Lamination device and battery string preparation device

A stacking device and stacking technology, applied in the manufacture of circuits, electrical components, final products, etc., can solve the problems of low production efficiency of battery strings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

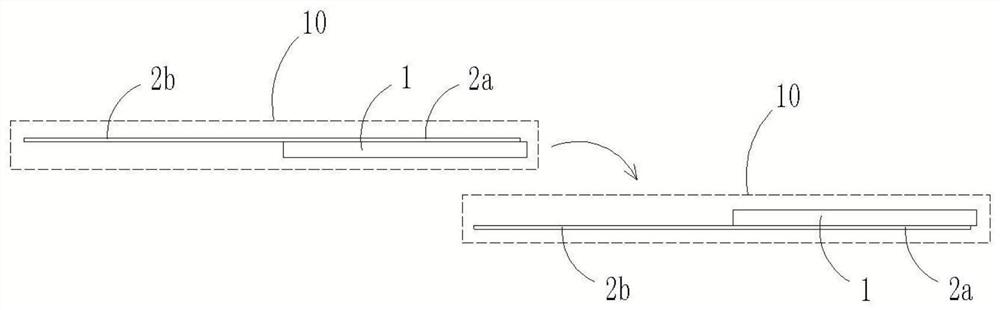

[0057] The stacking station 310 is only used for building or receiving the stringer unit 10 .

[0058] The stacking device 300 also includes a stacking driving mechanism capable of transporting the stringing unit 10 on the stacking table 310 and then stacking the stringing unit 10 .

[0059] In this embodiment, the lamination drive mechanism includes a lamination transport assembly (not shown) and a lamination transfer platform (not shown). At this time, the lamination transport assembly can transport the stringer unit 10 from the lamination table 310 and transfer the stringer unit 10 to the lamination transfer platform; the lamination transfer platform is used for the stringer unit 10 to perform lamination.

[0060] Since the second stringer unit 10 is carried by the lamination handling assembly, the stringer unit 10 transported later can be stacked on the stringer unit 10 that has been placed in place, so that the battery of the rear stringer unit 10 The sheet 1 is stacked ...

Embodiment 2

[0066] The stacking station 310 is not only used for building or receiving the stringer unit 10, but also serves as a stacking station.

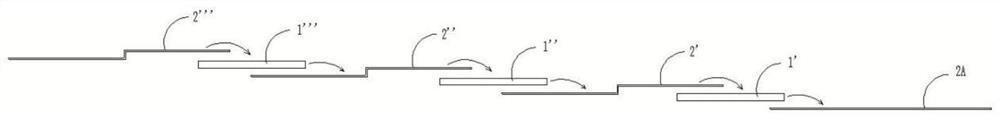

[0067] At this time, the stacking device 300 includes a plurality of stacking stages 310 arranged along a straight line and capable of receiving one string welding unit 10 respectively. The stacking device 300 also includes a stacking driving mechanism; the stacking driving mechanism includes: a stacking lifting mechanism 320, connected to the stacking platform 310, and capable of driving the stacking platform 310 to move in the vertical direction; a stacking translation mechanism 330, connected to the stacking sheet stage 310, and can drive the sheet stacking stage 310 to move in a straight line.

[0068] In this embodiment, the straight line direction is the arrangement direction of the multiple stacking stages 310 .

[0069] refer to Figure 9 , Figure 16 and Figure 17 , by providing a plurality of lamination stages 310 , the lamina...

Embodiment 3

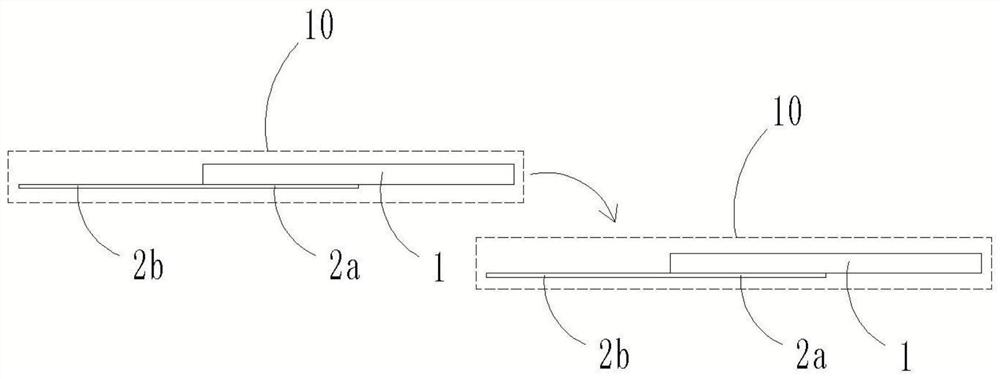

[0084] The stacking station 310 is not only used for building or receiving the stringer unit 10, but also serves as a stacking station.

[0085] At this time, the stacking device 300 includes a plurality of stacking stages 310 arranged along a straight line and capable of receiving one string welding unit 10 respectively. The stacking device 300 also includes a stacking driving mechanism; the stacking driving mechanism is used to drive a plurality of stacking stages 310 to move in a straight line. In this embodiment, the straight line direction is the arrangement direction of the multiple stacking stages 310 .

[0086] Since the surface of the battery sheet 1 is indented at the position of the grid lines to form a groove, and the solder ribbon 2 will be stuck in the groove, so, in this embodiment, the stacking table 310 approaches each other in a straight line, so that two adjacent There are two stacking stages 310, in which the second end 2b of the ribbon of one stringing un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com