A similar material combination and method for preparing simulated fold structures

A technology of similar materials and models, applied in the field of materials, can solve the problems of large differences, loose quartz sand materials, and difficulty in preparing model test blocks, etc., and achieve the effect of wide source of materials and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

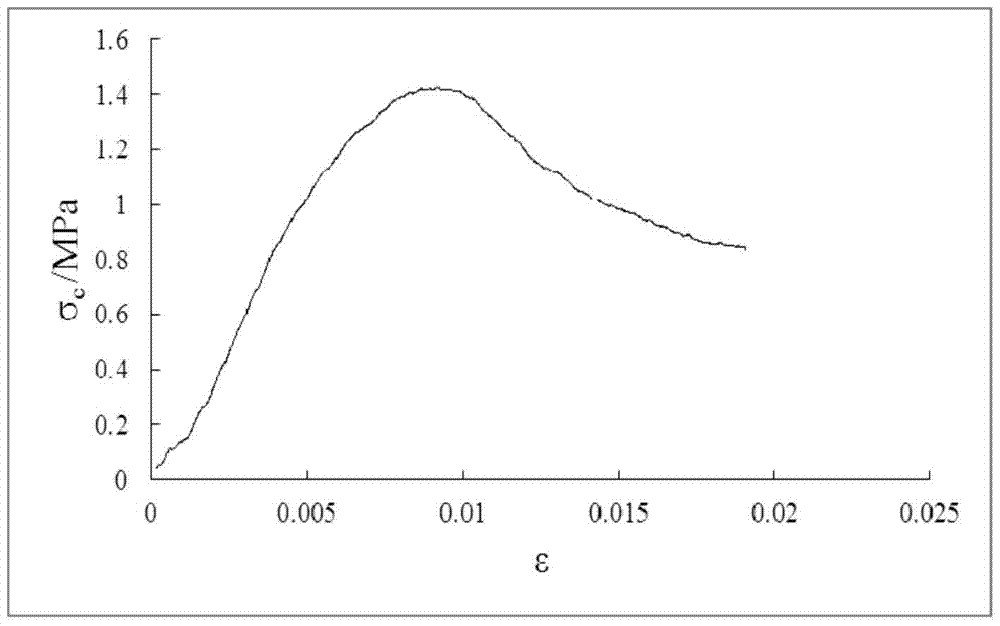

Embodiment 1

[0054] Similar material one includes: 30% fine sand, 45% gypsum powder, 2.3% white latex and 22.7% water;

[0055] Similar material two includes: 30% coal powder, 45% gypsum powder, 1.5% white latex and 23.5% water.

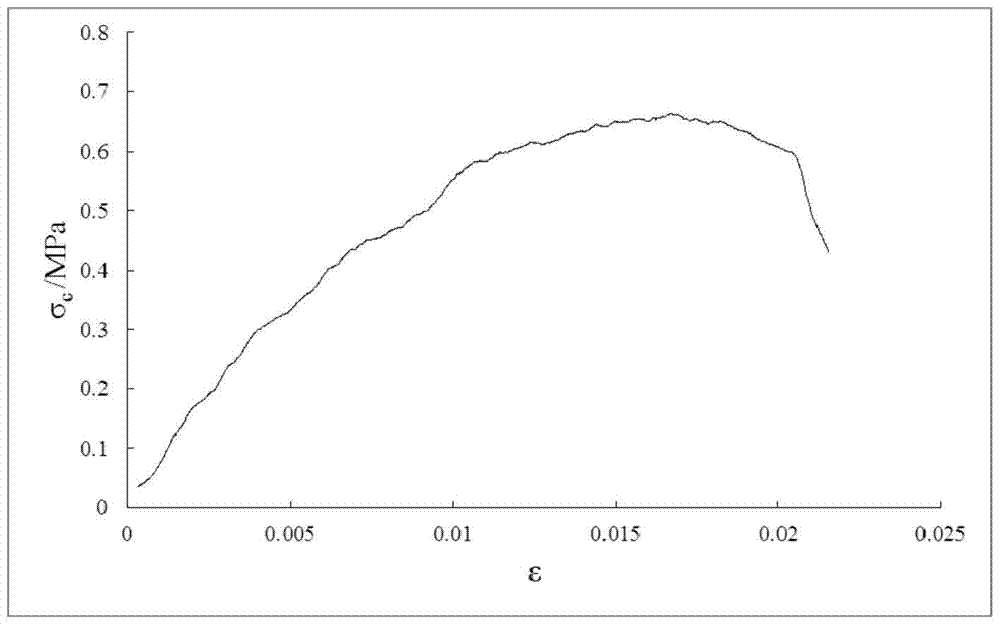

Embodiment 2

[0057] Similar materials include: 22.5% fine sand, 52.5% gypsum powder, 4% white latex, 17% water, 1% borax, 0.5% saponified oil, 2% mica powder, 0.5% iron powder , 0.5% fine wood chips and 0.5% starch paste;

[0058] Similar material two includes: 22.5% coal powder, 52.5% gypsum powder, 1% white latex, 18% water, 2% borax, 0.5% saponified oil, 1% mica powder, 1% iron powder , 1% wood chips and 0.5% starch paste.

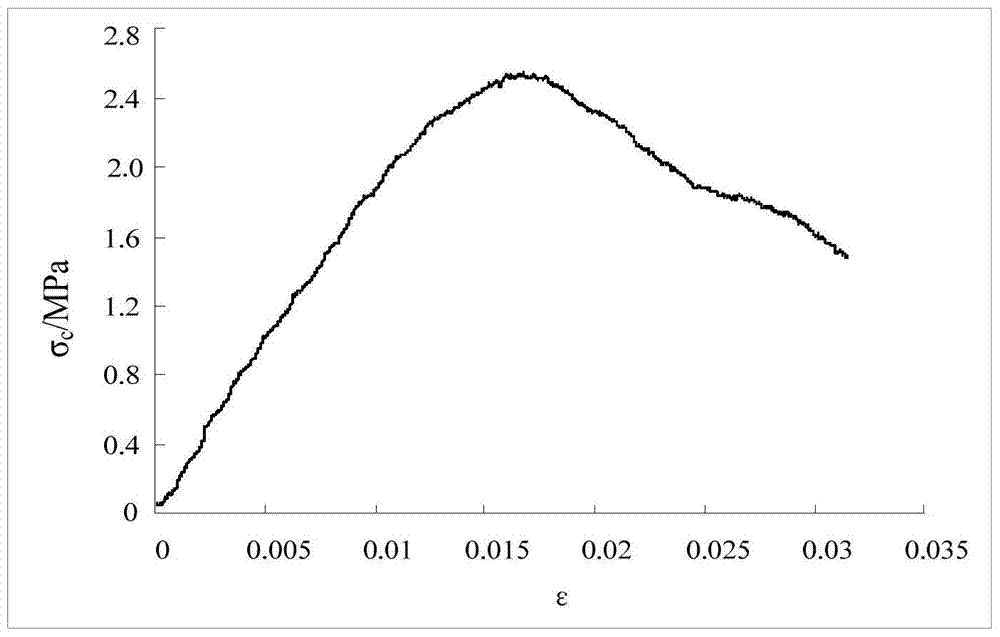

Embodiment 3

[0060] Similar materials include: 37.5% fine sand, 37.5% gypsum powder, 3% white latex, 15.5% water, 1.5% borax, 1% saponified oil, 1% mica powder, 2% iron powder with 1% starch paste;

[0061] Similar material two includes: 37.5% coal powder, 37.5% gypsum powder, 2% white latex, 17% water, 1% borax, 0.5% saponified oil, 1% mica powder, 2% wood chips Paste with 0.5% starch.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com