied in data processing application, prediction, calculation and other directions, can solve the problems of lack of accuracy, difficulty in fully considering the diversity of coal quality into the furnace, etc., to achieve the effect of ensuring rationality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The invention aims at the problem that it is difficult to determine the coal quality parameter of the lowest boiler cost coal blending, and proposes a method for obtaining the coal quality parameter value of the lowest boiler cost coal blending.

[0037] The specific implementation method is as follows:

[0038] Step 1: Collect common single coal data of power plant boilers and establish a single coal information database;

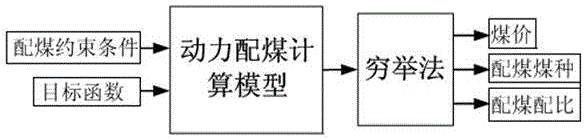

[0039] Step 2: Taking the minimum blending ratio of high-quality coal, the largest blending ratio of inferior coal, and the lowest unit price of raw coal as the objective function, and using the single coal database, boiler design coal quality and historical coal data as constraints, establish a mathematical model for power coal blending;

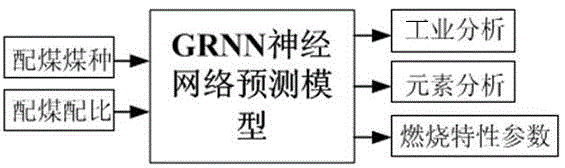

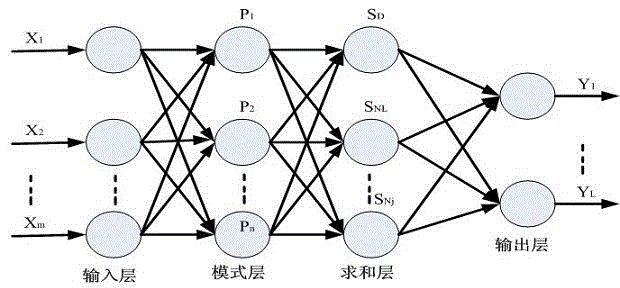

[0040] Step 3: Based on the mathematical model of power coal blending established in step 2, use the exhaustive method to search all coal blending combinations in the single coal database, determine the coal blen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com