Profile-steel-based steel bar storage yard manufacturing method

A technology for steel bar storage yards and production methods, which is applied in the processing of building materials, construction, building construction, etc., and can solve problems such as inconvenient production methods for steel bar storage yards, easy damage to steel bar signboards, and failure to use materials. , to achieve the effect of good use and management of steel bars, simple structure, and reduced engineering costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The method for making steel bar yard based on section steel of the present invention includes the following steps:

[0034] a. Preparation of steel yard site.

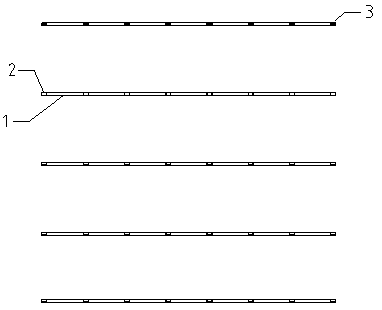

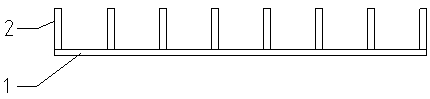

[0035] See now figure 1 , figure 1 Is a plan layout diagram of a steel bar storage yard according to an embodiment of the present invention, figure 2 It is an elevation view of a steel bar storage yard according to an embodiment of the present invention. As shown in the figure, the steel bar storage site needs to be hardened according to the site layout and mechanical installation. The steel bar storage site is hardened according to the layout size and the concrete site is poured. The concrete adopts C20 concrete and the concrete thickness is 150mm.

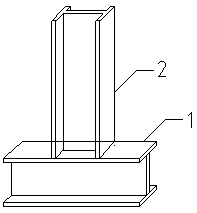

[0036] b. Make bottom beams and columns. According to the needs of the steel bar yard, five rows of bottom beams 1 are arranged in parallel on the hardened concrete, each row of bottom beams is 9m long, and the distance between two adjacent rows of bottom beams is 2105mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com