Ring forming mechanism of long-ring rapid steamer

A long-ring steamer and ring-forming technology, which is used in liquid/gas/vapor textile processing, textile and papermaking, textile material processing, etc., can solve the problem of short working life of crank structure and ring-forming plate The problems of poor working stability and high mechanical performance requirements of the machine can achieve the effects of long service life, reduced lifting distance and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

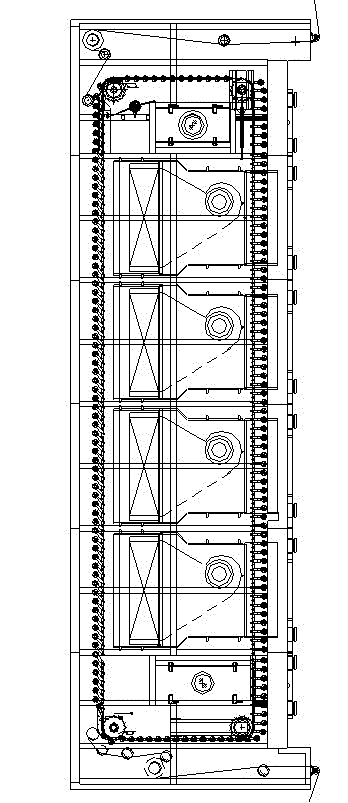

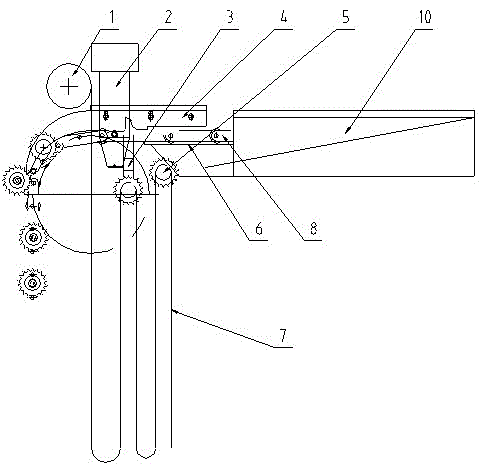

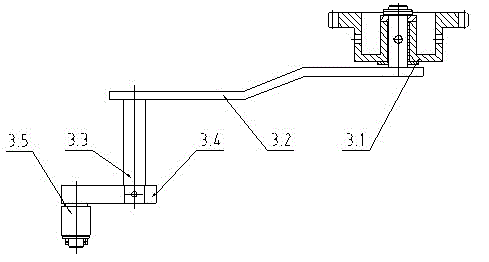

[0044] see figure 1 , figure 2 , The present invention relates to a loop forming mechanism of a long loop steamer, which includes a cloth feeding roller 1, a crank joint 3, a loop forming plate 4, a cloth hanging roller 5, a main track 6, an endless chain 8 and a secondary track 10.

[0045] Described main track 6 has four, each two of upper and lower, two two devices are arranged on the upper inner side and the lower inner side of the left and right wallboards of the long ring steamer.

[0046] There are two ring chains 8, one on the left and one on the right, which are installed on the inside of the left and right wallboards of the long-ring steamer.

[0047] Described cloth feeding roller 1 places the front top of endless chain 8.

[0048] There are two secondary rails 10 , one for the left and one for the right. The secondary rails 10 are arranged in parallel with the main rail 6 and are located inside the upper main rail 6 .

[0049] Described crank joint 3 has severa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com