Production technique for reclaiming ammonium thiosulfate and ammonium thiocyanate from desulfurization waste liquor

A technology of ammonium thiosulfate and ammonium thiocyanate, applied in thiosulfate/dithionite/polythionite, inorganic chemistry, non-metallic elements, etc., can solve the environmental pollution of coal blending system, increase the Coke sulfur content, coke quality decline and other issues, to increase economic benefits, reduce emissions and environmental pollution, good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

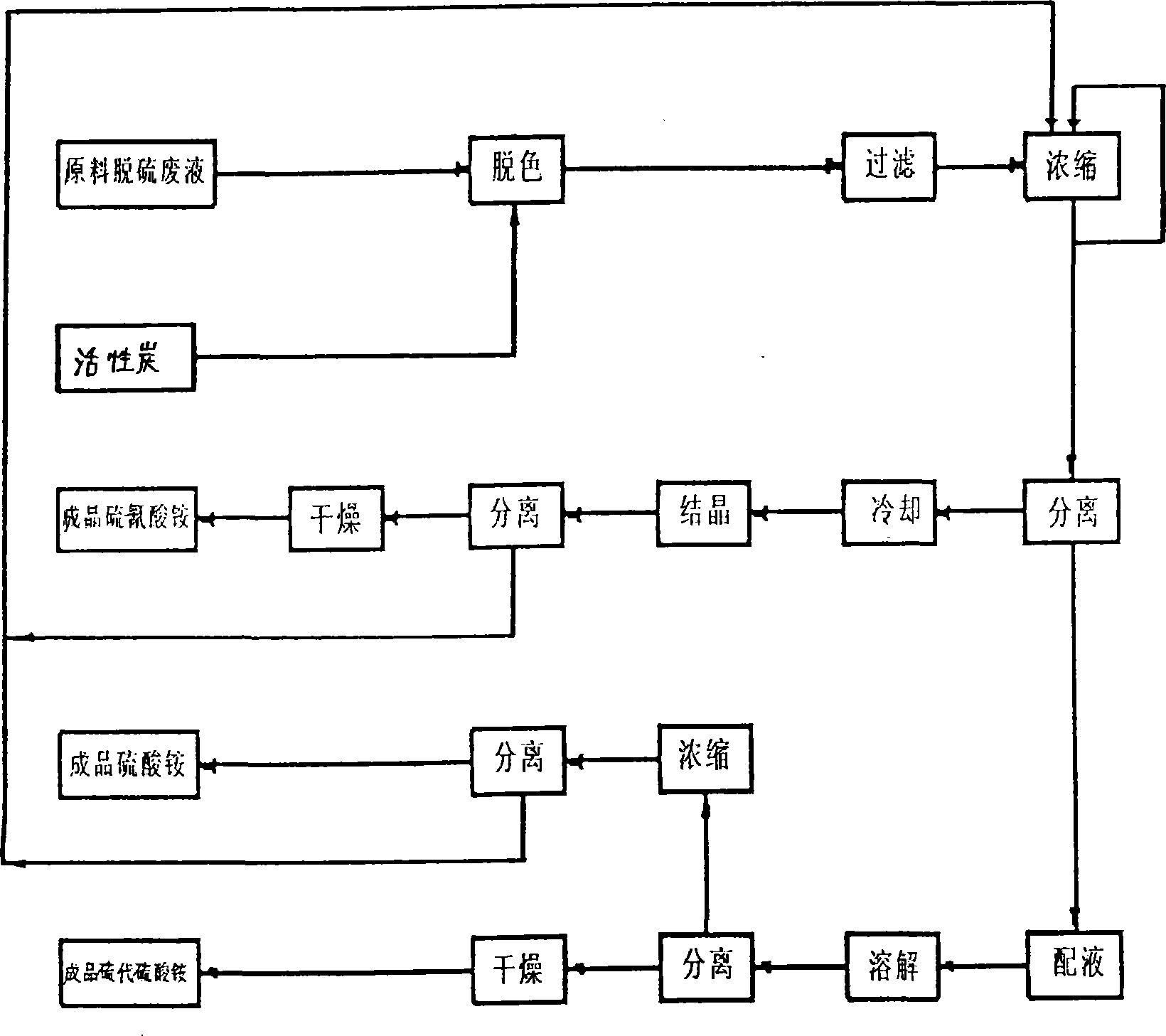

Image

Examples

Embodiment

[0017] 1. Pretreatment of sulfur-containing waste liquid

[0018] Send the desulfurization waste liquid of the coking plant into the raw material tank, (the composition of the sulfur-containing waste liquid: volatile ammonia: 0.85%; ammonium thiocyanate: 16%; ammonium thiosulfate: 15%; suspended sulfur: 0.361%; Diphenol: 0.361%), the upper part of the raw material tank is directly heated by steam, so that the temperature of the sulfur-containing waste liquid is controlled at 85°C, and the sulfur-containing waste liquid in the raw material tank is driven into the decolorization tank by the feed pump, and activated carbon is added at the same time to decolorize The tank adopts circular stirring, the average residence time of the solution is 6 hours, and the temperature is controlled at 85°C. After the sulfur-containing waste liquid is decolorized, it enters the tubular ceramic membrane filter. The infusion is pumped to the next process for processing, while the suspended solids ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com