Hoisting tool for bearing bush of steam turbine

A hoisting tool and steam turbine technology, applied in the directions of transportation and packaging, load hoisting components, etc., can solve problems such as dismantling steam guide pipes, and achieve the effects of reducing workload, avoiding disassembly, and saving maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Further detailed explanation through specific implementation mode below:

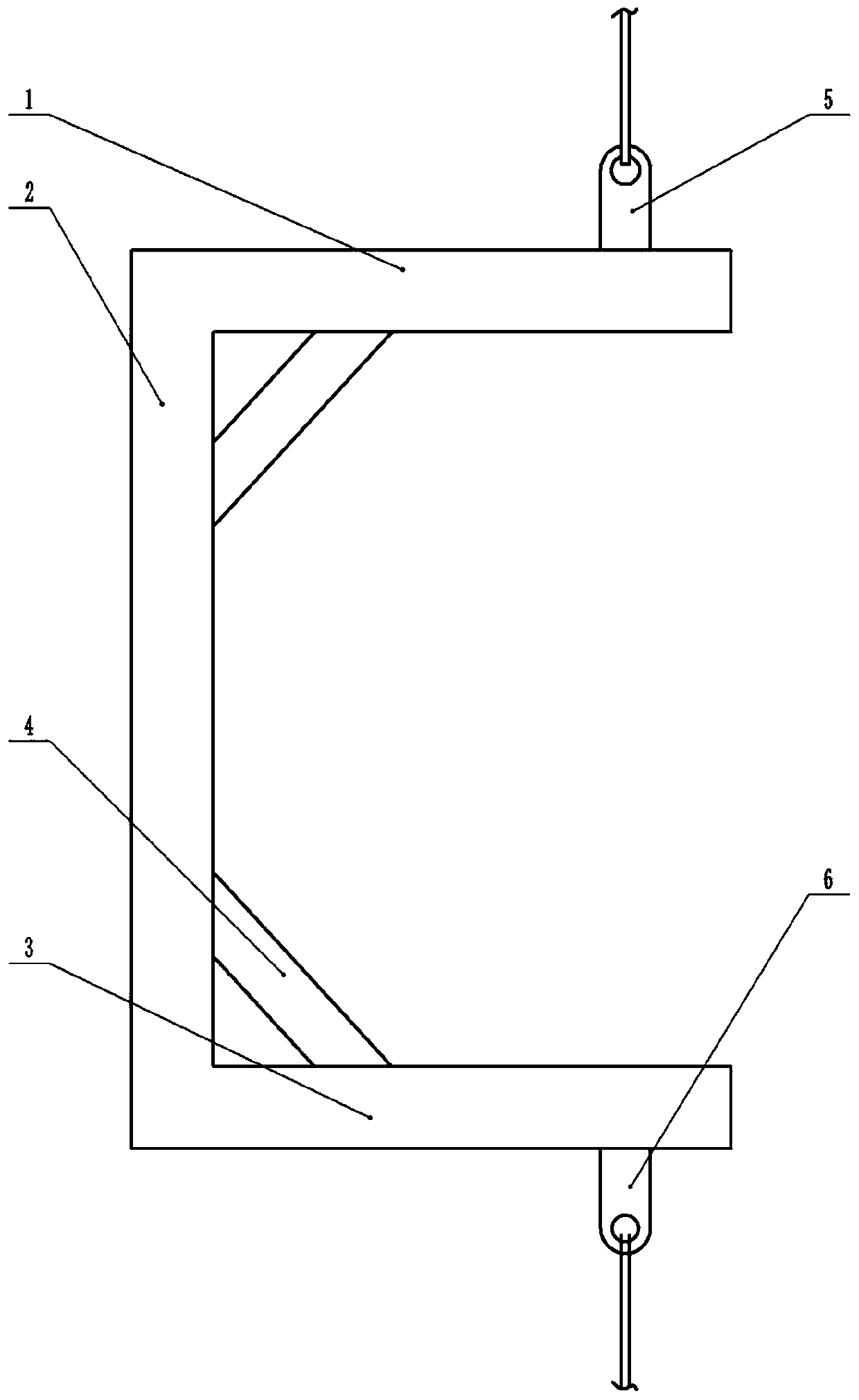

[0017] The reference signs in the drawings of the description include: upper beam 1 , vertical beam 2 , lower beam 3 , section steel 4 , upper lifting lug 5 , and lower lifting lug 6 .

[0018] Such as figure 1 As shown, a steam turbine bearing bush hoisting tool includes an upper beam 1, a lower beam 3, and a vertical beam 2 connecting and fixing the upper beam 1 and the lower beam 3. The upper beam 1 is provided with an upper lug 5, and the lower beam 3 is provided with a lower beam. The spacing between the lifting lug 6, the upper beam 1 and the lower beam 3 is greater than the diameter of the steam guide pipe. Specifically, the spacing can be 2-3 times the diameter of the steam guide tube. In this embodiment, the spacing can be Twice the diameter of the steam pipe.

[0019] The upper beam 1 and the lower beam 3 are parallel to each other and perpendicular to the vertical beam 2 . Such arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com