System for heating hot primary air of coal-fired boiler by groove type solar heat-conducting oil heat-collecting working medium

A trough solar, coal-fired boiler technology, applied in solar heating systems, solar collectors, solar collectors using working fluid, etc., can solve the problem of insufficient drying output of coal mills and unsatisfactory boiler hot primary air temperature requirements and other issues to achieve the effect of improving drying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

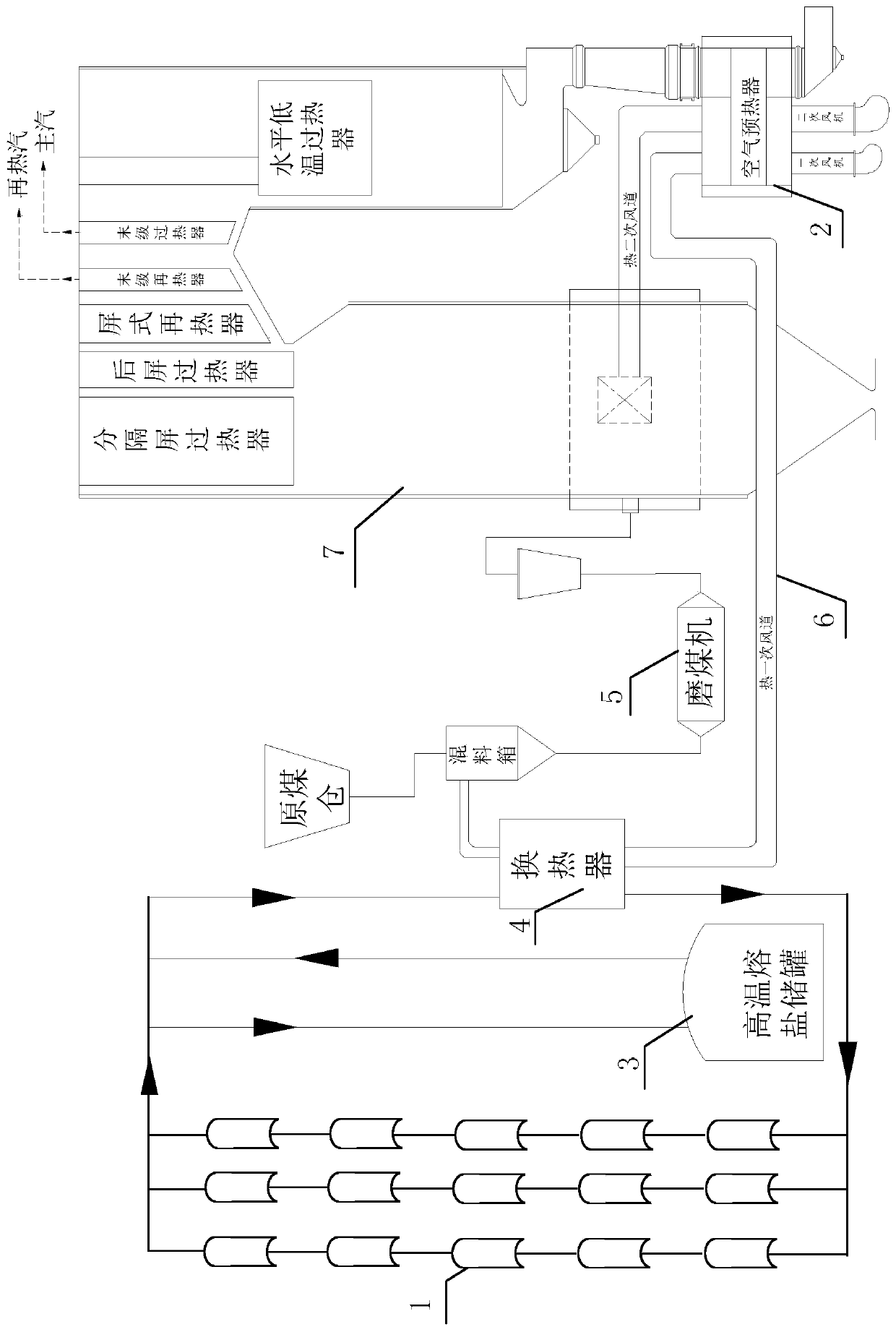

[0012] Specific implementation mode one: refer to figure 1 Describe this embodiment in detail. The system for heating the primary air of a coal-fired boiler using trough-type solar heat-conducting oil heat-collecting working medium described in this embodiment includes: a trough-type heat collector 1 and a heat exchanger 4;

[0013] The trough collector 1 is used to collect the heat of solar energy into the heat transfer oil, and the heat transfer oil after collecting the heat is used to exchange heat to the hot primary air output by the air preheater 2 of the coal-fired boiler through the heat exchanger 4 .

[0014] Further, the trough heat collector 1 is located on the ground or the top of the factory building, the heat transfer oil outlet of the trough heat collector 1 is connected with the heat transfer oil inlet of the heat exchanger 4, and the cold heat transfer oil outlet of the heat exchanger 4 is connected with the trough heat transfer oil outlet. The cold heat transf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com