Patents

Literature

30results about How to "Stacked in order" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

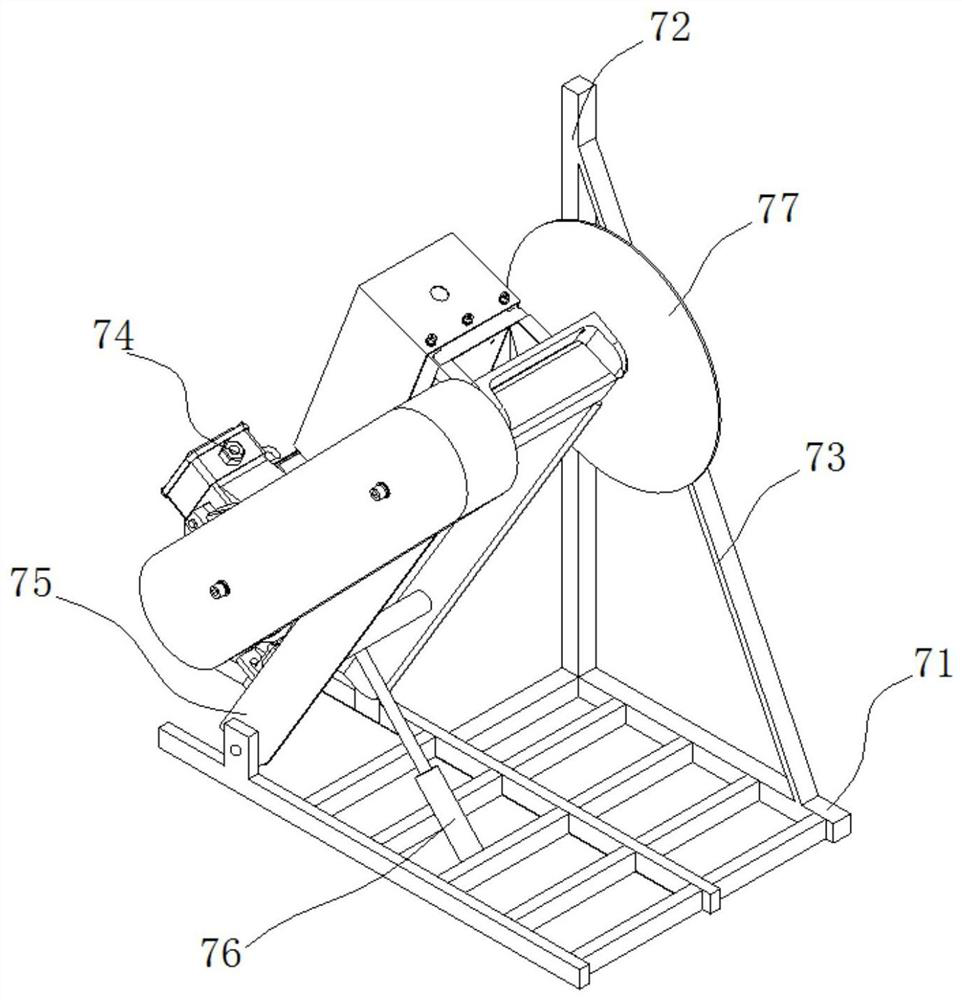

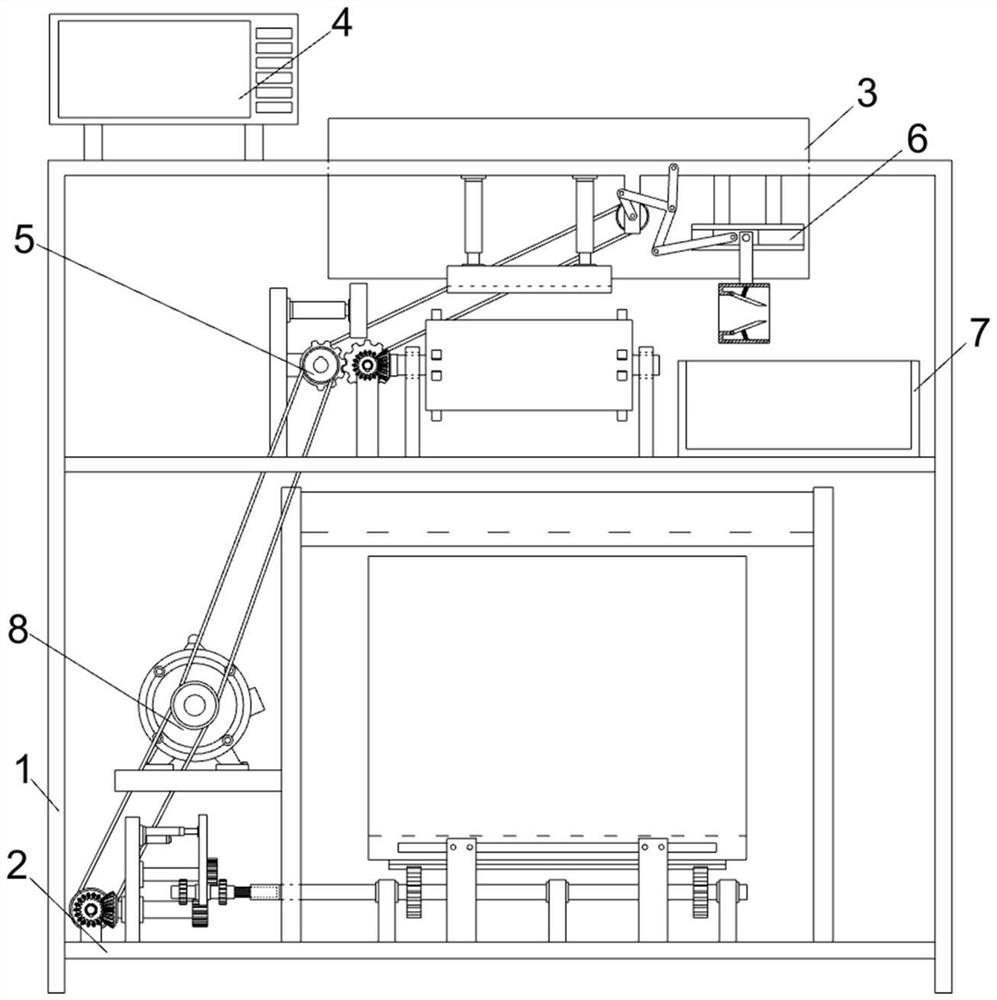

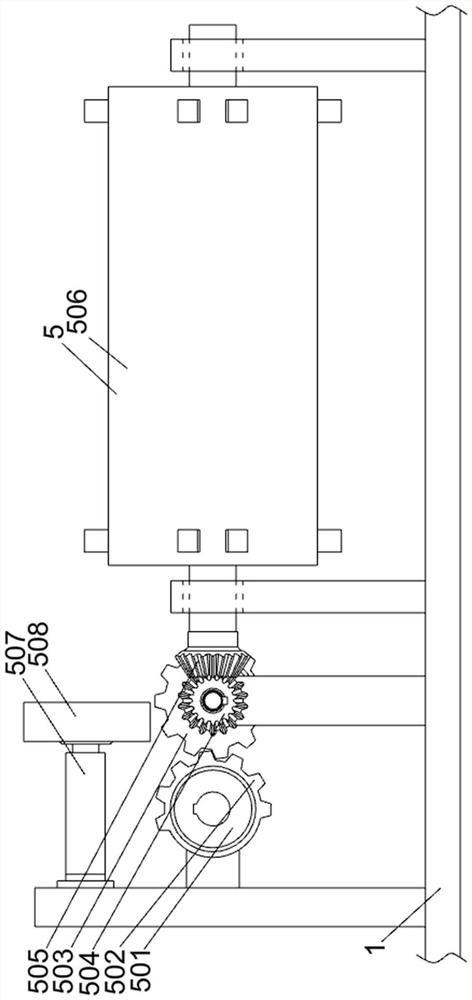

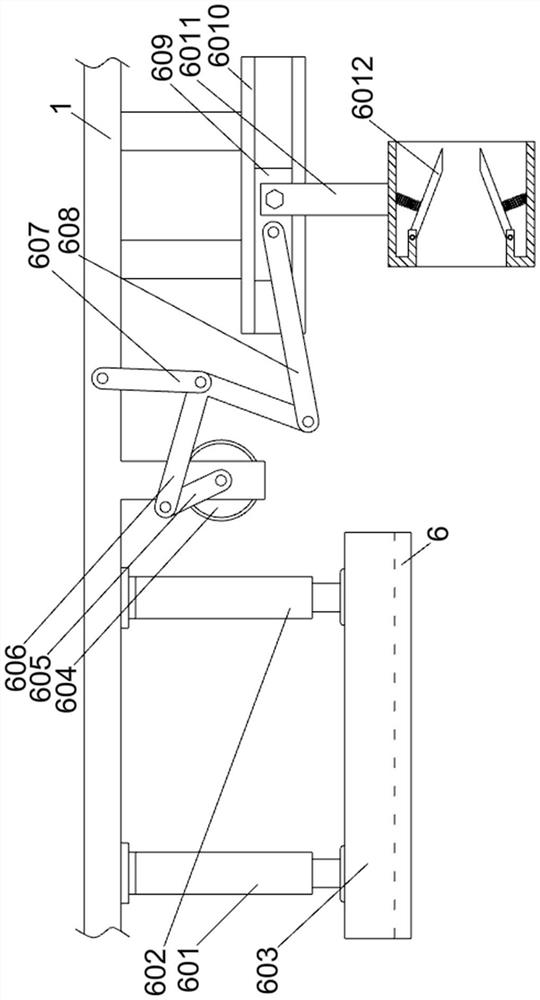

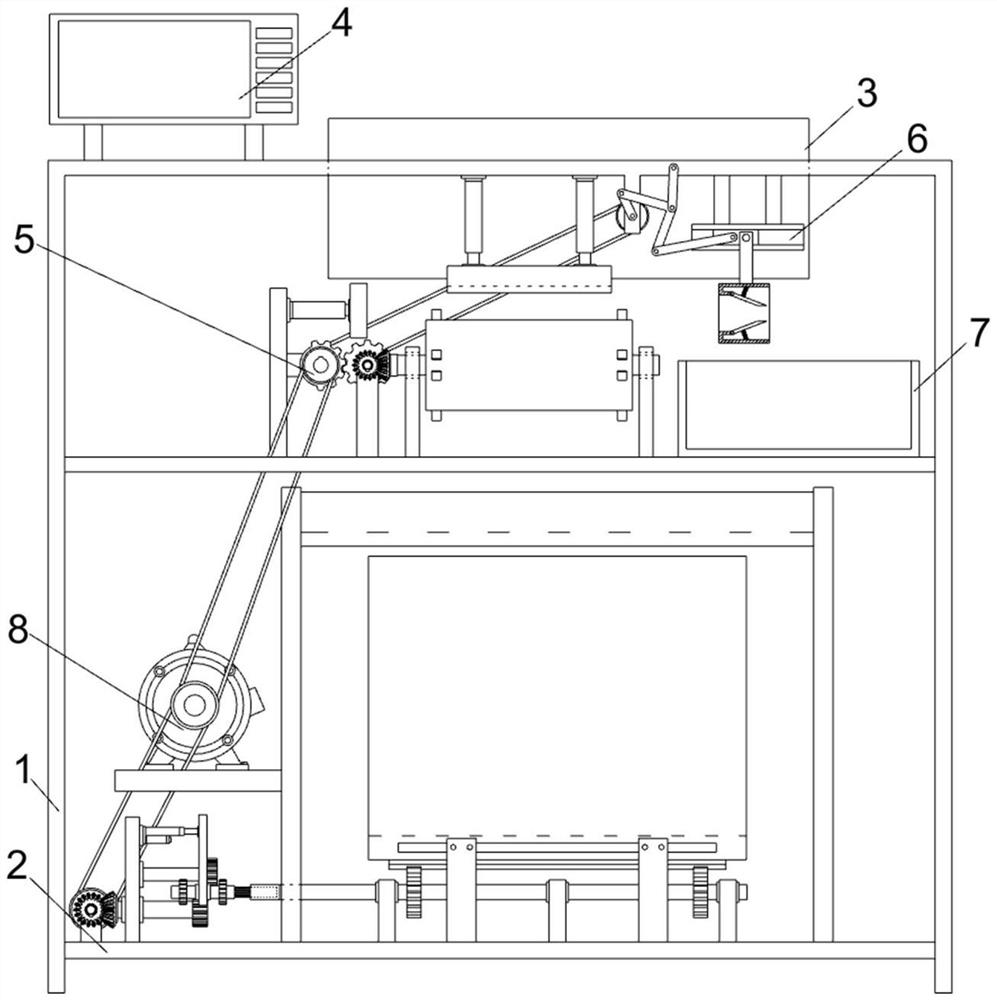

Full-automatic loading-unloading and visual inspection device

ActiveCN106124520AReduce labor intensityImprove efficiencyMaterial analysis by optical meansSortingEngineeringAssembly line

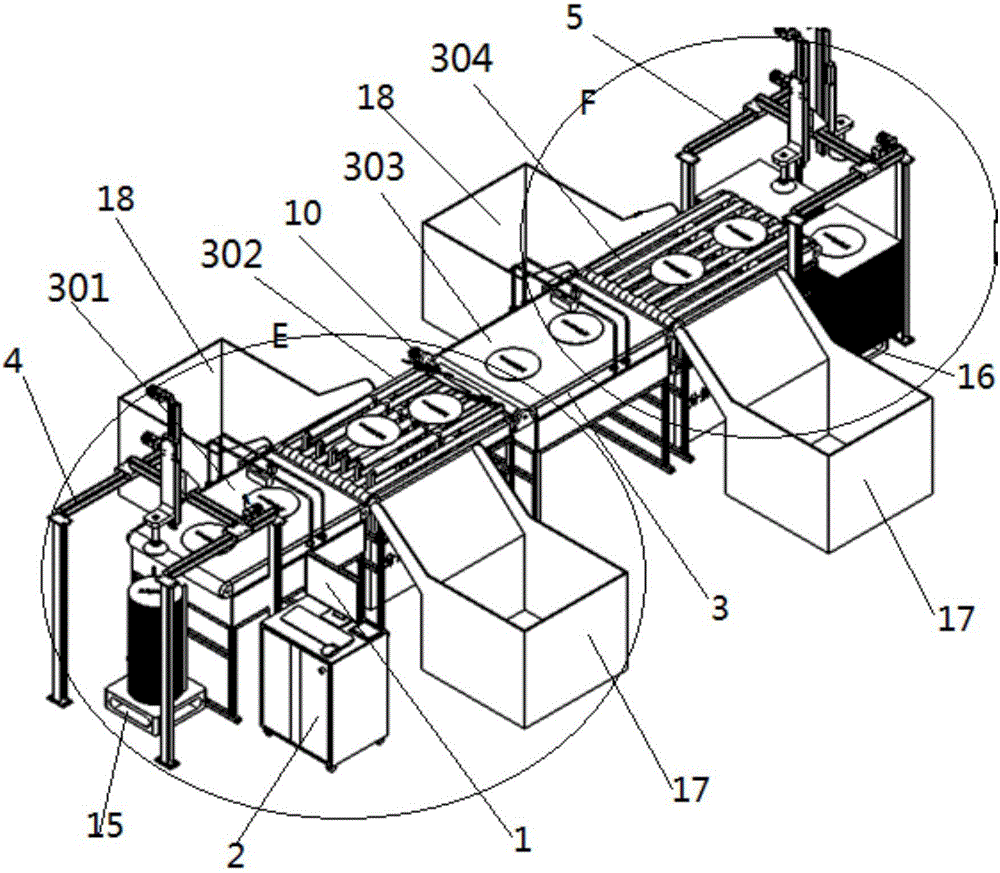

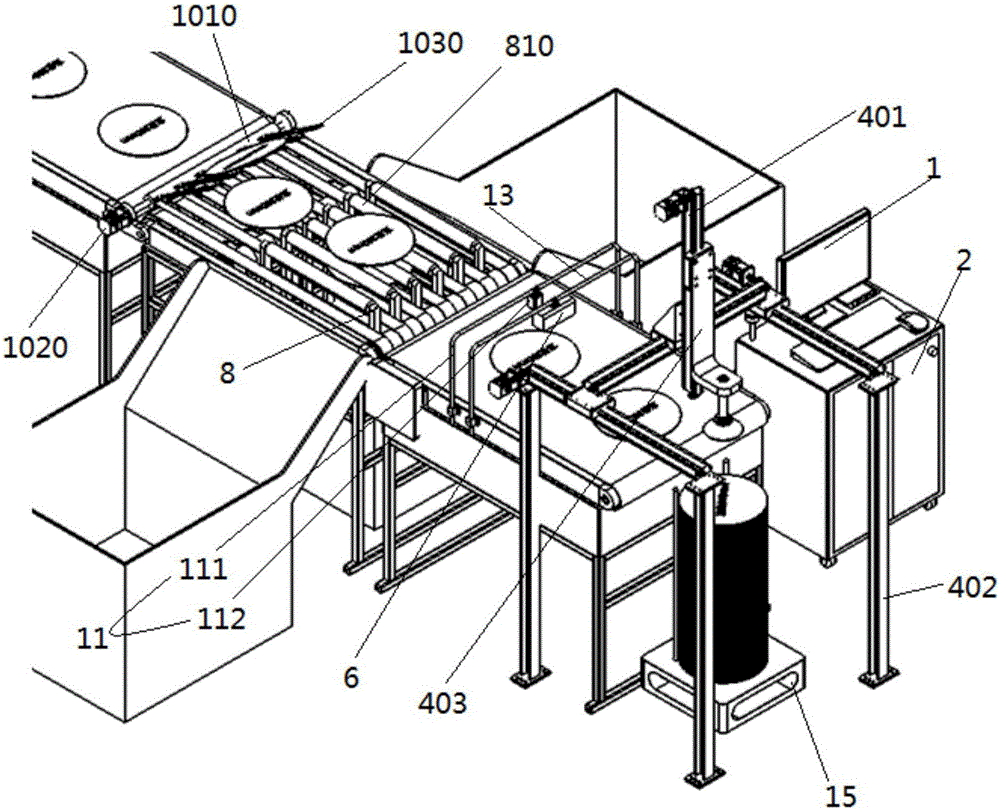

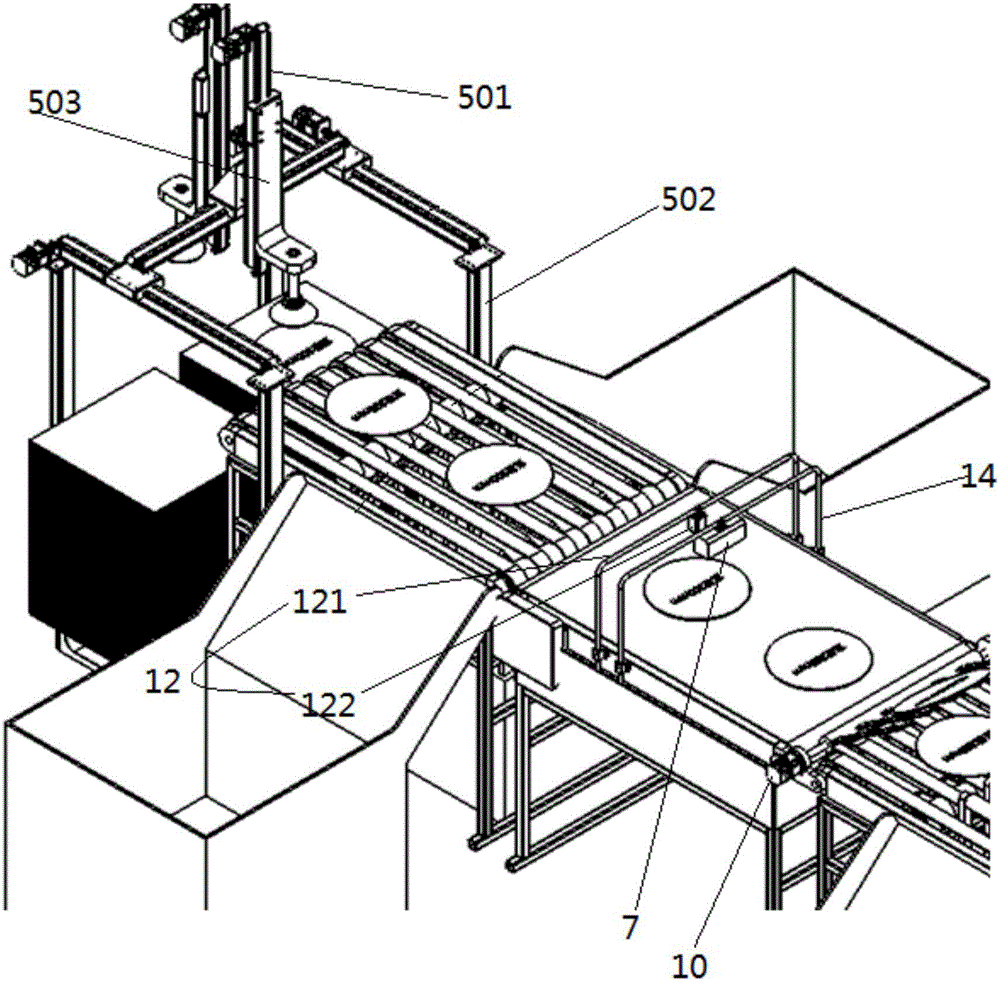

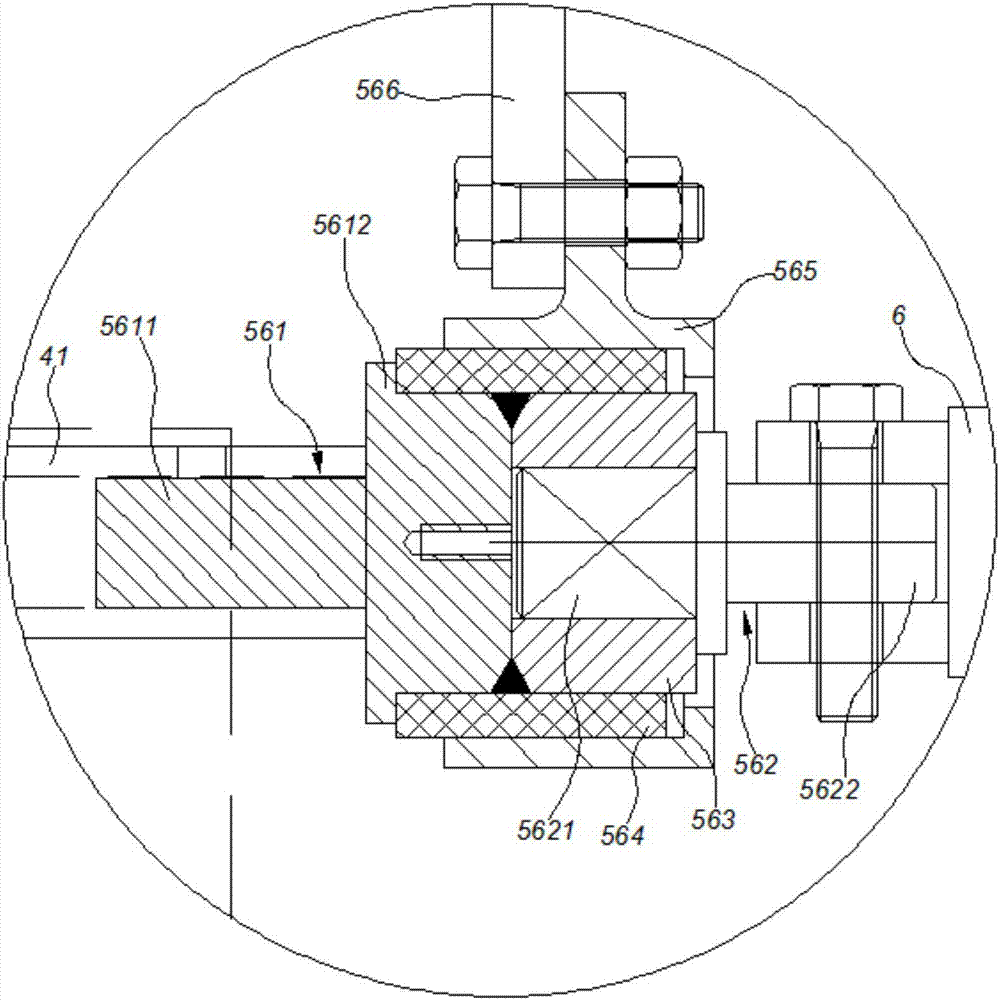

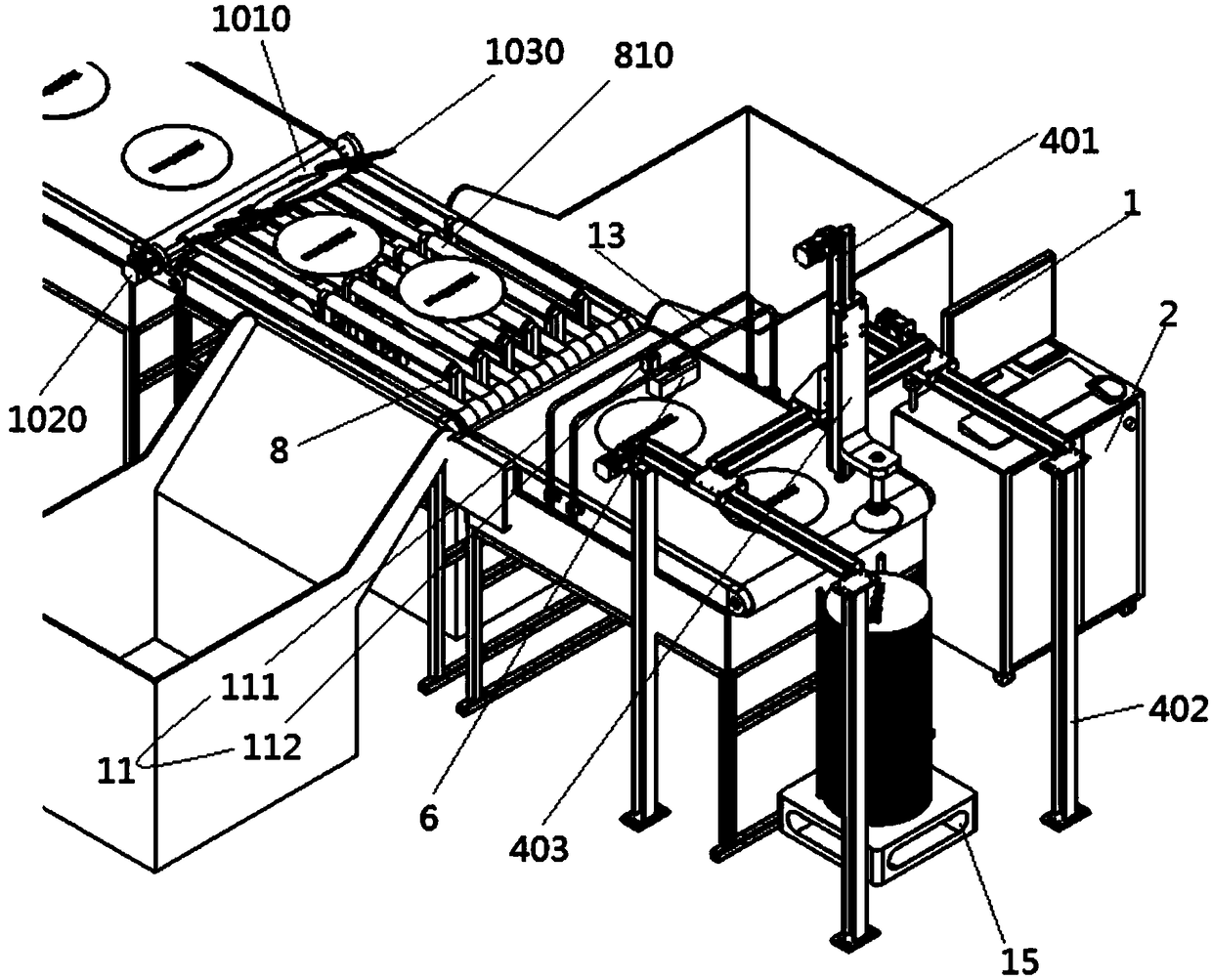

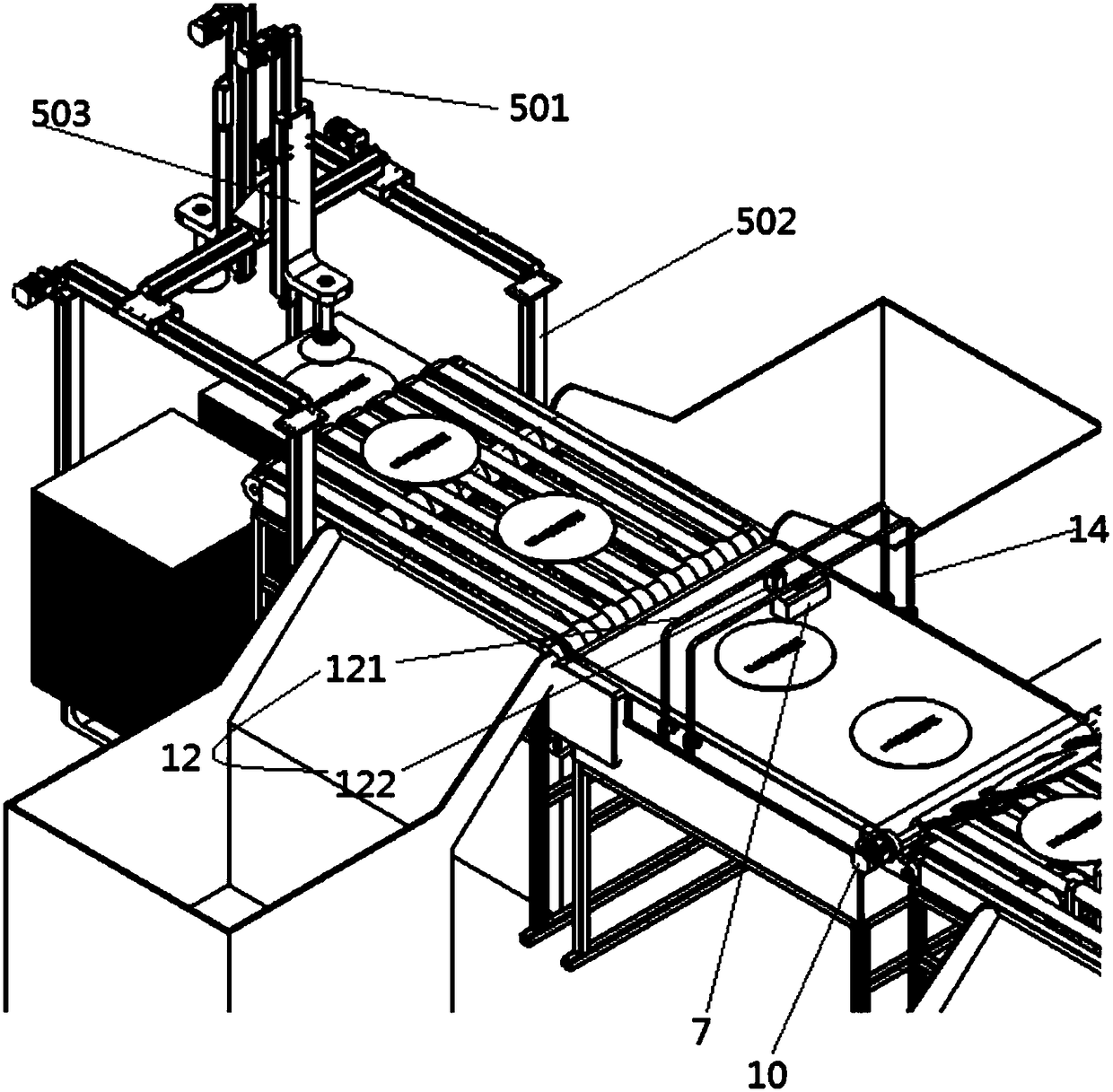

The invention relates to a full-automatic loading-unloading and visual inspection device. The device comprises a combined assembly line, a first image collecting device, a first product conveying device, an overturning device, a second image collecting device, a second product conveying device, an industrial computer, an electric appliance control cabinet, a loading device and an unloading device. The full-automatic loading-unloading and visual inspection device has the beneficial effects that a manual loading-unloading manner is changed into an automatic loading-unloading manner, so that the labor intensity of workers is reduced, and the device is high in efficiency and practical and can be applied to long-term scale production; besides, a manual detection manner is changed into an online automatic detection manner, so that the quality of products with front and back surfaces can be accurately detected, the economic loss of a user caused by manual erroneous judgment can be reduced, the detection efficiency is high, and the detection is accurate and reliable, the online automatic detection is realized, and the 24-hour ceaseless working can be realized; and data can be stored in real time, and the user can analyze the product process according to the detection data, so that the economic benefit of a factory is increased.

Owner:武汉智慧眼智能科技有限公司

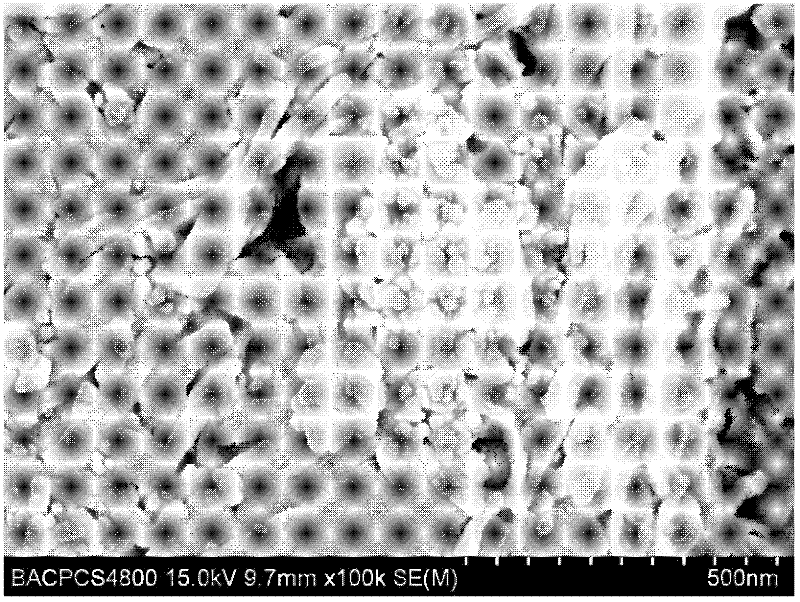

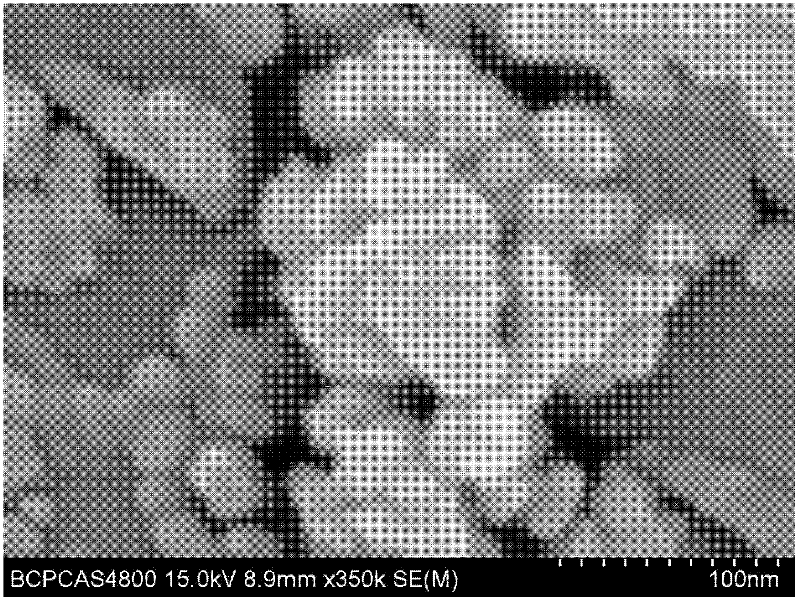

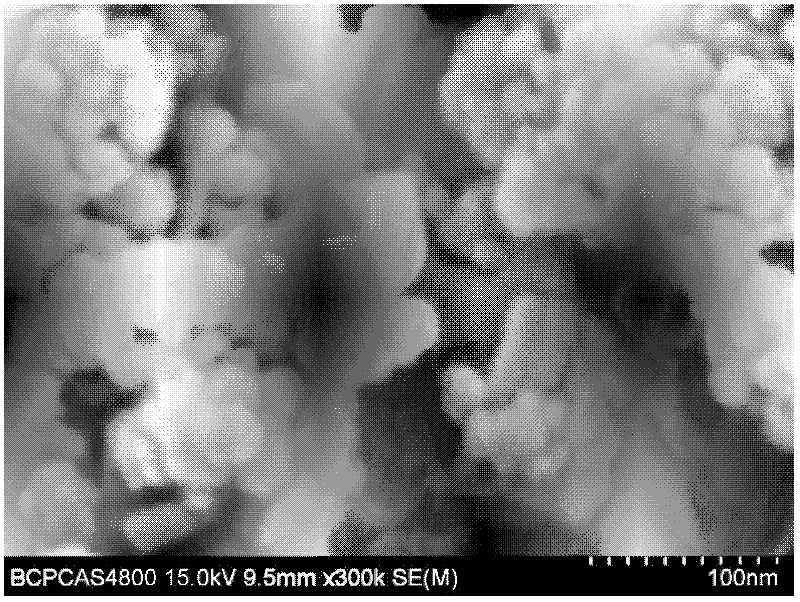

A kind of preparation method of lithium iron phosphate positive electrode material of lithium ion battery

The invention discloses a preparation method of lithium iron phosphate, a positive electrode material of a lithium ion battery, comprising the following steps: 1) preparing nanoscale primary particles of lithium iron phosphate: weighing according to the molar ratio of P:Fe:Li=1:1:3 Phosphate, iron salt, lithium salt, using the co-precipitation method to prepare nano-scale lithium iron phosphate primary particles; 2) drying and carbon coating: dry the primary lithium iron phosphate particles prepared in step 1) and add graphene powder , ball milling to obtain secondary particles; 3) sintering of the lithium iron phosphate precursor: roasting the secondary particles obtained in step 2) from ball milling to obtain lithium iron phosphate, a cathode material for lithium ion batteries. In the present invention, graphene is added for carbon coating, which can greatly improve the electrical conductivity of the lithium iron phosphate material, and facilitate the entry and exit of electrons on the surface of the material particles; an extremely thin coating layer is formed on the surface of the material, which greatly improves the packing density of the material and makes phosphoric acid Iron-lithium particles can be stacked more orderly, greatly improving the ability of Li+ and electrons to enter and exit.

Owner:IRICO

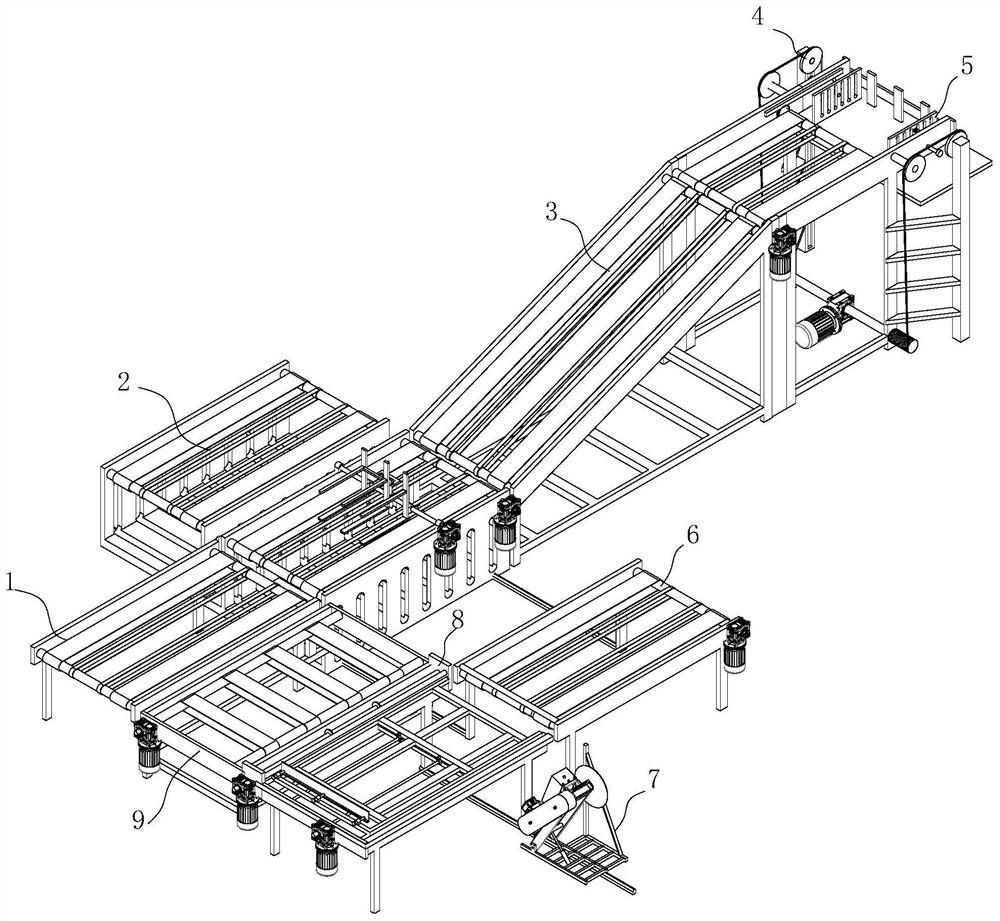

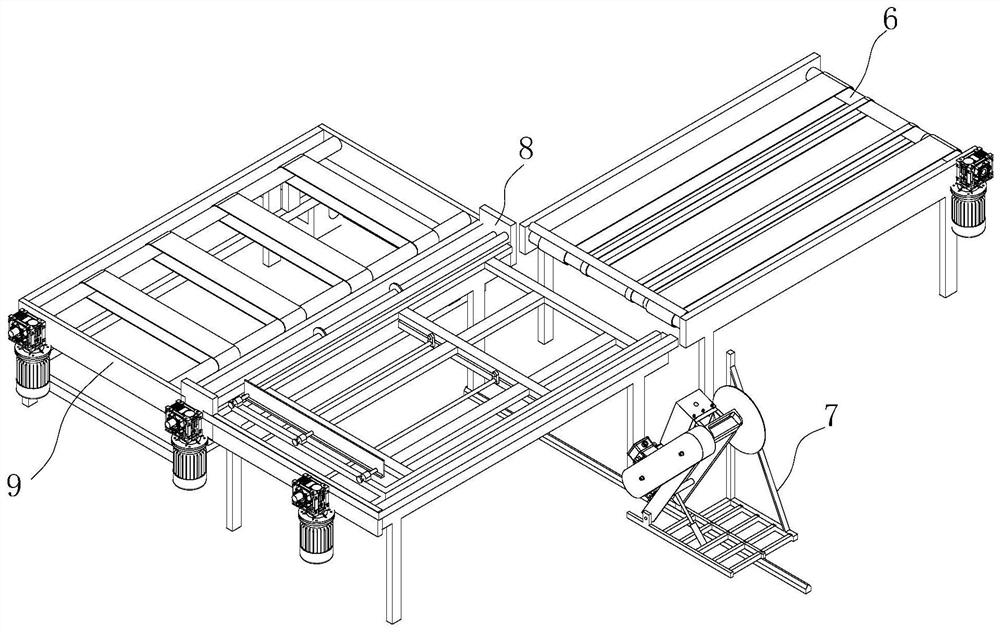

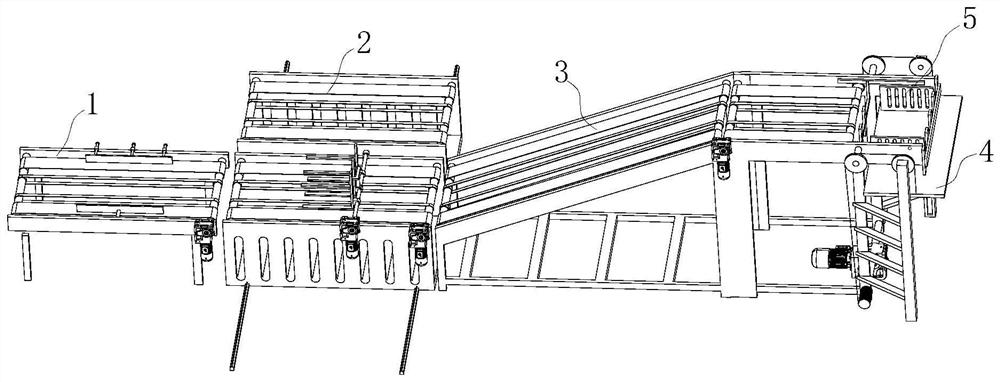

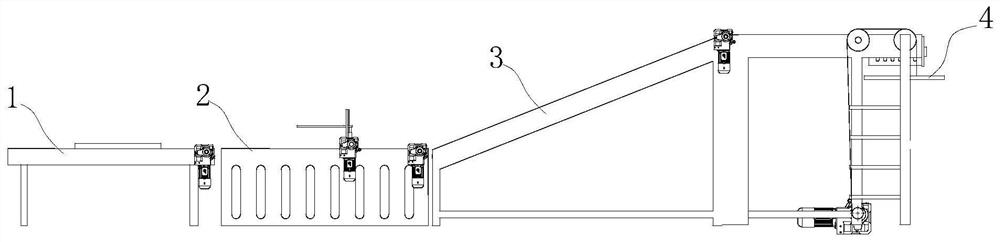

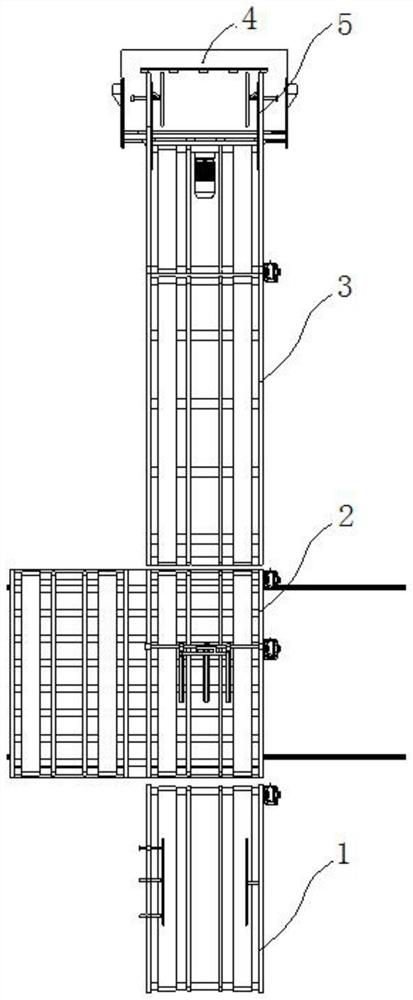

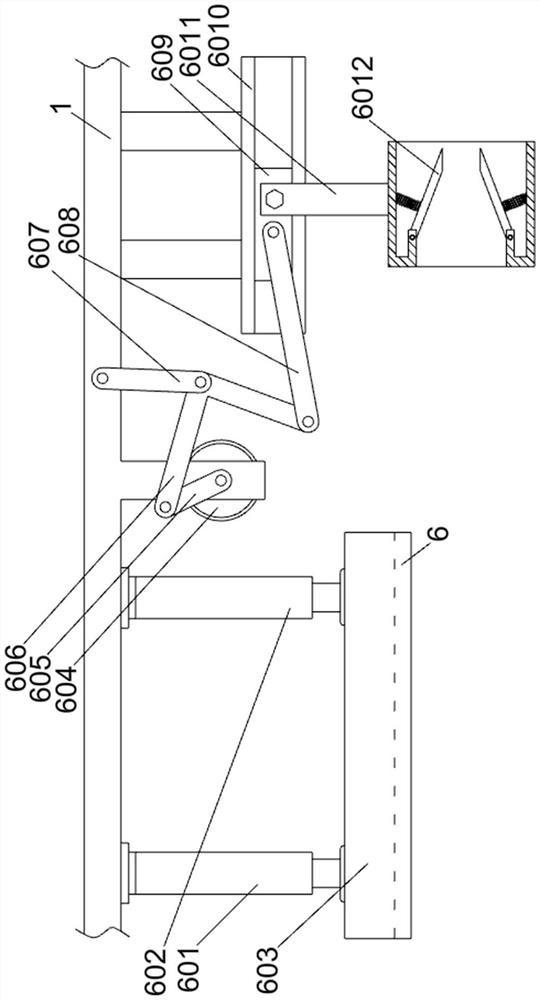

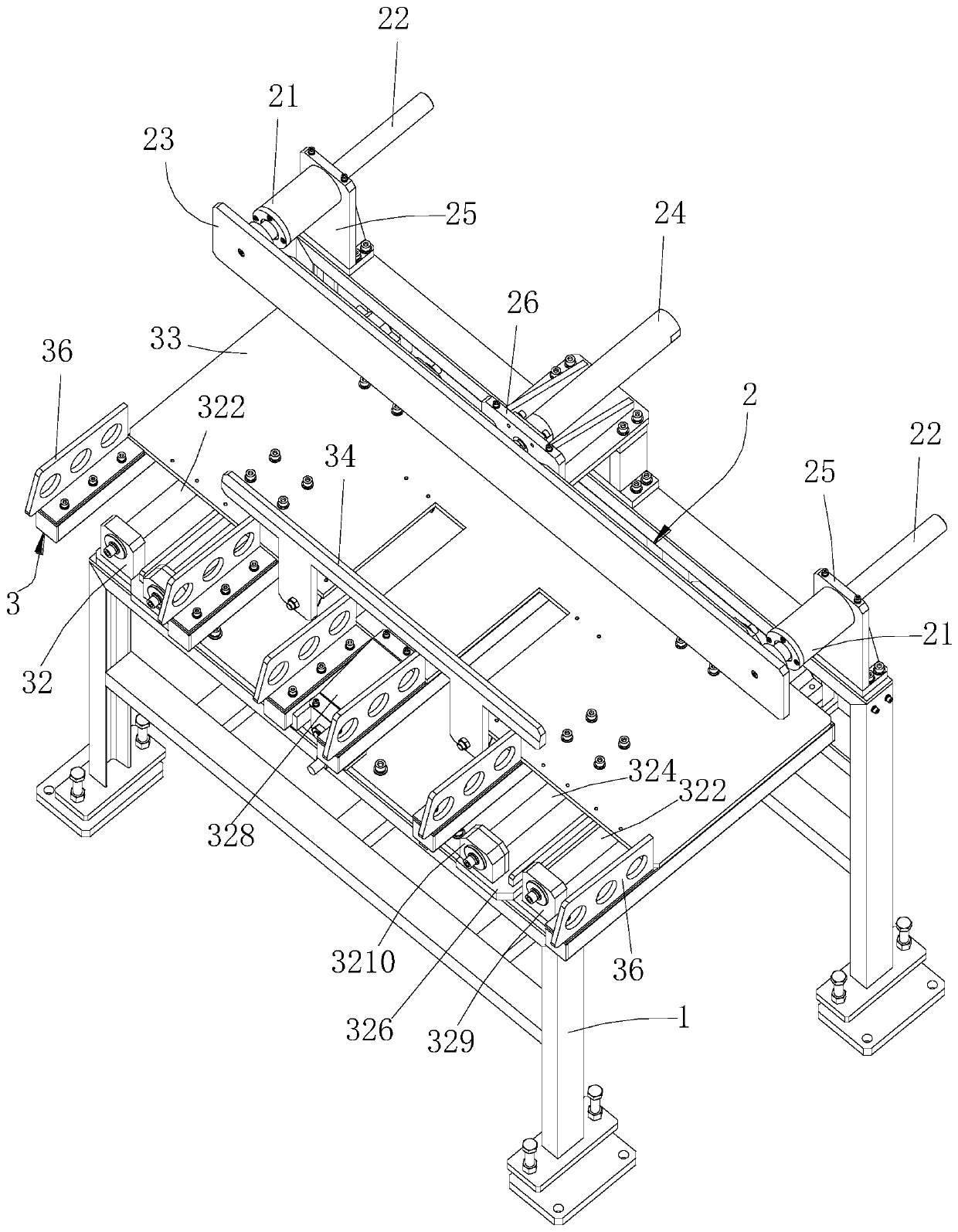

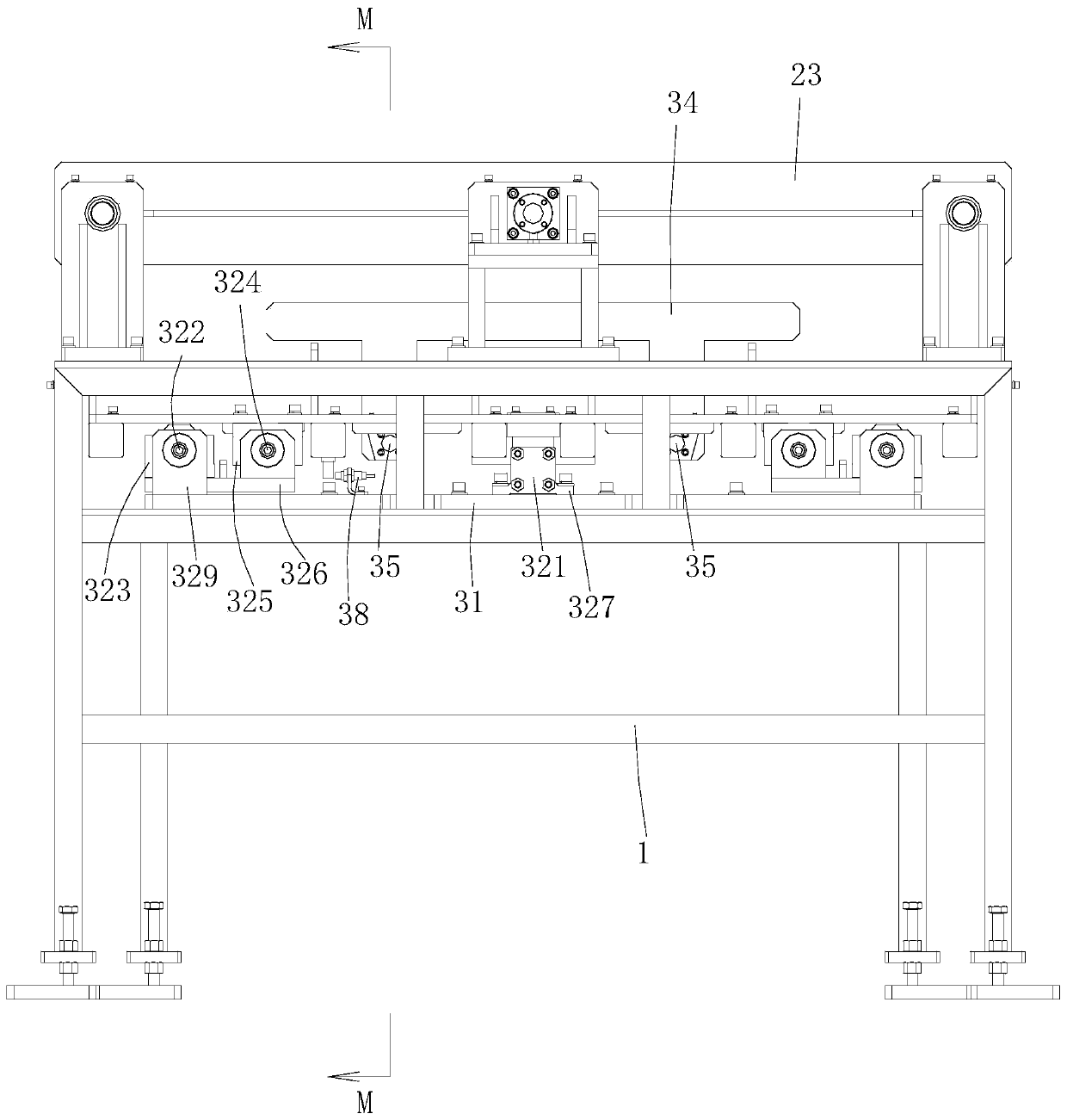

Paperboard processing line

InactiveCN111807107AImprove cutting efficiencyFunctionalOverturning articlesPile receiversPaperboardStructural engineering

The invention provides a paperboard processing line. A paperboard cutting device is used for cutting a strip-shaped paperboard into paperboard blocks and stacking the paperboard blocks into a plurality of stacks; a paperboard stacking device comprises a conveying device and a stacking mechanism; the conveying device comprises a trolley, two fourth conveying mechanisms and an overturning mechanism,the trolley can move in the longitudinal direction, the two fourth conveying mechanisms are distributed at an interval in the longitudinal direction and used for receiving the paperboard blocks separated from a third conveying mechanism, and the overturning mechanism is used for overturning the paperboard stacks on one of the fourth conveying mechanisms by 180 degrees; a fifth conveying mechanismis used for receiving the paperboard blocks separated from the fourth conveying mechanism; and the stacking mechanism is used for stacking the paperboard stacks separated from the fifth conveying mechanism. According to the paperboard processing line, paperboards are stacked forwards and reversely alternately stack by stack instead of piece by piece, so that the stacking efficiency is greatly improved; and the automation degree of the processing line is high without manual guarding in the process, so that the labor cost is reduced while the labor intensity is reduced.

Owner:朱蓉

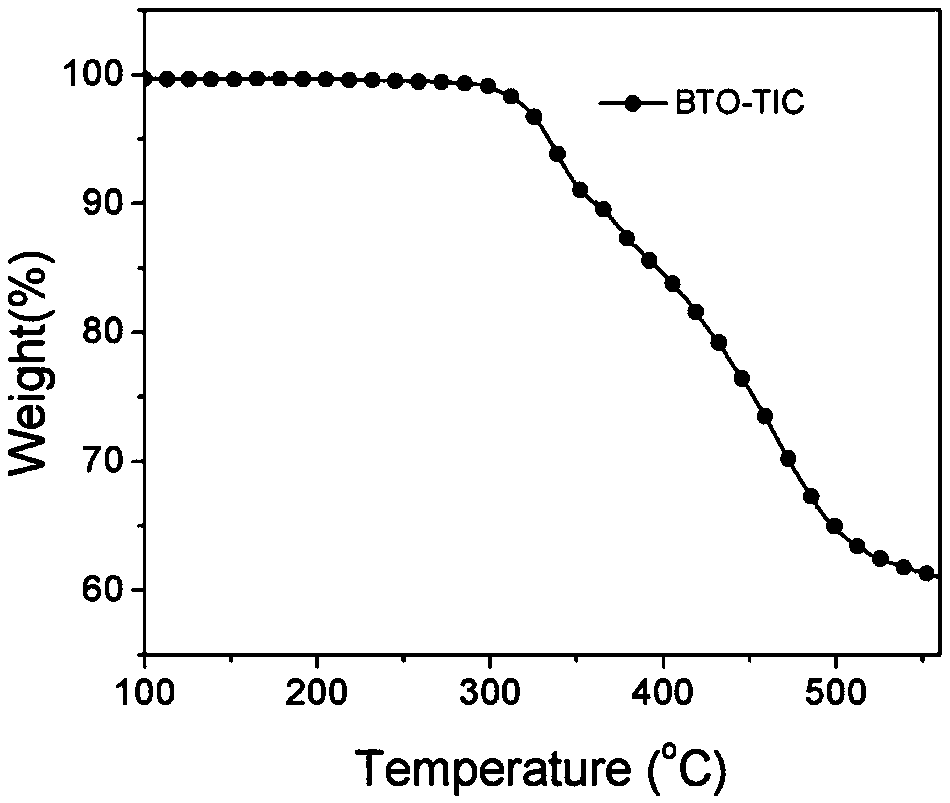

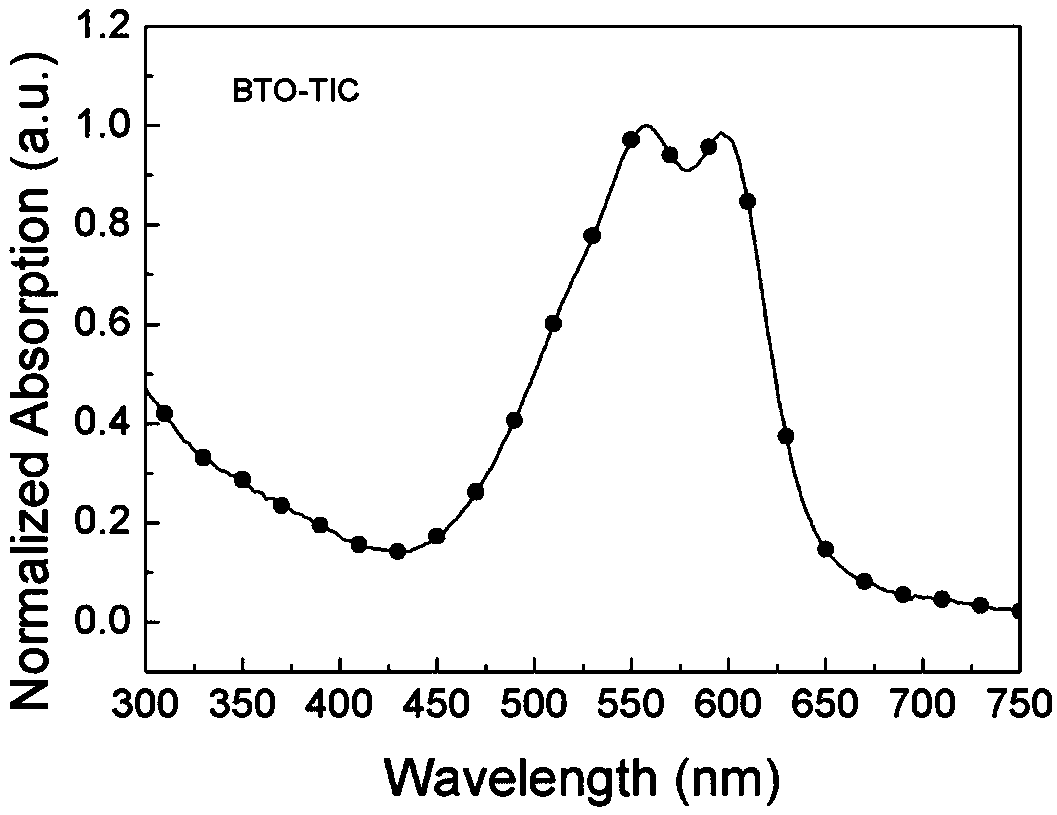

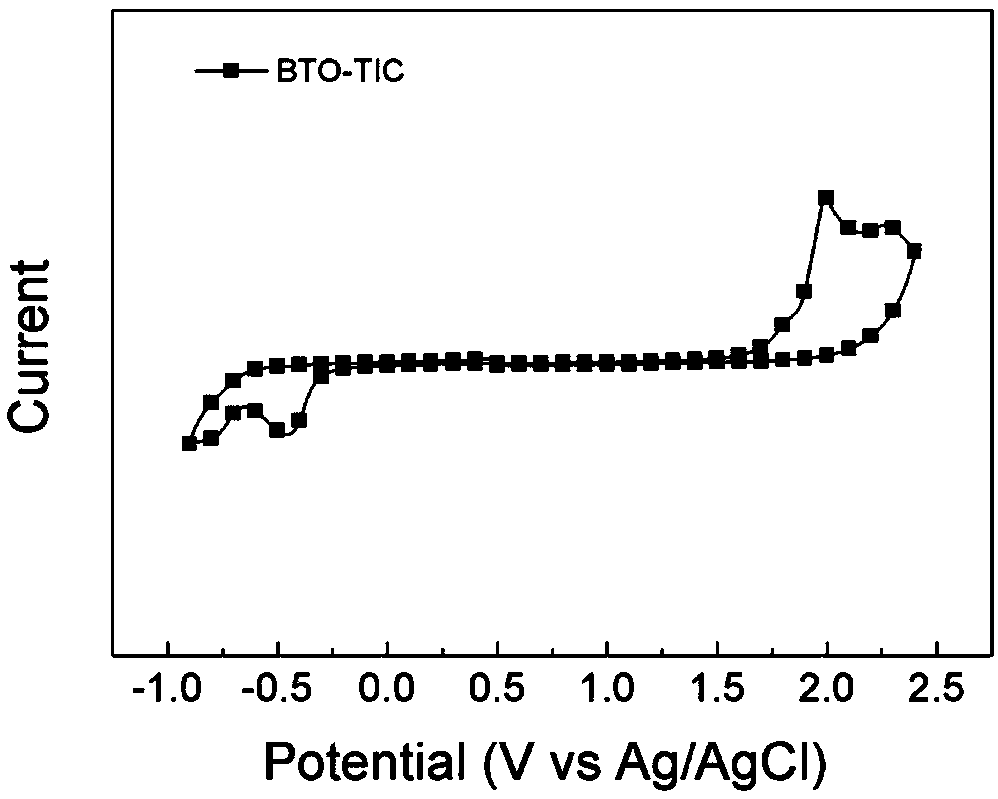

A2-(pi-A1)2 wide band gap non-fullerene receptor material based on diphenylthiophenyl sulfone and preparation method and application thereof

InactiveCN109081825AHigh crystallinityReduce interactionOrganic chemistrySolid-state devicesHeterojunctionElectrochemistry

The invention relates to a preparation method of an A2-(pi-A1)2 wide band gap non-fullerene receptor material based on diphenylthiophenyl sulfone and an application thereof in a polymer photovoltaic device. The A2-(pi-A1)2 wide band gap non-fullerene receptor material based on the diphenylthiophenyl sulfone and the preparation method and application thereof are characterized in that the diphenylthiophenyl sulfone is a weak acceptor electron (A2) unit; the pi bridge is 3-alkyl thiophene or 3-oxyalkyl thiophene; a terminal strong acceptor electron (A1) unit is cyano indanone and fluorinated andchlorinated derivatives thereof; the wide band gap non-fullerene acceptor material has an electrochemical band gap of up to 2.01 electron volts and can be used as a receptor material applied to solution-processed polymer solar cells with narrow band gap polymers; when the polymer PTB7-Th is utilized as a donor, the maximum energy conversion efficiency and open circuit voltage of bulk heterojunction polymer solar cell are 1.77% and 0.89 volts, respectively. The A2-(pi-A1)2 wide band gap non-fullerene receptor material based on the diphenylthiophenyl sulfone has the advantage of achieving efficient energy conversion of the A2(pi-A1)2 wide band gap non-fullerene receptor material in the polymer solar cells.

Owner:CHANGZHOU UNIV

Corrugated board stacking device and stacking method

InactiveCN111807106AAvoid warpingQuality assuranceOverturning articlesPile receiversCorrugated fiberboardStructural engineering

The invention provides a corrugated board stacking device. The corrugated board stacking device comprises a third conveying mechanism, a conveying device, a fifth conveying mechanism and a stacking mechanism; a paperboard stack is conveyed on the third conveying mechanism; the conveying device comprises a trolley, two fourth conveying mechanisms and a overturning mechanism, the two fourth conveying mechanisms and the overturning mechanism are installed on the trolley, the trolley can move in the longitudinal direction, and the two fourth conveying mechanisms are distributed at intervals in thelongitudinal direction and used for bearing the paperboards separated from the third conveying mechanism; the overturning mechanism is used for overturning the paperboard stack on one fourth conveying mechanism by 180 degrees; the fifth conveying mechanism is used for bearing the paperboards separated from the fourth conveying mechanism; and the stacking mechanism is used for stacking the paperboard stack separated from the fifth conveying mechanism. According to the corrugated board stacking device, stacking is carried out in a forward-stacking and reverse-stacking mode, compared with a forward-stacking and reverse-stacking mode, the stacking efficiency is greatly improved, the automation degree of a processing line is high, manual guarding is not needed in the process, the labor intensity is reduced, and meanwhile the labor cost is saved.

Owner:朱蓉

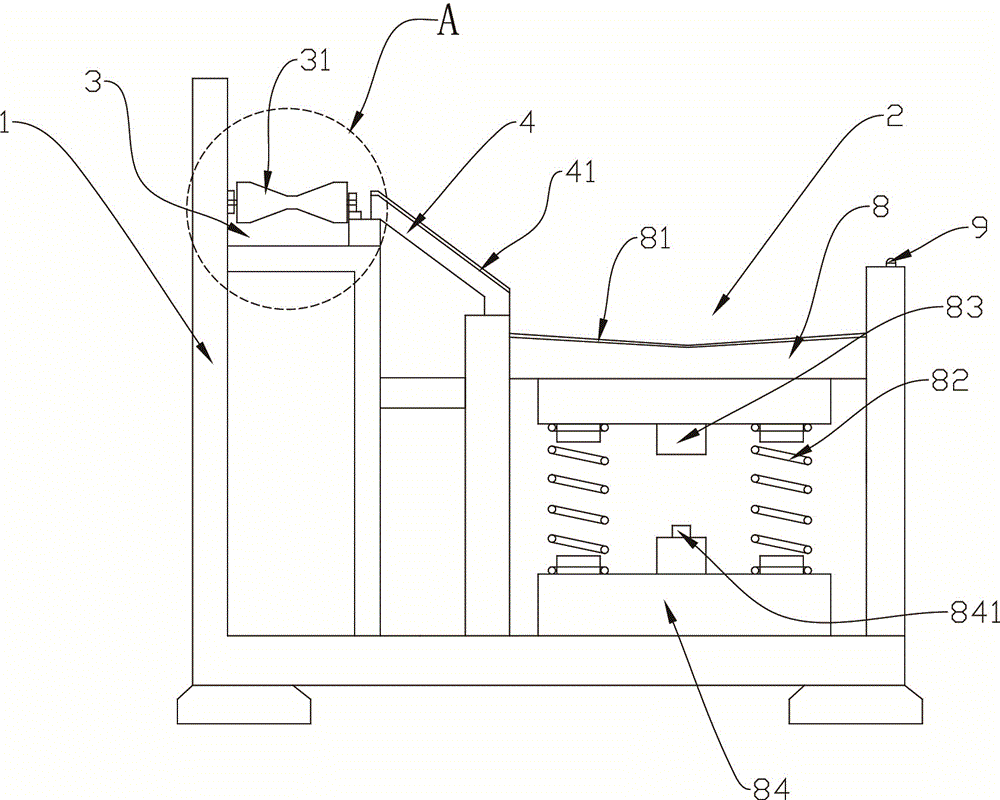

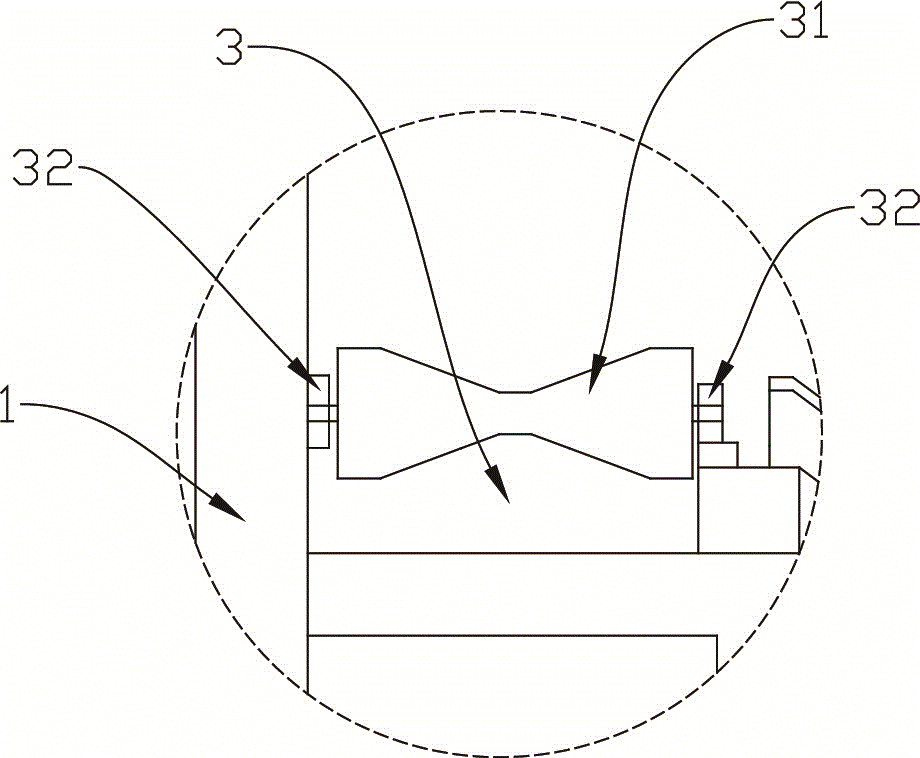

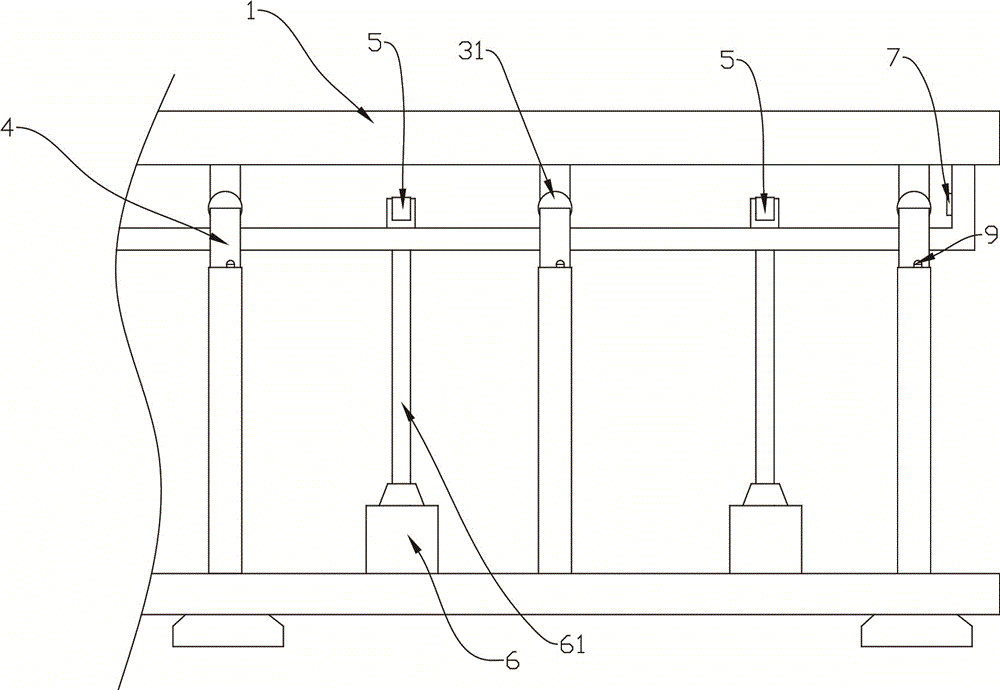

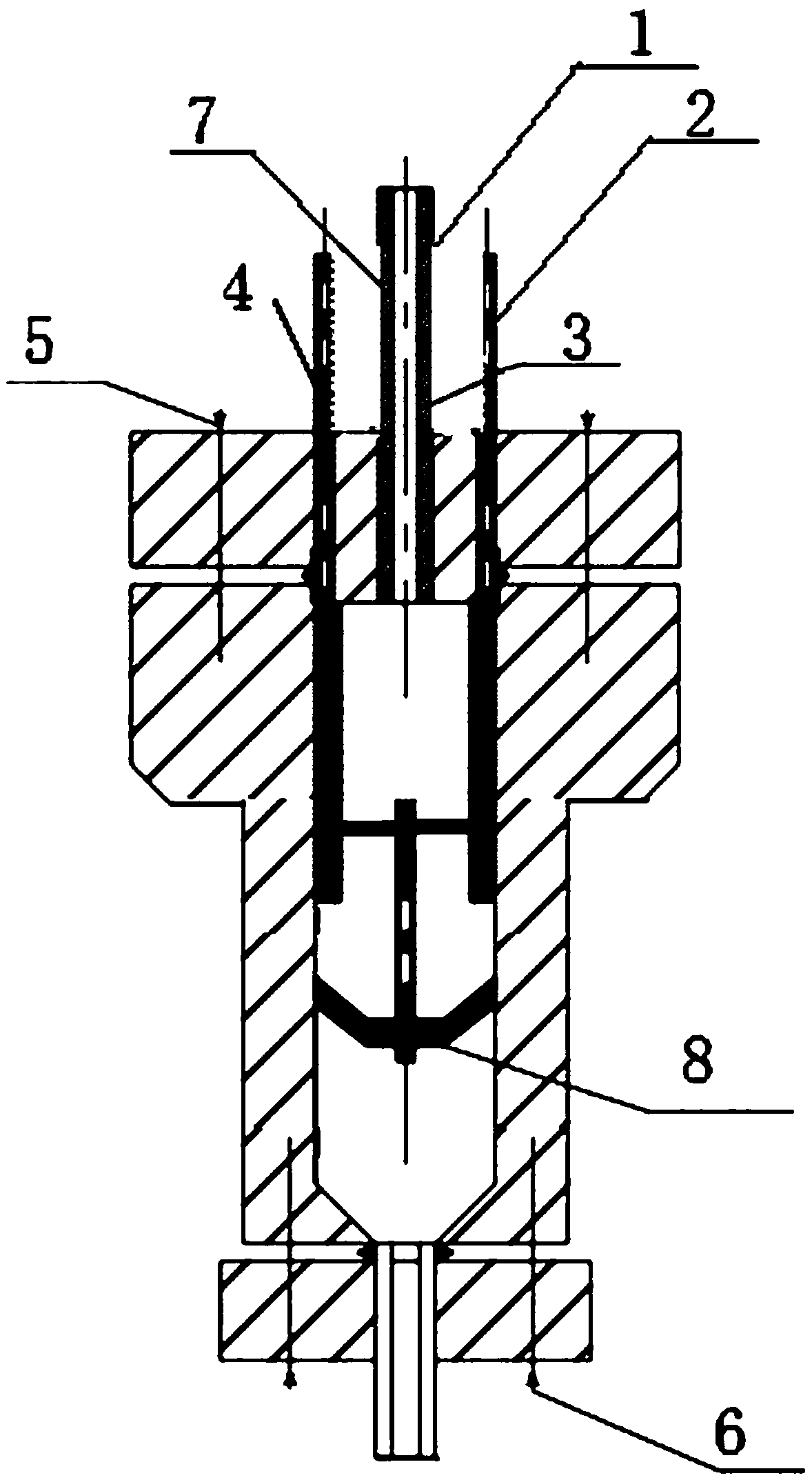

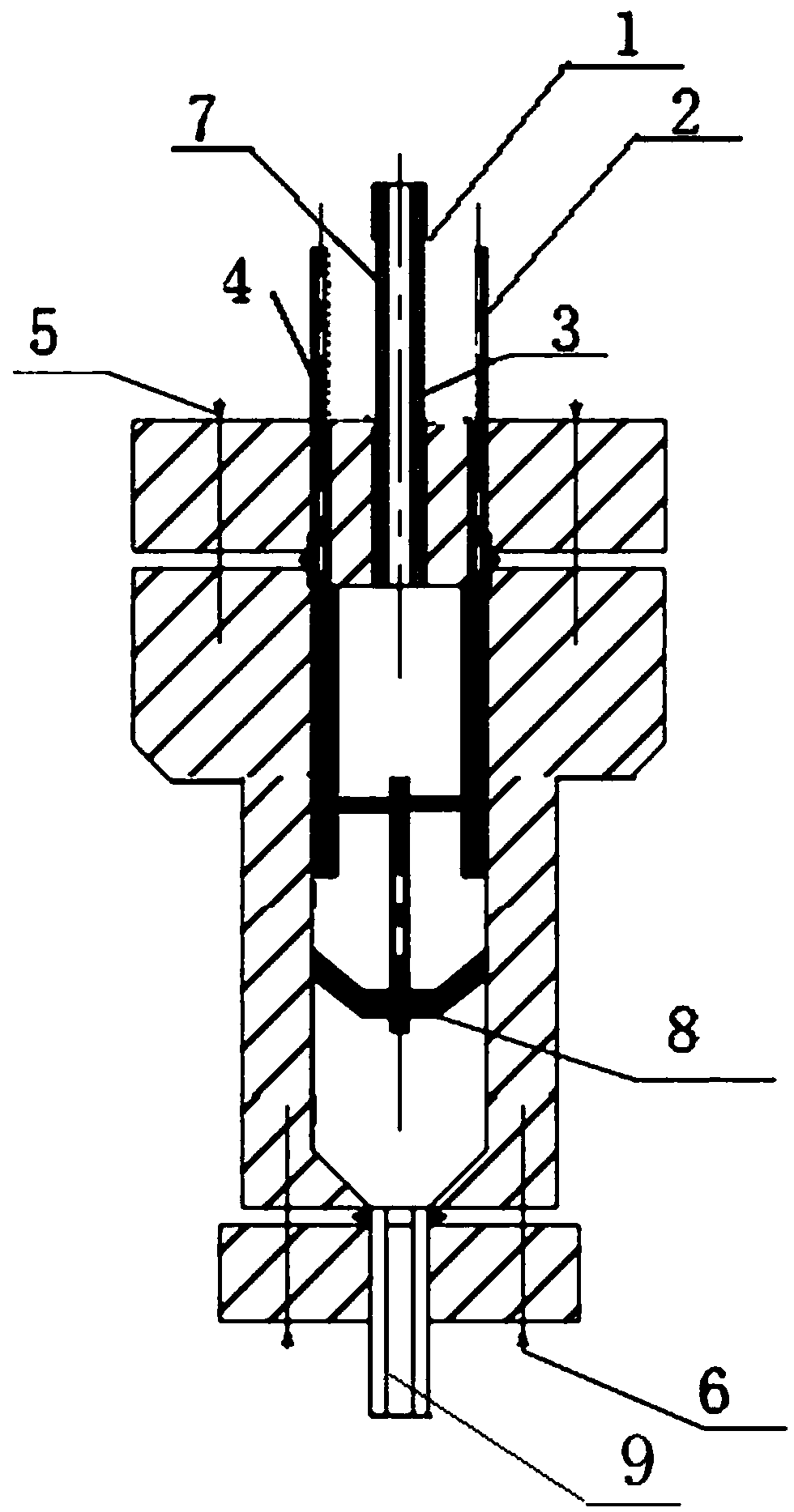

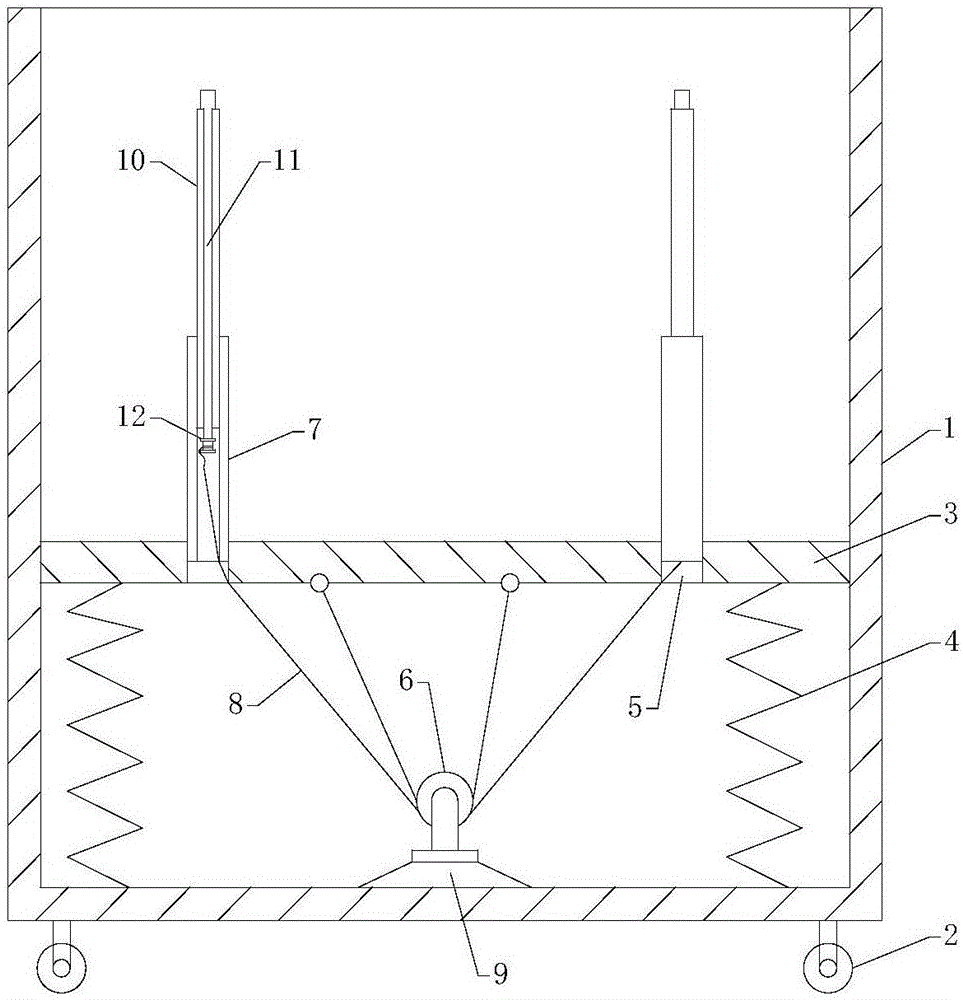

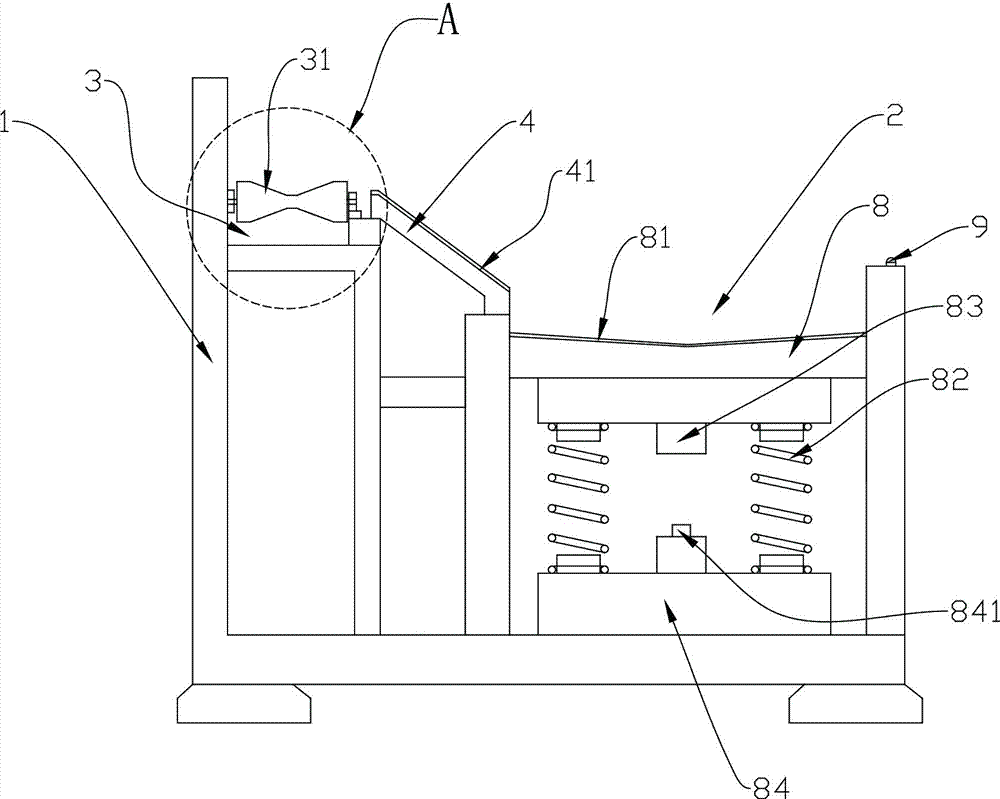

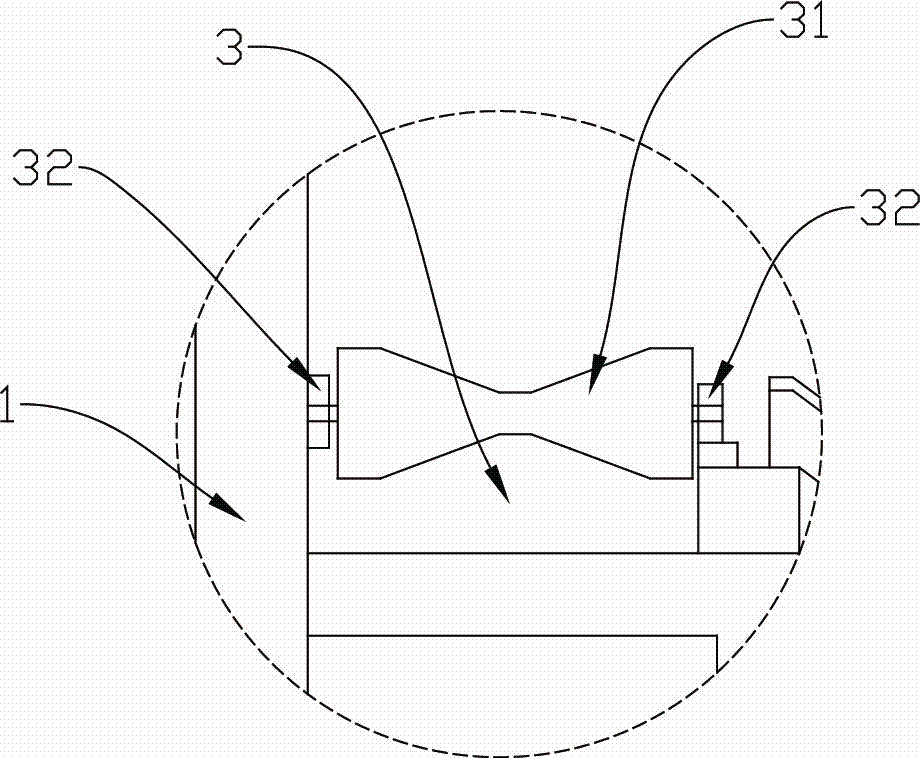

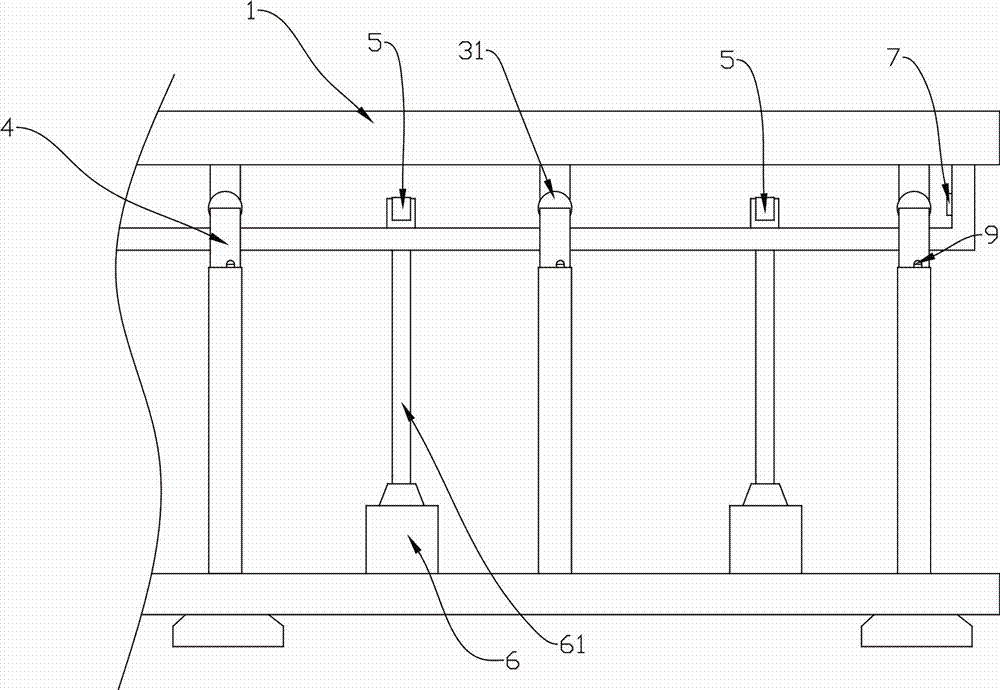

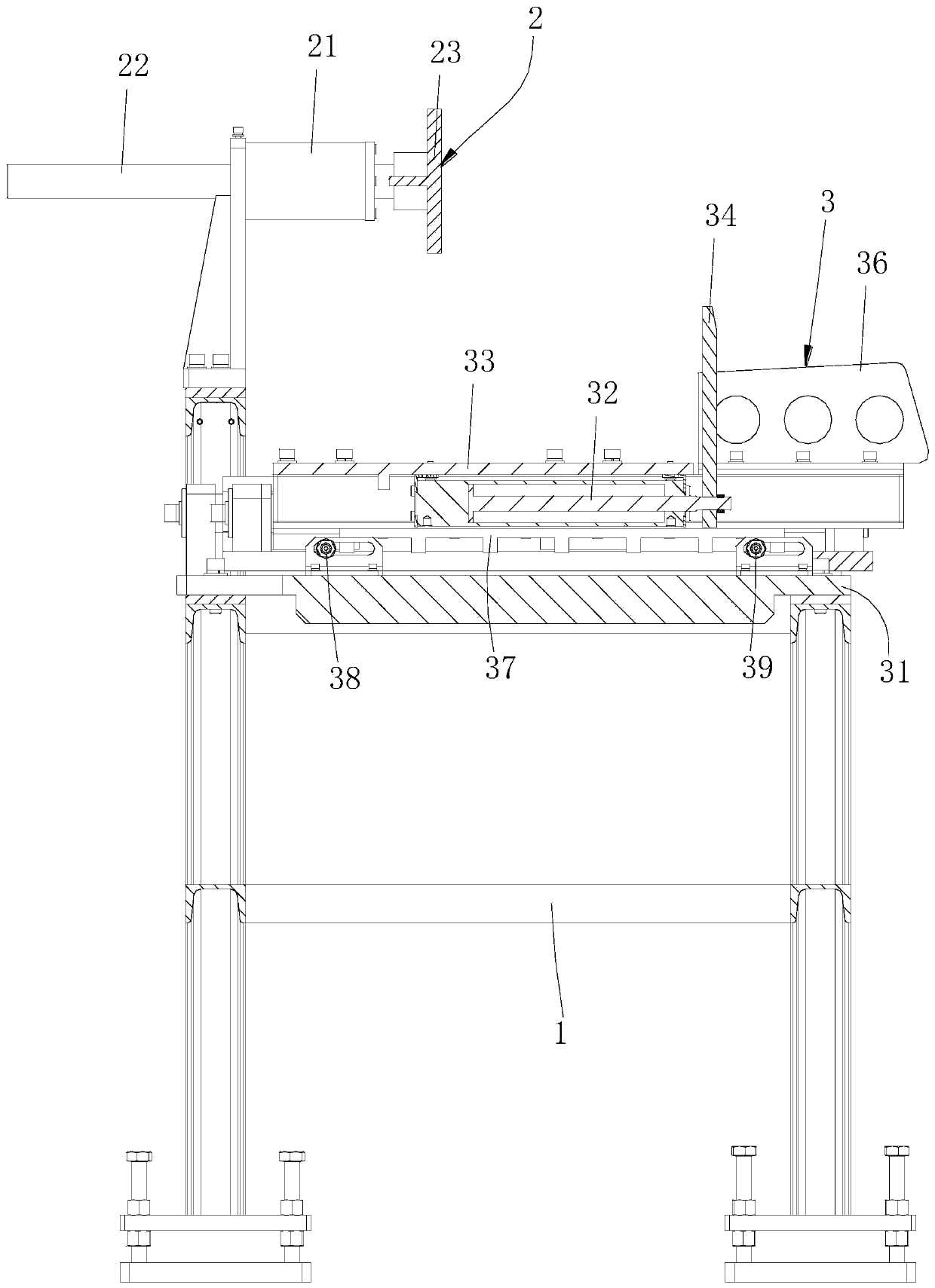

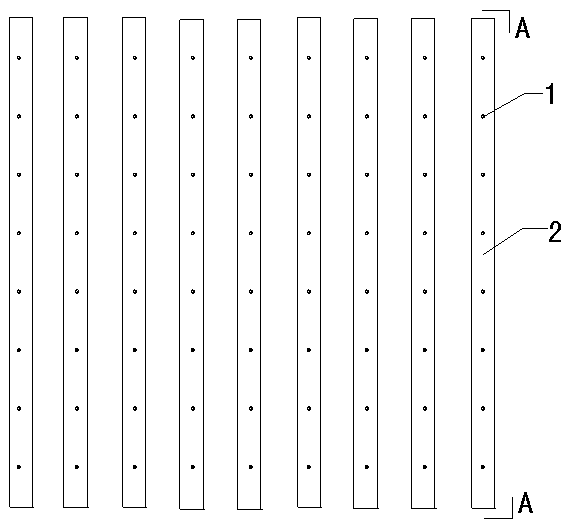

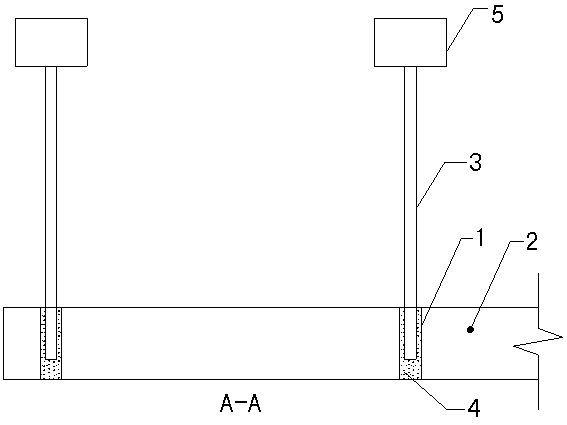

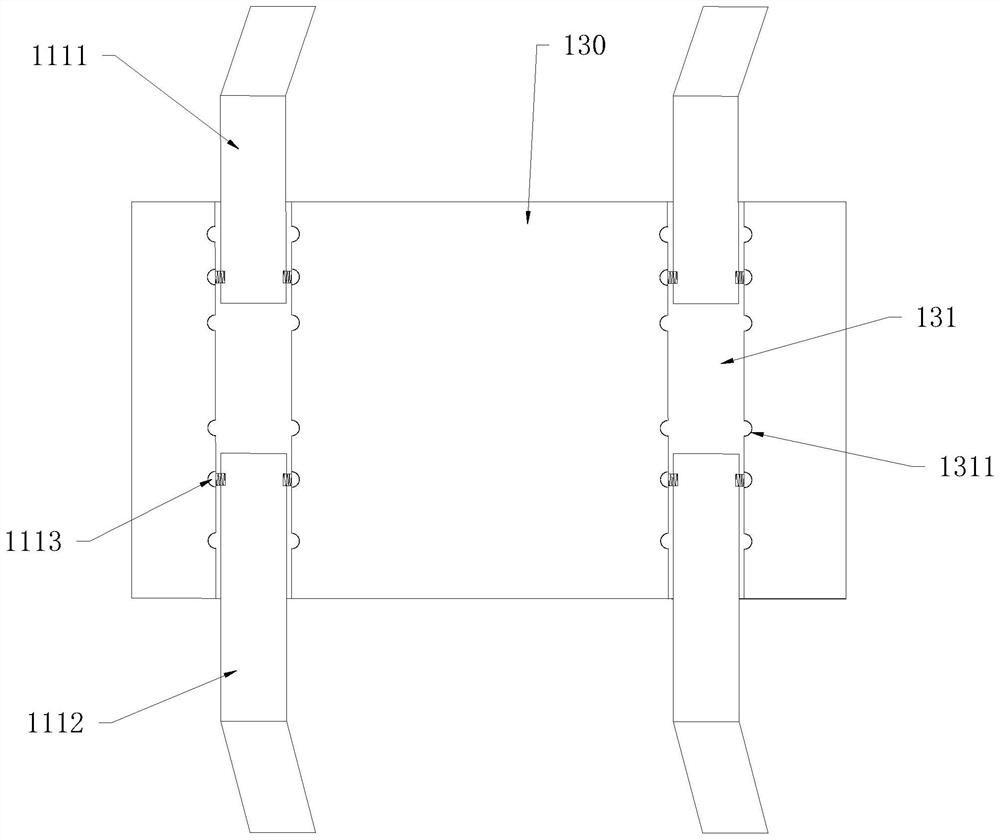

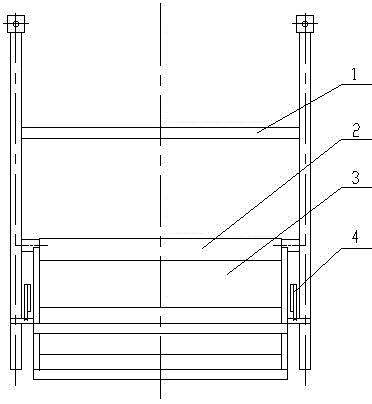

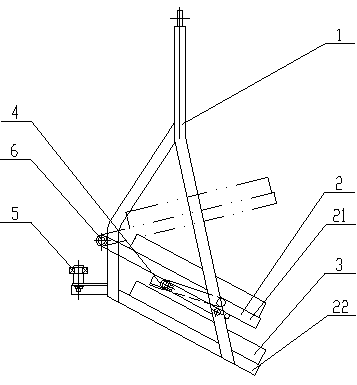

Automatic material-receiving frame of draw tube straightening machine

ActiveCN104942177AStacked in orderAvoid damageMetal-working feeding devicesPositioning devicesEngineeringRejection rate

An automatic material-receiving frame of a draw tube straightening machine comprises a frame body, wherein a draw pipe guide zone, a draw pipe falling zone and a draw pipe storage zone are arranged on the frame body, a guide roller, a turnover mechanism and a switch for opening the turnover mechanism in a control mode are arranged in the draw pipe guide zone, the turnover mechanism comprises a motor, and the motor is connected with the other end of a swing rod with one end movably connected to the frame body through a connecting rod. A liftable base is arranged in the draw pipe storage zone, the base is connected with a fixing block arranged on the frame body through an elastic supporting part arranged under the base, a reminding switch connected with a reminding device is arranged on the fixing block, and the base can trigger the reminding switch during descending. By means of the automatic material-receiving frame, the labor cost is reduced, rejection rate is reduced, and production efficiency is improved.

Owner:NINGBO KENO ALUMINUM

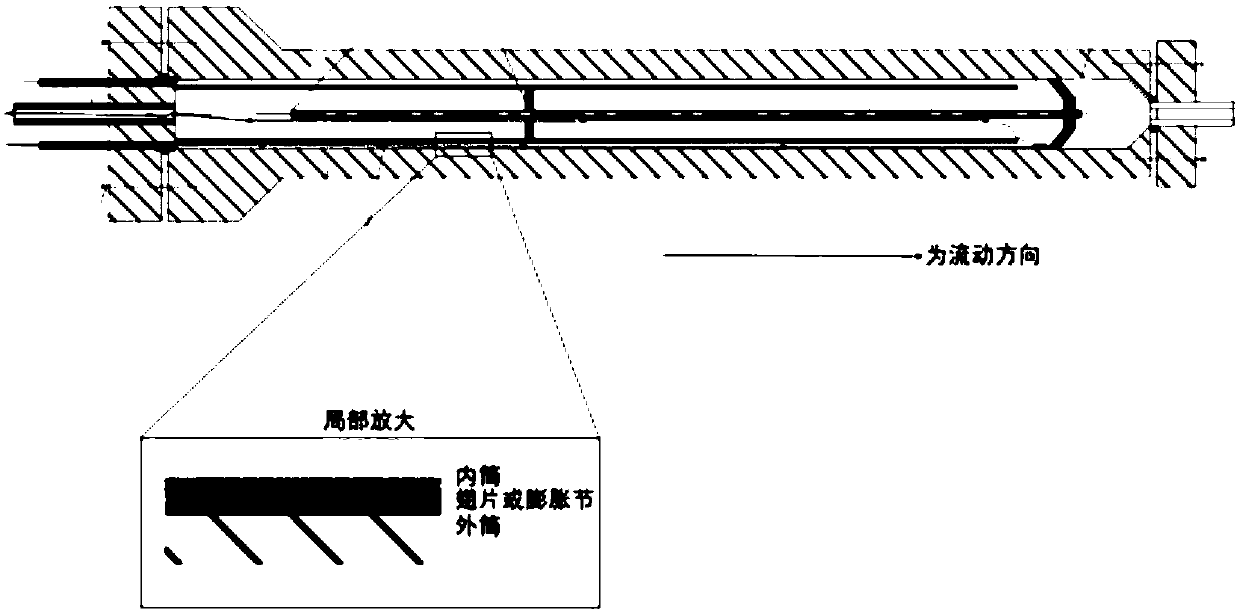

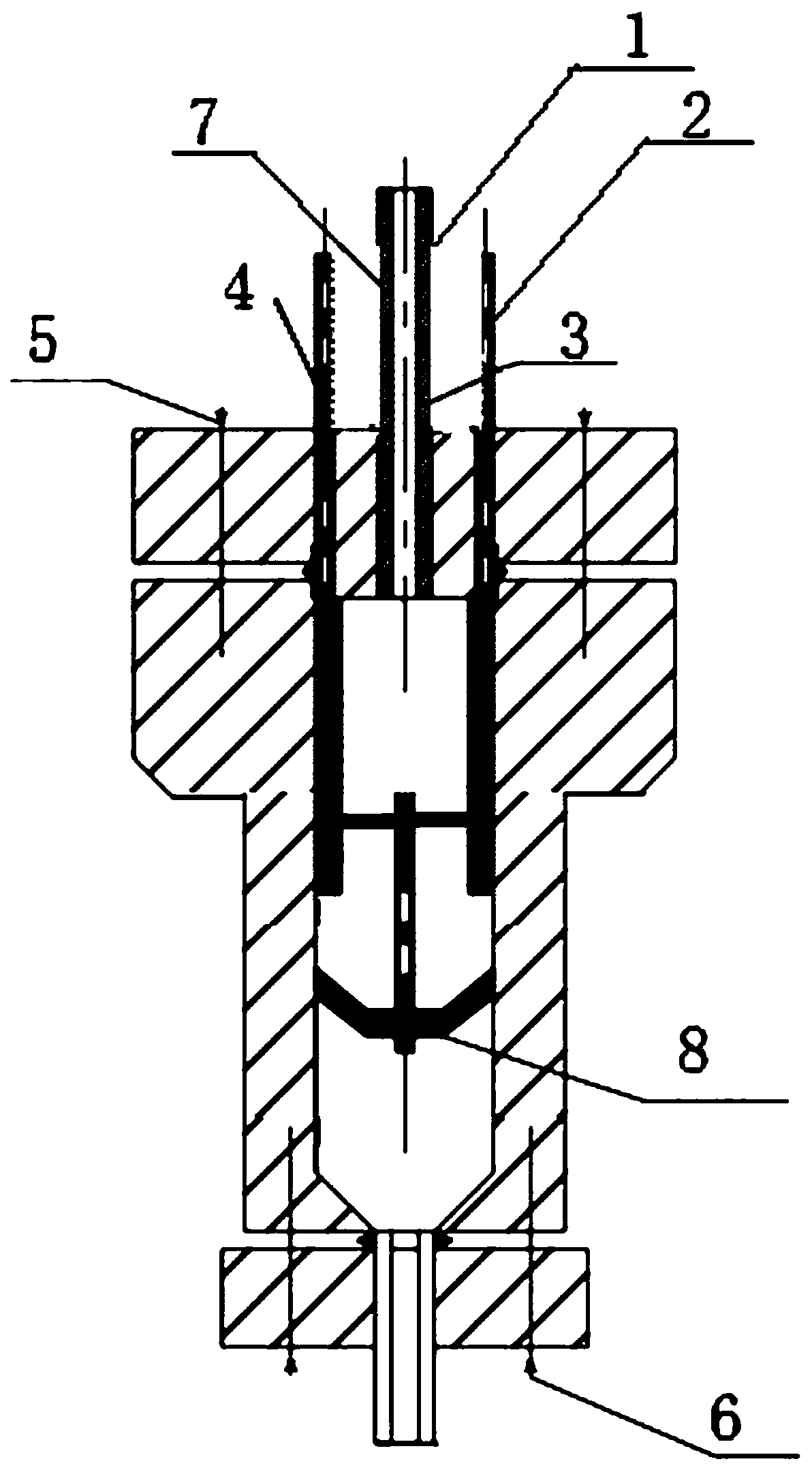

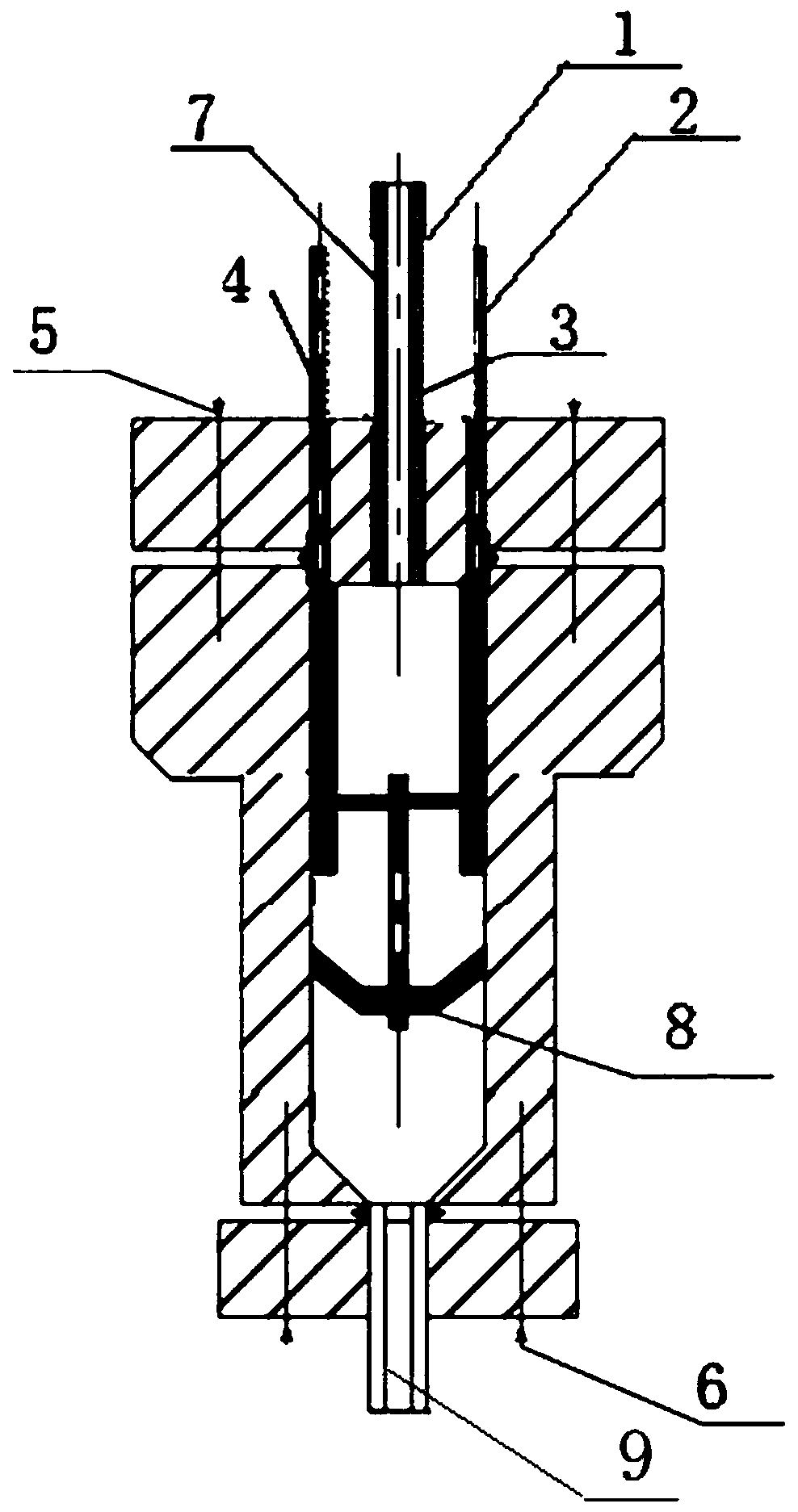

Pipe type supercritical water oxidization reactor and supercritical water oxidization system and method

ActiveCN109592774AIncrease flow itinerarySimple processWater/sewage treatment apparatusWater/sewage treatment by oxidationEngineeringExpansion joint

The invention provides a pipe type supercritical water oxidization reactor and a supercritical water oxidization system and method. The pipe type supercritical water oxidization reactor comprises an inner barrel and an outer barrel; the outer barrel sleeves the outer part of the inner barrel; a material inlet is arranged between the inner barrel and the outer barrel; a material outlet is formed inthe top of the inner barrel and a working medium flows in from the gap between the inner barrel and the outer barrel and flows out from the top of the inner barrel; and a fin or an expansion joint isadditionally arranged in the gap between the inner barrel and the outer barrel, so that the turbulent flow is increased, a flow path is lengthened and the heat exchange is reinforced.

Owner:SHANDONG UNIV

Medical cotton swab processing device

ActiveCN111992571AStacked in orderTimely collectionSolid waste disposalFurniture waste recoveryBiotechnologyCross infection

The invention relates to the field of medical treatment, and particularly relates to a medical cotton swab processing device. The medical cotton swab processing device comprises a working frame plate,a fixed bottom plate, a feeding port, an operation control screen, a transfer mechanism, a cotton ball separation mechanism, a storage cabin and a stick collection mechanism, wherein the working frame plate is welded with the fixed bottom plate. The medical cotton swab processing device has the advantages that used cotton swabs are collected in time, the risk of cross infection caused by volatilization of liquid with germs is prevented, the cotton swabs are separated from cotton balls and sticks, the cotton balls with the liquid are placed in a centralized manner, the cotton balls can be processed in a centralized manner, the sticks are stacked in order, space is saved, and subsequent processing is benefited.

Owner:山东昊硕世纪医疗科技有限公司

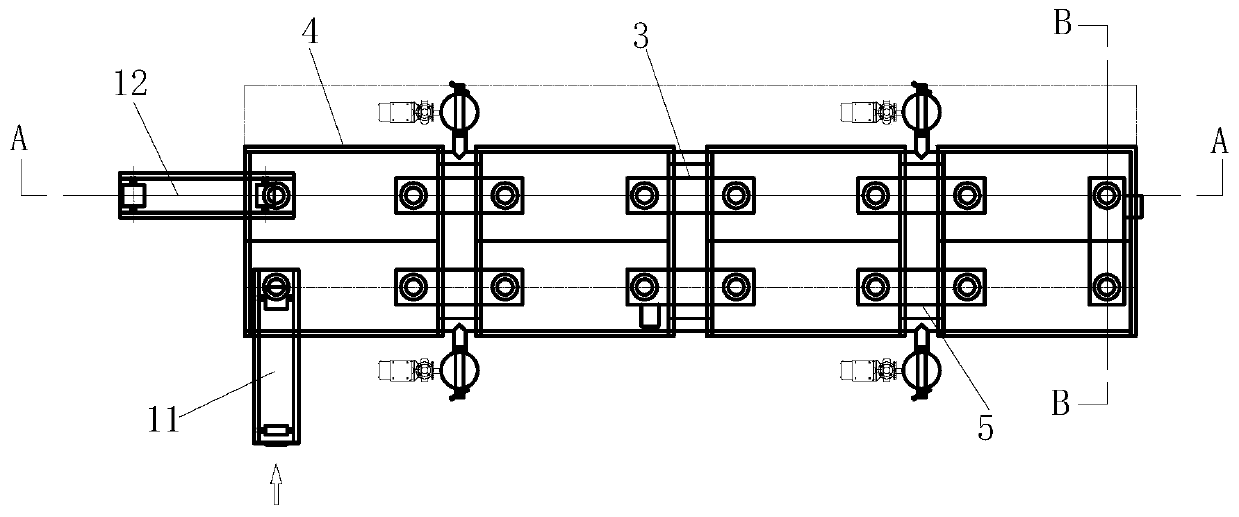

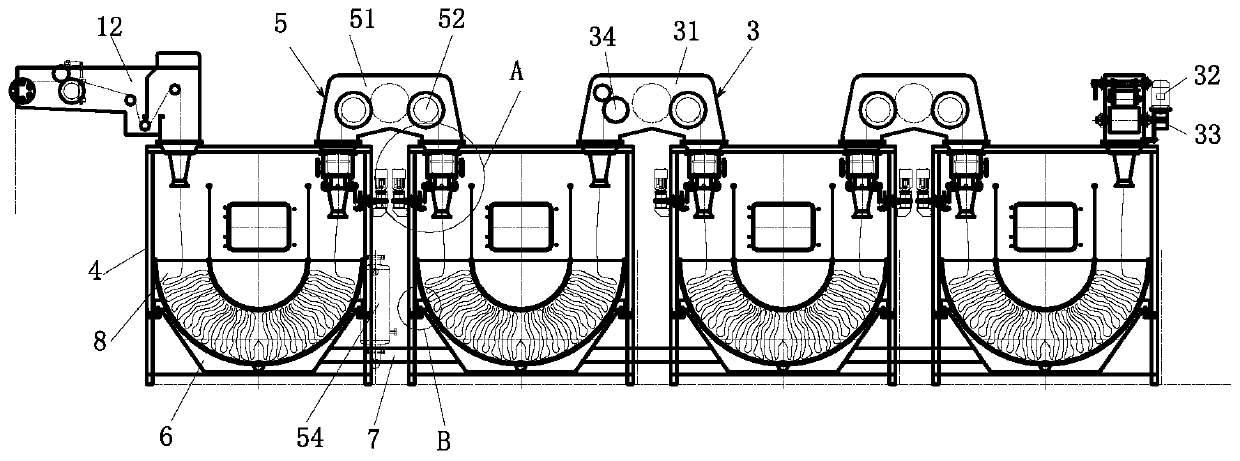

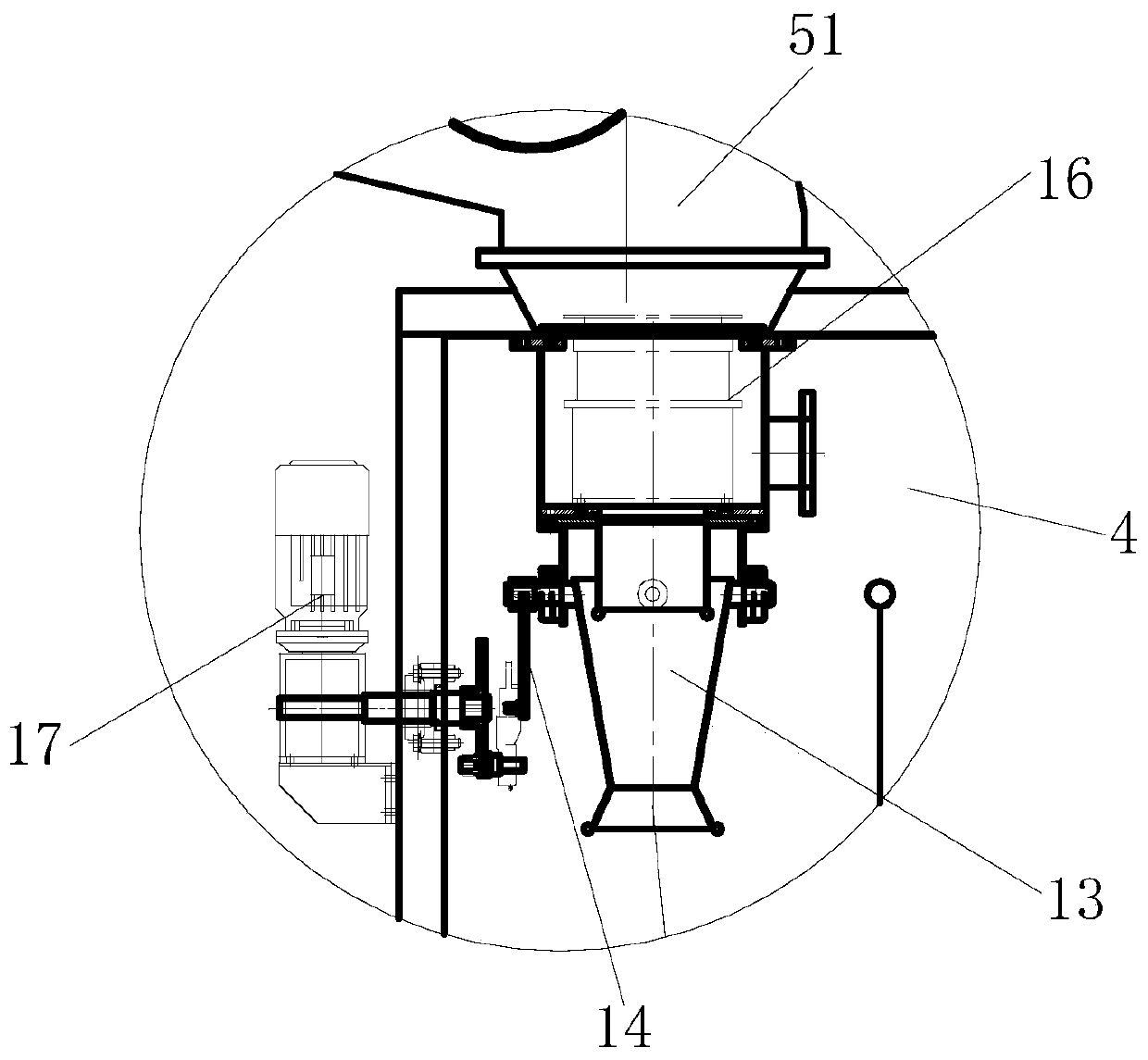

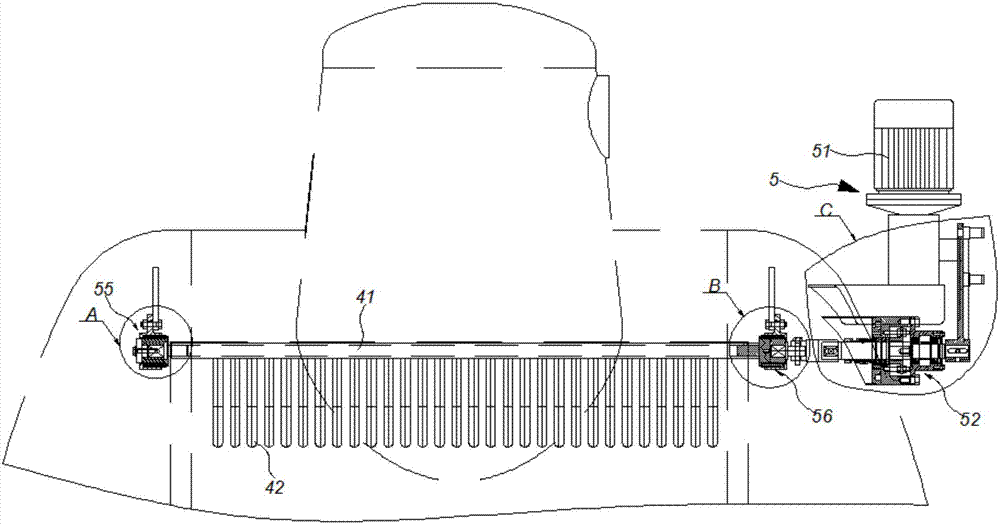

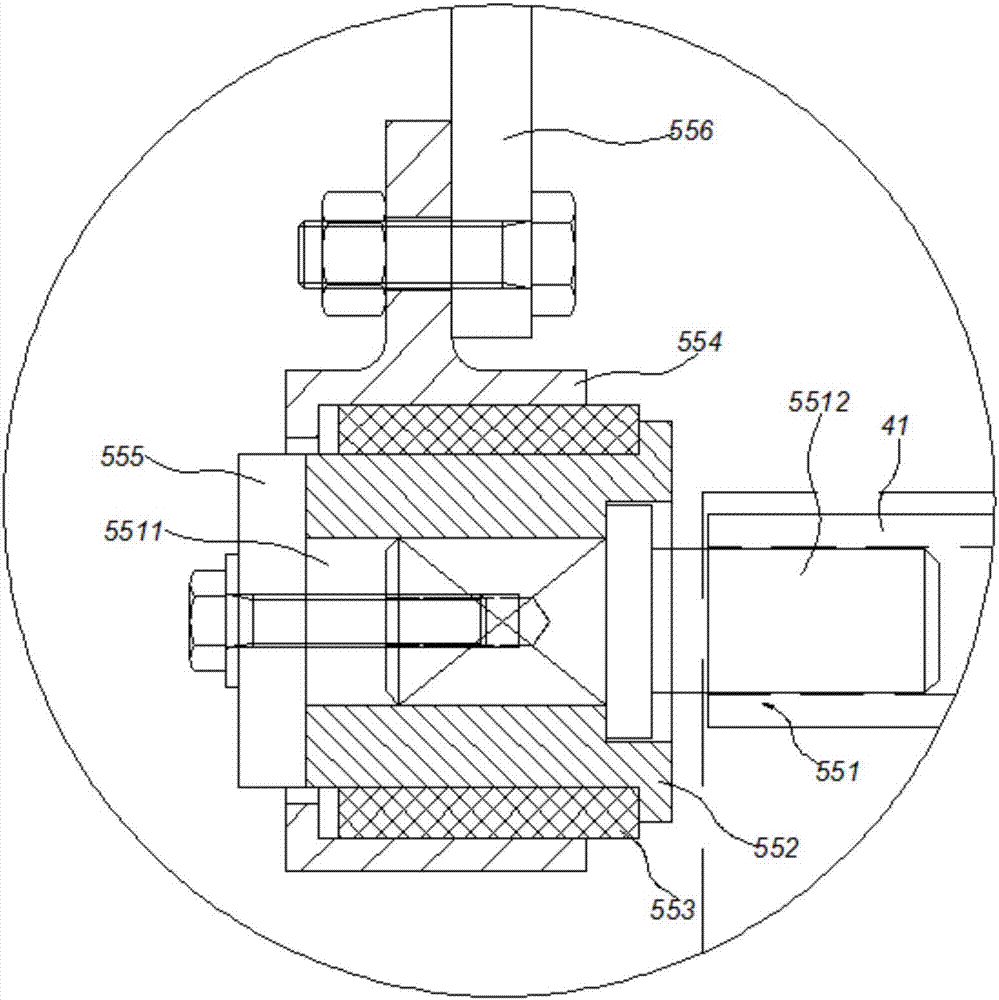

Intelligent jet airflow overflow combination machine

ActiveCN111088624AIntelligent operationIncrease productivityTextile treatment containersLiquid/gas/vapor treatment of propelled fabricsReciprocating motionEngineering

The invention belongs to the technical field of printing and dyeing equipment, and discloses an intelligent jet airflow overflow combination machine. The intelligent jet airflow overflow combination machine comprises a combination machine body composed of a plurality of sets of airflow overflow nozzles which achieve high-speed reciprocating motion of fabric between cloth containing cylinders through a high-pressure water pump, the front part of a combination body has a cloth feeding function, and the rear part of the combination body has a cloth discharging function. According to the intelligent jet airflow overflow combination machine, a plurality of sets of U-shaped cloth containing cylinder bodies are connected in series, the fabric is driven to reciprocate through the high-speed large-flow water pump between the cylinder bodies, and the fabric continuously runs from a cloth feeding direction to a cloth discharging direction at the production process speed of 20-100 m / min; the clothcontaining amount of each cloth containing cylinder is about 1200 m (according to the difference of fabric gram amounts), the cloth containing amount of each cloth containing cylinder is detected bya gravity sensor in the production operation process, signals generated by the gravity sensor are processed by a PLC, the flow speed and the flow direction of water are controlled by controlling the pump and a valve, the equipment operates intelligently, and the production efficiency is greatly improved.

Owner:江苏赛格纺织机械有限公司

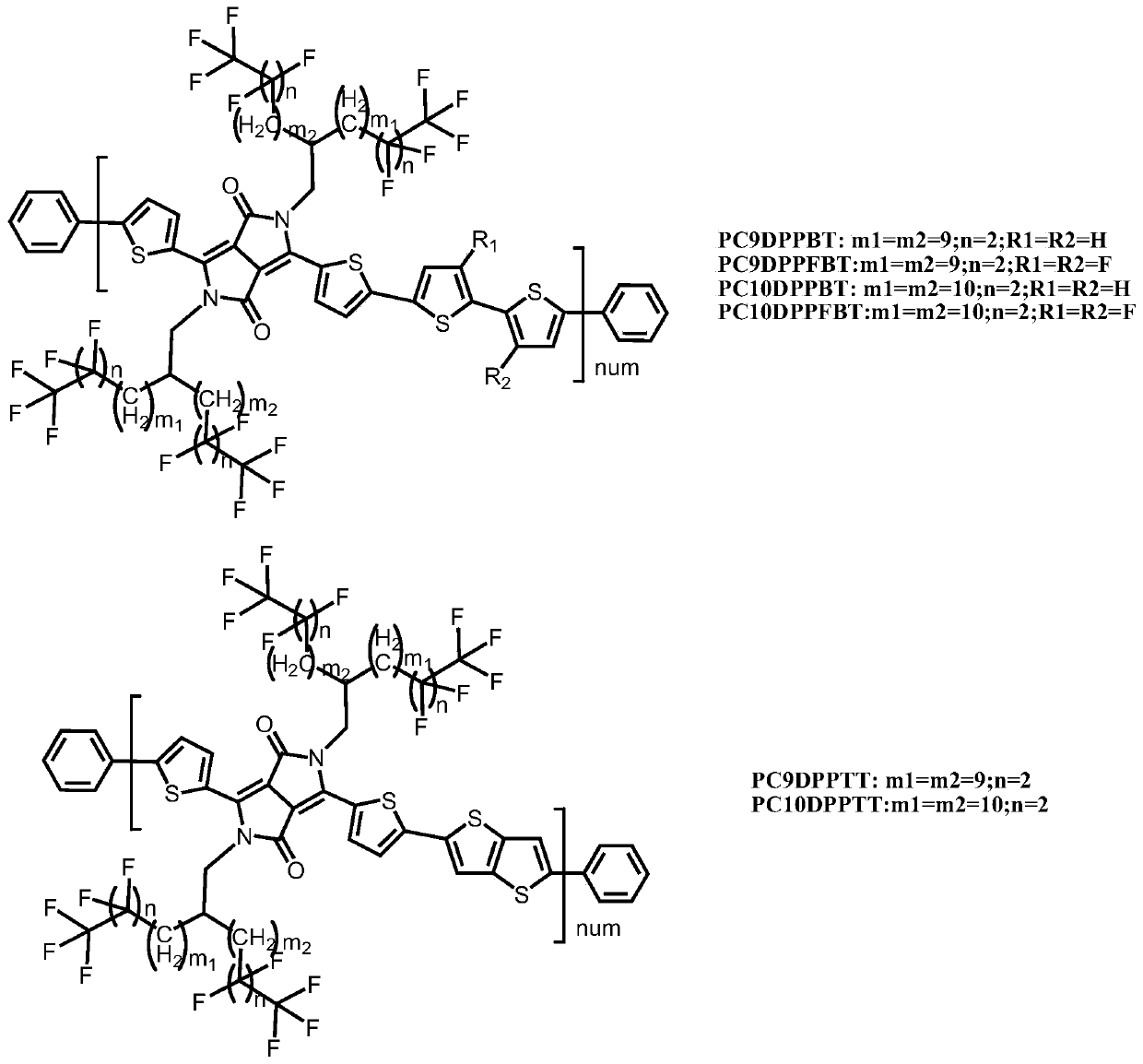

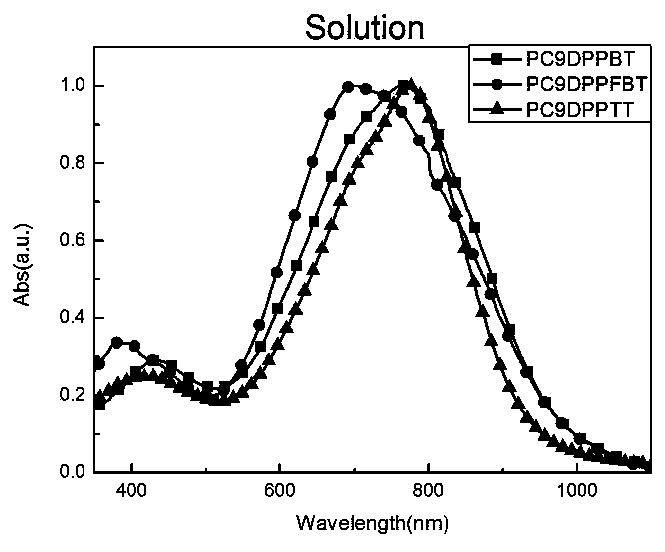

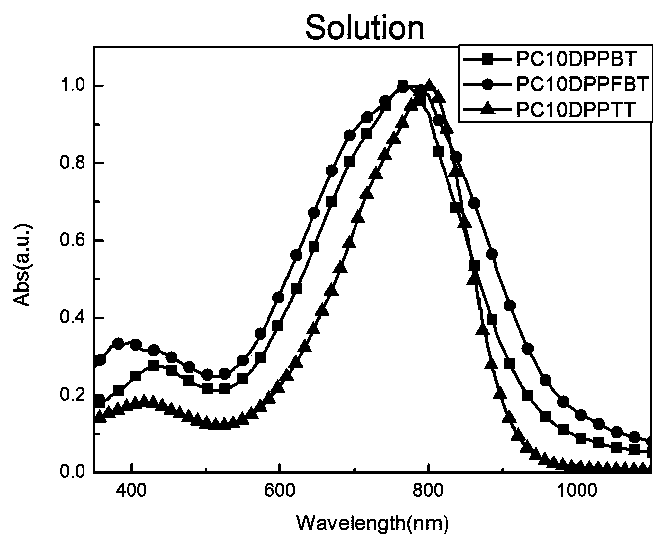

Semi-fluoroalkyl containing side chain substituted pyrrolo pyrroledione polymer as well as preparation method and application of semi-fluoroalkyl containing side chain substituted pyrrolo pyrroledione polymer

PendingCN109912784AEasy to synthesizeLow costSolid-state devicesSemiconductor/solid-state device manufacturingPolymer scienceSide chain

The invention discloses a semi-fluoroalkyl containing side chain substituted pyrrolo pyrroledione polymer, and particularly relates to the semi-fluoroalkyl containing side chain substituted pyrrolo pyrroledione polymer as well as a preparation method and an application of the semi-fluoroalkyl containing side chain substituted pyrrolo pyrroledione polymer. The provided synthesis route has the advantages of simplicity, high efficiency, low synthesis cost, good universality and repeatability, and the like, and can be popularized and applied to the synthesis of pyrrolo pyrroledione polymers of other various substituent groups. The migration rate of OTFTs (Organic Thin Film Transistors) prepared by taking the polymer PC10DPPBT as an organic semiconductor layer is as high as 0.0082 cm<2> / V.s, and the excellent application prospect of the polymer material in the OTFTs is fully shown.

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION

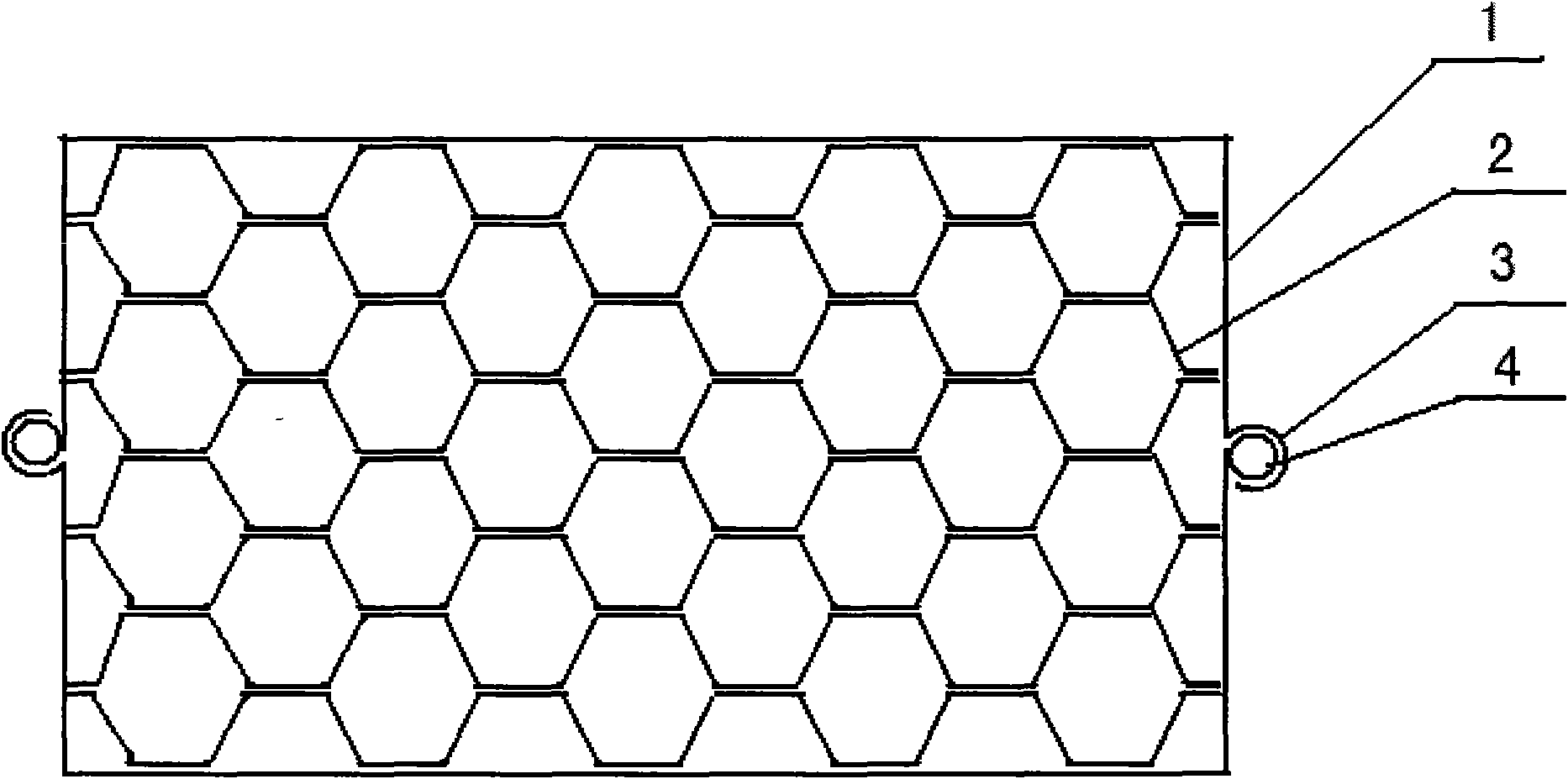

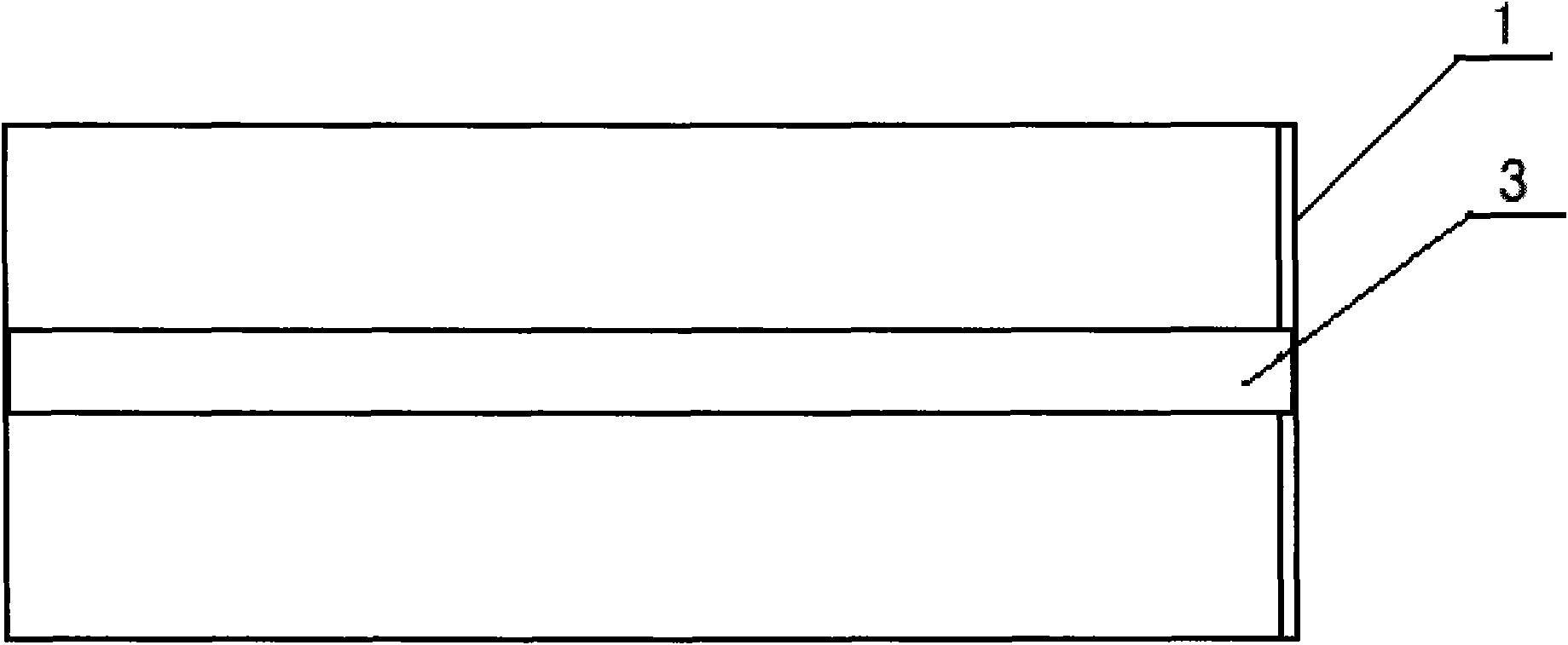

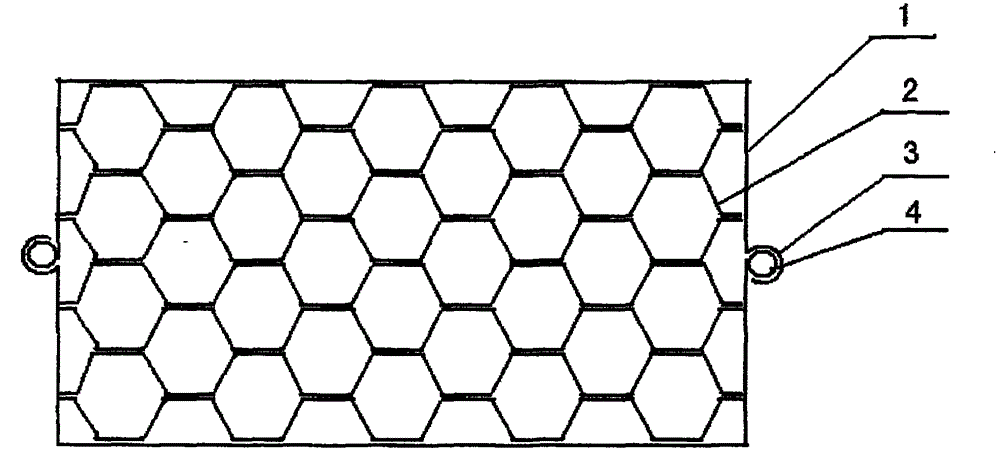

Osmia panzer honeycomb box

The invention relates to an osmia panzer honeycomb box used for fruit tree pollination, comprising a shell, honeycomb plates, clamping grooves and positioning bolts, wherein the upper part and the lower part of the shell are movably connected together through the clamping grooves and the positioning bolts; and the honeycomb plates are stacked in the shell to form a hexagonal honeycomb-shaped structure. The invention has simple operation, no damages to bee cocoons, higher osmia panzer nidificating efficiency, benefit to storage, recycling and investment saving.

Owner:宋海涛

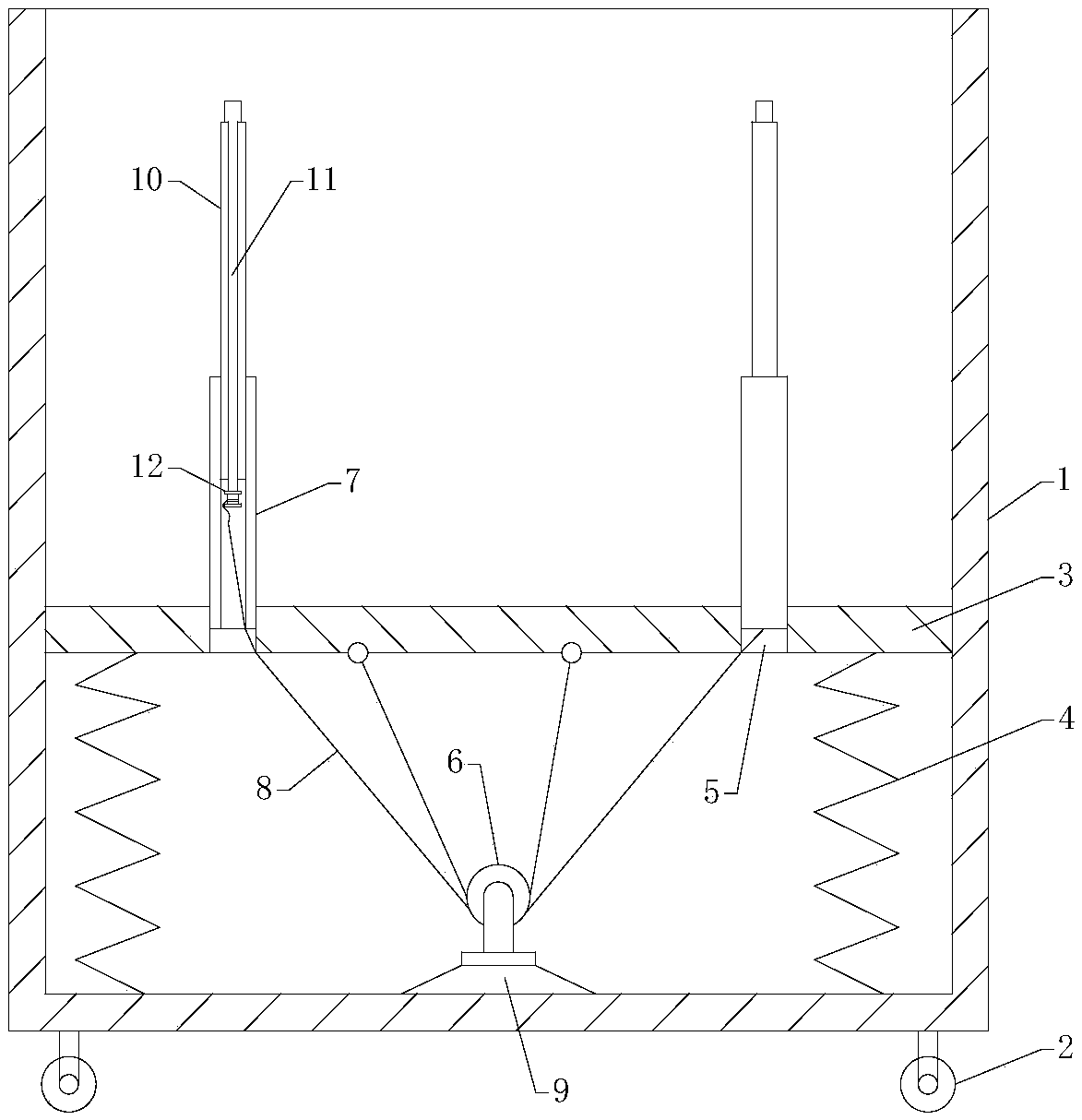

Automobile stamped part transfer trolley

InactiveCN106218677AStacked in orderMaintenance saves time and effortHand carts with multiple axesPulp and paper industryScrew thread

The invention discloses an automobile stamped part transfer trolley which comprises a box with the top provided with an opening. Wheels are arranged at the bottom of the box. A supporting plate is arranged in the box and connected with the bottom of the box through springs. A plurality of through holes are evenly formed in the supporting plate. The trolley further comprises a fixed pulley and a plurality of positioning rods, and the number of the positioning rods is not greater than the number of the through holes. Each positioning rod comprises a lower pipe body in threaded connection with the corresponding through hole and an upper rod body in sliding connection with the lower pipe body, wherein the upper rod body is connected with the bottom of the supporting plate through a pull rope, one end of the pull rope is connected with the upper rod body, and the other end of the pull rope sequentially penetrates through the lower pipe body and the corresponding through hole and then winds across the fixed pulley to be connected with the bottom of the supporting plate. When the automobile stamped part transfer trolley of the structure is used for transferring stamped parts, the stamped parts can be stacked in order, and time and labor can be saved when the stamped parts are taken.

Owner:重庆达升源汽车零部件有限公司

Cloth swinging device on side of dyeing machine

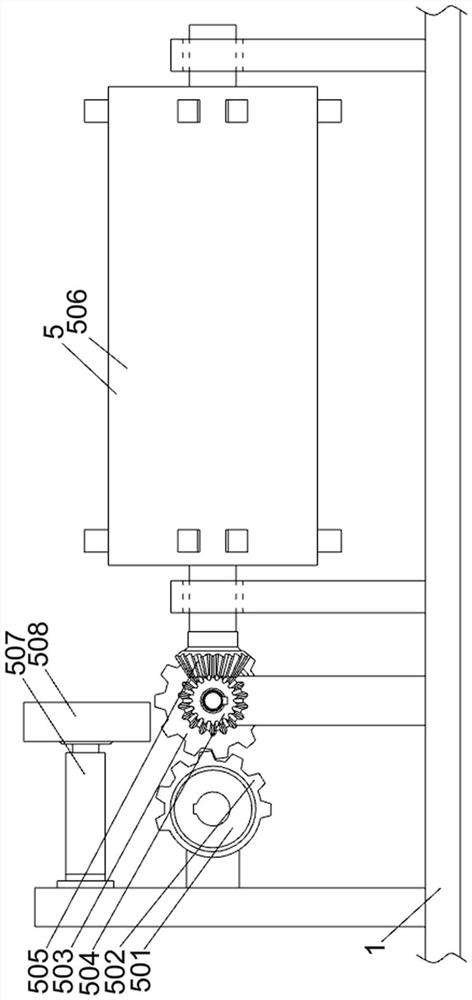

PendingCN107460677AImprove stacking statusStacked in orderTextile treatment carriersEngineeringGuide tube

The invention discloses a cloth swinging device on a side of a dyeing machine. The cloth swinging device on the side of the dyeing machine comprises a cylinder body, a cloth storage tank, a cloth guiding tube, a cloth beating plate and a swinging mechanism, wherein the cloth storage tank, the cloth guiding tube and the cloth beating plate are placed in the cylinder body; the swinging mechanism is mounted on the cylinder body; an output end of the cloth guiding tube and the cloth beating plate are oppositely placed in the cloth storage tank; and the swinging mechanism is in power connection to the cloth beating plate and drives the cloth beating plate to swing in the front-back direction of the cloth storage tank in a reciprocating manner. By the cloth swinging device on the side of the dyeing machine, the cloth-water separation effect is guaranteed, the bath ratio is reduced, meanwhile, fabrics are stacked orderly, and the device runs smoothly.

Owner:FOSHAN SON TECH PRECISION MACHINERY

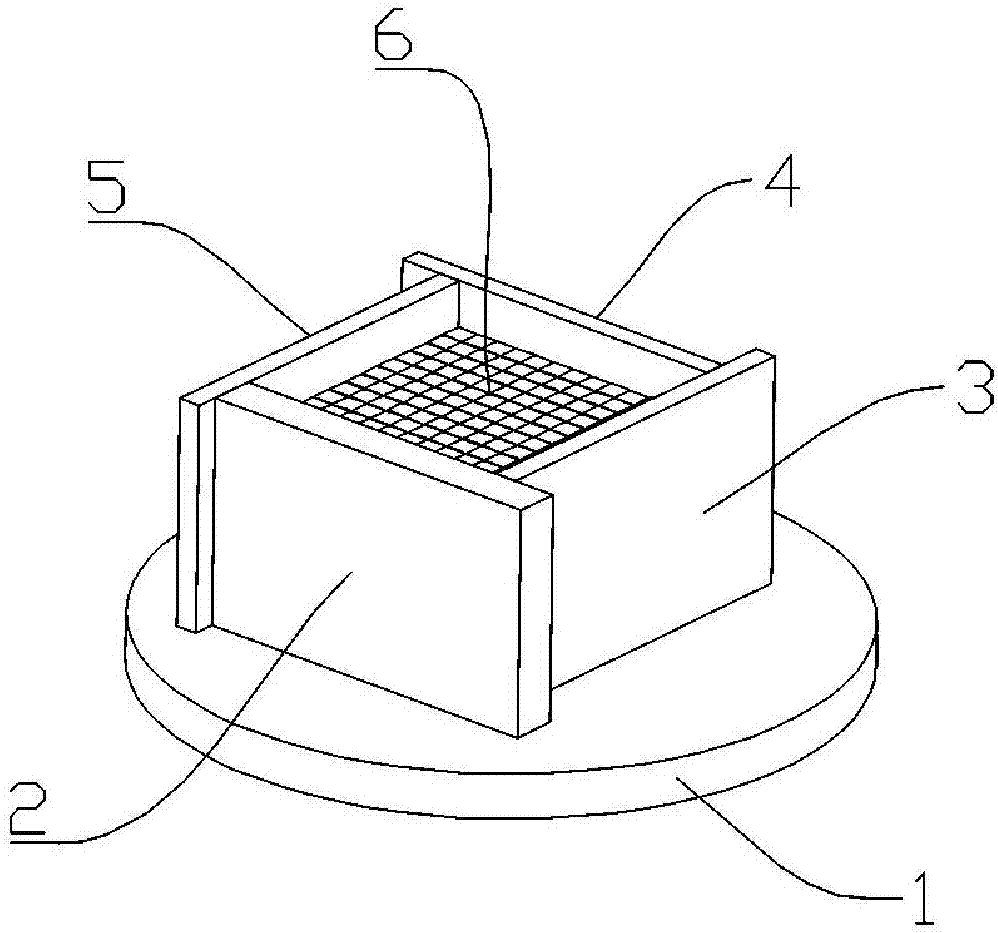

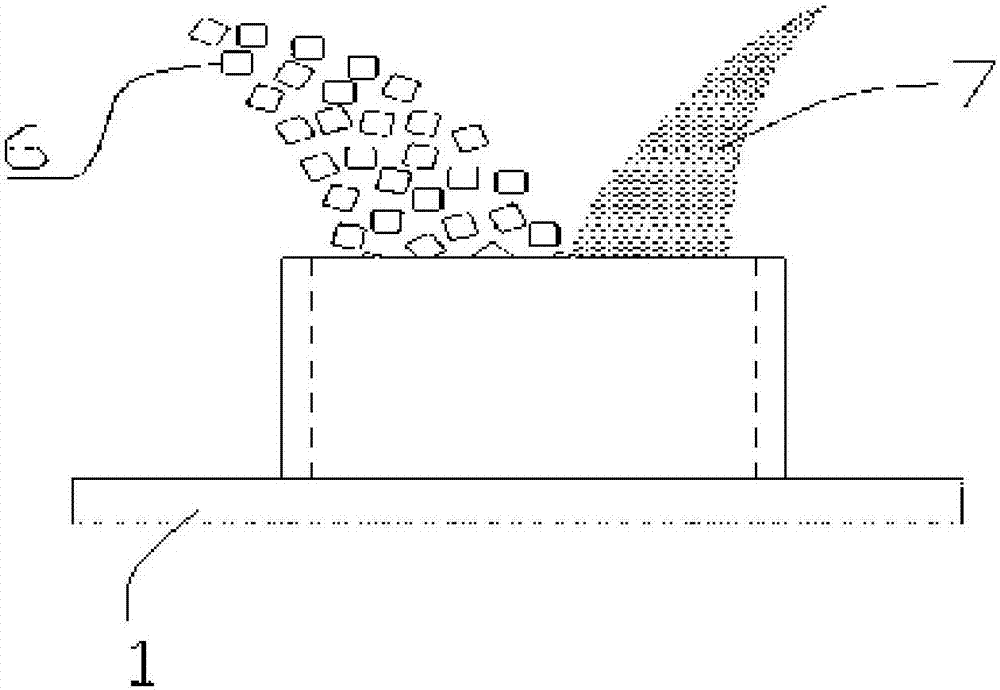

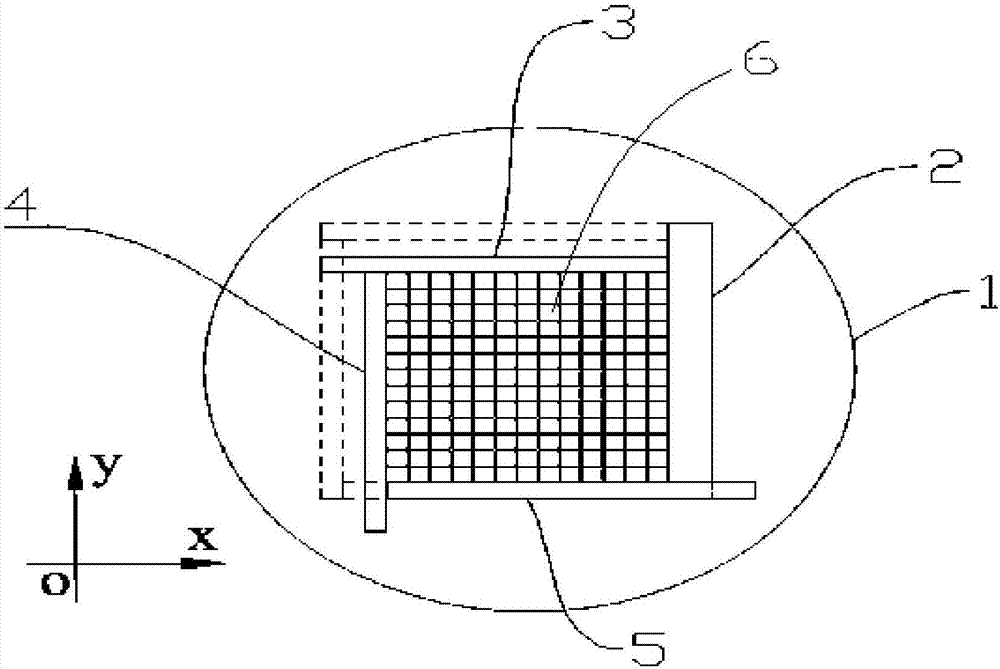

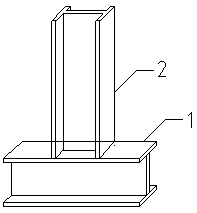

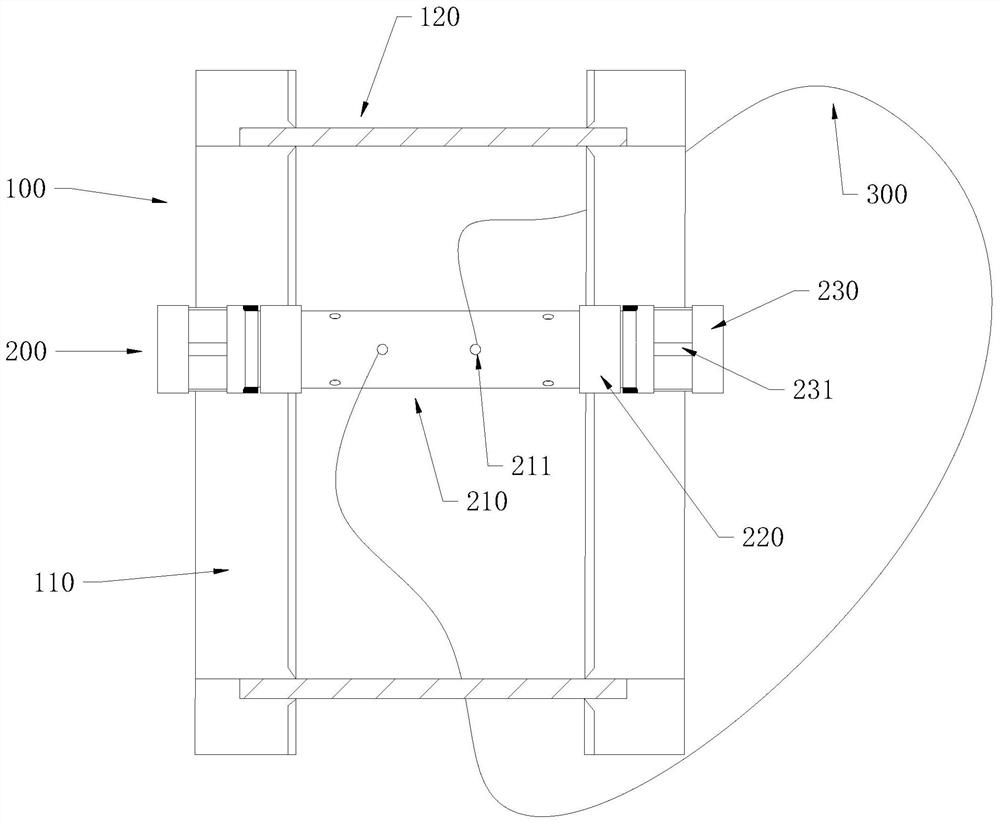

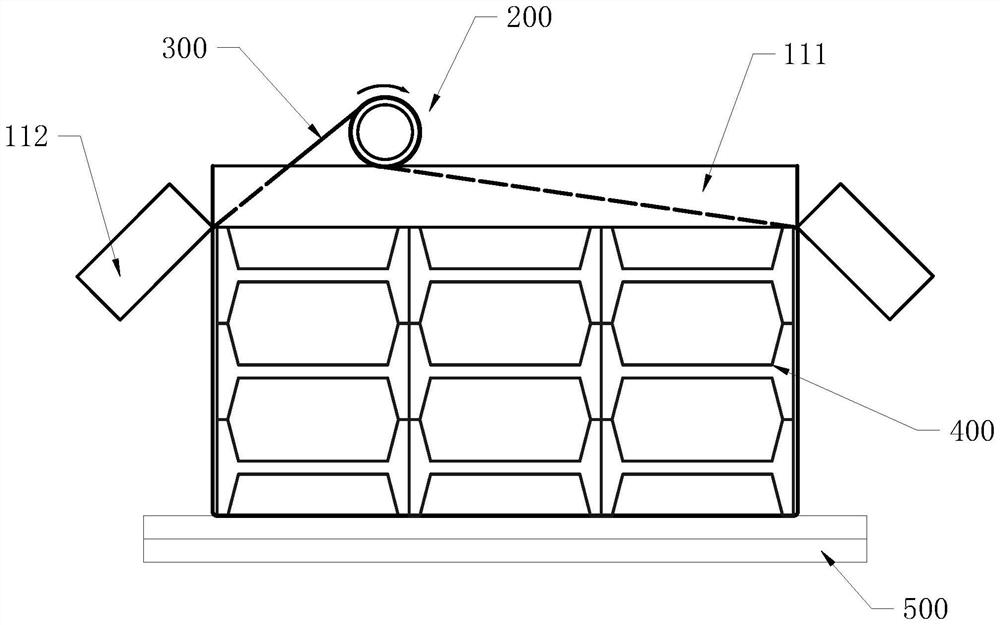

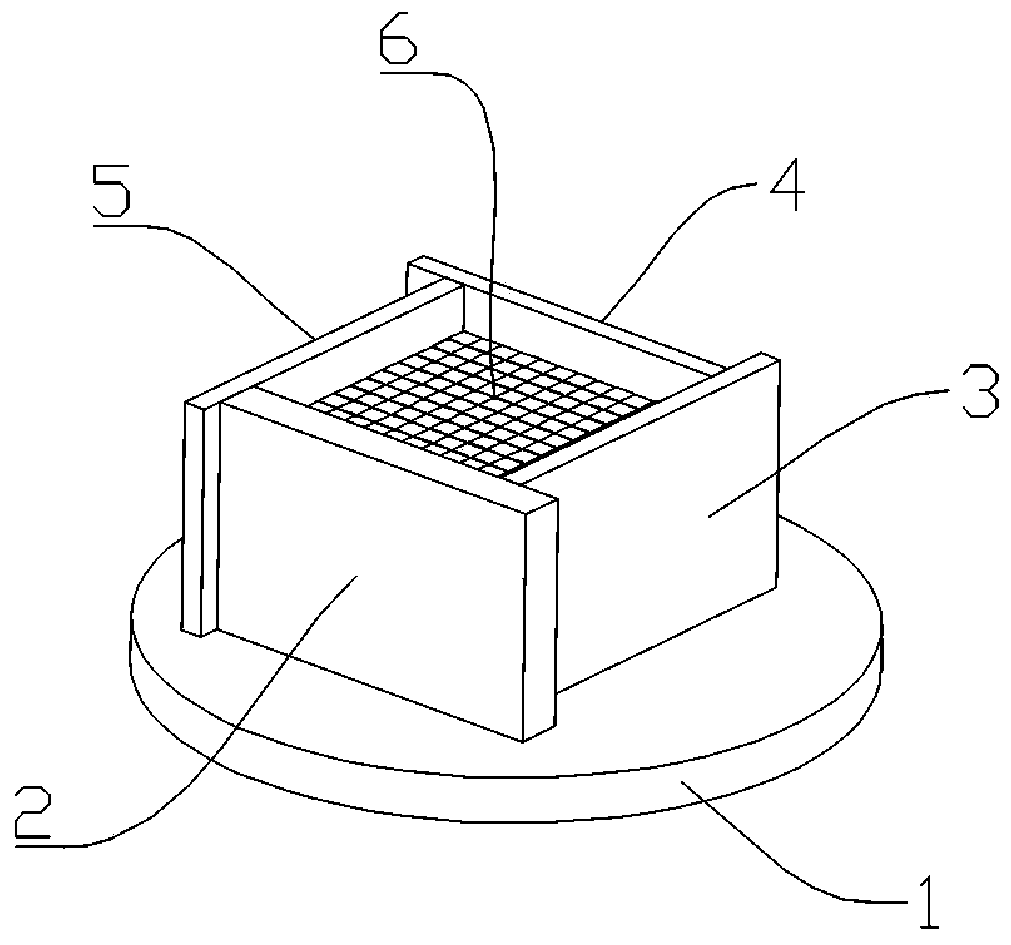

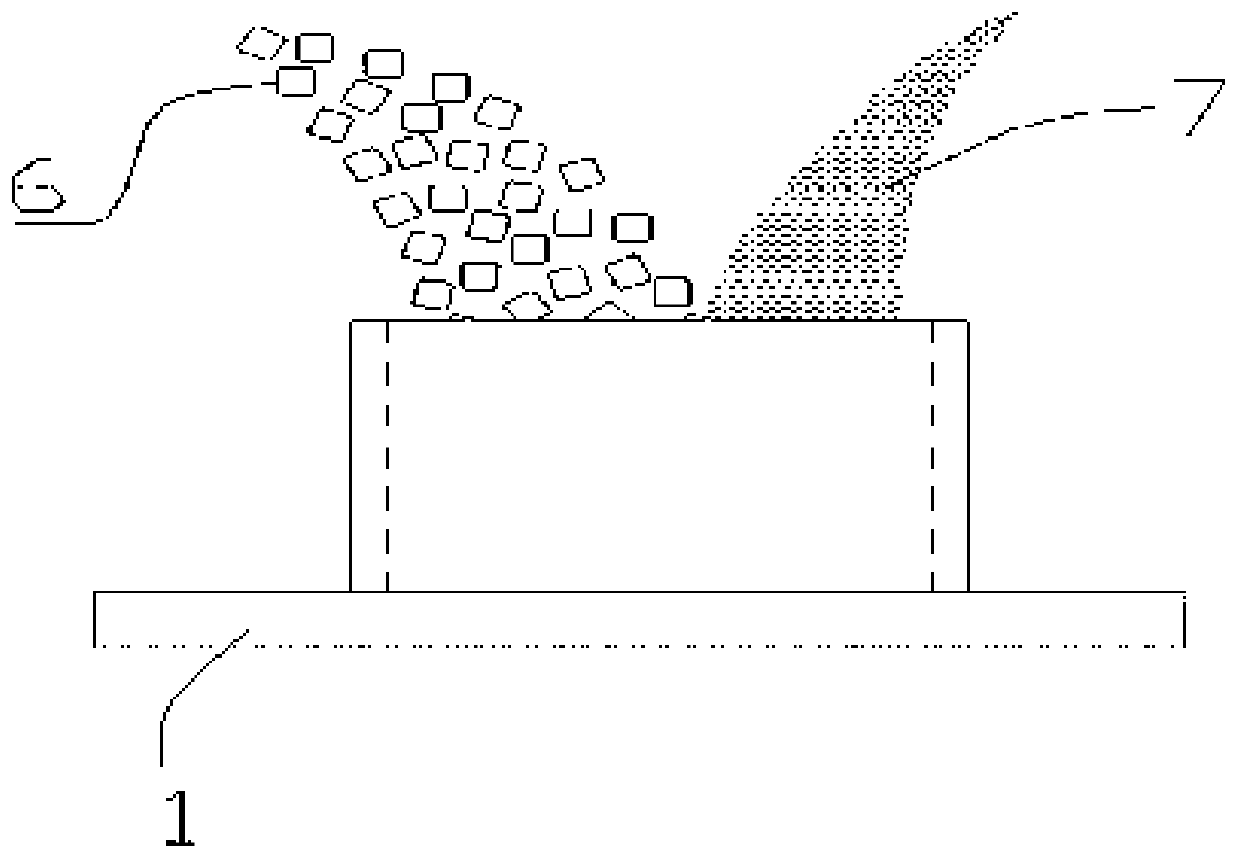

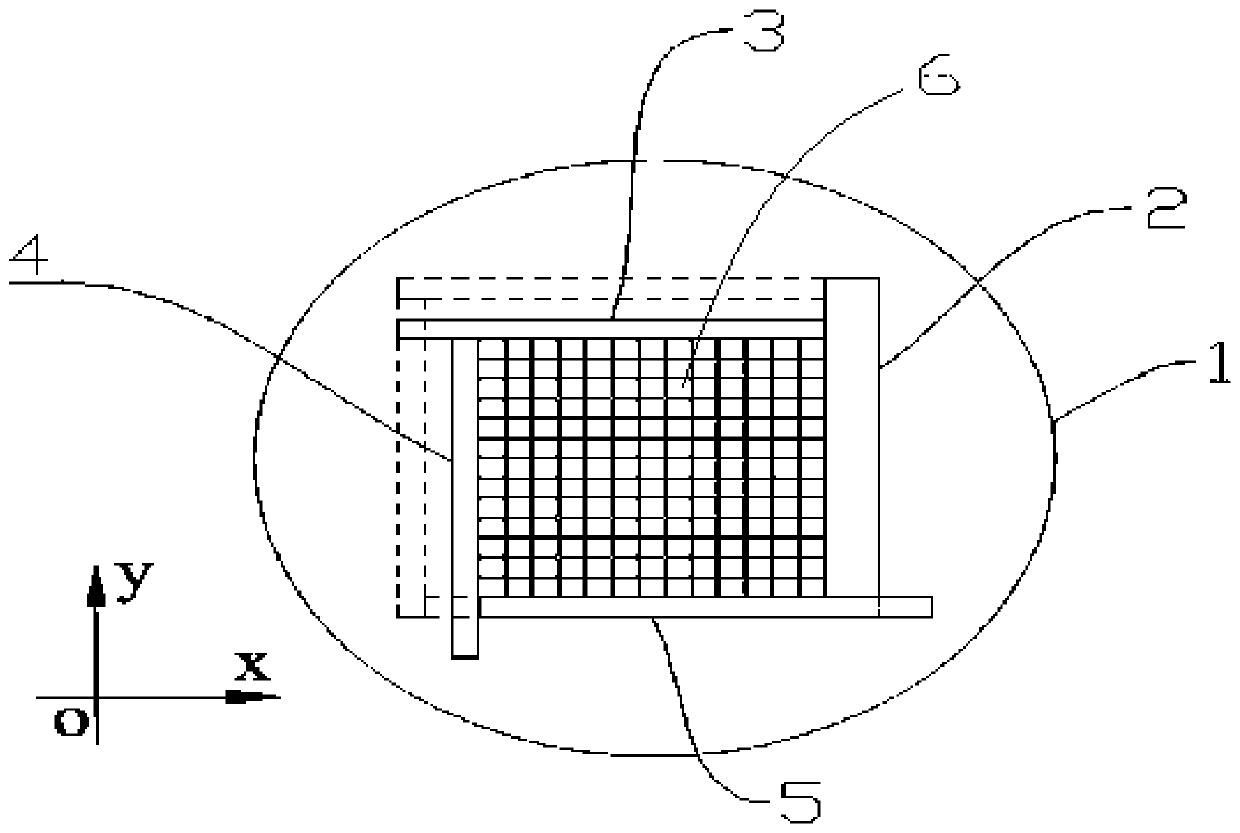

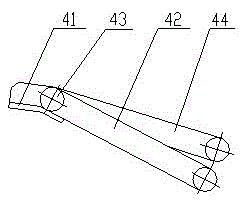

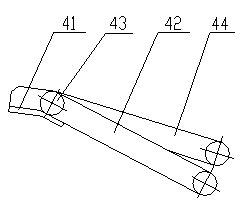

Method and device for manufacturing regular porous metal material

ActiveCN107159984AEfficient stackingStacked in orderWelding/soldering/cutting articlesMetal working apparatusMetallic materialsMaterials science

The invention provides a method and device for manufacturing a regular porous metal material. The device for manufacturing the regular porous metal material comprises a vibrating disc, a fixed plate, a first push plate, a second push plate and a third push plate. The vibrating disc is provided with a flat piling surface. One end of the fixed plate is fixedly connected to the piling surface of the vibrating disc. The first push plate is movably connected to the vibrating disc. One side of the first push plate is connected with the fixed plate. The second push plate is movably connected to the vibrating disc. The third push plate is movably connected to the vibrating disc. The piling space formed by the fixed plate, the first push plate, the second push plate and the third push plate can be gradually shrunk or expanded. By applying the technical scheme, the technical problems that in the prior art, metal unit cell bodies of a porous metal material cannot be arranged and piled efficiently and orderly, and consequently, the manufacturing and production efficiency is low can be solved.

Owner:SHENZHEN INST OF ADVANCED TECH

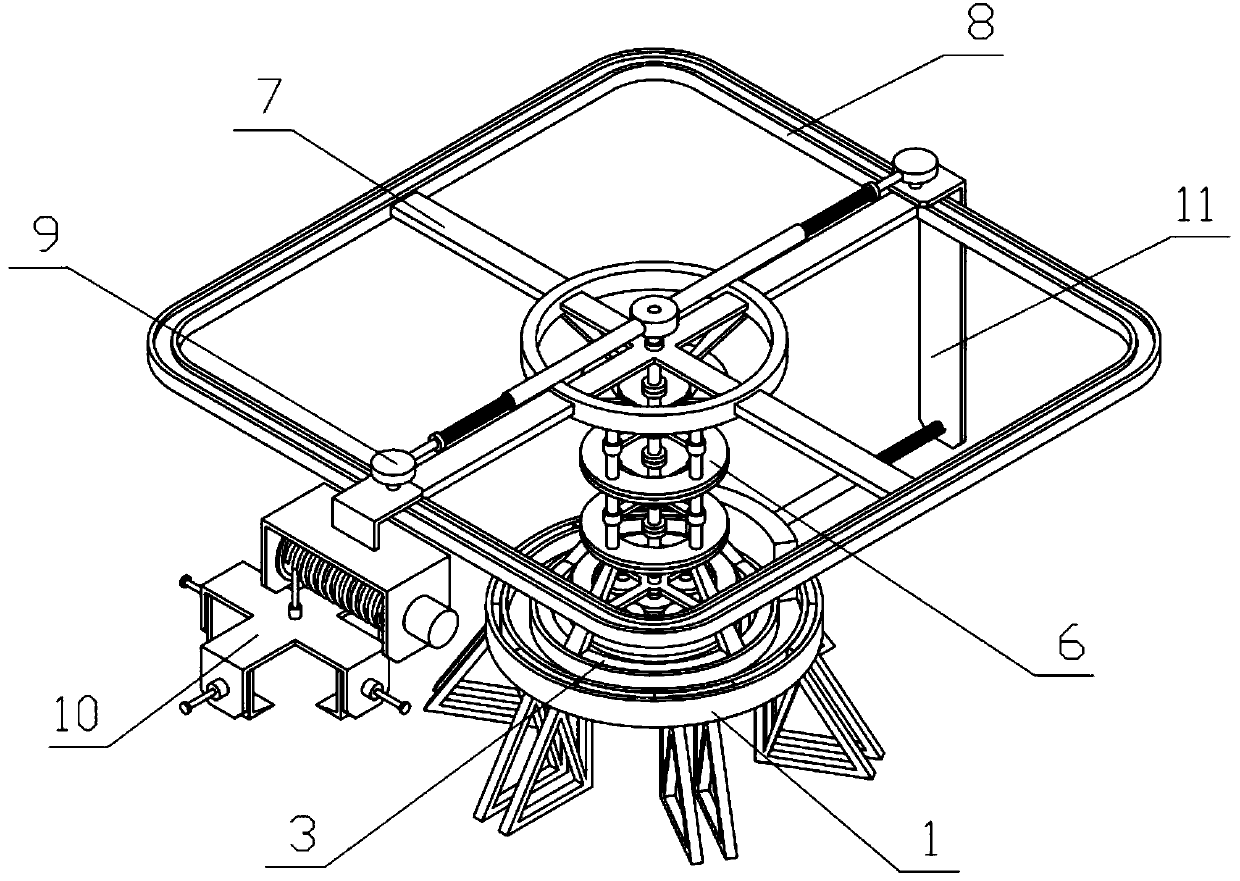

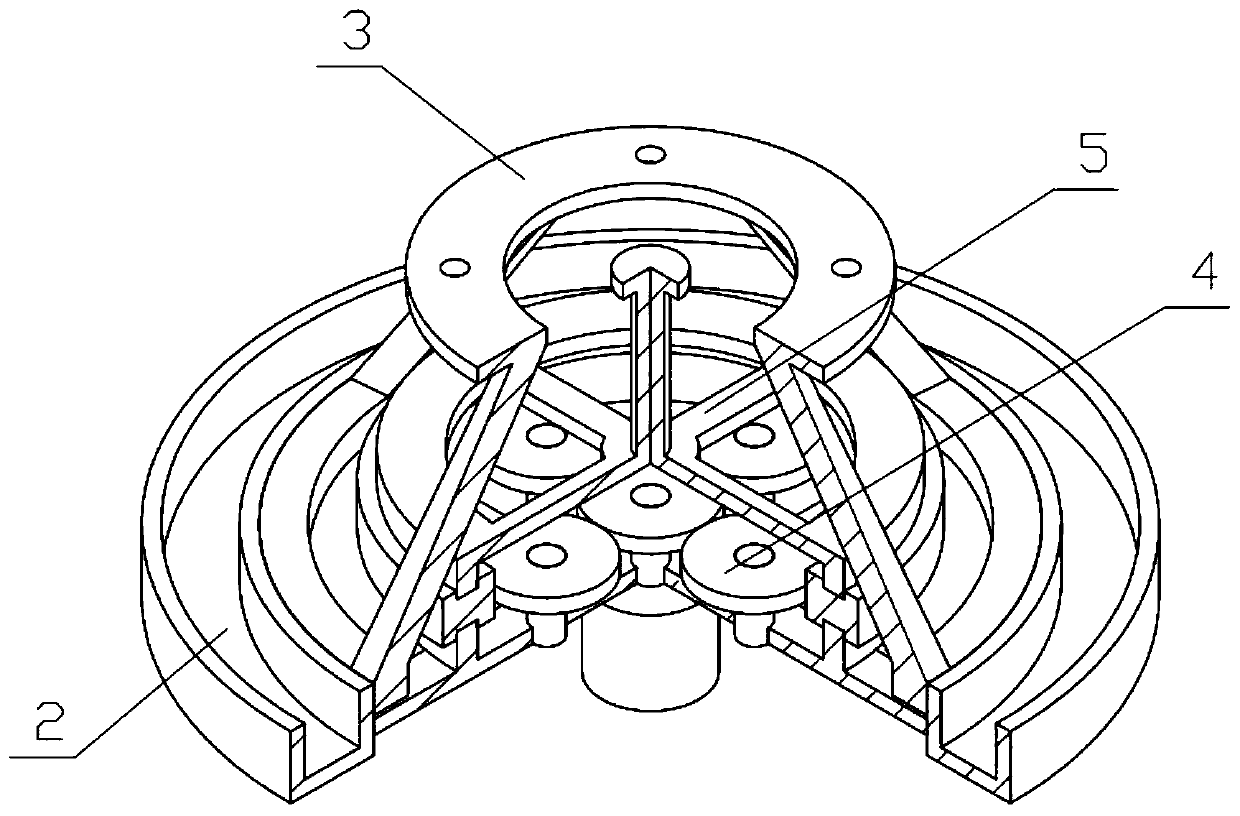

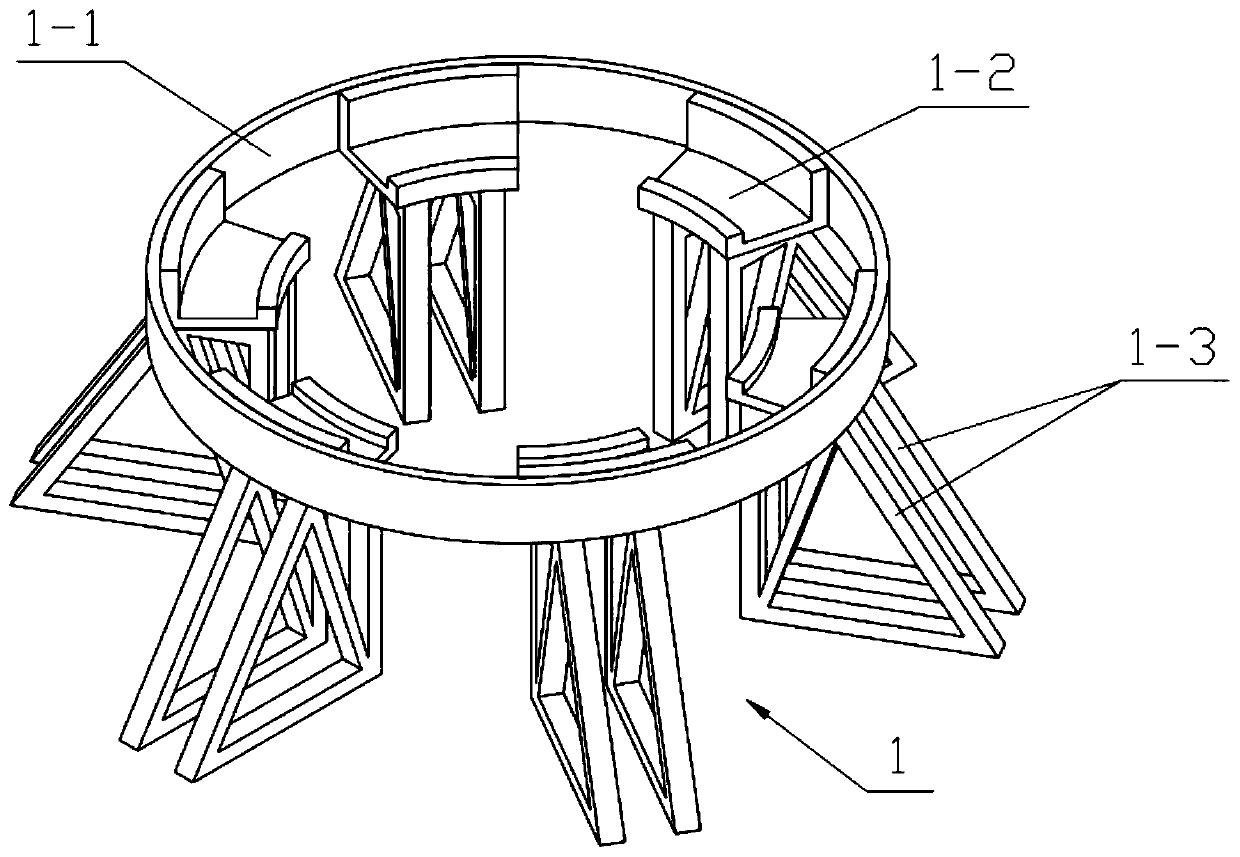

A port cargo stacking crane

The invention relates to a stacking hoisting tower, in particular to a port cargo stacking tower. The hoisting tower comprises a supporting bottom frame, a rotary supporting frame, an installing supporting frame, a planetary mechanism, a driving mechanism, supporting frames, a supporting top frame, a rectangular rail, a pushing mechanism, a hoisting mechanism and a weighing mechanism. The hoistingtower has the advantages that the using height of a device can be changed through the mutual accumulation of multiple supporting frames between the supporting bottom frame and the supporting top frame, the using height of the device can be adjusted by rotating the rotary supporting frame, the driving mechanism is driven to rotate through the planetary mechanism, multiple transmission shafts are driven to rotate by the driving mechanism, the pushing mechanism is driven to slide in the rectangular rail by the transmission shafts, the hoisting mechanism and the weighing mechanism are pushed to move by the pushing mechanism under the limitation by the pushing mechanism, and cargo is orderly and rapidly placed by the hoisting mechanism due to the fact that there exists straight edges on the rectangular rail.

Owner:温岭市城北广进鞋业有限公司

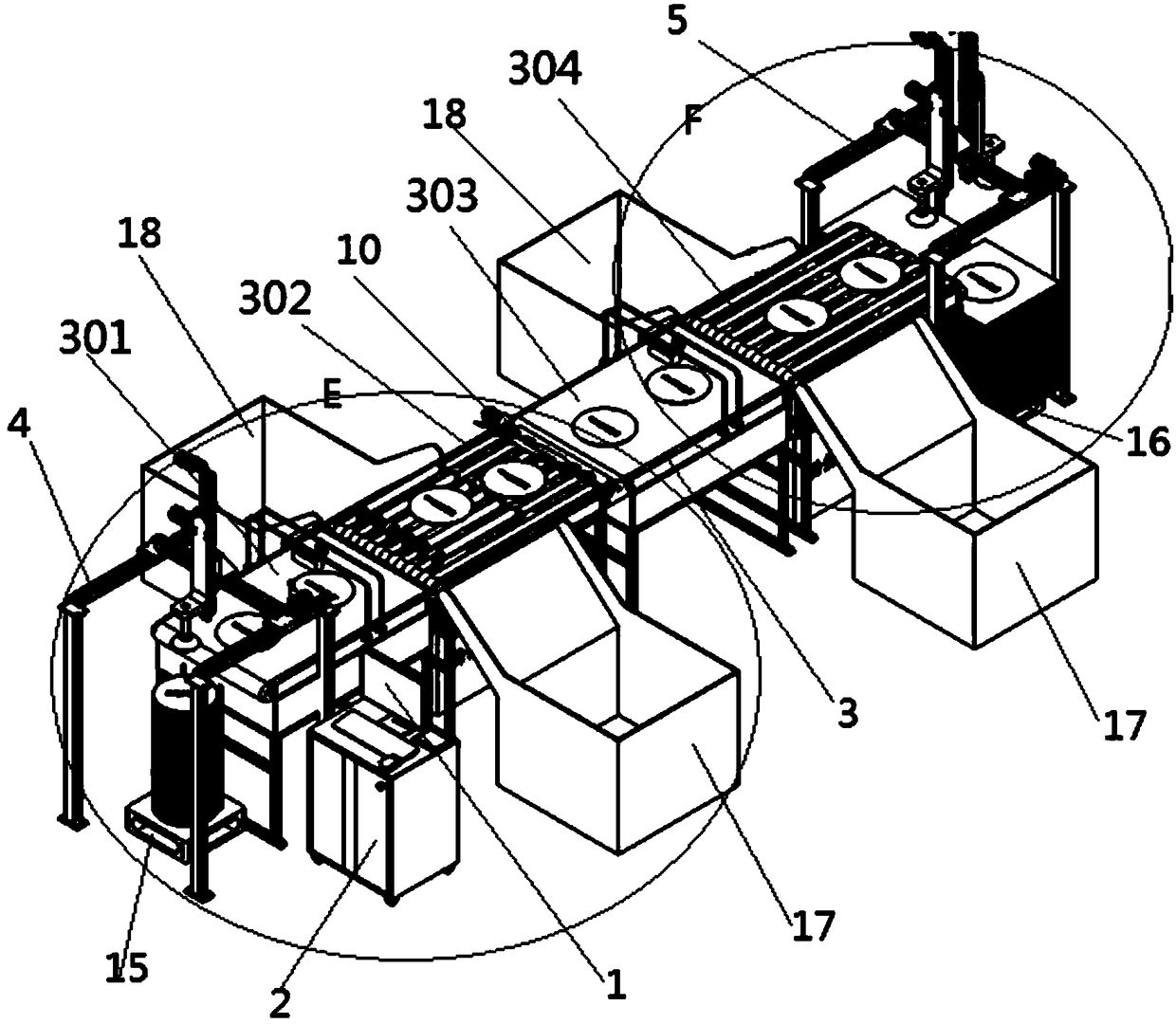

A device for fully automatic loading and unloading and visual inspection

ActiveCN106124520BReduce economic lossCause some damagesMaterial analysis by optical meansSortingEconomic benefitsVisual inspection

The invention relates to a full-automatic loading-unloading and visual inspection device. The device comprises a combined assembly line, a first image collecting device, a first product conveying device, an overturning device, a second image collecting device, a second product conveying device, an industrial computer, an electric appliance control cabinet, a loading device and an unloading device. The full-automatic loading-unloading and visual inspection device has the beneficial effects that a manual loading-unloading manner is changed into an automatic loading-unloading manner, so that the labor intensity of workers is reduced, and the device is high in efficiency and practical and can be applied to long-term scale production; besides, a manual detection manner is changed into an online automatic detection manner, so that the quality of products with front and back surfaces can be accurately detected, the economic loss of a user caused by manual erroneous judgment can be reduced, the detection efficiency is high, and the detection is accurate and reliable, the online automatic detection is realized, and the 24-hour ceaseless working can be realized; and data can be stored in real time, and the user can analyze the product process according to the detection data, so that the economic benefit of a factory is increased.

Owner:武汉智慧眼智能科技有限公司

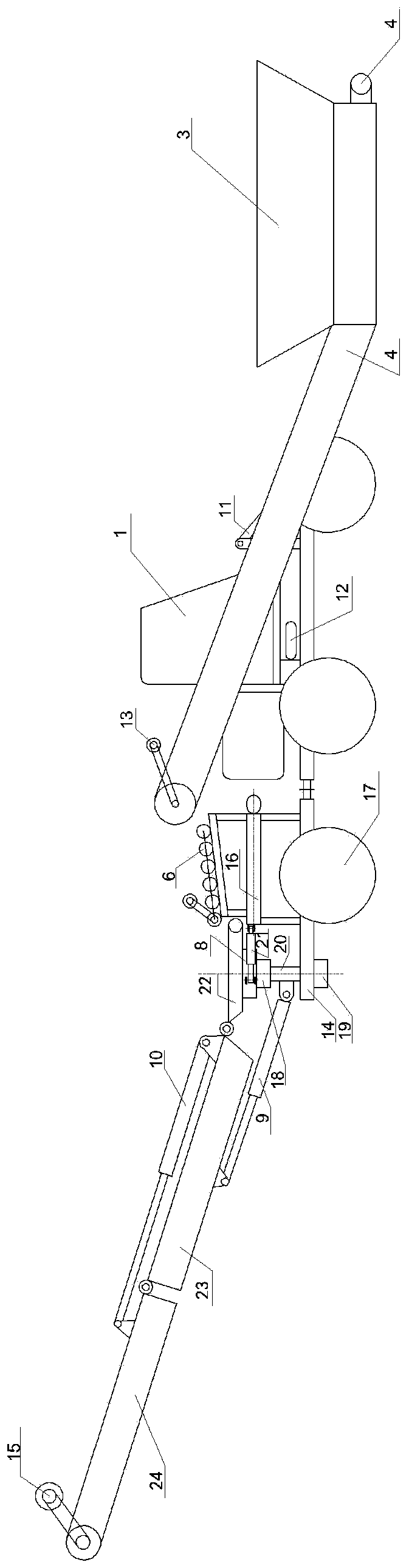

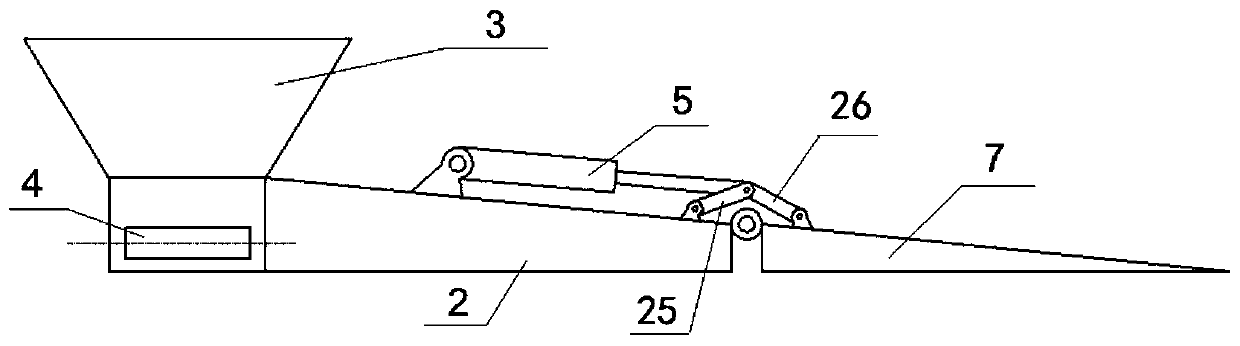

Self-propelled sugarbeet stacking and truck loading dual-purpose equipment

PendingCN111591787AStacked in orderFast stackingConveyorsStacking articlesAgricultural engineeringTruck

The invention discloses self-propelled sugarbeet stacking and truck loading dual-purpose equipment, and relates to the technical field of agricultural machinery. The equipment comprises a loading machine, a foldable get-on table, a sugarbeet unloading hopper, a main conveying belt device, an impurity and soil removal device, a foldable stacking conveying belt device, a lifting large arm, a power device, a traction chassis, an impurity and soil receiving conveying belt device and a thrust wheel. The lifting large arm is arranged at the front end of the loading machine, and the lower end of thelifting large arm is connected with the foldable get-on table. The sugarbeet unloading hopper is fixed to one side of the foldable get-on table. One end of the main conveying belt device is mounted below the sugarbeet unloading hopper, and the other end of the main conveying belt device is arranged obliquely upwards. The rear end of the loading machine is connected with the traction chassis. The impurity and soil removal device and the impurity and soil receiving conveying belt device are arranged at the upper end of the traction chassis. The impurity and soil receiving conveying belt device is located under the impurity and soil removal device. The foldable stacking conveying belt device is rotationally mounted at the rear end of the traction chassis. The stacking speed of the equipment is high, storage space is saved, impurity removal and soil removal can be carried out on sugarbeet conveniently, and the phenomenon that sugarbeet is rotten is avoided.

Owner:乌兰浩特市群兴机械制造有限公司 +1

An automatic material receiving rack for a pipe straightening machine

ActiveCN104942177BStacked in orderAvoid damageMetal-working feeding devicesPositioning devicesEngineeringRejection rate

An automatic material-receiving frame of a draw tube straightening machine comprises a frame body, wherein a draw pipe guide zone, a draw pipe falling zone and a draw pipe storage zone are arranged on the frame body, a guide roller, a turnover mechanism and a switch for opening the turnover mechanism in a control mode are arranged in the draw pipe guide zone, the turnover mechanism comprises a motor, and the motor is connected with the other end of a swing rod with one end movably connected to the frame body through a connecting rod. A liftable base is arranged in the draw pipe storage zone, the base is connected with a fixing block arranged on the frame body through an elastic supporting part arranged under the base, a reminding switch connected with a reminding device is arranged on the fixing block, and the base can trigger the reminding switch during descending. By means of the automatic material-receiving frame, the labor cost is reduced, rejection rate is reduced, and production efficiency is improved.

Owner:NINGBO KENO ALUMINUM

A medical cotton swab processing device

ActiveCN111992571BStacked in orderTimely collectionSolid waste disposalTransportation and packagingSurgeryCross infection

The invention relates to the medical field, in particular to a medical cotton swab processing device. The technical problem of the present invention is to provide a medical cotton swab processing device. A medical cotton swab processing device includes a working frame plate, a fixed bottom plate, a material inlet, an operation control panel, a transfer mechanism, a cotton ball separation mechanism, a material storage compartment and a wooden stick collection mechanism; the working frame plate and the fixed bottom plate are welded. The present invention can collect the used cotton swabs in time to prevent the volatilization of the liquid with germs and the risk of cross-infection, and separate the cotton balls from the wooden sticks on the cotton swabs, so that the cotton balls with liquid can be placed in a centralized manner, and then Cotton balls can be processed centrally, and wooden sticks can be stacked in an orderly manner, which saves space and is conducive to the effect of subsequent processing.

Owner:山东昊硕世纪医疗科技有限公司

Profile discharging and placing device and conveying line and method using profile discharging and placing device

PendingCN110125714AFully automatedIntelligent sorting and unloadingMetal working apparatusEngineeringMechanical engineering

The invention relates to a profile discharging and placing device. The profile discharging and placing device comprises a supporting frame, a flat pushing device and a secondary pushing device mountedon the supporting frame, the secondary pushing device comprises a bottom plate, a telescopic mechanism, a connecting plate, a secondary pushing plate, a pushing-down cylinder, and a loading and supporting plate, the flat pushing device frontwards pushes the profile located on the connecting plate to the loading and supporting plate, the loading and supporting plate and the profile on the loadingand supporting plate move frontwards along with the connecting plate under the drive of the telescopic mechanism, the secondary pushing plate frontwards pushes the profile away from the loading and supporting plate, and the profile falls into a loading frame at the front part of the supporting frame. The invention further discloses a conveying line and method using the profile discharging and placing device. The profile discharging and placing device meets automatic sorting and discharging of the profile processing products of various types and specifications and has the ordering function, theprofile finished parts are stacked orderly in a material frame, and the sorting and placing efficiency is high.

Owner:杭州晨龙智能科技有限公司

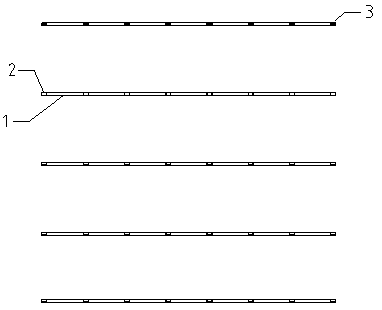

Profile-steel-based steel bar storage yard manufacturing method

The invention discloses a profile-steel-based steel bar storage yard manufacturing method. The profile-steel-based steel bar storage yard manufacturing method is characterized by comprising the following steps: a, a steel bar storage yard site is prepared; b, bottom beams and vertical columns are manufactured; c, a material identification sign is arranged, and profile-steel-based steel bar storageyard manufacturing is completed. The profile-steel-based steel bar storage yard manufacturing method has the advantages that a steel bar storage yard is simple in structure and convenient to manufacture, steel bars are stacked in order, identification is clear, moving is convenient, site steel bar use and management work can be better standardized, multiple turnover use can be achieved, a profilesteel welding identification sign can be inserted into a profile steel groove, and the profile steel welding identification sign is not prone to being damaged in the hoisting process of constructionmaterials, and the engineering cost is lowered.

Owner:MCC5 GROUP CORP SHANGHAI

Concrete reinforced cap platform manufacturing method for construction site

A method for manufacturing a concrete reinforcement bearing platform used for a construction site is characterized by comprises the following steps: a, arranging a concrete reinforcement bearing platform used as a reinforcement storage yard; b, hardening a site; c, manufacturing a load-bearing boss of the concrete reinforcement bearing platform; and d, manufacturing a reinforcement signboard fixed on the top end of a steel pipe or a square steel pipe through welding. According to the method, the concrete reinforcement bearing platform is simple in structure, convenient to manufacture and low in cost. After use, the steel pipe or square steel pipe can be recycled, and the cost is saved. The concrete reinforcement bearing platform has the advantages that reinforcements are piled up in order, the marking is clear and misuse of the reinforcements is avoided.

Owner:MCC5 GROUP CORP SHANGHAI

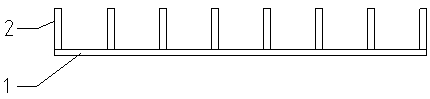

On-site automatic bundling device for I-shaped steel

ActiveCN113511359AEasy to shapeStacked in orderBundling machine detailsArchitectural engineeringWire rope

The invention relates to the technical field of building construction, and discloses an on-site automatic bundling device for I-shaped steel. The on-site automatic bundling device for the I-shaped steel comprises a fixing frame, a rotating rolling shaft and a steel wire rope. The fixing frame comprises two frame strips arranged in parallel, the rotating rolling shaft is arranged between the two frame strips, penetrating holes are formed in the rotating rolling shaft, and the two ends of the steel wire rope are arranged in the penetrating holes in a penetrating mode. A surrounding section surrounding an I-shaped steel group is defined by the middle part of the steel wire rope. By rotating the rotating rolling shaft, the surrounding section is pulled and shortened, and the I-shaped steel group is tightly bundled. According to the on-site automatic bundling device for the I-shaped steel, the I-shaped steel group is shaped through the specially designed on-site automatic bundling device for the I-shaped steel, the I-shaped steel group is fixed below the on-site automatic bundling device for the I-shaped steel through the fixing frame, the I-shaped steel group is prevented from moving before bundling, and the I-shaped steel group is shaped by applying force to the rotating rolling shaft and tensioning the steel wire rope, so that follow-up bundling is facilitated; and through the on-site automatic bundling device for the I-shaped steel, a group of I-shaped steel can be conveniently shaped, compacted and bundled on a construction site.

Owner:深圳市工勘基础工程有限公司

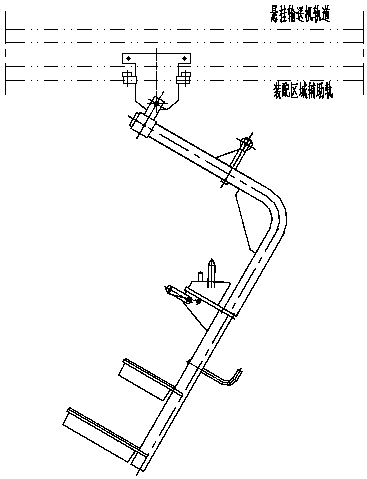

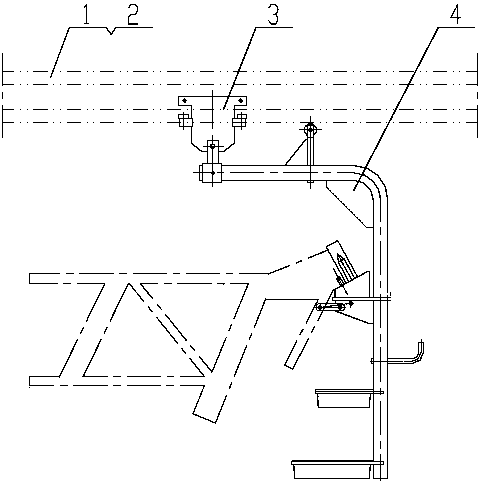

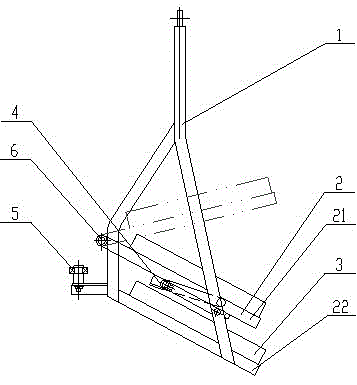

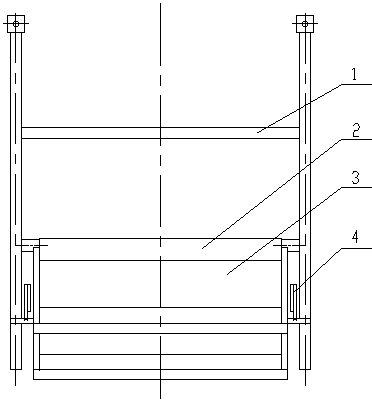

Assembly system and method for suspended motorcycle frame assembly

ActiveCN106514254BRun at a constant speedNeatly stackedAssembly machinesMetal working apparatusVehicle frameElectrical control

The invention discloses a suspended type motorcycle frame assembly assembling system which comprises a suspended conveyor (1), a conveying rail (2), a transition lifting sling (3), a combined type hanging bracket (4) and an electrical control device. The upper portion of a lifting sling body is fixed to a traction chain lifting plate of the suspended conveyor, and a connecting block is fixedly mounted on the lower portion of the lifting sling body and connected with the combined type hanging bracket. The combined type hanging bracket comprises a right-angle metal rod, a bearing assembly, a frame positioning piece, a frame locking piece, a cantilever hook and a part tray. The horizontal end of the right-angle metal rod is provided with a plurality of through holes. Bolts are inserted into the through holes to fix the connecting block of the transition lifting sling and the right-angle metal rod. The frame positioning piece is mounted on a frame positioning base. A positioning rod and a positioning pin are mounted on the top face of a base of the frame positioning piece so that a frame steering stand pipe can be hooked conveniently. The frame locking piece is mounted on a perpendicular plate on the lower portion of the frame positioning base. The suspended type motorcycle frame assembly assembling system is a multifunctional independent system integrating feeding, conveying, and assembling.

Owner:SHANGHAI ELECTROMECHANICAL DESIGN & RES INST CO LTD

Method and device for preparing regular porous metal material

ActiveCN107159984BEfficient stackingStacked in orderWelding/soldering/cutting articlesMetal working apparatusMetallic materialsMaterials science

Owner:SHENZHEN INST OF ADVANCED TECH

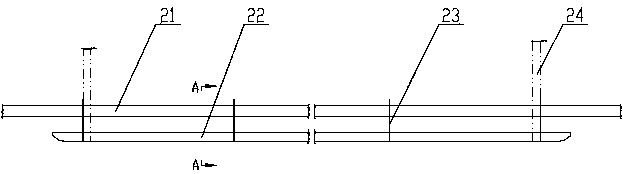

Simultaneous distribution spreader for small fuel engine assembly

The invention discloses a synchronous distribution lifting device for assembling a small fuel oil engine. The synchronous distribution lifting device comprises a hanging bracket (1), a bracket (2), trays (3), telescopic mechanisms (4) and a guide wheel (5), the hanging bracket is formed by welding inverted Y-shaped frames on the two sides and a connecting rod in the middle, the bracket is a frame-shaped bracket, and the trays are arranged on the bracket. The bracket comprises an upper bracket body (21) and a lower bracket body (22), the rear side of the upper bracket body (21) is arranged on a rear support of the inverted Y-shaped frames of the hanging bracket through a hinge (6), the front portion of the upper bracket body is arranged on telescopic arms of the telescopic mechanisms with the self-locking function, and the other ends of the telescopic mechanisms are fixed to a front support of the inverted Y-shaped frames of the hanging bracket. The rear side of the lower bracket body is fixedly arranged on the lower portion of the rear support of the inverted Y-shaped frames of the hanging bracket. Round holes are formed in the tops of upper connecting rods of the inverted Y-shaped frames of the hanging bracket, the synchronous distribution lifting device can be hung on a hanging conveyor conveniently, the guide wheel is arranged on the rear support of the inverted Y-shaped frames of the hanging bracket, and the guide wheel can slide into a groove type guide rail below the conveyor conveniently.

Owner:SHANGHAI ELECTROMECHANICAL DESIGN & RES INST CO LTD

Osmia nest box

The invention relates to an osmia nest box used for fruit tree pollination. The osmia nest box is composed of a shell, beehive plates, clamping grooves and positioning bolts; the upper portion and the lower portion of the shell are movably connected through the clamping grooves and the positioning bolts, the beehive plates are located inside the shell, and a hexagonal beehive-shaped structure is formed. The osmia nest box is easy to operate, bee cocoons are not damaged, osmia nesting is high, storing is promoted, the osmia nest box can be recycled, and investment is saved.

Owner:天津市正达蜂业有限公司

A tubular supercritical water oxidation reactor, supercritical water oxidation system and method

ActiveCN109592774BIncrease flow itinerarySimple processWater/sewage treatment apparatusWater/sewage treatment by oxidationThermodynamicsSupercritical water oxidation

The invention provides a pipe type supercritical water oxidization reactor and a supercritical water oxidization system and method. The pipe type supercritical water oxidization reactor comprises an inner barrel and an outer barrel; the outer barrel sleeves the outer part of the inner barrel; a material inlet is arranged between the inner barrel and the outer barrel; a material outlet is formed inthe top of the inner barrel and a working medium flows in from the gap between the inner barrel and the outer barrel and flows out from the top of the inner barrel; and a fin or an expansion joint isadditionally arranged in the gap between the inner barrel and the outer barrel, so that the turbulent flow is increased, a flow path is lengthened and the heat exchange is reinforced.

Owner:SHANDONG UNIV

Automobile stamping parts transfer trolley

InactiveCN106218677BStacked in orderMaintenance saves time and effortHand carts with multiple axesEngineeringPulp and paper industry

The invention discloses an automobile stamped part transfer trolley which comprises a box with the top provided with an opening. Wheels are arranged at the bottom of the box. A supporting plate is arranged in the box and connected with the bottom of the box through springs. A plurality of through holes are evenly formed in the supporting plate. The trolley further comprises a fixed pulley and a plurality of positioning rods, and the number of the positioning rods is not greater than the number of the through holes. Each positioning rod comprises a lower pipe body in threaded connection with the corresponding through hole and an upper rod body in sliding connection with the lower pipe body, wherein the upper rod body is connected with the bottom of the supporting plate through a pull rope, one end of the pull rope is connected with the upper rod body, and the other end of the pull rope sequentially penetrates through the lower pipe body and the corresponding through hole and then winds across the fixed pulley to be connected with the bottom of the supporting plate. When the automobile stamped part transfer trolley of the structure is used for transferring stamped parts, the stamped parts can be stacked in order, and time and labor can be saved when the stamped parts are taken.

Owner:重庆达升源汽车零部件有限公司

Synchronous distribution lifting device for assembling small fuel oil engine

The invention discloses a synchronous distribution lifting device for assembling a small fuel oil engine. The synchronous distribution lifting device comprises a hanging bracket (1), a bracket (2), trays (3), telescopic mechanisms (4) and a guide wheel (5), the hanging bracket is formed by welding inverted Y-shaped frames on the two sides and a connecting rod in the middle, the bracket is a frame-shaped bracket, and the trays are arranged on the bracket. The bracket comprises an upper bracket body (21) and a lower bracket body (22), the rear side of the upper bracket body (21) is arranged on a rear support of the inverted Y-shaped frames of the hanging bracket through a hinge (6), the front portion of the upper bracket body is arranged on telescopic arms of the telescopic mechanisms with the self-locking function, and the other ends of the telescopic mechanisms are fixed to a front support of the inverted Y-shaped frames of the hanging bracket. The rear side of the lower bracket body is fixedly arranged on the lower portion of the rear support of the inverted Y-shaped frames of the hanging bracket. Round holes are formed in the tops of upper connecting rods of the inverted Y-shaped frames of the hanging bracket, the synchronous distribution lifting device can be hung on a hanging conveyor conveniently, the guide wheel is arranged on the rear support of the inverted Y-shaped frames of the hanging bracket, and the guide wheel can slide into a groove type guide rail below the conveyor conveniently.

Owner:SHANGHAI ELECTROMECHANICAL DESIGN & RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com