Universal clamp of wind driven generator blades

A technology of wind power generators and fixtures, which is applied in the direction of manufacturing tools, workpiece clamping devices, etc., can solve the problems of frequent replacement, small application range, and low utilization rate of fixtures, and achieve the goal of improving general performance, improving general performance, and saving space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

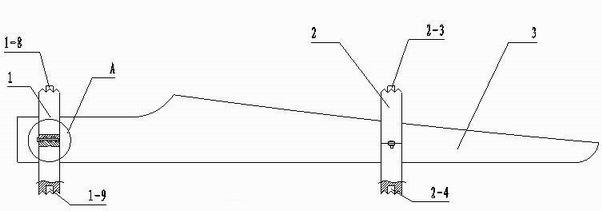

[0031] Referring to Fig. 1, the present invention includes a blade root fixture 1 and a blade airfoil fixture 2, the blade root fixture 1 is fitted with a blade root cylinder 3-1, and the blade airfoil fixture 2 is fitted with a blade wing 3- 2 Assembling, at the top of the blade root fixture and the blade airfoil fixture, there are sawtooth-shaped insertion surfaces 1-8, 2-3 with cylindrical bosses, and at the lower ends of the blade root fixture and the blade airfoil fixture Both are provided with sawtooth-shaped inserting surfaces 1-9, 2-4 with round-hole grooves, the top cylindrical boss and the lower end round-hole-shaped grooves, and the upper and lower sawtooth-shaped inserting surfaces match each other .

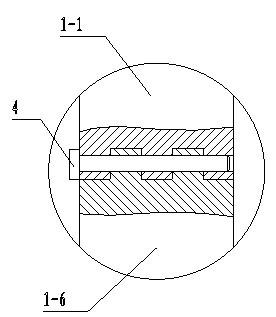

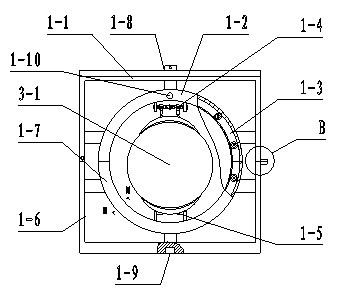

[0032] See Figure 1, figure 2 , image 3 , Figure 4 , the blade root clamp 1 of the present invention comprises a blade root clamp rectangular frame, a blade root clamp rolling ring 1-3, a blade root clamp adjustable jaw 1-4, a blade root clamp fixed jaw 1-5 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com