Intelligent automatic box falling machine

A box drop machine and automatic technology, applied in the field of box drop machines, can solve the problems of heavy burden on workers, low production efficiency, and inability to control the speed of product drop boxes, so as to reduce the burden on workers and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

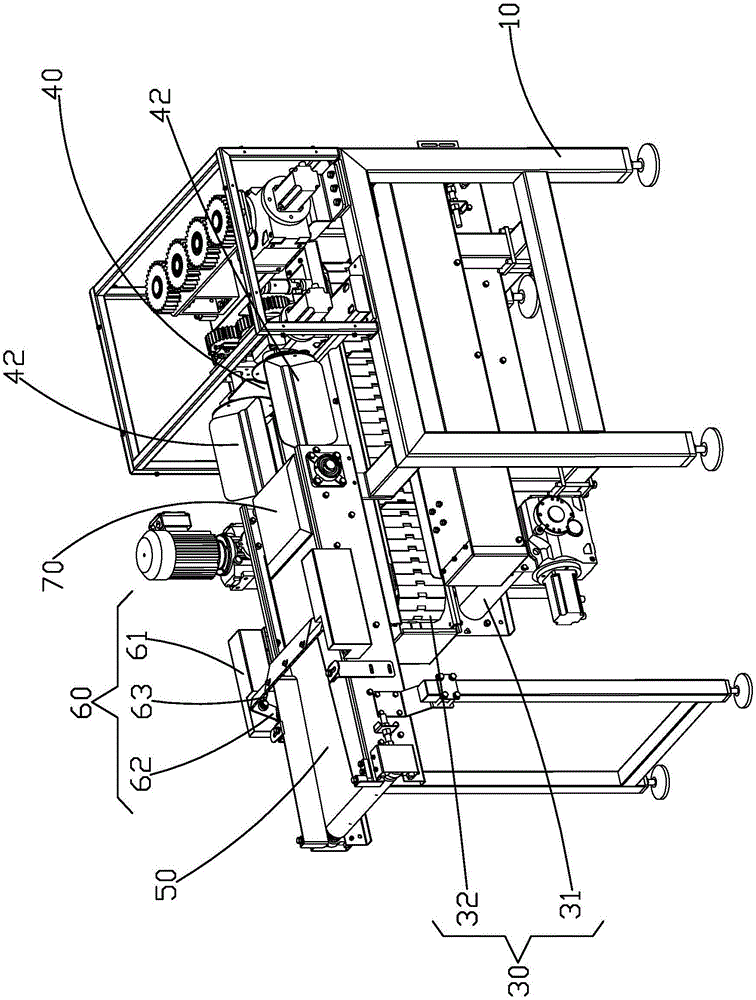

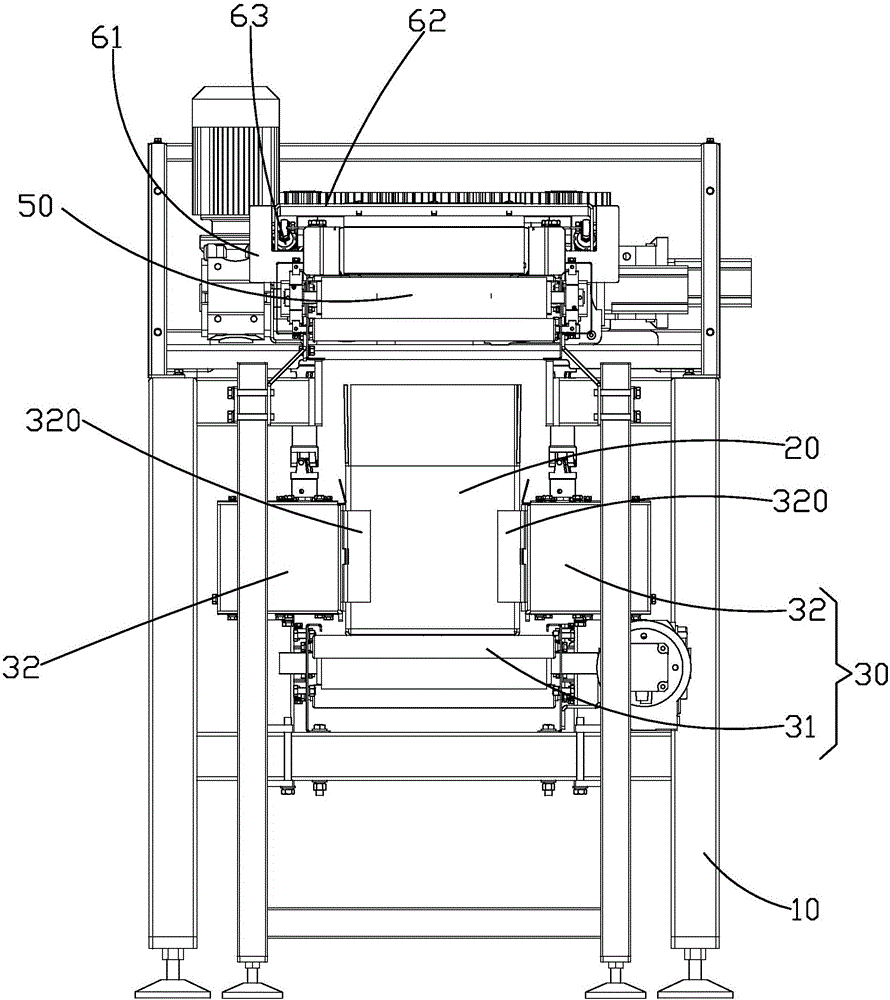

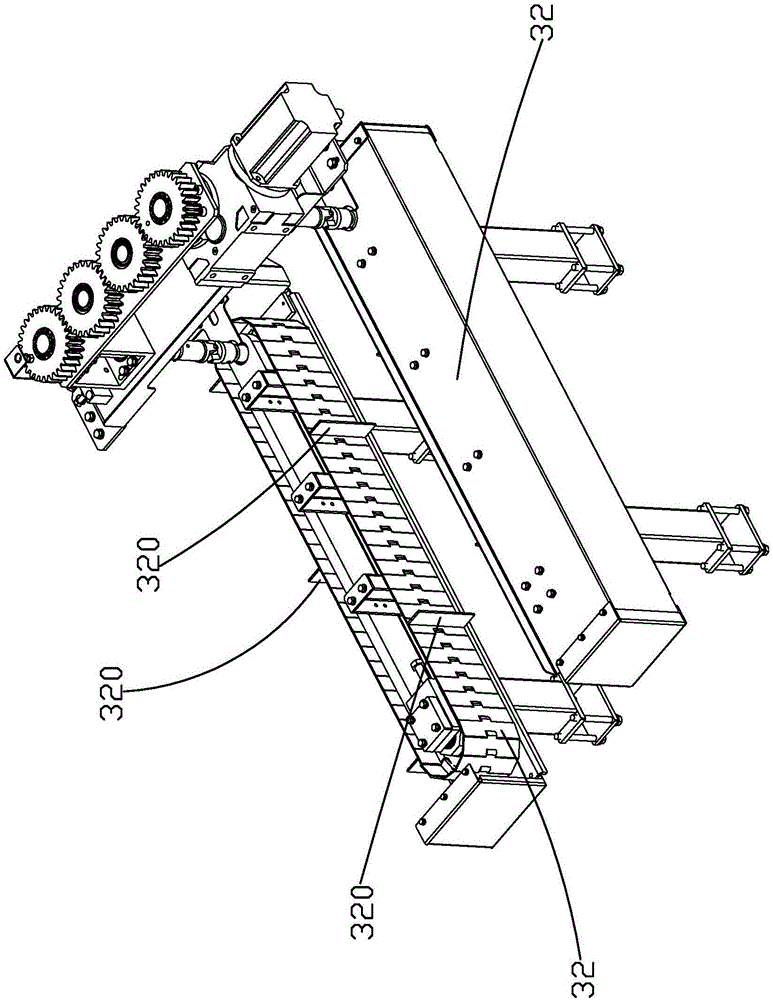

[0024] refer to figure 1 , Figure 2 and Figure 4 , an intelligent automatic drop box machine, including a frame 10, the lower part of the frame 10 is provided with a conveying device 30 that can drive the box body 20 to move and pack, and the frame 10 is also provided with a 70 and control the material 70 to fall into the blanking mechanism 40 in the box body 20. The blanking mechanism 40 is arranged above the conveying device 30, and the conveying device 30 and the blanking mechanism 40 are connected to control their actions. The control circuit of whether or not, here, as a preferred embodiment of the present invention, the conveying device 30 includes a conveying channel 31 for carrying and driving the box body 20 to move, further preferably, the conveying channel 31 is a roller Conveying line, when the box body 20 used to load the material 70 is placed on the delivery channel 31, the control circuit controls the delivery channel 31 to drive the box body 20 to move direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com