Intelligent sorting rack for warehousing

A technology of intelligent warehousing and sorting system, which is applied in the direction of sorting, conveyor objects, transportation and packaging, etc. It can solve the problems of being in the lower space of the car, unfavorable stability of goods, and increasing the work intensity of loading staff. Achieve the effects of improving reliability and stability, improving transportation efficiency, and increasing stacking capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to facilitate those skilled in the art to understand the technical solution of the present invention, the technical solution of the present invention will be further described in conjunction with the accompanying drawings.

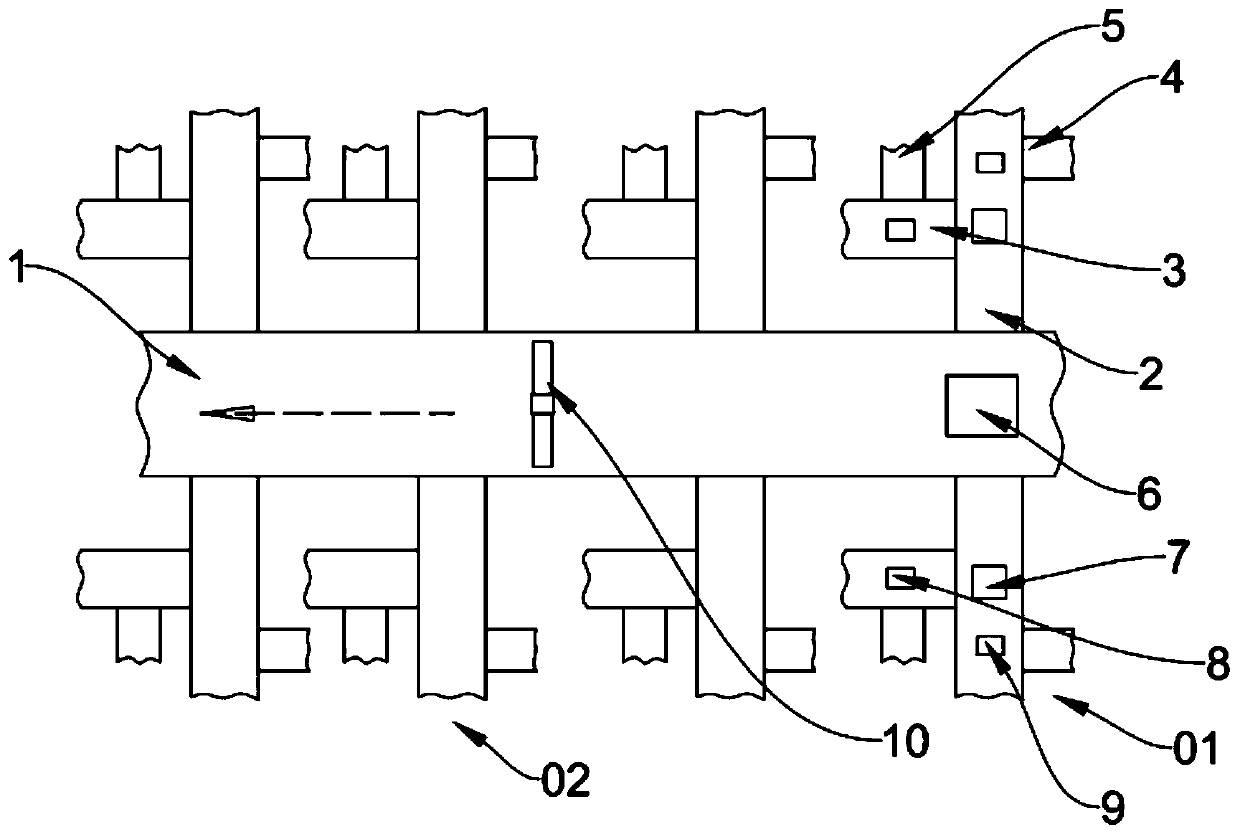

[0017] Such as figure 1 As shown, a sorting rack for intelligent storage includes a main conveyor belt 1 on which several primary sorting systems 01 and several secondary sorting systems 02 are sequentially arranged along the conveying direction.

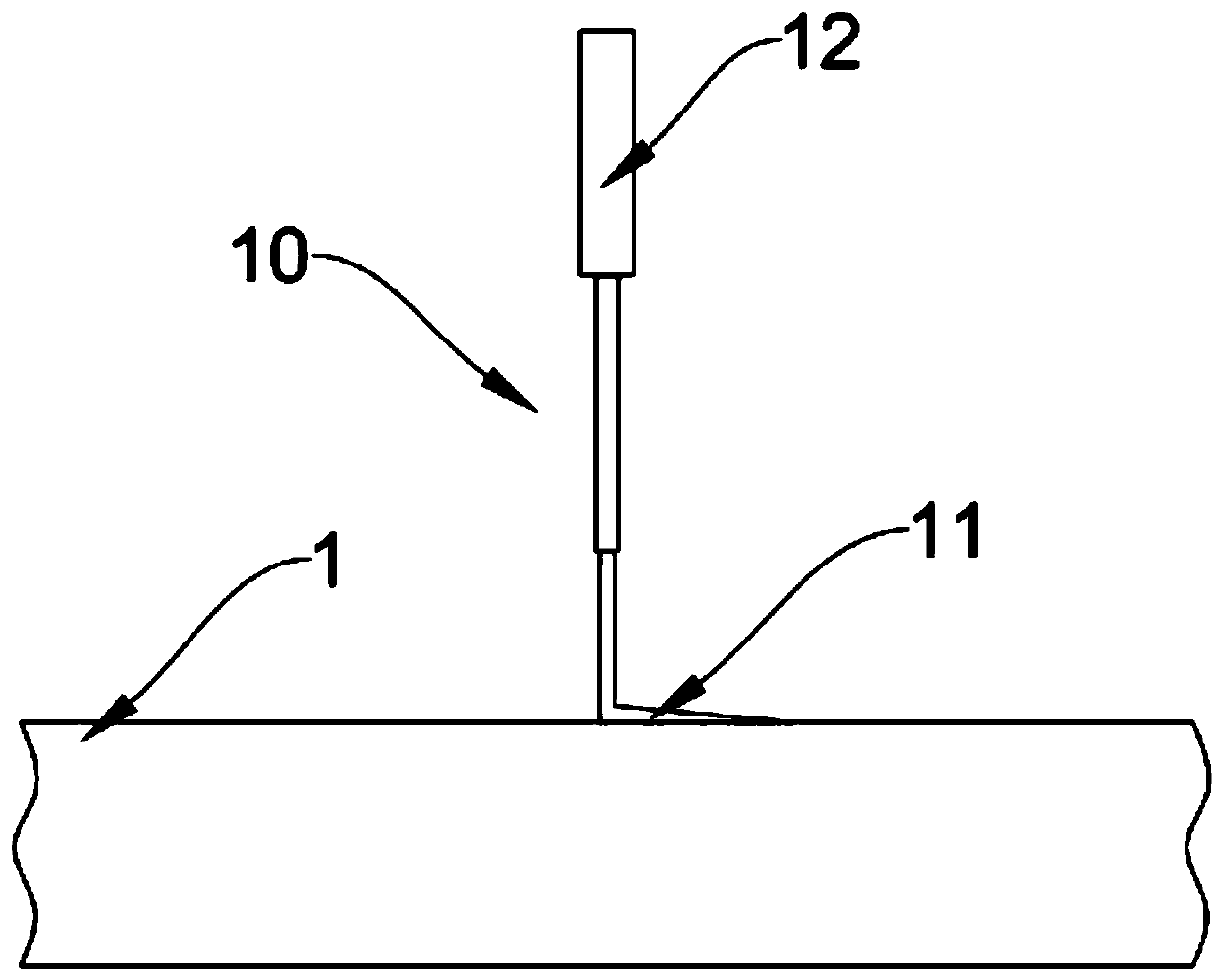

[0018] Both the primary sorting system 01 and the secondary sorting system 02 include several regional sorting modules 6 and several regional sorting conveyor belts 2 respectively arranged on the side of the main conveyor belt 1 . An integrated sorting conveyor belt 3 and a weight sorting conveyor belt 4 are sequentially connected to the side of each area sorting conveyor belt 2 along the conveying direction. A weight sorting conveyor belt 5 is also connected to the side of the volume sorting co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com