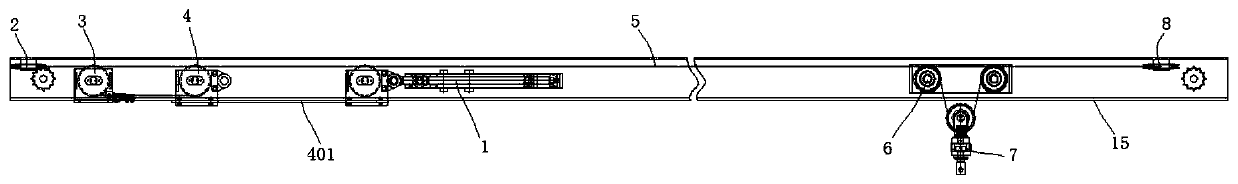

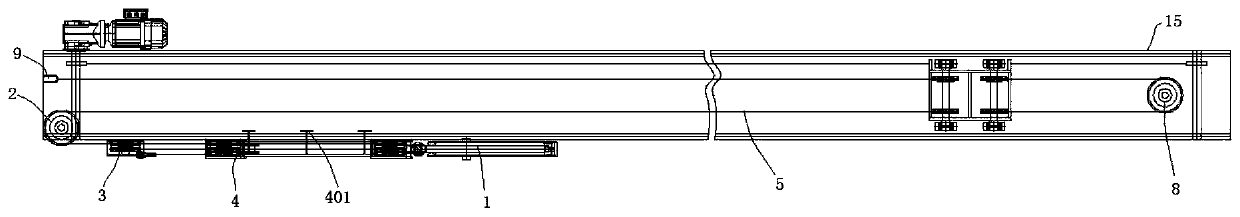

Integrated box type track beam closed chain-driven steel wire rope single beam crane

A technology of rail beam and wire rope, which is applied in the field of integrated box-type rail beam closed chain-driven wire rope single beam crane, can solve the problems of increased fault point, large headroom, narrow application range, etc., and achieves small installation space and control loop. Simple, selectable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

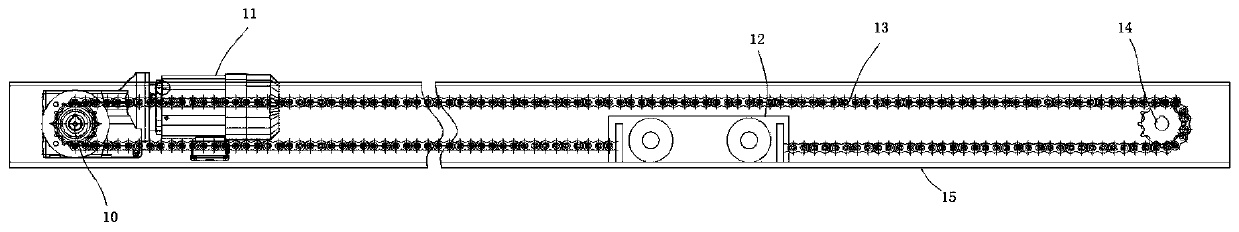

[0057] Taking the integrated crane whose technical parameters are "load 3 tons / lifting 3 meters" as an example, a single steel wire rope with a force of 0.75 tons is selected, and the horizontal tension at the fixed end is 0.75 tons. There are a total of There are 4 steel wire ropes, so the load strength can reach 0.75*4=3 tons. After finishing the wire rope winding of the hoisting spreader and the hoisting pulley, a single wire rope is output from the top of the other pulley on the double pulley side of the hoisting pulley. At this time, the tensile force that needs to be borne on the steel wire rope is still 0.75 tons, and then the steel wire rope first enters the movable pulley block, according to Figure 7 As shown, the steel wire rope between the movable pulley block and the fixed pulley block is completed in sequence, and finally the steel wire rope is fixed on the fixed pulley block. In this way, there are 6 steel wire ropes on the movable pulley block, and the total pul...

specific Embodiment 2

[0060] In this scheme, a spreader pulley with two pulleys is selected for the lifting part. According to actual needs, different lifting speeds and load capacities can be selected by increasing or decreasing the number of spreader pulleys.

specific Embodiment 3

[0062] In this scheme, 3 pulleys are used for the movable pulley block, and 2 pulleys are used for the fixed pulley block. According to actual needs, the number of pulleys can be increased or decreased (such as 6 pulleys for the movable pulley block) to meet the design requirements of different loads and to select Corresponding pressure hydraulic cylinder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com