Large mechanical test system for combined adjustable constraint concrete arch frame

A mechanical test and adjustable technology, used in shaft equipment, shaft lining, mining equipment, etc., can solve the problems of arch failure, increased cost, high hydraulic measurement and control accuracy, and achieve reduced stress concentration, sufficient contact, and good stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

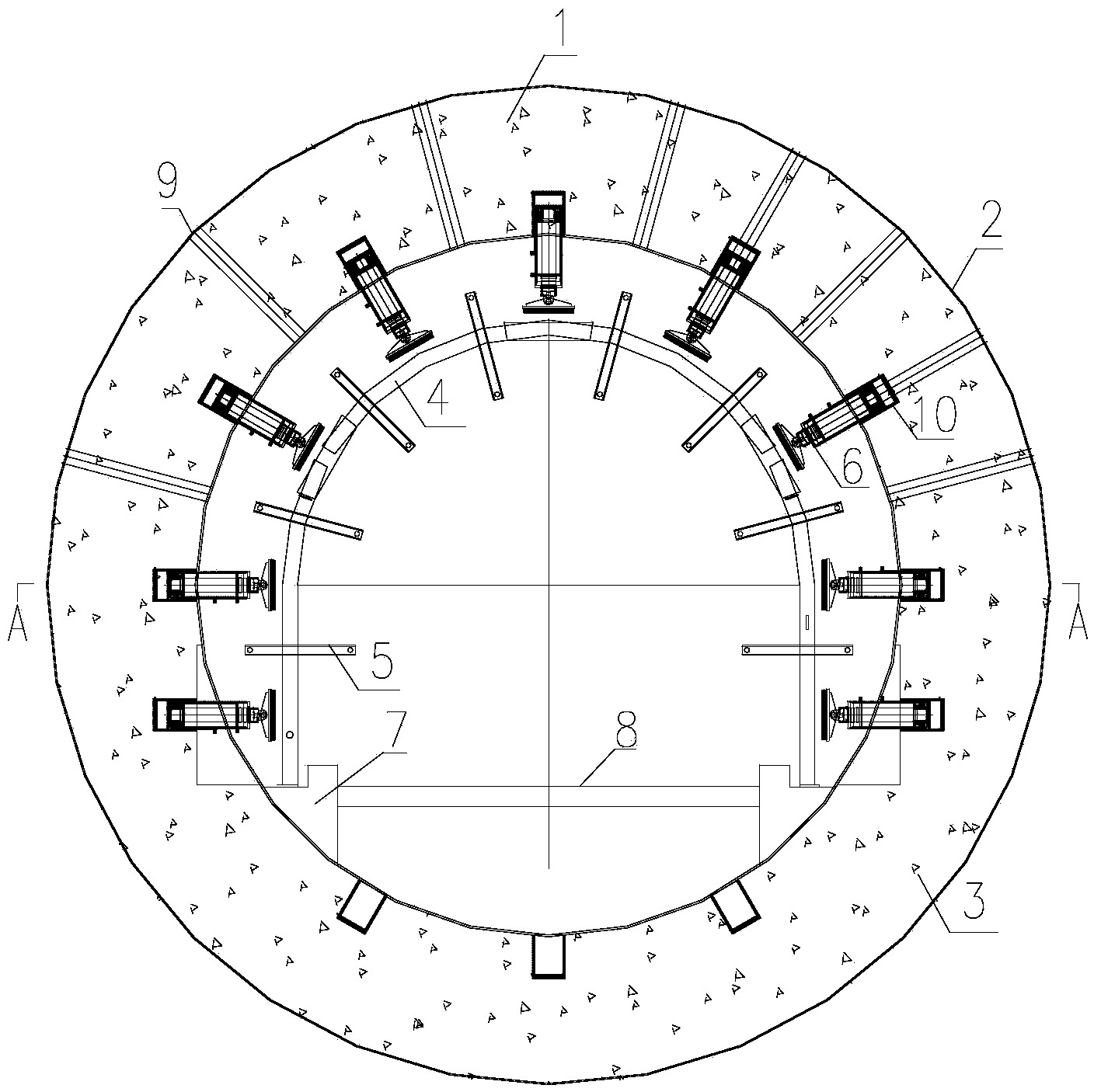

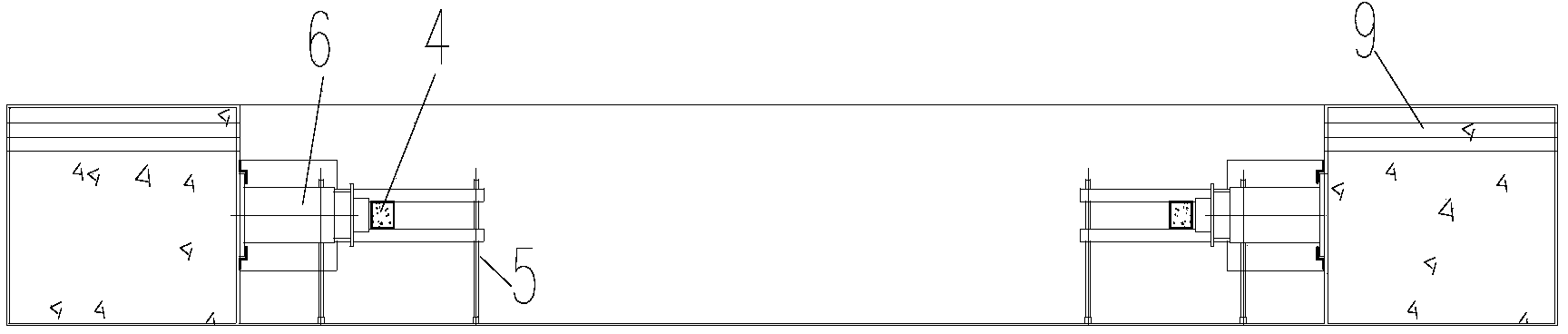

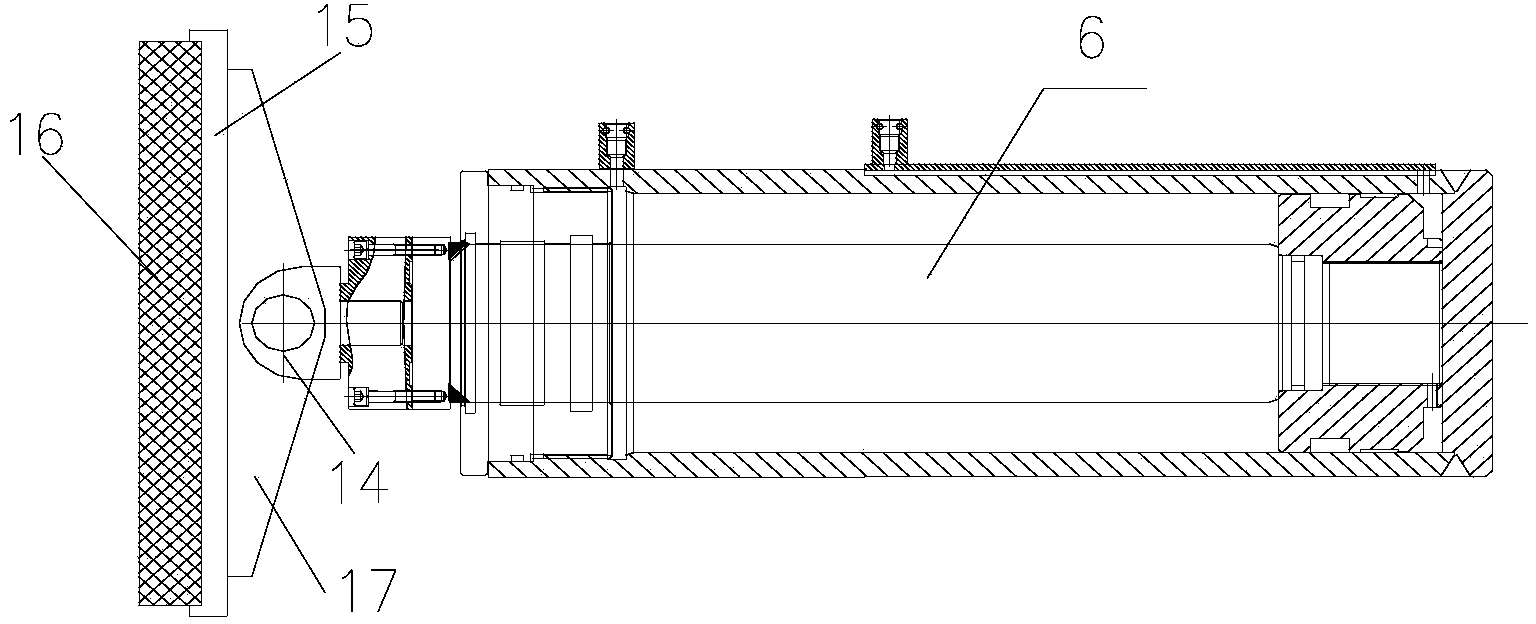

[0044] Combined adjustable constrained concrete arch large-scale mechanical test system, including monitoring system for monitoring and collecting arch parameter data, hollow cylindrical reaction force structure 1, hydraulic loading device, auxiliary loading device, inner cylindrical surface of reaction force structure 1 A plurality of oil cylinder positioning holes 10 are distributed on the top, and a hydraulic loading device is fixed in the oil cylinder positioning holes 10. The hydraulic loading device includes a hydraulic cylinder 6 in the oil cylinder positioning hole 10, a force transmission dispersion device connected to the hydraulic cylinder 6 and a control system. , the hydraulic cylinder 6 is loaded by contacting the arch frame to be tested through the force transmission and dispersion device.

[0045] The reaction force structure 1 is welded by steel plates 2 and filled with concrete 3 inside. Twelve oil cylinder positioning holes 10 are arranged on the reaction fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com