Lifting mechanism of cab side window glass of bulletproof vehicle

A lifting mechanism and window glass technology, which is applied to the control mechanism of wing sash, windshield, power control mechanism, etc., can solve problems such as inability to lift bulletproof glass, driver fatigue, affecting driver contact, etc. Light, easy to operate, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to better understand the technical solution of the present invention, it will be described in detail below through specific embodiments in conjunction with the accompanying drawings:

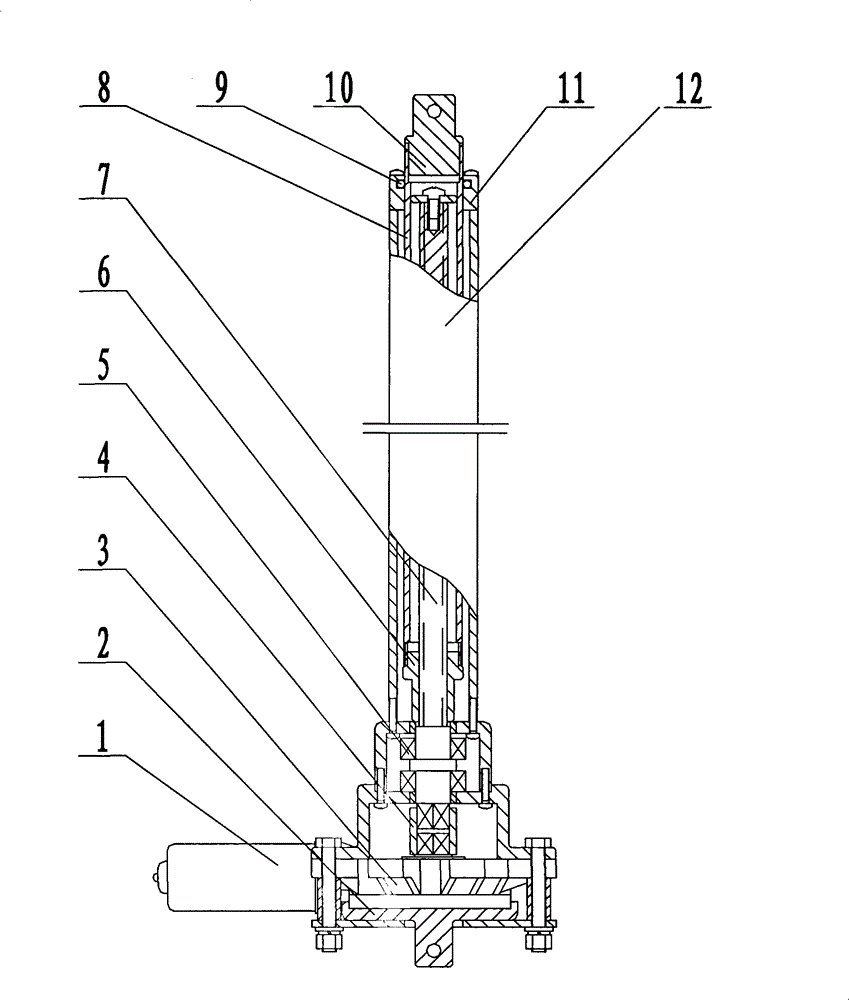

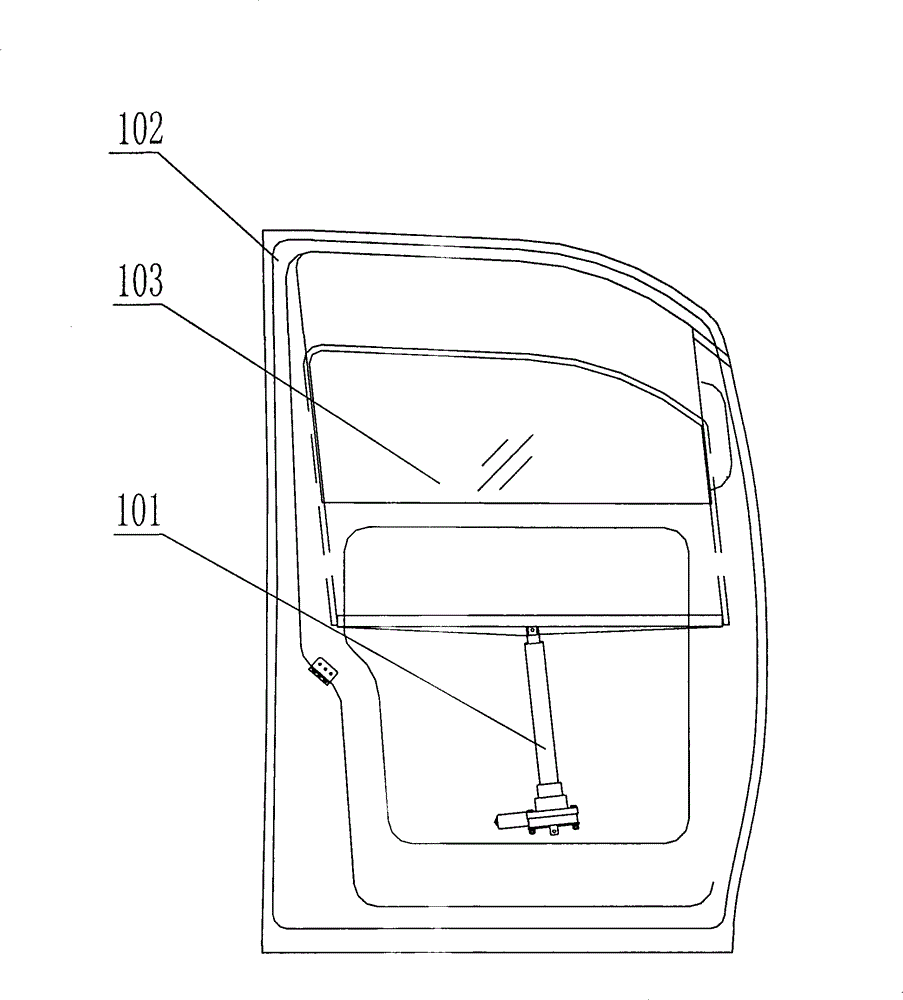

[0019] see figure 1 , the lifting mechanism of the bulletproof vehicle driver's cab side window glass of the present invention comprises a micro-motor 1, a base 2, a pair of intermeshing worm gear reduction devices 3, a coupling sleeve 4, a pair of thrust bearings 5, a nut 6. A threaded rod 7, a threaded rod sleeve 8, an O-ring 9, a joint 10, a guide block 11 and a housing 12. in,

[0020] The micro-motor 1 is fixedly installed on the outside of the base 2, and its output shaft is inserted into the side hole of the base 2;

[0021] The worm gear 3 is located in the inner cavity of the base 2 and the worm is installed on the output shaft of the micro-motor 1 through the coupling sleeve;

[0022] The worm gear 3 is fixedly connected with the screw mandrel 7 through the coupling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com