Automatic material-receiving frame of draw tube straightening machine

A material receiving frame and straightening machine technology, which is applied to metal processing equipment, feeding devices, manufacturing tools, etc., can solve the problems of low production efficiency, uneven material receiving, bending of aluminum pipes, etc. The effect of improving production efficiency and reducing scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

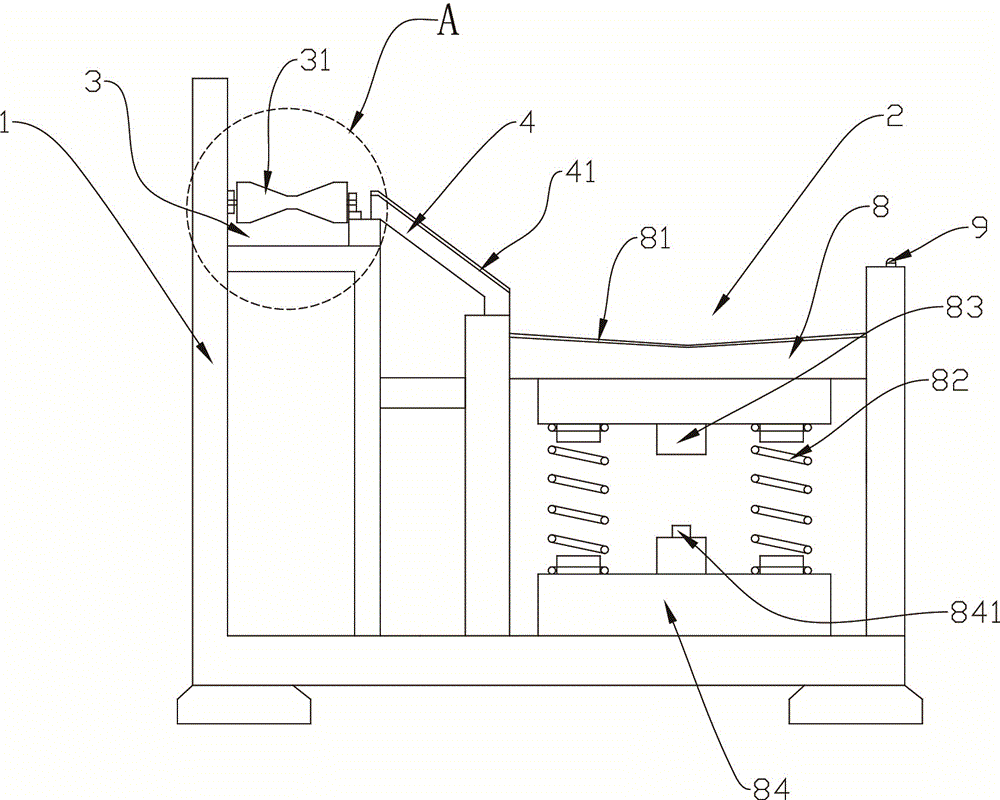

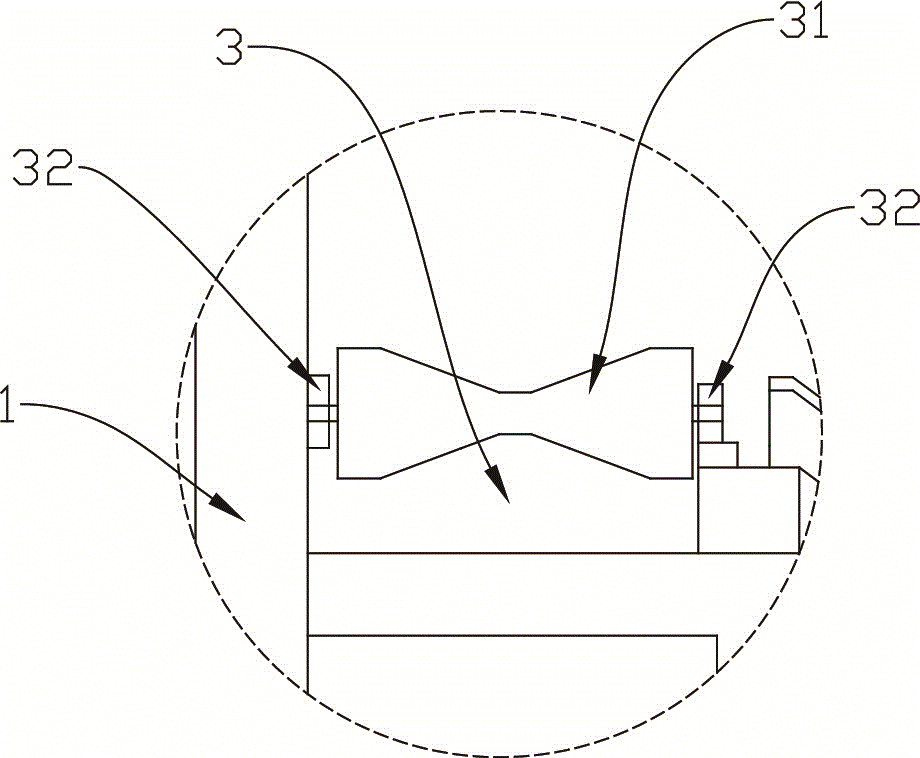

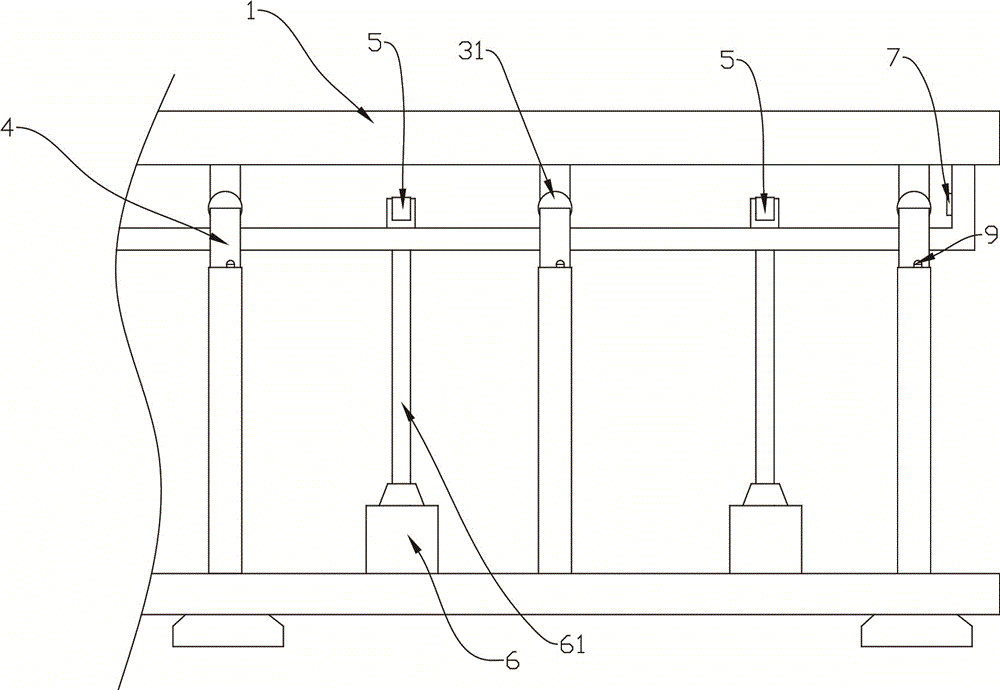

[0023] See Figure 1 to Figure 5 , an automatic feeding rack for a pumped pipe straightening machine, comprising a frame body 1, the frame body 1 is provided with a pumped pipe guide area 3, a suction pipe drop area 4, and a suction pipe storage area 2, and the suction pipe guide area 3 is provided with several guide rollers 31 arranged in parallel, a turn-up mechanism and a switch 7 for controlling the opening of the turn-up mechanism, the turn-up mechanism includes a motor 6, and the motor 6 is movably connected with one end through a connecting rod The other end of the swing rod 5 on the frame body 1 is connected; the drawer storage area 2 is provided with a liftable base 8, and the base 8 is connected to the frame body 1 through the elastic support member arranged below it. The fixed block 84 is connected, and the fixed block 84 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com