A sheet automatic blanking and punching production line

A blanking punching, production line technology, applied in the direction of feeding devices, manufacturing tools, positioning devices, etc., can solve the punching steps that cannot match the interval of sheet stamping dies, low punching efficiency of sheet stamping dies, manual stacking speed Slow and other problems, to achieve the effect of good sheet stacking, high production efficiency, and stable feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

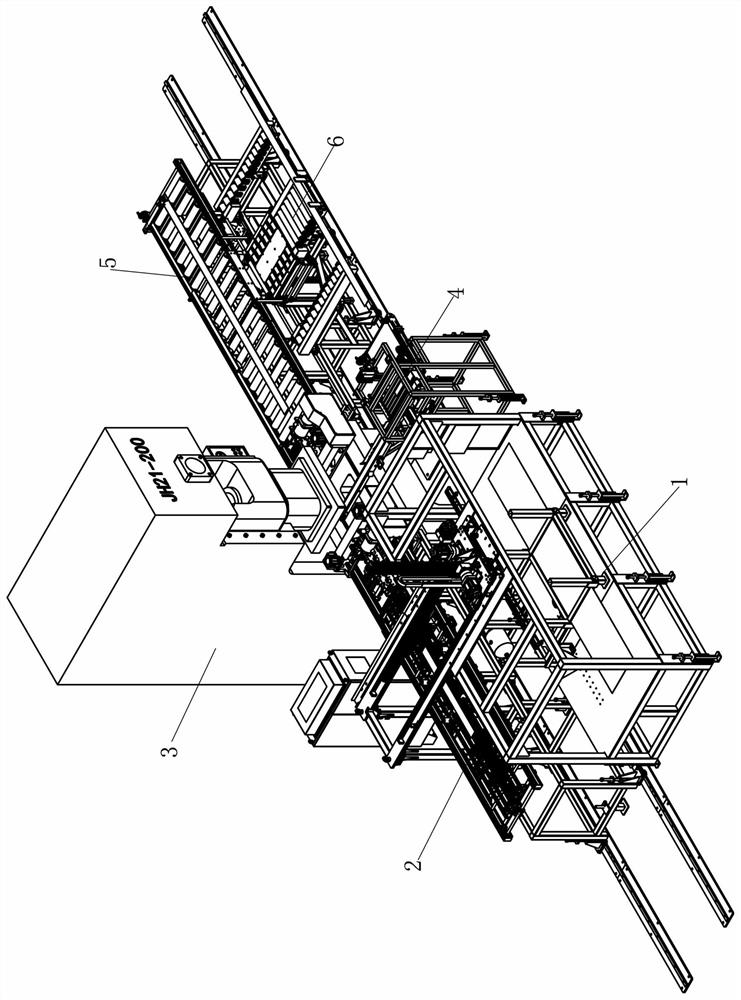

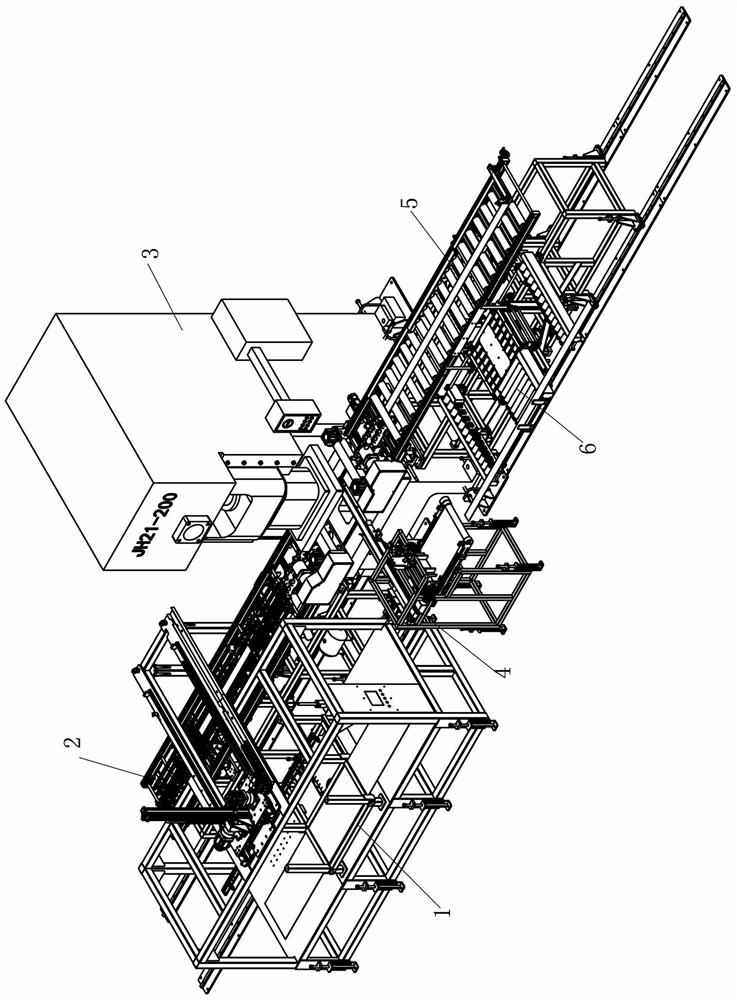

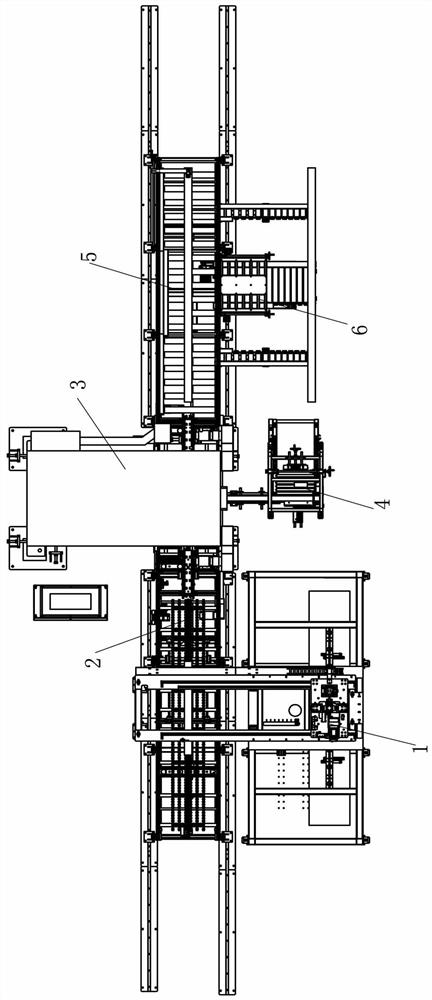

[0084] Embodiment one, such as Figure 1 to Figure 23 As shown, a sheet material automatic blanking and punching production line includes a sheet material feeding device 1 , a sheet material feeding device 2 , a sheet material stamping die 3 , a sheet material discharging device 5 and a blanking piece receiving device 4 .

[0085] The sheet feeding device 1 is used for grabbing a single sheet onto the sheet feeding device 2 .

[0086] The sheet feeding device 2 is used for intermittently and horizontally feeding a single sheet into the sheet stamping die 3 .

[0087] The sheet stamping die 3 is used for punching holes on the sheet, and the punched parts corresponding to the holes drop from the sheet.

[0088] The sheet material discharging device 5 is used for conveying out the punched sheet materials and stacking them.

[0089] The blanking piece receiving device 4 is used for conveying out the blanking pieces punched out by the sheet stamping die 3 and stacking them.

[009...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com