Method for recovering vanadium in vanadium-titanium magnetite ore

A technology of vanadium titanomagnetite and calcium additives, applied in the field of iron and steel metallurgy, can solve problems such as loss, and achieve the effects of low cost of raw materials, recycling and clean utilization, and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

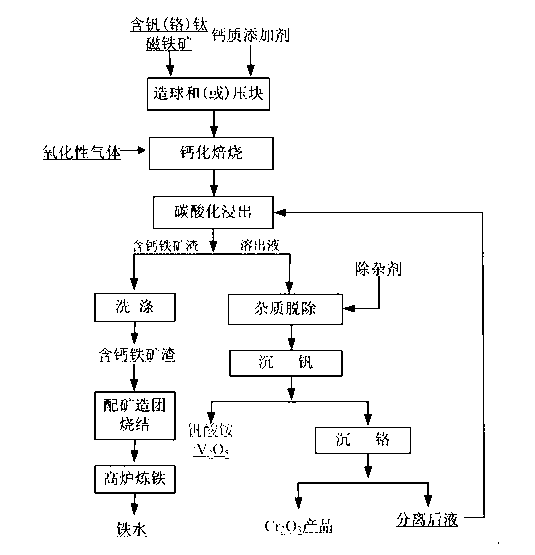

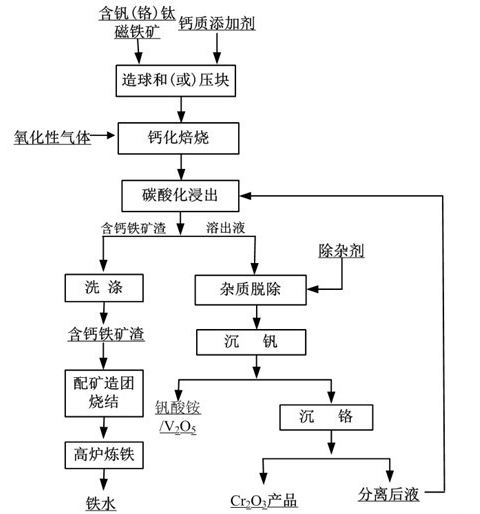

[0027] Example 1: figure 1 As shown, the processing steps of the method for recovering vanadium in this vanadium-titanium magnetite are as follows.

[0028] (1) Ingredients: Vanadium titanomagnetite and vanadium titanomagnetite 10% CaCO 3 1. Starch with 1% weight of vanadium-titanium magnetite is pelletized in a disc granulator, and then dried in an oven at 100°C to obtain agglomerate material; wherein, vanadium-titanium magnetite contains V 2 o 5 1.2wt%, Cr 2 o 3 0.4wt%, CaO 2.4wt%, SiO 2 6.5wt%;

[0029] (2) Reaction: Put the agglomerate material into a rotary furnace and heat it to 1200°C for 1 hour. After the reaction, the low-valent vanadium (chromium) is oxidized to pentavalent (hexavalent) and reacts with calcium additives to form calcium vanadate (chromic acid calcium), to obtain roasted clinker;

[0030] (3) Leaching: put the roasted clinker obtained in step (2) in CO 3 2- The mass percentage is 15wt% NaHCO 3 The solution is leached, and 2 kg of CO is injec...

Embodiment 2

[0035] Embodiment 2: The process steps of the method for recovering vanadium in this vanadium-titanium magnetite are as follows.

[0036] (1) Ingredients: high-chromium vanadium-titanium magnetite, CaO with 5% weight of high-chromium vanadium-titanium magnetite, and bentonite with 5% weight of high-chromium vanadium-titanium magnetite are agglomerated in a disc granulator, Then dry it in an oven at 100°C to obtain the agglomeration material; among them, the high chromium vanadium titanomagnetite contains V 2 o 5 0.9wt%, Cr 2 o 3 3.5wt%, CaO 1.4wt%, SiO 2 1.5wt%;

[0037] (2) Reaction: Put the agglomerate material into a tunnel kiln and heat it to 1100°C for 2 hours. During the reaction, oxygen is introduced to obtain roasted clinker;

[0038] (3) Leaching: put the roasted clinker obtained in step (2) in CO 3 2- The mass percentage is 40wt% NaHCO 3 Leaching in the solution, passing 1 kg of CO under pressure during the leaching process 2 ; Then filter to obtain calci...

Embodiment 3

[0043] Embodiment 3: The process steps of the method for recovering vanadium in this vanadium-titanium magnetite are as follows.

[0044] (1) Ingredients: direct reduction slag of vanadium titanomagnetite and 8% CaSO by weight of direct reduction slag 4 1. A metallurgical agglomeration binder with a weight of 3% of the direct reduction slag is used for agglomeration in a disc granulator, and then dried in an oven at 200°C to obtain an agglomeration material; wherein, the direct reduction slag contains V 2 o 5 8.9%, Cr 2 o 3 3.5%, CaO2.4%, SiO 2 17%;

[0045] (2) Reaction: The agglomeration material is put into a shaft furnace and heated to 900°C for 10 hours. During the reaction, oxygen-enriched air is introduced to obtain roasted clinker;

[0046] (3) Leaching: put the roasted clinker obtained in step (2) in CO 3 2- The mass percentage is 20wt% Na 2 CO 3 solution, and 10 kg pressure of CO 2 Afterwards, filter to obtain the eluate containing calcium-iron slag and van...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com