Method for forging super-long hollow part from short core rod through free forging press

A technology of forging presses and short mandrels, applied in the field of forging, can solve the problems of limited forging tonnage, potential safety hazards, increased production costs, etc., and achieve the effect of improving forging capacity and tonnage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

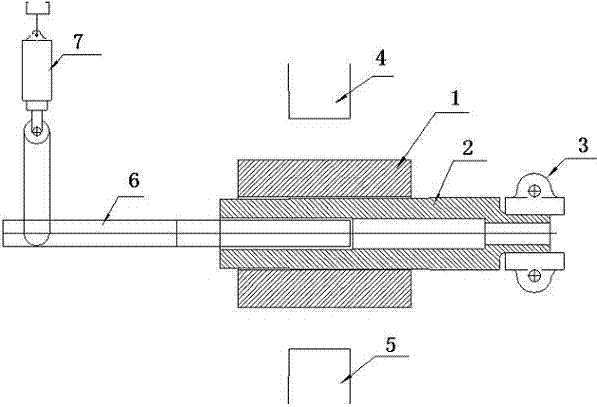

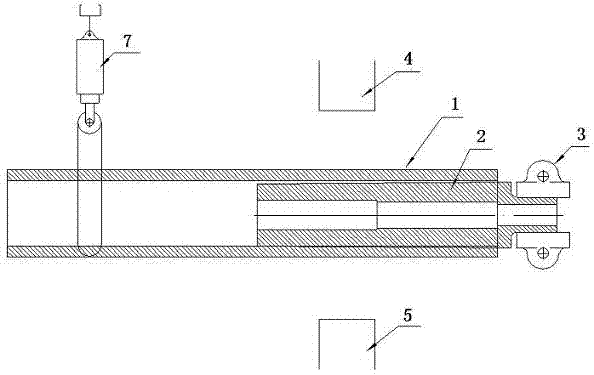

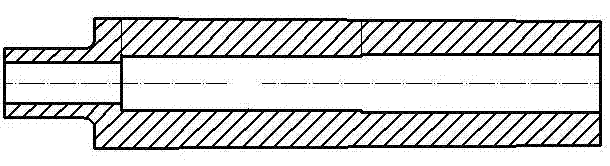

[0025] Such as figure 1 , 2 , 3, 4, 5, and 6, taking a 2000mm pipe mold blank and a 5200mm elongated mandrel as an example, the forging method of forging a super-long hollow part with a short mandrel of a free forging press is explained in detail, and the following steps are followed: Finish:

[0026] The first step: first heat the steel ingot, put the steel ingot into the heating furnace, the heating temperature rises to 1230°C, and keep it warm for 8 hours, so that the temperature inside and outside the steel ingot is uniform;

[0027] Step 2: Cut the heated steel ingot by hydraulic press, cut the steel ingot into only the ingot body, and go through the deformation rate of 70% through the forging hammer, and upset the steel ingot into a billet with a rod-shaped structure;

[0028] Step 3: Punch and ream the blank of the cake-shaped structure in the second step. The diameter of the hole should not be too large, between 830mm-850mm, to form a 2000mm pipe mold blank;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com