Application method of modeling sand substituting blocks in casting of large cast steel

An application method and technology of steel castings, applied to casting molding equipment, molds, cores, etc., can solve the problems of sand mold air permeability reduction, high consumption, heavy sand mold weight of large steel castings, etc., and reduce the amount of sand used , reduce casting cost and meet lifting requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

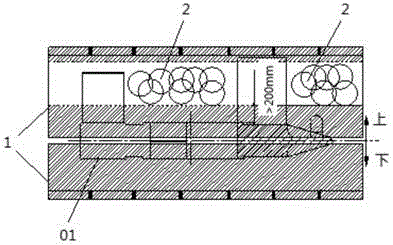

[0043] This embodiment takes the casting process of the main bearing seat of a marine low-speed diesel engine as an example to illustrate the practical application of the method of the present invention in detail.

[0044] The parameters of main bearing housing castings for marine low-speed diesel engines are as follows:

[0045] Dimensions of casting: 2944mm×2650mm×455mm;

[0046] Casting blank weight: about 10200Kg.

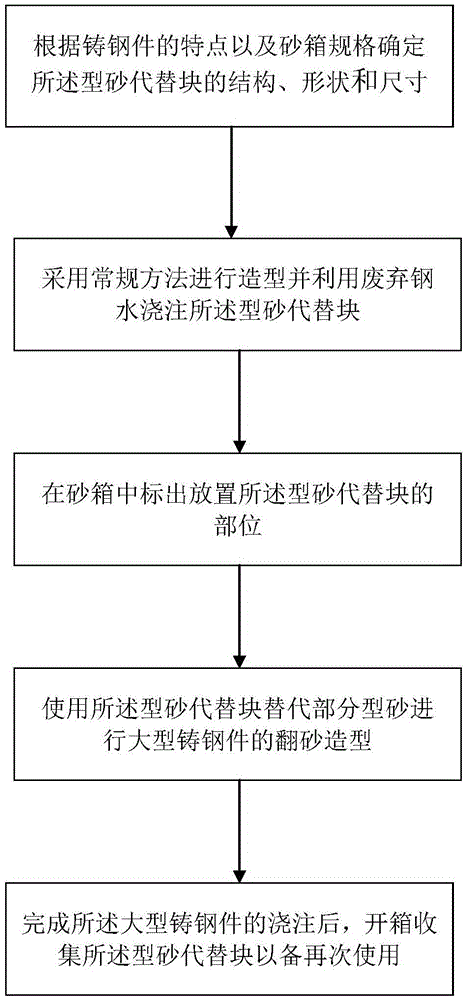

[0047] According to the method of the present invention, the foundry molding of the main bearing seat mainly includes the following steps:

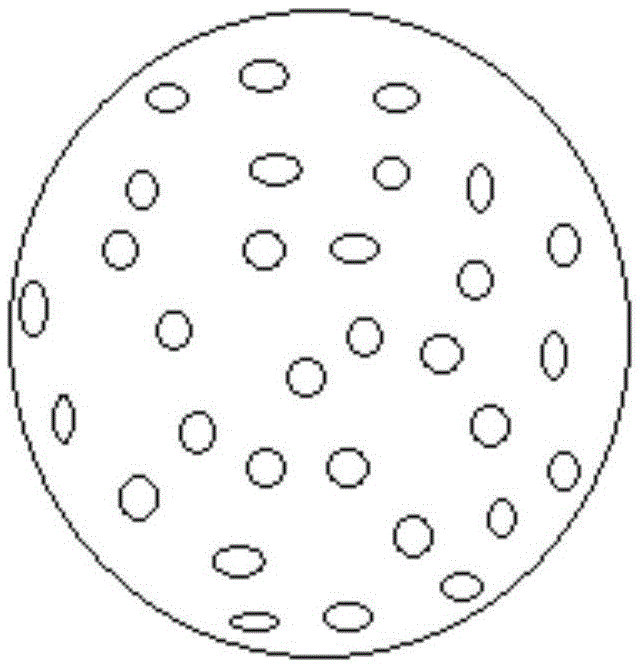

[0048] 1) Prepare the casting process of the main bearing seat according to the conventional method, and design and determine the structure, shape and size of the molding sand replacement block according to the space between the sand box and the casting selected by the process.

[0049] 2) Cast molding sand instead of blocks according to the conventional method.

[0050] 3) On the main bearing seat molding process card,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Shell thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com