A push-and-stack paper stacking equipment and forming process

A technology of stacking paper and equipment, applied in the direction of cardboard items, etc., can solve the problems of affecting the filtration performance of glass fiber filter paper, uneven molding quality, broken glass fibers, etc., to achieve good molding quality, improve production efficiency, push stacking fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be described in detail below in conjunction with the accompanying drawings.

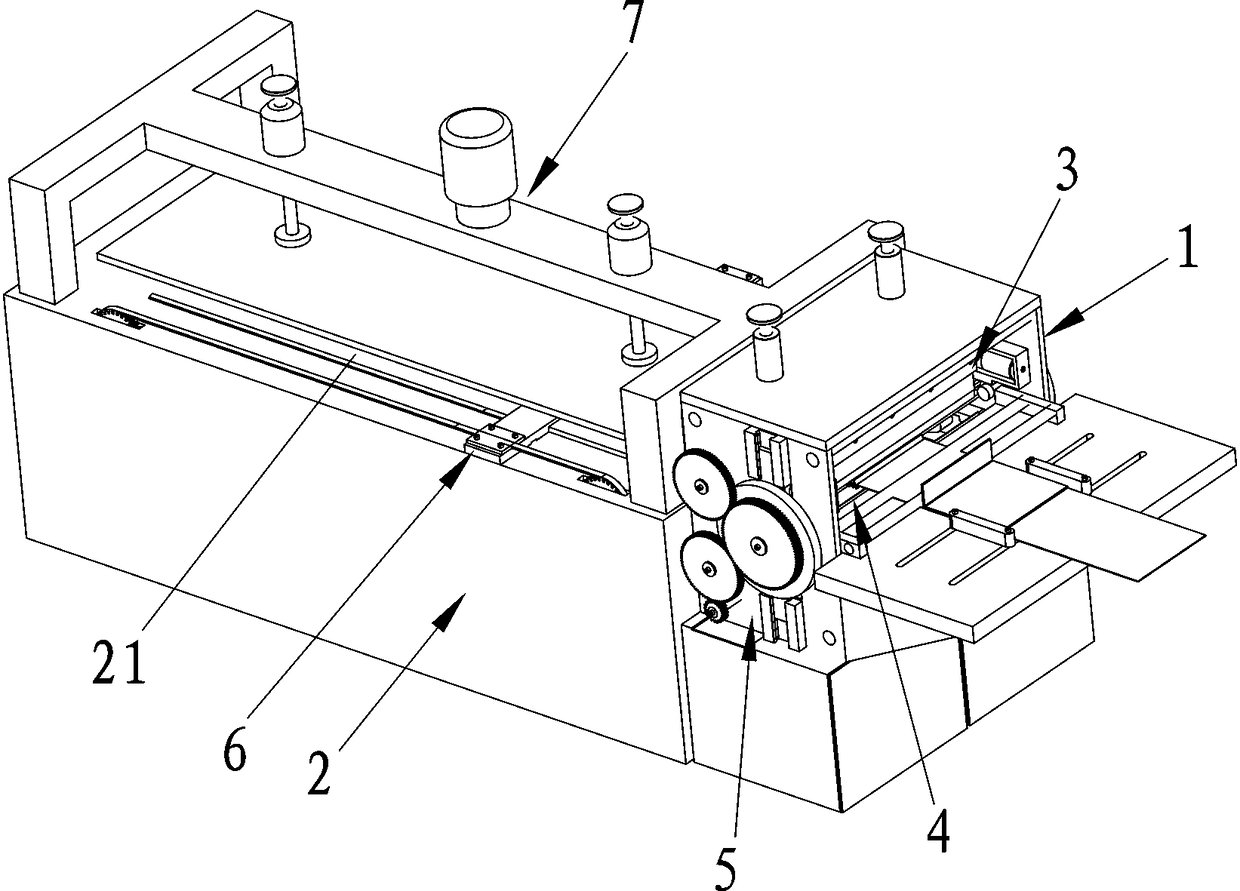

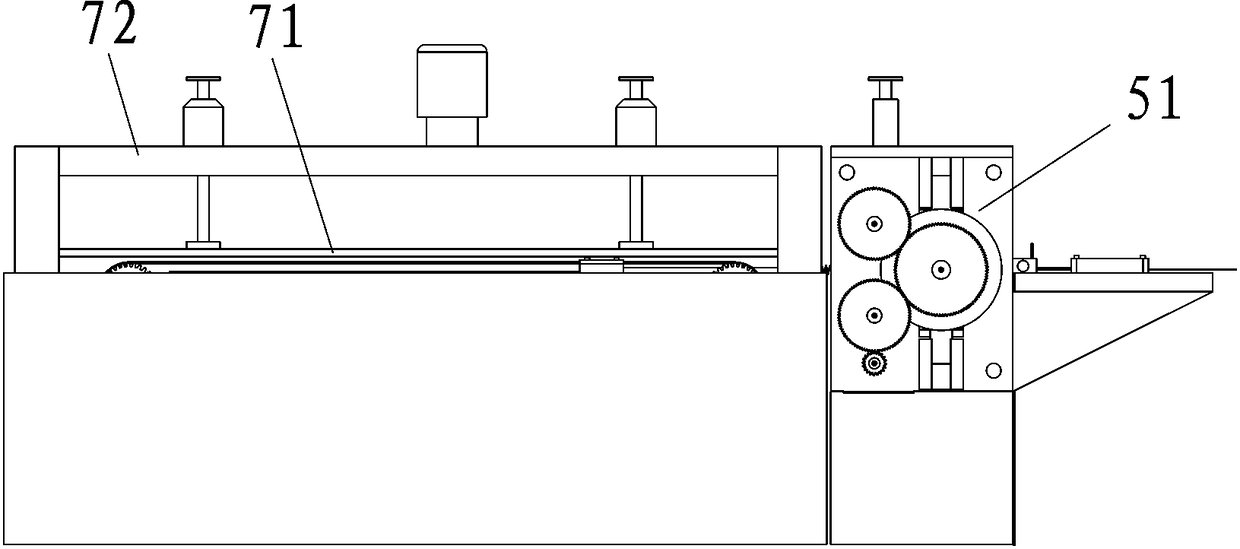

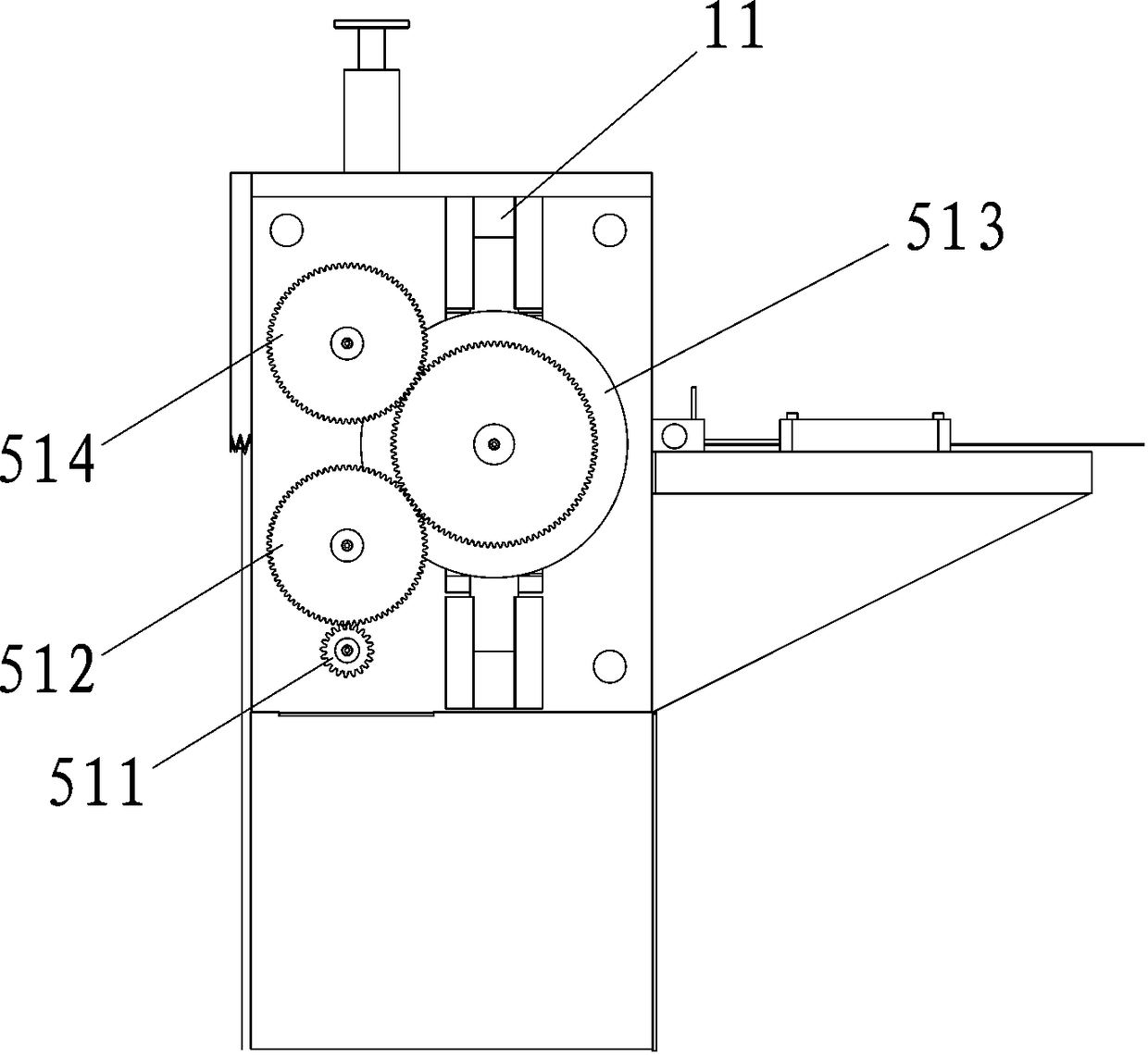

[0054] see Figure 1 to Figure 13, the present invention provides a push-and-stack stacking device, which includes a support base 1 and a receiving table 2 for accommodating stacks of paper, and also includes an upper push plate device 3, a lower push plate device 4, a driving device 5 and a The damping sliding device 6 connected to the forming filter paper, the driving device 5 drives the upper push plate device 3 and the lower push plate device 4 to alternately push the stacked filter paper to form, and the upper push plate device 3 and the lower push plate device 4 push the stacked filter paper, so that The filter paper pushes the damping slide device 6 to slide along the receiving platform 2 , and the upper push plate device 3 , the lower push plate device 4 and the driving device 5 are all connected to the support base 1 . The working principle of this paper st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com