Automobile stamped part transfer trolley

A technology for automobile stamping parts and trolleys, which is applied to trolleys, motor vehicles, multi-axis trolleys, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

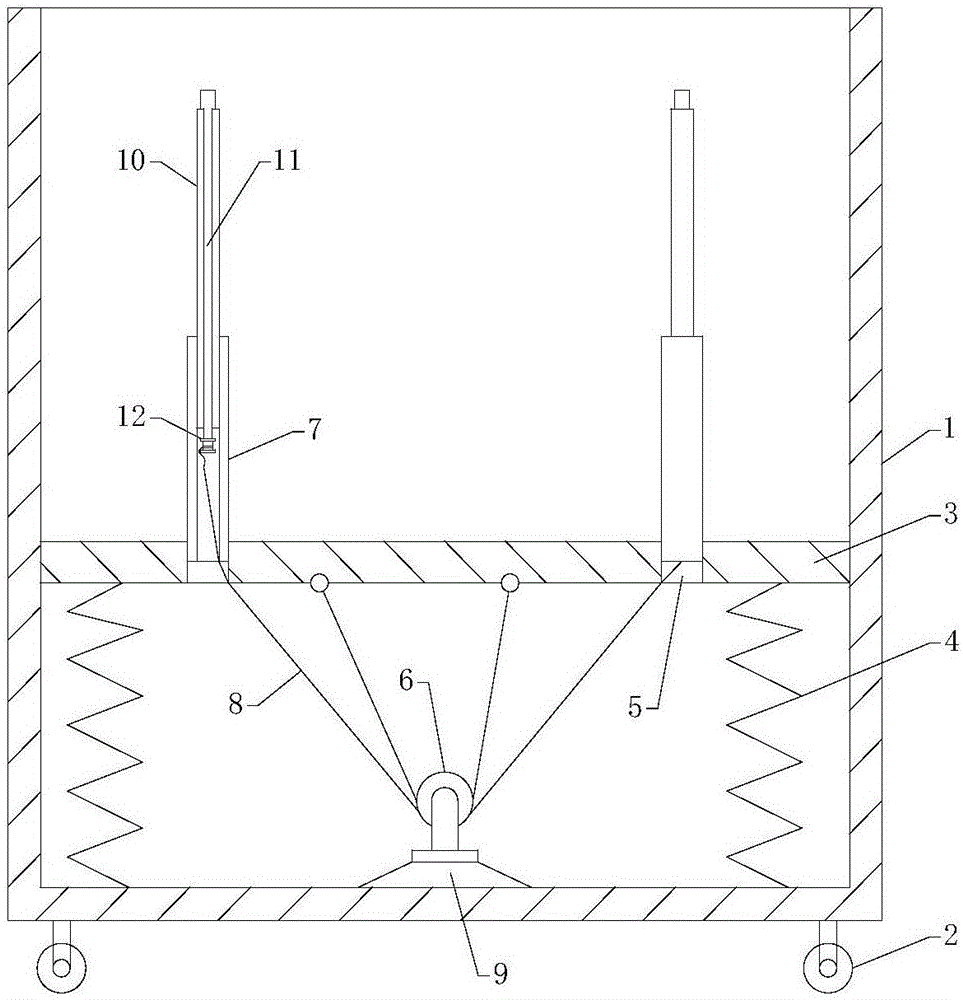

[0011] The present invention will be described in detail below in conjunction with accompanying drawing, as figure 1 Shown: a transfer trolley for automobile stamping parts, including a box body 1 with an open top, wheels 1 are arranged at the bottom of the box body, a supporting plate 3 is arranged in the box body, and the supporting plate is connected to the bottom of the box body through a spring 4 connection, a plurality of through holes 5 are evenly arranged on the supporting plate, and a fixed pulley 6 and a plurality of positioning rods are also included. Body 7 and the upper rod body slidingly connected with the lower tube body, the upper rod body is connected with the bottom of the pallet through the stay rope 8, one end of the stay cord is connected with the upper rod body, and the other end passes through the lower tube body and the through hole and around the After passing the fixed pulley, it is connected with the bottom of the supporting board, and the stay rope ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com