Portable cable terminal lifting device

A cable terminal and hoisting device technology, used in portable hoisting devices, hoisting devices, overhead line/cable equipment, etc., can solve the problems of dangerous disassembly and assembly, long maintenance cycle, heavy weight, etc. Solid base

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

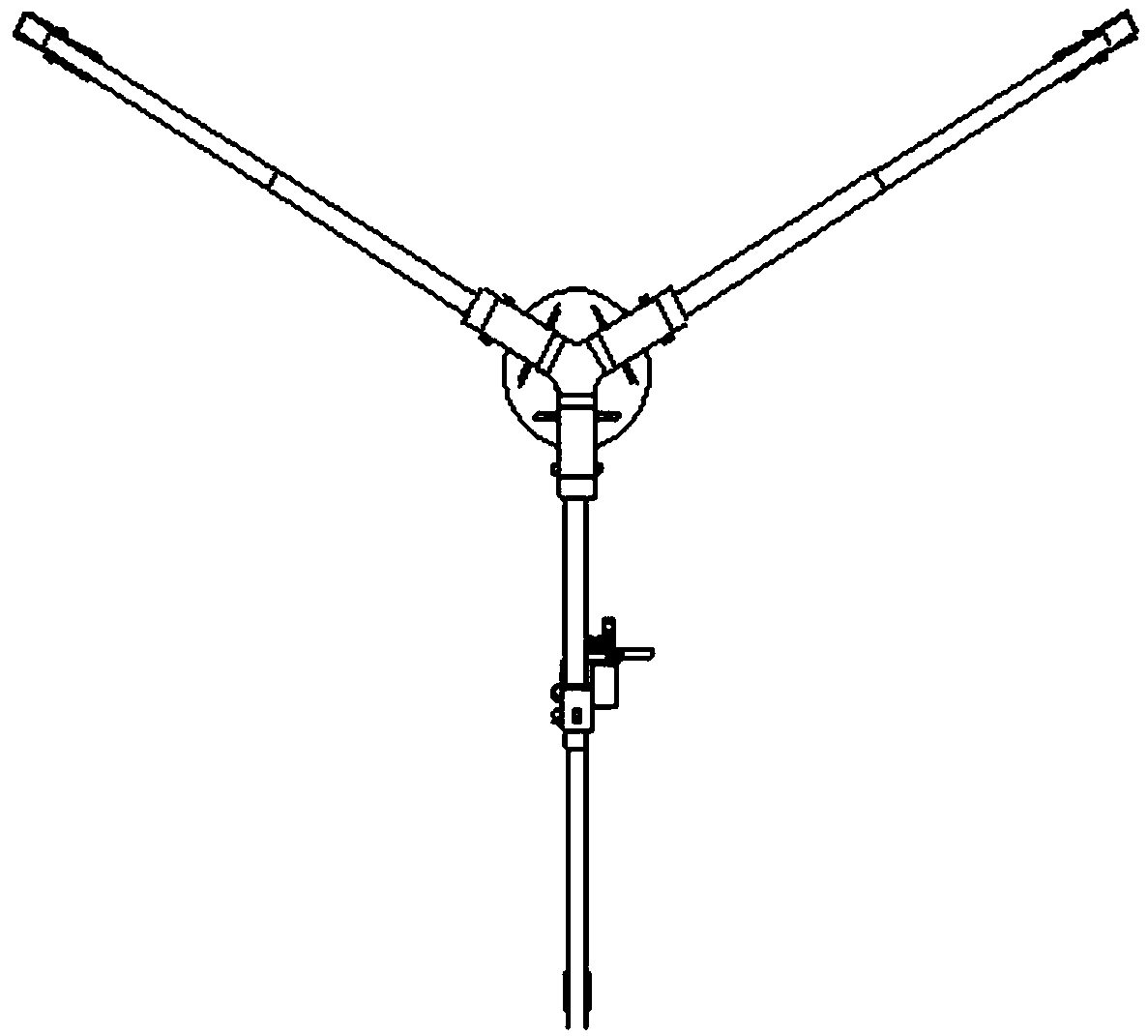

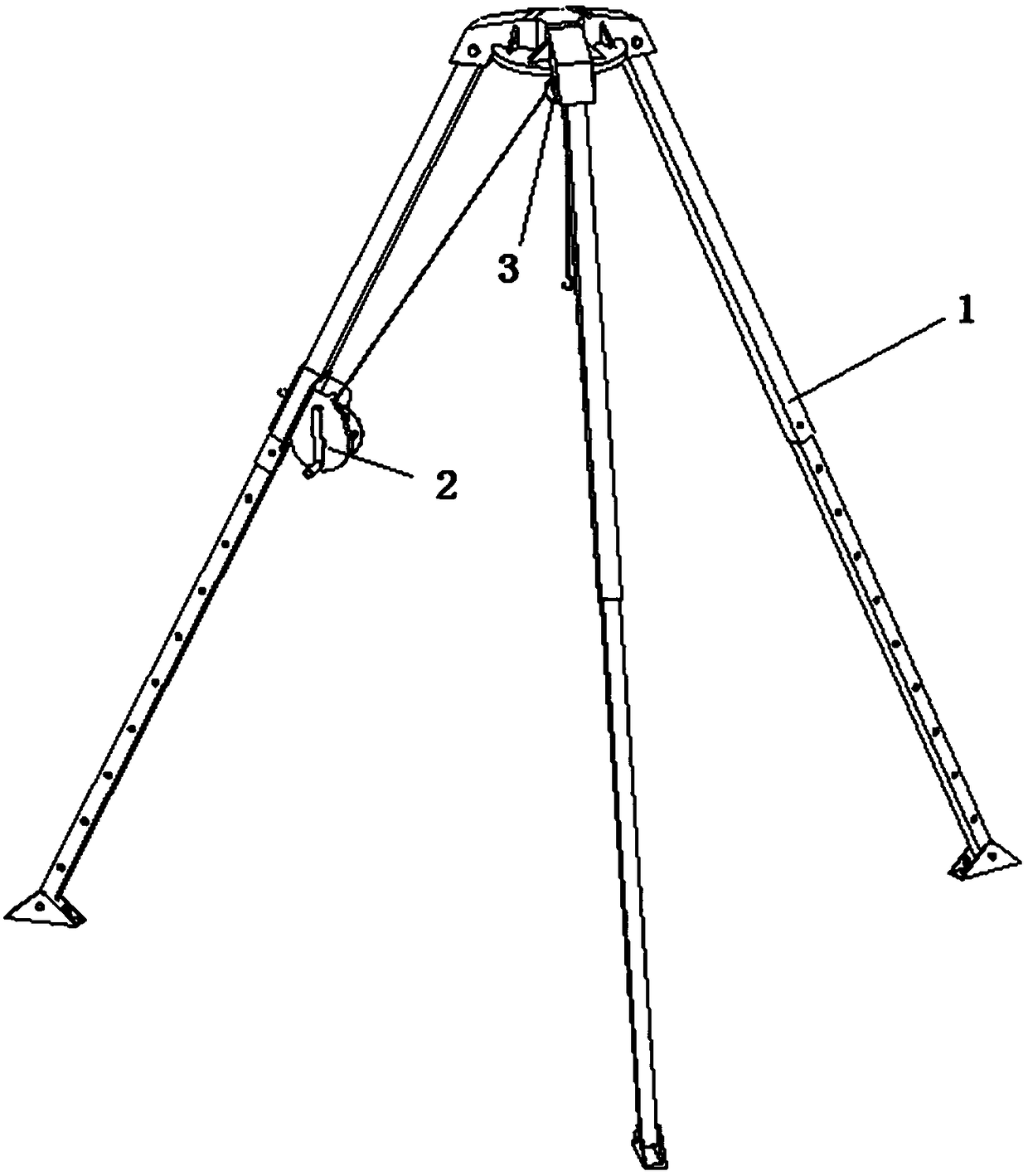

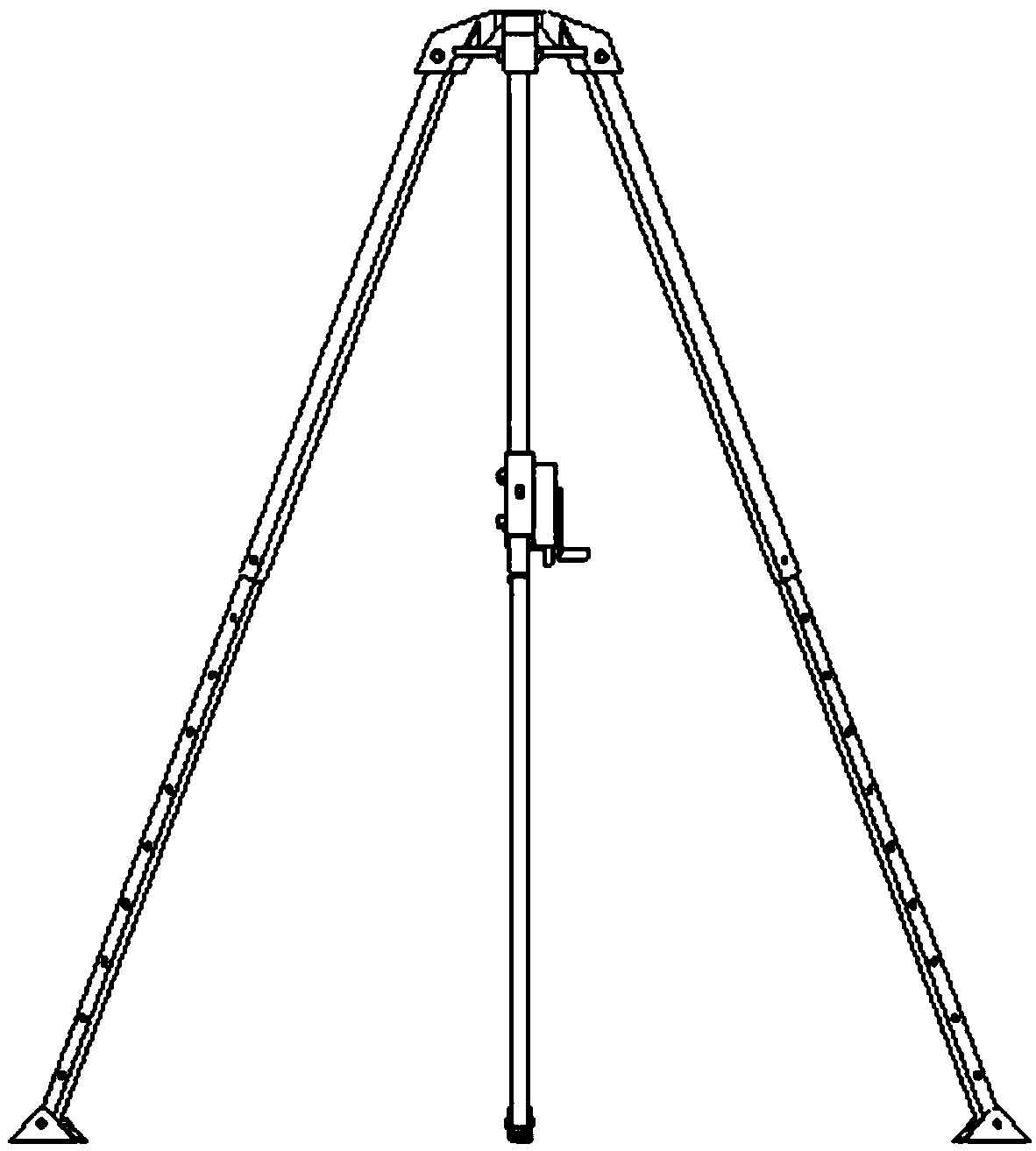

[0033] Such as Figure 1-4 As shown, the present invention provides a portable cable terminal lifting device for lifting the cable terminal porcelain bushing. The device includes:

[0034] Telescopic tripod 1: It is used to provide support and adjust the height. The telescopic tripod includes three telescopic legs and a fixed plate used to connect the top of the legs. The fixed pulley is fixed at the bottom of the fixed plate. The fixed plate is circular. The outer edge is evenly provided with three fixing parts for fixing the top of the foot through bolts. The fixed pulley is fixed vertically at the center of the bottom surface of the fixed plate. The foot includes a telescopic part and a sleeve part set from bottom to top. On the cylinder part, the sleeve part is equidistantly provided with a plurality of pin holes for adjusting the position, and the telescopic part is provided with pin holes corresponding to the position of the sleeve part;

[0035] Winch 2: adjustable and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com