Novel hopper loading and unloading vehicle

A loading and unloading truck and bucket technology, which is applied in loading/unloading, transportation and packaging, conveyors, etc., can solve the problems of deviation, complicated structure of the upper hopper, inconvenient movement and direction adjustment, etc., and achieves convenient and practical stacking. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

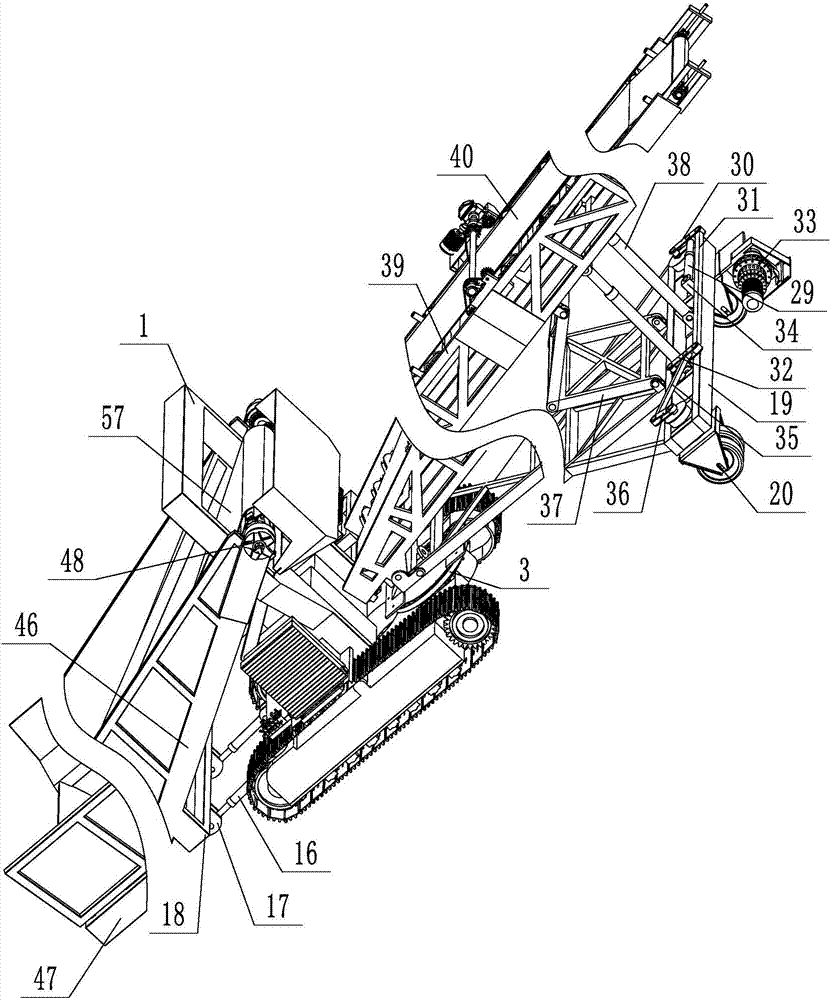

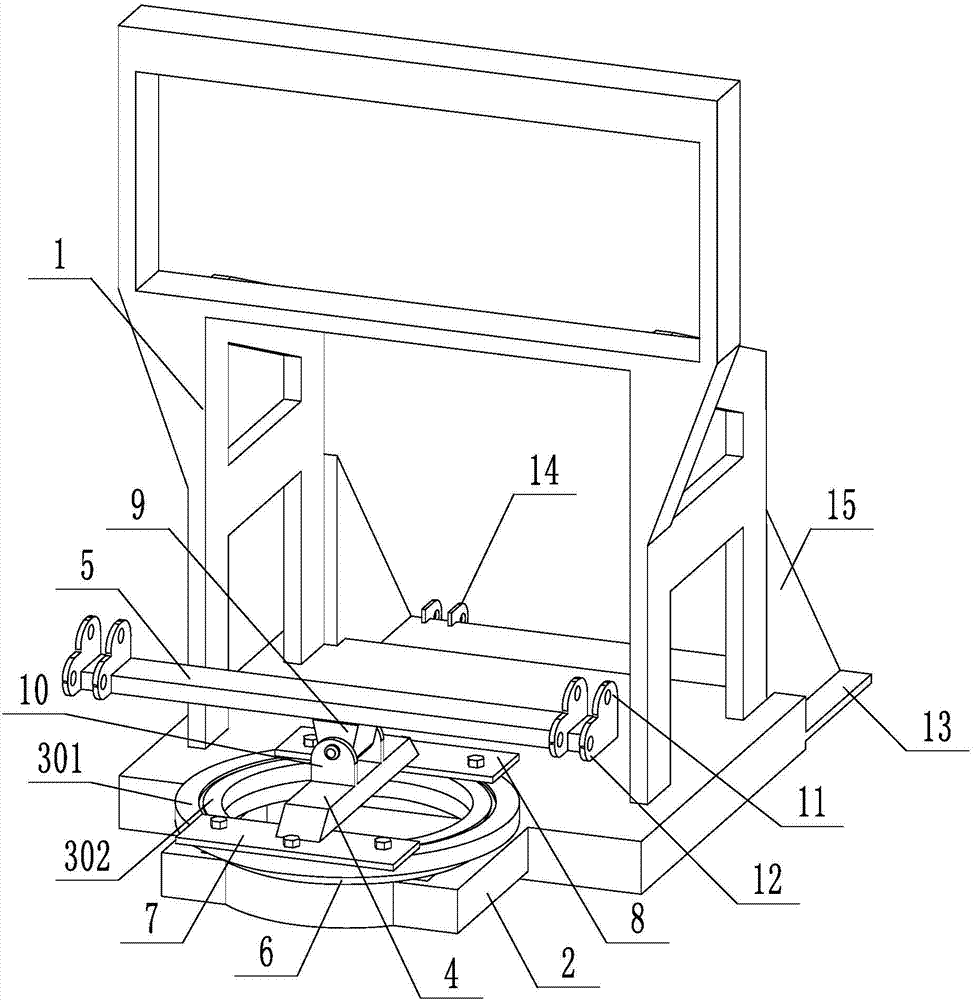

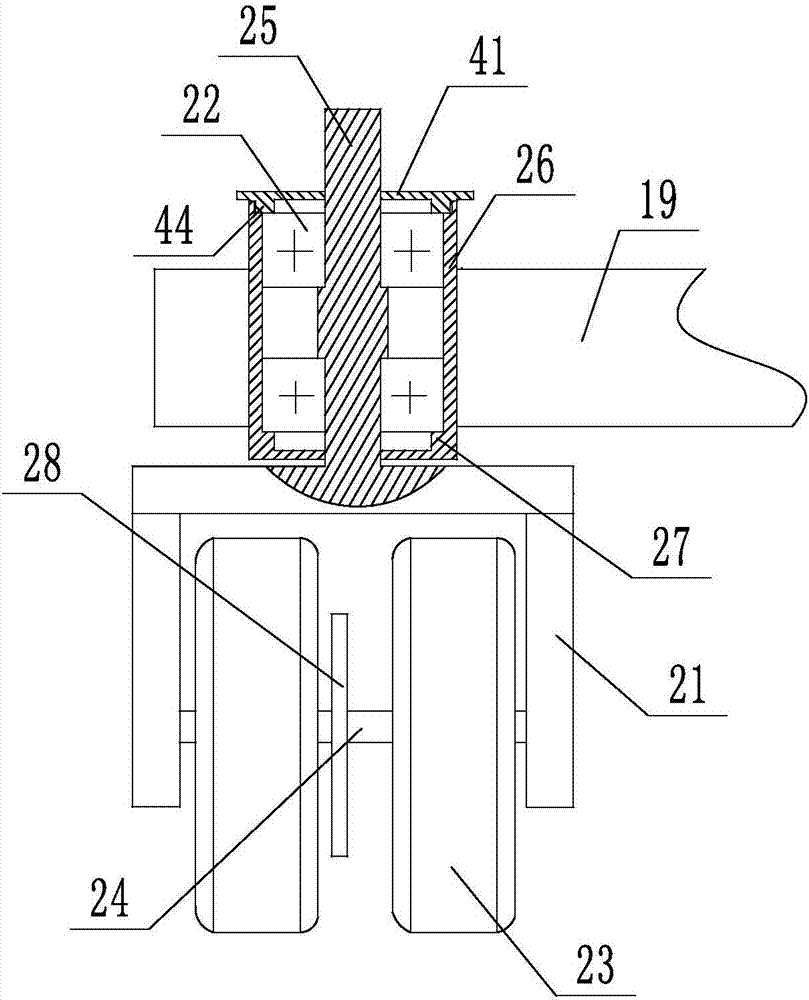

[0045] according to Figure 1 to Figure 7 As shown, a new type of hopper loading and unloading truck includes a feeding structure, a rotary steering device and a supporting rotary mechanism. The feeding mechanism, the rotary steering mechanism and the supporting rotary mechanism are flexibly connected. The input end of the slewing steering device corresponds to the input end; the supporting slewing mechanism includes a loading and unloading truck body 1, a first slewing group and a second slewing group, the first slewing group is located at the front end of the loading and unloading truck body 1, and the second slewing group is located at The rear end of the loading and unloading vehicle body 1; the rotary steering device includes a rotary steering mechanism, and the rotary steering mechanism includes a support frame 19, a rotary wheel set 20 and a transmission mechanism, and the transmission mechanism drives the two rotary wheel sets 20 Figure-eight rotation; the feeding stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com