Five-beam four-column type explosive pressing hydraulic machine

A four-column, hydraulic press technology, applied in the field of hydraulic presses, can solve the problems of not being able to meet the development needs of the military industry and the small tonnage of the press, and achieve the effect of increasing the tonnage and meeting the development needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

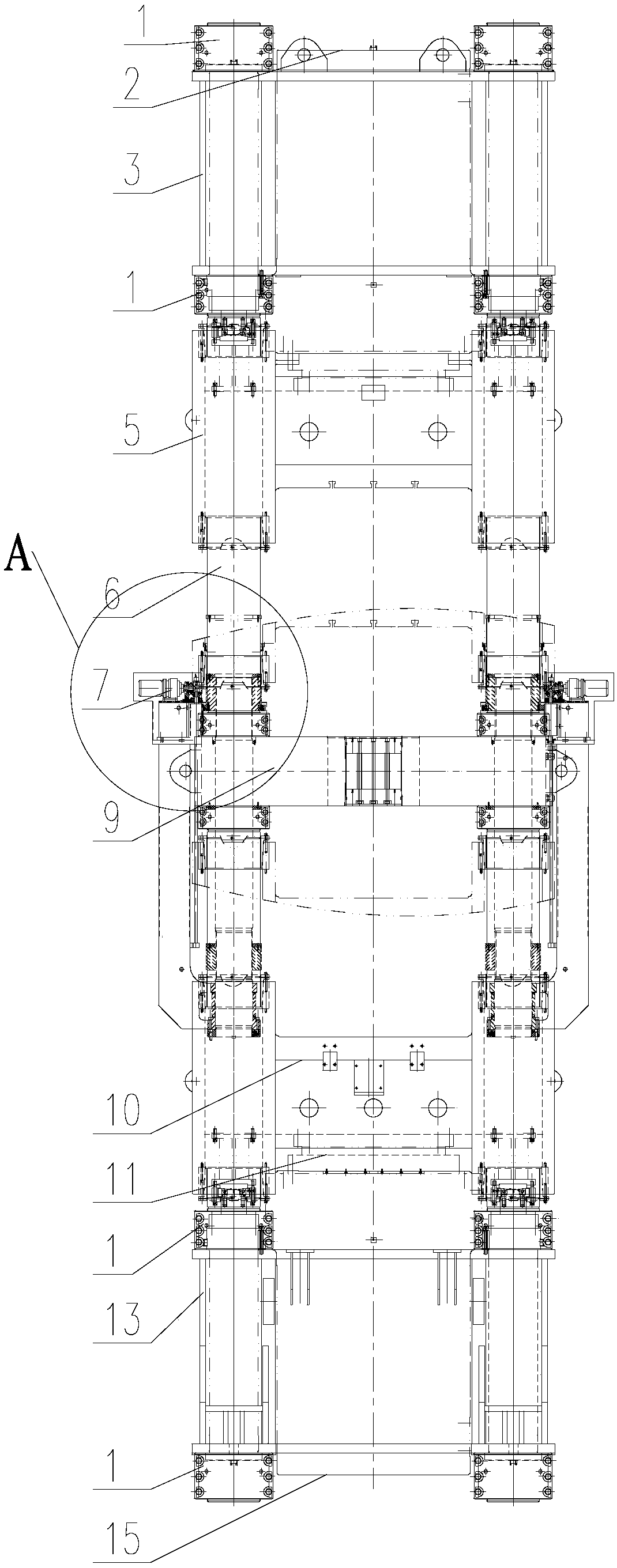

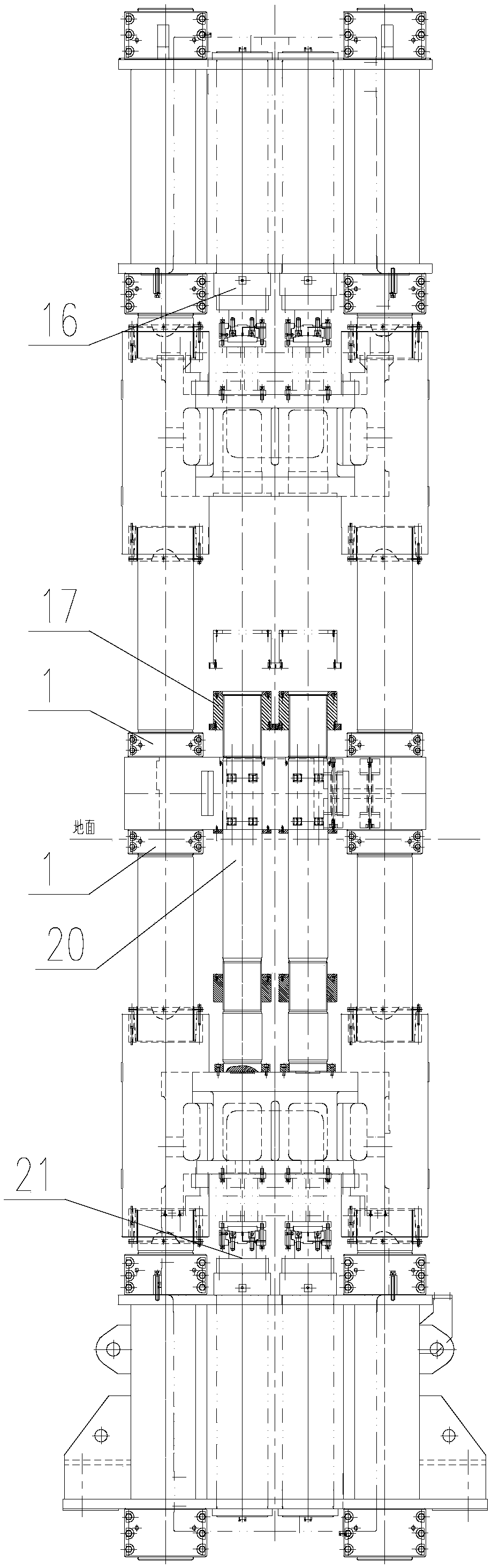

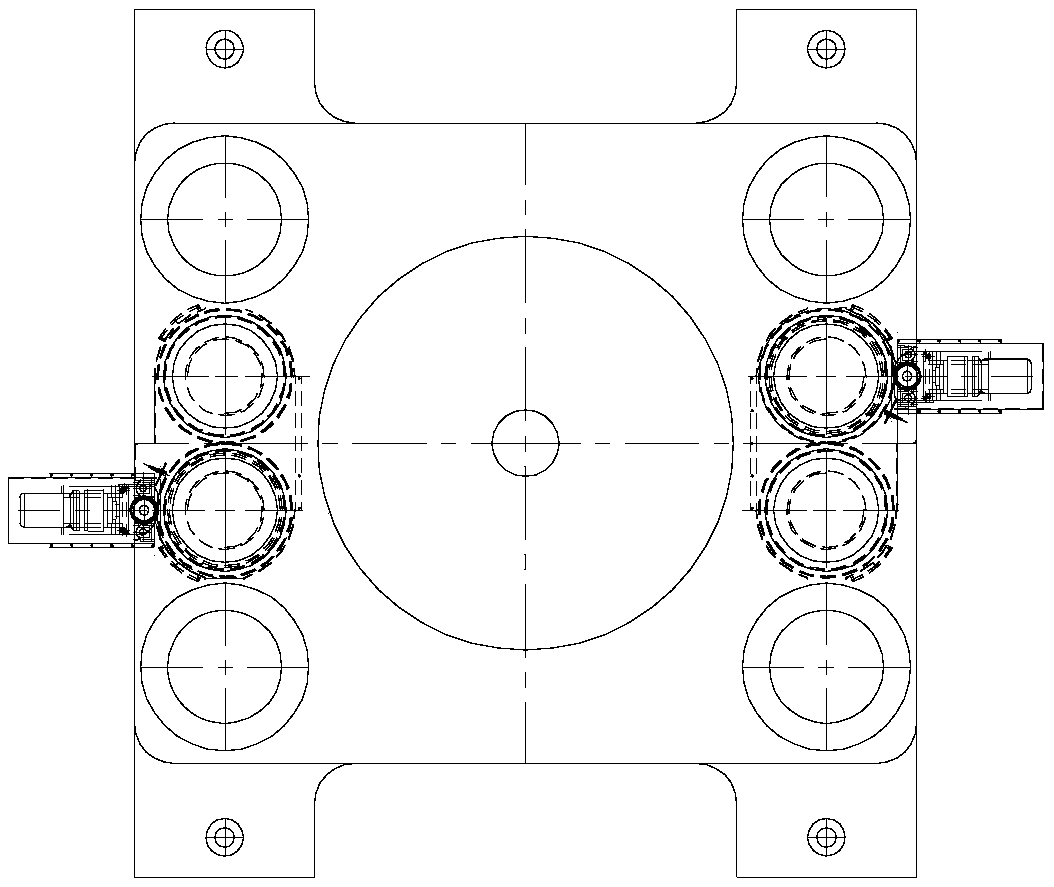

[0029] This embodiment provides a five-beam four-column pressurized hydraulic press, which includes: a column, an upper beam, a lower beam, an upper slider, a lower slider, a middle fixed beam, an upper main cylinder, a lower main cylinder, an upper side cylinder and Lower cylinder.

[0030] The uprights are arranged vertically, and the number is four, which are respectively located at the four corners of the rectangle; the upper end of the uprights is fixed with an upper crossbeam through a upright nut, and the lower end of the upright is fixed with a lower crossbeam through a upright nut; more preferably Specifically, the column nuts are two halves of split nut assemblies, thereby reducing the workload of assembling screw nuts and facilitating the installation of the upper beam and the lower beam.

[0031] The upper main oil cylinder and the lower main oil cylinder are all large plunger cylinders, and the four upper side oil cylinders and four lower side oil cylinders are al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com