Concrete reinforced cap platform manufacturing method for construction site

A technology for concrete reinforcement and construction sites, which is applied to storage devices, building materials, transportation and packaging, etc. It can solve problems such as the inability to place reinforcement in a standardized manner, the inability to track the use of reinforcement, and the easy damage of concrete caps. The effect of low cost, orderly stacking and convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The method for making concrete reinforced caps for construction sites of the present invention is characterized in that it comprises the following steps:

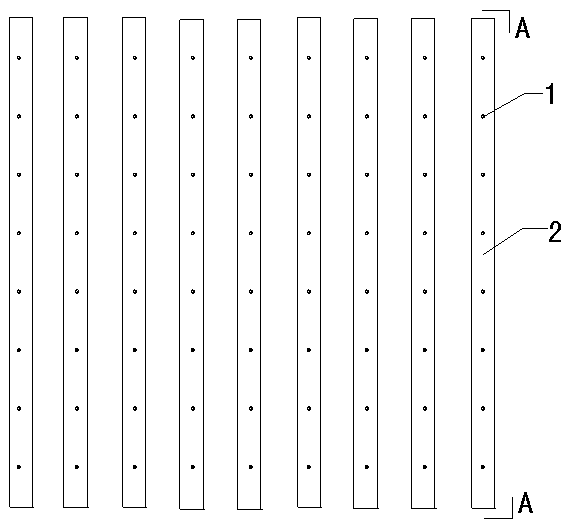

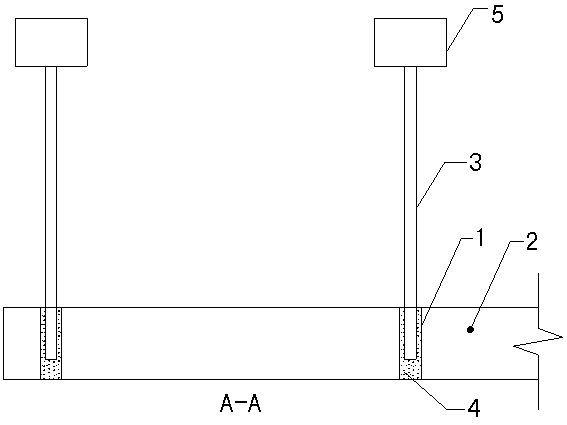

[0031] a. Set up the concrete reinforced cap for the reinforced yard

[0032] see now figure 1 and 2 , figure 1 It is the plane layout diagram of the concrete reinforced cap platform of the embodiment of the present invention, figure 2 for figure 1 A-A sectional view in . As shown in the figure, the concrete reinforced cap is rectangular, with a length of 12000mm and a width of 10900mm. Nine load-bearing bosses 2 are arranged parallel to the length, and the distance between the bosses is 1500mm. Eight piles are arranged for each boss in the width direction. 1500mm, used as reinforcement stacking space, the width of the boss is 200mm to both ends; the boss is a reinforced concrete structure, the cross-sectional size is 200×300mm, and four HRB400 diameter 14mm steel bars and HPB300 diameter 8mm stirrups are equip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com