Stacking mechanical arm with brick support plates

A technology of supporting bricks and manipulators, applied in the field of stacking manipulators, can solve problems such as effective stacking, affecting brick quality, and curing time constraints.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present case will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

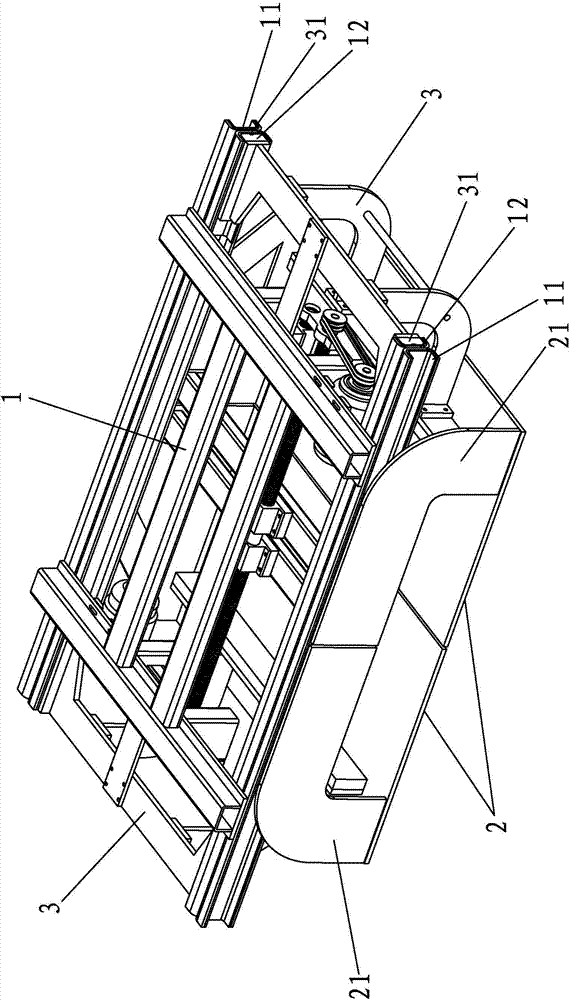

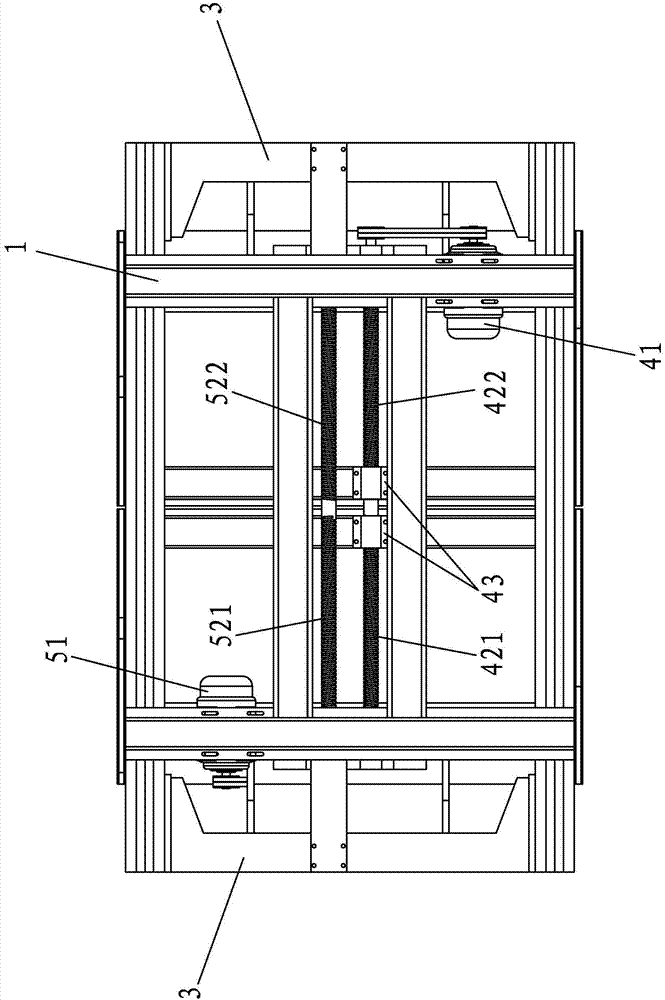

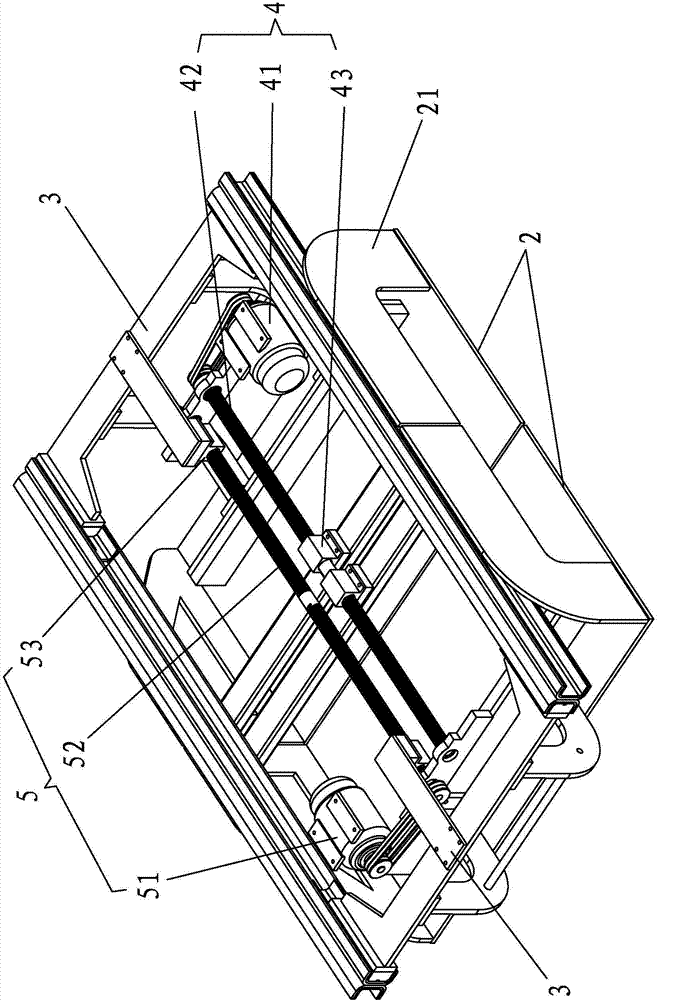

[0030] This case involves a palletizing manipulator with a brick support, such as Figure 1-3 As shown, it mainly includes a base frame 1 and two supporting brick panels 2 and two sandwiching brick panels 3 arranged on the base frame 1 .

[0031] The two supporting brick boards 2 are erected side by side under the base frame 1 at the same height, and an accommodating chamber is formed between the two supporting brick boards 2 and the base frame 1 for accommodating brick products 7 . The base frame 1 is provided with a first adjustment mechanism 4, which is used to drive the two supporting brick panels 2 to move closer or separate from each other synchronously.

[0032] The two sandwiched brick panels 3 are respectively arranged in the accommodating cavity (corresponding to the top of the second supporting brick panels 2 ), and the two san...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com