Simultaneous distribution spreader for small fuel engine assembly

A fuel engine and spreader technology, which is applied in transportation and packaging, manual conveying devices, etc., can solve the problems of mechanization, low degree of automation, high labor intensity of operators, crowded production workshop space, etc., to achieve standardized and orderly management, labor The effect of reducing strength and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

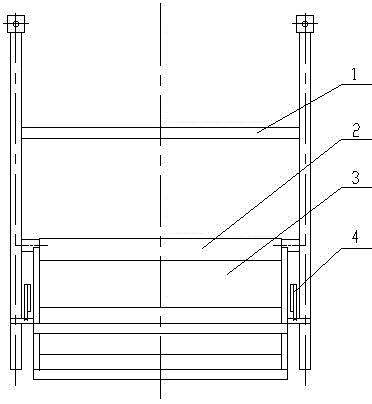

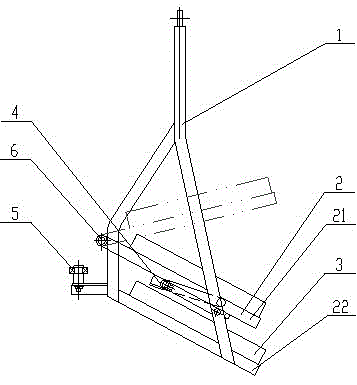

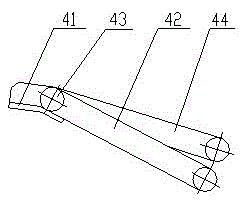

[0022] see Figure 1 to Figure 4 , a synchronous distribution spreader for small fuel engine assembly, including a hanger 1, a bracket 2, a tray 3, a telescoping mechanism 4 and a guide wheel 5, the two sides of the hanger 1 are inverted Y-shaped frames, and the middle is The connecting rod is welded; the bracket 2 is a frame frame, the tray 3 is placed on the bracket 2, and the tray 3 is an injection molded tray. Bracket 2 is an upper row of brackets 21 and a lower row of brackets 22, and the upper row of brackets 21 and the lower row of brackets 22 are at a certain inclination angle, that is, the upper row of brackets 21 and the lower row of brackets 22 are inverted from the hanger 1. The rear bracket of the Y-shaped frame is at an angle of 50 degrees to 80 degrees of downward inclination; the preferred value is the downward slope of the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com