Air cushion single ejector cap of press machine

A technology of single crown and air cushion, which is applied in the technical transformation of press accessories and in the field of machinery, can solve the problems of insufficient tonnage of stretching pads and higher and higher requirements for the tonnage of stretching pads, and achieve the effect of increasing the tonnage of stretching pads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

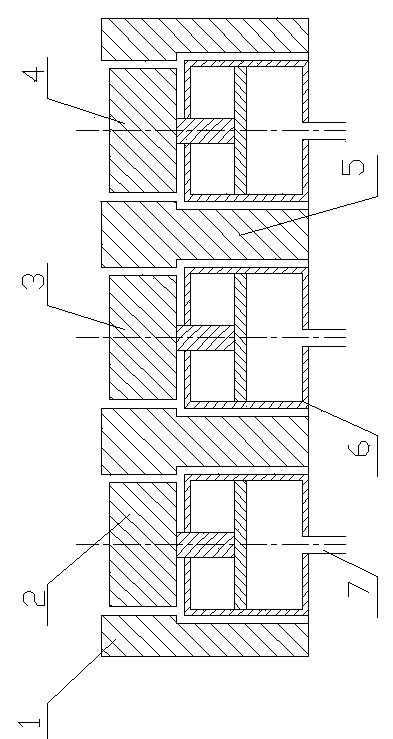

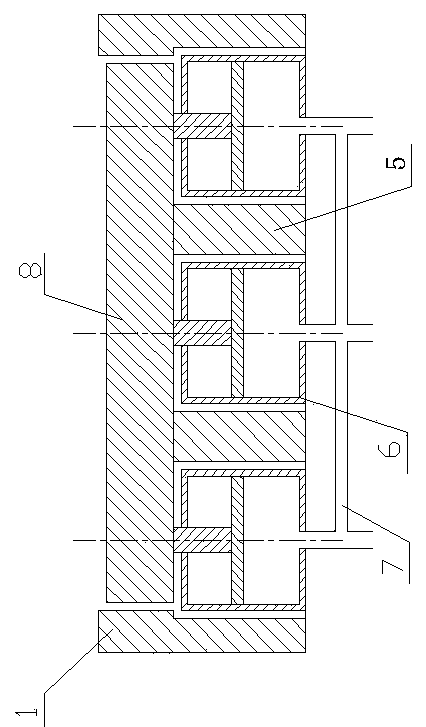

[0009] Such as figure 2 As shown, it is a press air cushion single crown, including a stretching cushion base 1, three cylinders 6 are vertically arranged in the tensioning cushion base 1, each cylinder 6 is respectively connected to an intake pipe 7, and the intake pipes 7 of the three cylinders 6 The gas pipelines are connected in parallel with 7 phases, and a control switch is used to realize the synchronous work of each cylinder. Separators 5 are respectively arranged between two adjacent cylinders 6, and the telescopic ends of the three cylinders 6 are connected to the integral top crown 8 of the same stretching pad, and each partition 5 is arranged under the integral crown 8 of the stretching pad respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com