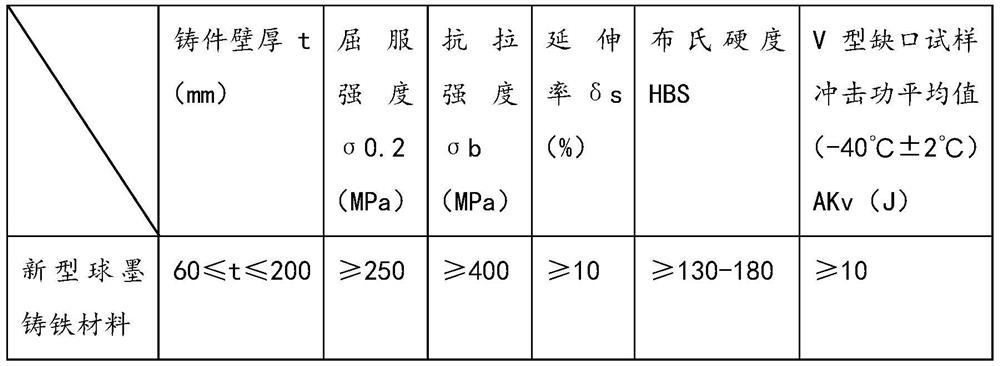

Nodular cast iron material for draught fan and preparation method and application of nodular cast iron for draught fan

A technology of ductile iron and fans, which is applied in mechanical equipment, wind engines, machines/engines, etc. It can solve problems such as yield strength, tensile strength and impact energy that are difficult to meet the development requirements of the fan industry, bulky, and complex structures. , to achieve the effect of simple structure, simple process operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

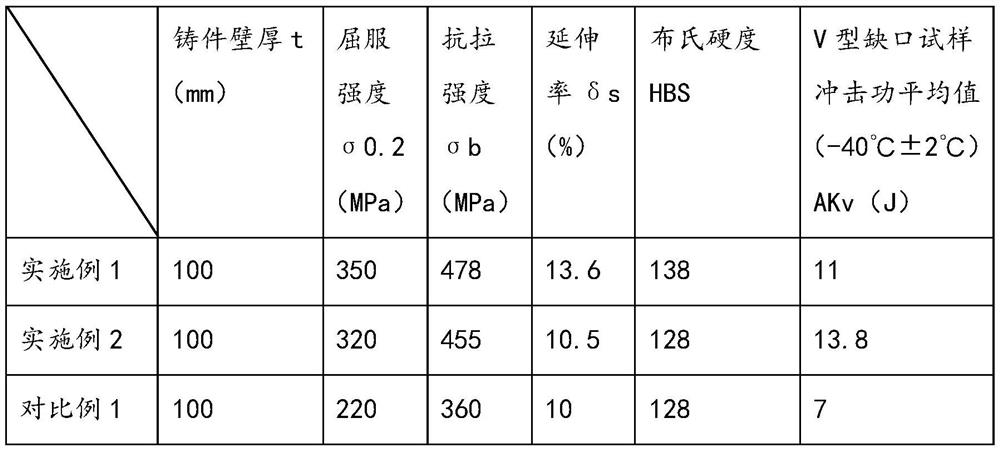

Embodiment 1

[0028] Pig iron is mainly used as the material, and the elemental composition of the ductile iron material: carbon 3.85%, manganese 0.19%, silicon 2.03%, phosphorus 0.003%, sulfur 0.022%, nickel 1.65%, antimony 0.002%, magnesium 0.03%, RE 0.03%, The rest is iron and impurities from the preparation process.

[0029] Prepare the ductile iron material according to the above recipe. First smelting, the temperature of the molten iron is controlled at 1420-1450°C. After the spheroidization treatment, the spheroidizer (FeSiMg 8 RE 3 ) in an amount of 1.0-1.2%, and the spheroidizing temperature is 1420-1450°C.

[0030] After pouring, slowly cool in the sand mold to 350-400°C and clear out from the mold.

Embodiment 2

[0032] Pig iron is mainly used as the material, and the elemental composition of the ductile iron material: carbon 3.85%, manganese 0.19%, silicon 2.03%, phosphorus 0.003%, sulfur 0.022%, nickel 1.20%, antimony 0.005%, magnesium 0.03%, RE 0.03%, The rest is iron and impurities from the preparation process.

[0033] Prepare the ductile iron material according to the above recipe. First smelting, the temperature of the molten iron is controlled at 1420-1450°C. After the spheroidizing treatment, the addition amount of the spheroidizing agent (FeSiMg8RE3) is 1.0-1.2%, and the spheroidizing temperature is 1420-1450°C.

[0034] After pouring, slowly cool in the sand mold to 350-400°C and clear out from the mold.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com