Assembly system and method for suspended motorcycle frame assembly

An assembly and suspension technology, which is applied in assembly machines, metal processing equipment, metal processing, etc., can solve the problems of high labor intensity of operators, frequent movement of operators, difficulty in feeding and retrieving materials, and achieve management standards. sequence, device functions are applicable, and the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

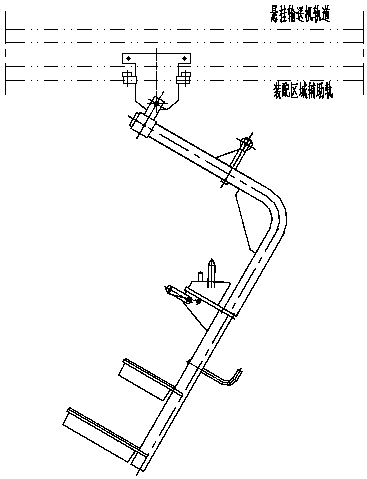

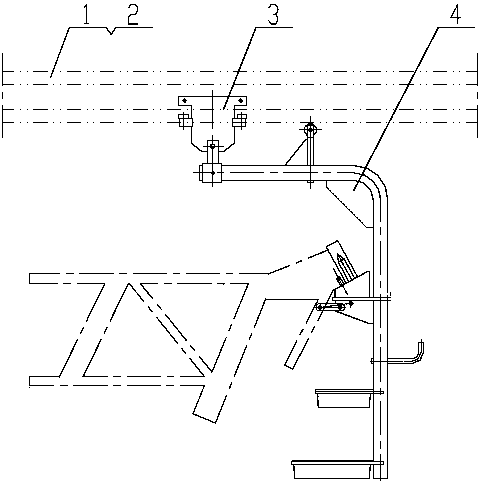

[0049] see figure 1 with figure 2 ,as well as Figure 11a , Figure 11b , Figure 12a with Figure 12b , a suspended motorcycle frame assembly assembly system, its no-load, loaded hanger state when going up, downhill and in the assembly area.

[0050] see figure 1 with figure 2 , an assembly system for a suspended motorcycle frame assembly, comprising: a suspended conveyor 1, a conveying track 2, a transition spreader 3, a combined hanger 4 and an electrical control device.

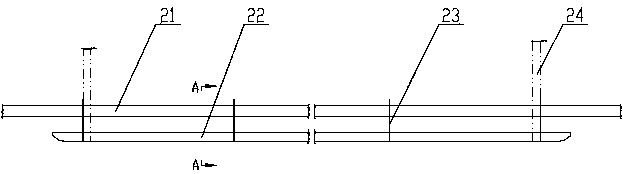

[0051] The conveying track 2 includes a conveyor track 21, an auxiliary rail 22 and a connecting plate 23, the conveyor track 21 and the auxiliary rail 22 are connected and fixed by the connecting plate 23, the auxiliary rails 22 are two, and are located side by side on the conveyor Below the track 21, the conveyor track 21 and the auxiliary rail 22 jointly form ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com