Automatic vending unit

A technology for automatic vending and magazines, which is applied to instruments, coin-operated equipment for distributing discrete items, and coin-operated equipment for distributing discrete items, etc. Advanced problems, to achieve the effect of wide application, avoiding interference and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

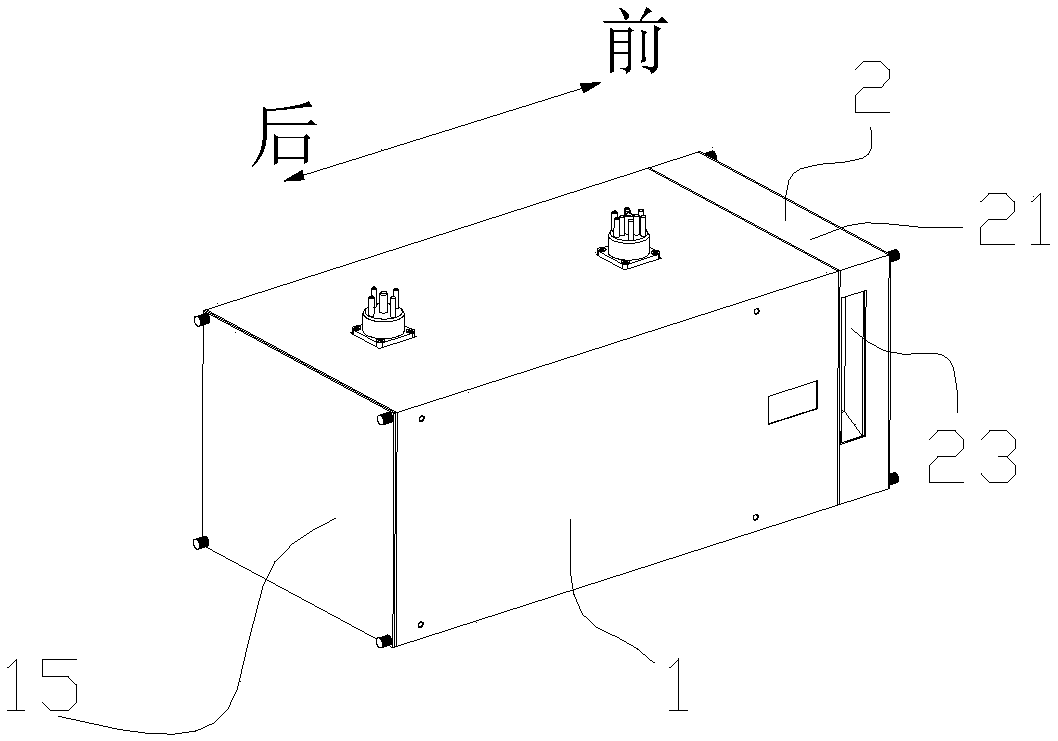

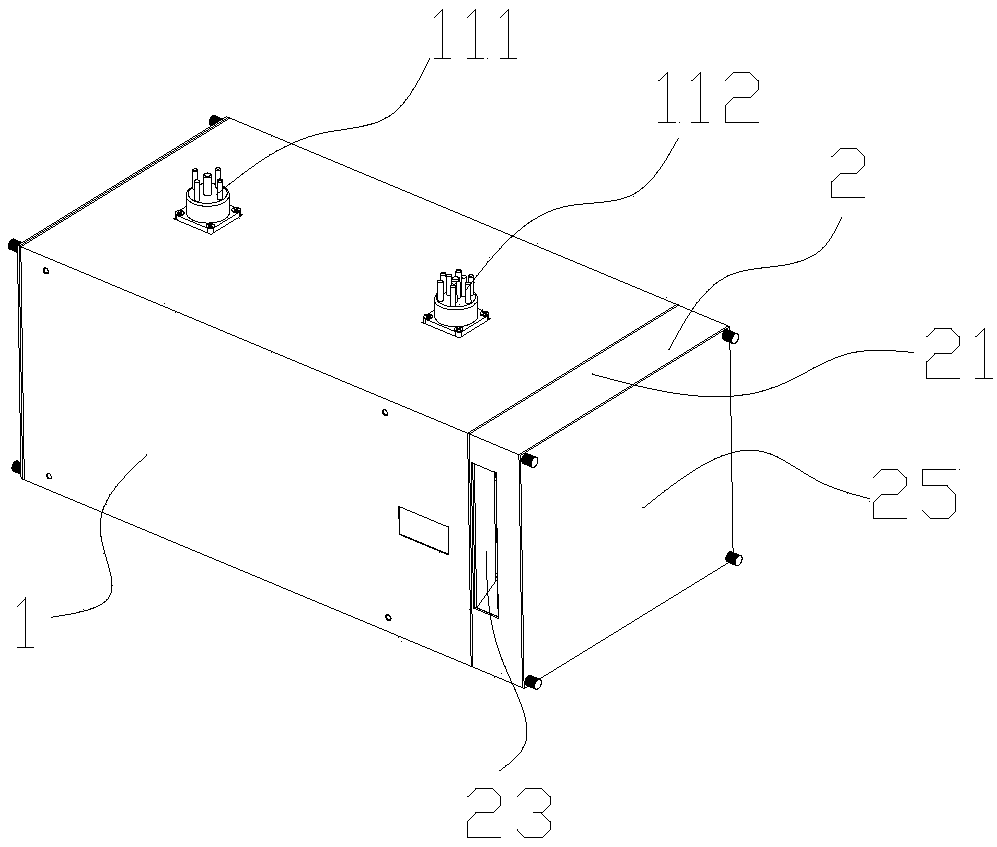

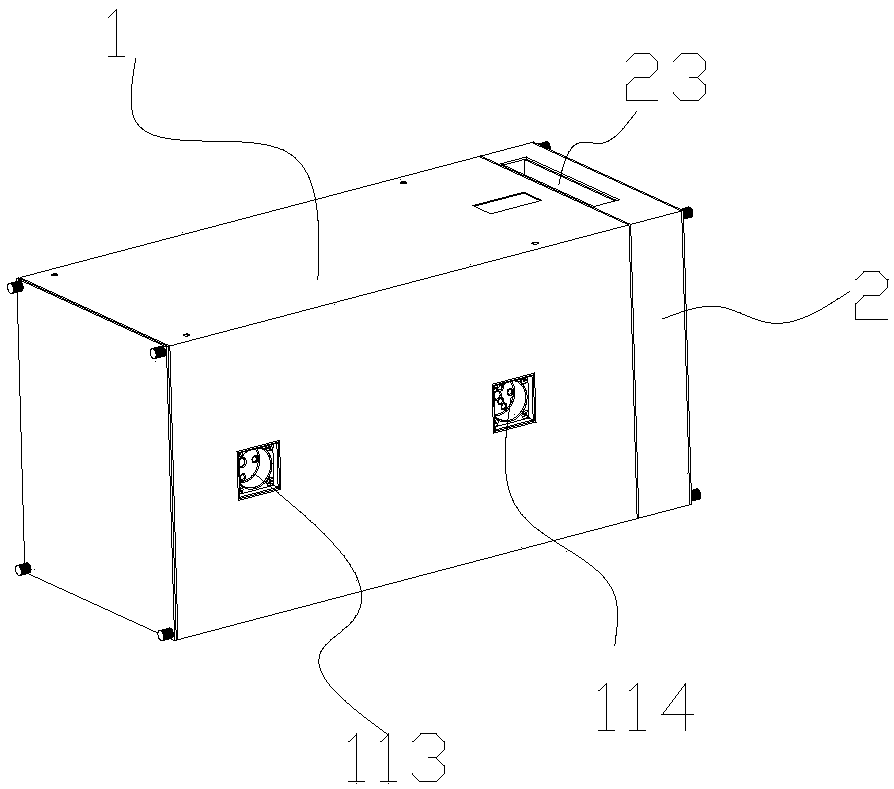

[0038] Such as Figure 1-10 , an automatic vending unit, comprising a material storage device 1 and an elastic material device 2, the material storage device 1 includes a material box 11, a material clip 12 is fixed in the material box 11, and a material guide channel for guiding materials is provided in the material folder 12 13. The rear end of the material guide channel 13 is closed, and the front end of the material guide channel 13 leads to the spring material device 2;

[0039] The material storage device 1 and the elastic material device 2 can be combined arbitrarily, without one-to-one correspondence, and have interchangeability.

[0040] The ejection device 2 includes an ejection box 21 positioned at the front end of the magazine 11 and fixedly connected with the magazine 11. The fixed connection can be a threaded connection, a mating connection or a buckle connection. The discharge cavity 22, the size of the discharge cavity 22 is constant, can be larger than the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com