Coating machine of diameter alloy fuse body for teflon lead

A Teflon lead wire, alloy type technology, which is applied to the device and coating of the surface coating liquid, can solve the problems of high production cost, difficult coating operation, high rejection rate, etc., and improve production efficiency. , The operation is simple and convenient, and the effect of improving the coating quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

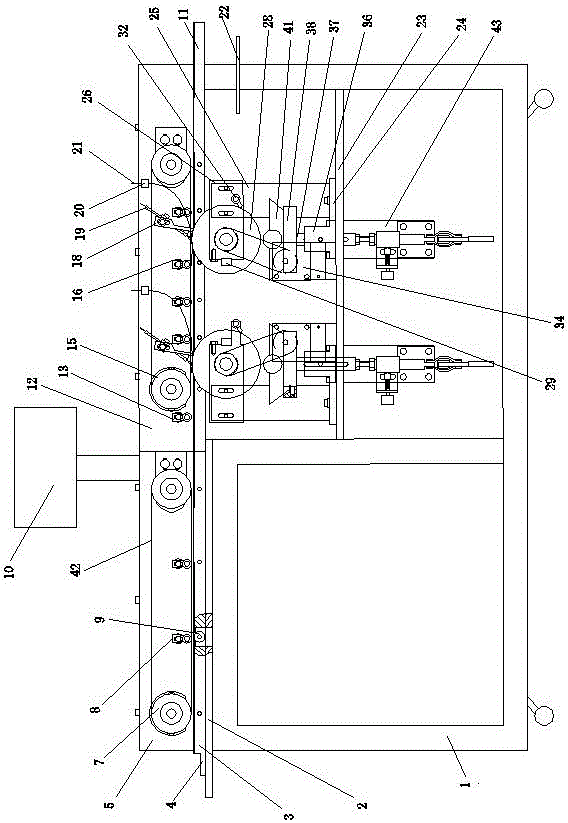

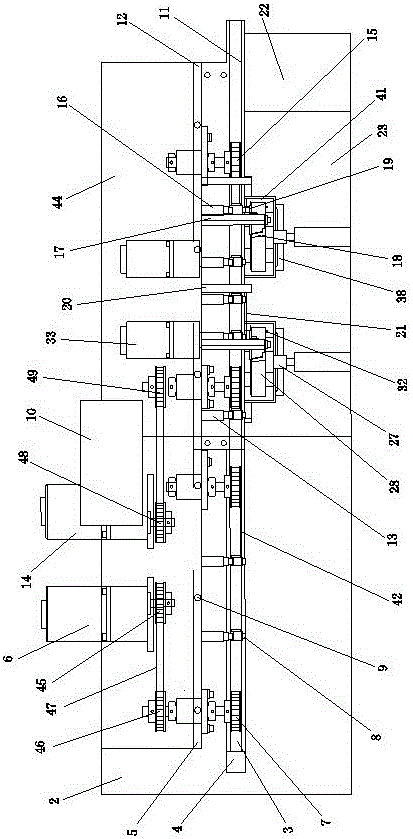

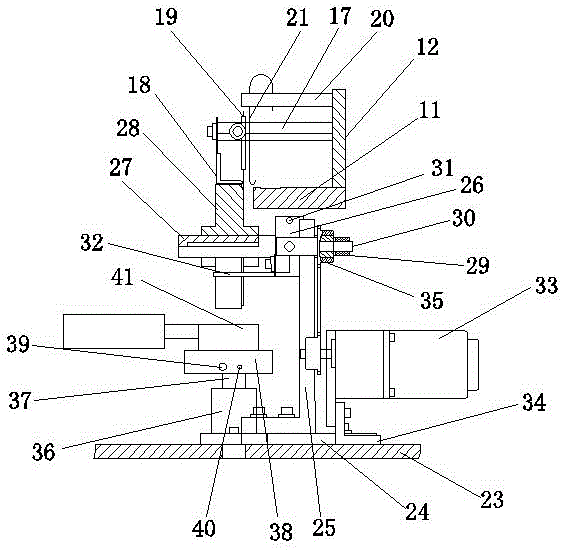

[0021] Attached below Figure 1-4 Further clearly and completely describe the technical solution of the present invention.

[0022] See attached Figure 1-4

[0023] 1. Setting of process parameters: the rotating speed of cooling motor 6, transfer motor 14 and coating motor 33, the numerical value of heating plate heater 39 and coating wheel heater 30, and coating wheel thermocouple 31 and heating plate thermoelectric The monitoring values of even 40 are respectively set in the electric control console 10;

[0024] 2. Preheating and operation of coating machine:

[0025] (1) Pre-running of the transmission mechanism 50: after the power is turned on, the transmission motor 14 installed on the back side of the working panel 2 and the cooling vertical plate 5 runs at the speed set in the electric control console 10, and drives the transmission driving wheel 48 Rotate, drive the transmission driven wheel 49 to rotate through the single-sided synchronous belt 47, drive the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com