Hydraulic machine and application method thereof

A technology of hydraulic press and body, applied in the field of presses, can solve the problem that the pressure cannot be further increased, and achieve the effect of increasing pressure, increasing tonnage, and increasing tonnage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

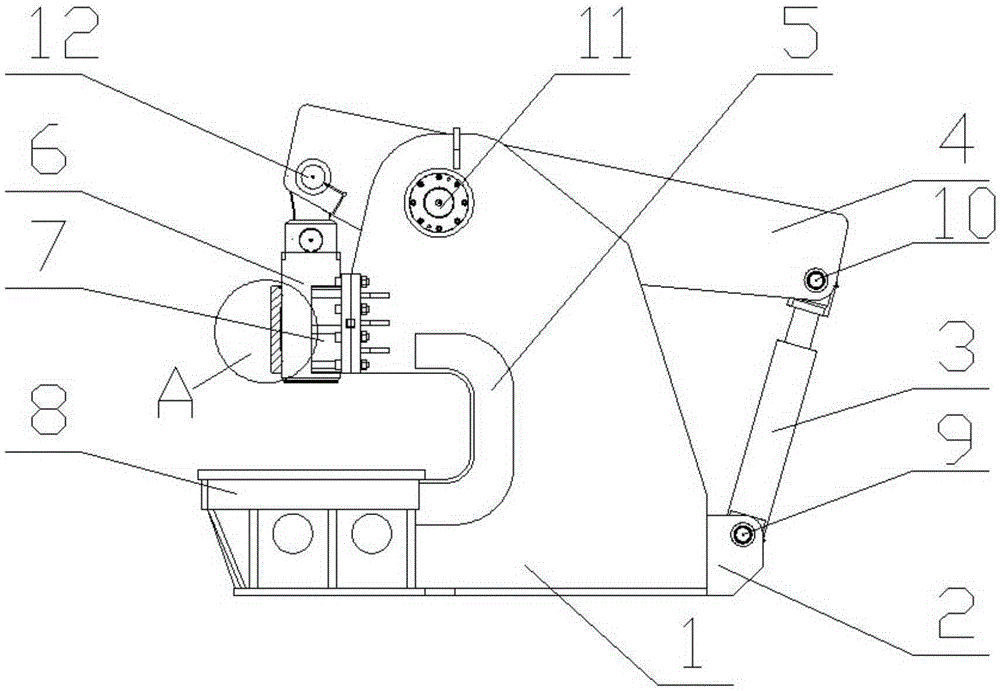

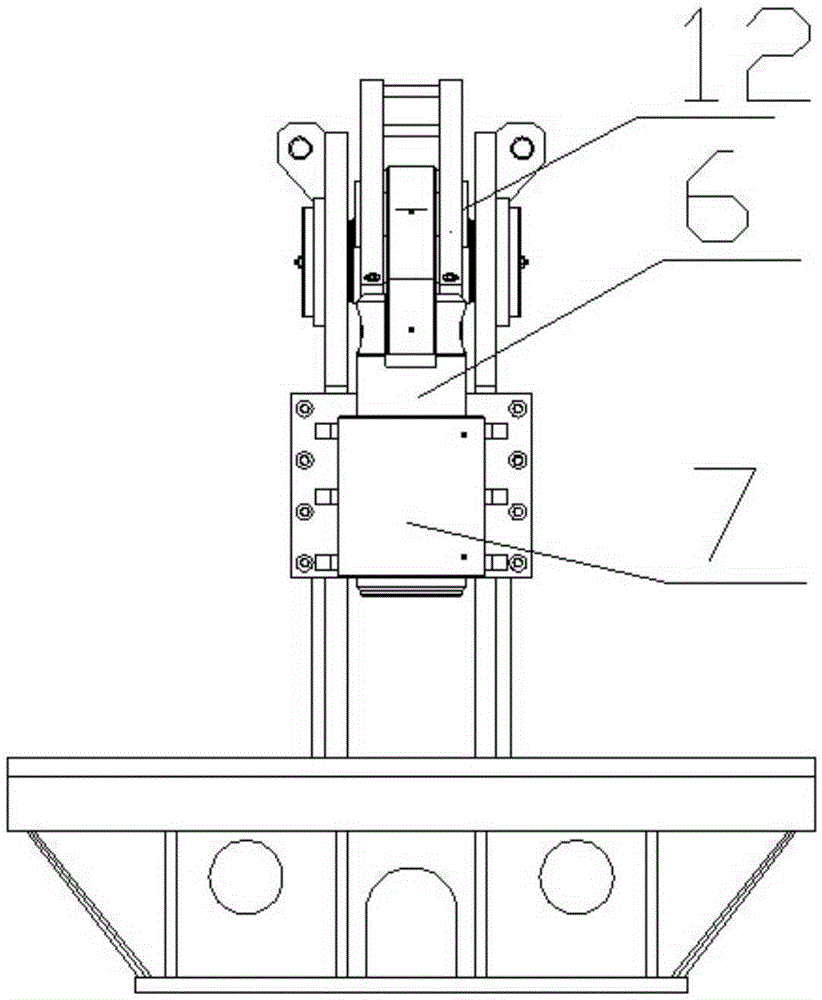

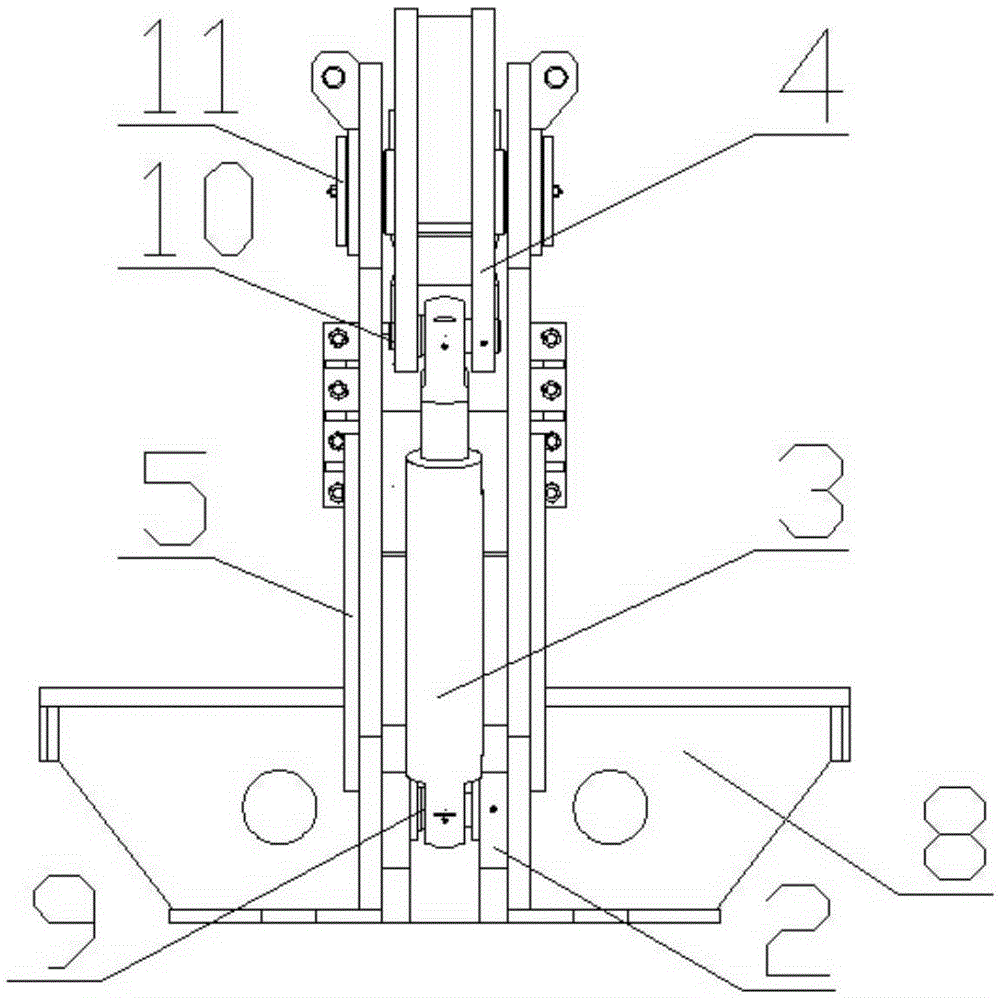

[0054] Such as Figure 1-8 As shown, a hydraulic machine includes a body 1, an oil cylinder 3, a slider 6 and a workbench 8. The body 1 is in the shape of a "C" and has a "C"-shaped opening; the workbench 8 is set on the "C"-shaped opening of the body 1. The lower side of the direction also includes a beam arm 4, a first pin shaft 9, a second pin shaft 10, a third pin shaft 11, a fourth pin shaft 12 and a guide slide 7; the beam arm 4 is arranged on the top of the body 1, and the beam arm 4. Pass the third pin shaft 11 through the third pin shaft hole 402 provided in the middle of the beam arm 4 and the pin shaft hole on the top of the body 1 to connect with the body 1;

[0055] The two ends of the beam arm 4 are respectively provided with a second pin hole 401 and a fourth pin hole 403; the second pin hole 401, the third pin hole 402, and the fourth pin hole 403 in the beam arm 4 are on the same section The centers of circles are on the same straight line, and on the same se...

Embodiment 2

[0067] Same as Example 1, the difference is: L 1 with L 2 The relationship between them is: L 1 =2.5L 2 ; The angle between the bottom surface 405 of the front end of the beam arm and the bottom surface 407 of the rear end of the beam arm is 150°.

[0068] The using method of the hydraulic press in the present embodiment is the same as the using method in the embodiment 1, the difference is: the oil cylinder 3 piston rod stretches out in the step 4), pushes the beam arm 4 one end along the radius L 1 The first circular arc trajectory moves upward, the beam arm 4 rotates around the first pin shaft 9, and the end of the beam arm 4 close to the worktable 8 along the radius L 2 =2 / 5L 1The circular arc track moves downward, and pushes the slider 6 to move. One end of the slider connecting plate 601 on the slider 6 rotates around the fourth pin 12, and the other end rotates around the pin connected to the slider connecting end 602. The slider The rotary motion at the two ends o...

Embodiment 3

[0070] Same as Example 1, the difference is: L 1 with L 2 The relationship between them is: L 1 =3.5L 2 ; The angle between the bottom surface 405 at the front end of the beam arm and the bottom surface 407 at the rear end of the beam arm is 160°.

[0071] The using method of the hydraulic press in the present embodiment is the same as the using method in the embodiment 1, the difference is: the oil cylinder 3 piston rod stretches out in the step 4), pushes the beam arm 4 one end along the radius L 1 The first circular arc trajectory moves upward, the beam arm 4 rotates around the first pin shaft 9, and the end of the beam arm 4 close to the worktable 8 along the radius L 2 =2 / 7L 1 The circular arc track moves downward, and pushes the slider 6 to move. One end of the slider connecting plate 601 on the slider 6 rotates around the fourth pin 12, and the other end rotates around the pin connected to the slider connecting end 602. The slider The rotary motion at the two ends ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com